Solar-Tracking Phone Charger

Haoyu Liu, Esther Xu, Josiah Soegiharto, Mohammed Bamhraz and Daisy Zhao

The University of British Columbia Vancouver Canada

Corresponding author: 2316544785@qq.com

Keywords: Solar energy, temperature sensors, the solar panel, store, environmental concerns.

Abstract: This project uses solar energy from the light, then stores it and finally converts it into electric energy. The

electric energy is used to charge any electronics. In our project solar panels absorb the energy and

temperature sensors detect the temperature and change the direction of the solar panel to follow the

direction of the light. Thus, temperature sensor plays an important role in our project. Then the electricity

stores in the capacitor and go into the electronics by wire. In the introduction, the main steps of the project

are provided, similarly, the purpose and importance of project are shown. In the discussion section, the

details of coding, solidwork drawing and actual work are examined. The experimental setup lists the

materials that are used in the project and show how the process is carried out to achieve the goals.

1 INTRODUCTION ON THE

PROJECT CONCEPT

The increasing functionality and performance of

mobile phones increases the demand for a power

recharging and storage technology that can allow

phone batteries to last longer and to be recharged

more practically. The device that we made in our

project provides a way of recharging and storing

power for mobile phones that satisfies this

increasing need. Our device is a portable external

battery (also known as power bank) that contains

embedded solar panels, which allow it to be

recharged using solar energy. The battery can orient

itself to face towards the light source that yields the

highest energy. Due to its capacity of being recharge

mobile phones and thus is very helpful when

traveling long distance. Furthermore, its capability

of being recharged by solar energy allows the

mobile phone to be moved around while it is being

charged, provided that the solar panels are exposed

to enough light or some power remains in the

batteries, unlike the charging process using electrical

energy. If light is not available, the device can be

recharged using a conventional power socket. The

device is composed of components that are

compatible with the Arduino hardware and soft ware;

its casing is 3D printed.

2 EXPERIMENTAL SET UP

2.1 Design and drawing

Firstly, all parts needed were ordered online, after

the parts were picked up, it’s necessary to measure

the dimension of parts in order to design the shape,

electrical part and mechanical part by drawing by

hand. Then the solidworks is needed to setup the 3D

shape, all dimensions should suit the real parts.

2.2 Mechanical of solar tracker

Tracker is a dual axis tracker, meaning it tracks in

both X -axis and Y-axis. To put it into even more

simple terms, it goes left, right, up, and down. This

means once the tracker was set up nothing need to

change or adjust, since anywhere the sun moves the

tracker will follow. This also impresses people at

parties because a flashlight can be tracked around.

This method gives the best results for power

generation.

2.3 Assemble of parts

To start out the Servos are attached to their mounts

Liu, H., Xu, E., Soegiharto, J., Bamhraz, M. and Zhao, D.

Solar-Tracking Phone Charger.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 23-26

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

23

Open up the bag the Servo came in. There will

be three screws. Two pointy wood screws with large

heads, and one small machine screw. Place the

single machine screw to the side, we won't be using

it now.

Pick up the large round wooden piece without an

arrow on it. The Servo is mounted on the bottom of

the piece.

Line the servo up with the screw holes, and then

carefully use the two Servo screws to secure it in

place. Once in place give it a little tug to make sure

it's secure. Find the second wooden Servo mount.

We'll be doing the same thing here with our second

Servo. Mount it on the "back" of the mount with the

two screws it came with.

Grab the very base plate, the four legs, and the

large round piece that now has a Servo attached to it.

You'll also need 8 of the 6-32 Screws and 8 nuts.

First attach the four legs to the round servo

holder. The Servo needs to be inside all the legs,

between the the base plate and the round servo

holder. Don't tighten the screws all the way, leave

them a bit loose.

Now fit the four legs into the base plate. Make

sure that when you do this the servo wire is

positioned so that it's coming out towards the back

where all our electronics will be.

Once all our legs are screwed into the base plate

go back and tighten the four screws that attach the

legs to the round servo holder.

Lastly, put the four rubber feet on the bottom of

the base plate so that the screw heads don't scratch

up your work surface.

At this time you can also put together the LED

display holder. The LED display just fits between

the two wooden holders and is secured by two

screws and nuts.

Grab the large solar array face. It's the one that

says "Solar Cell Here" on it. We'll also need the two

triangle wings, the small rounded corner square

piece, and the two small sensor divider pieces. To

connect it all we'll need six 6-32 Screws and nuts.

Put the face plate on the table in front of you so

that you can read the words. Attach the triangle wing

piece with the servo arm on the right side, and the

other triangle wing piece onto the left side. We want

the plastic servo arm to be facing the inside.

Use four screws and nuts to hold that together.

Now use the three remaining pieces to build the

sensor divider. Rounded square first, then the tall

skinny piece, and finally the longer piece with the

two screw T slots. Once it's all together use two

screws and nuts to secure it.

Servos move in 180 degrees. The Servo knows

where "zero" degree is and where "180" degree is.

Since we don't want or need full 180 degree range

on our servos we want to set our "zero" degree to

some very specific locations.

Start with the Base plate Servo. Without using

the little screws push the Servo Arm that’s attached

to the Center into the servo. This may take a little

effort, so you may wish to brace the

servo with your other hand. Once together,

slowly rotate the Center counter clockwise until

there servo stops. This is "zero" degrees on the

Servo.

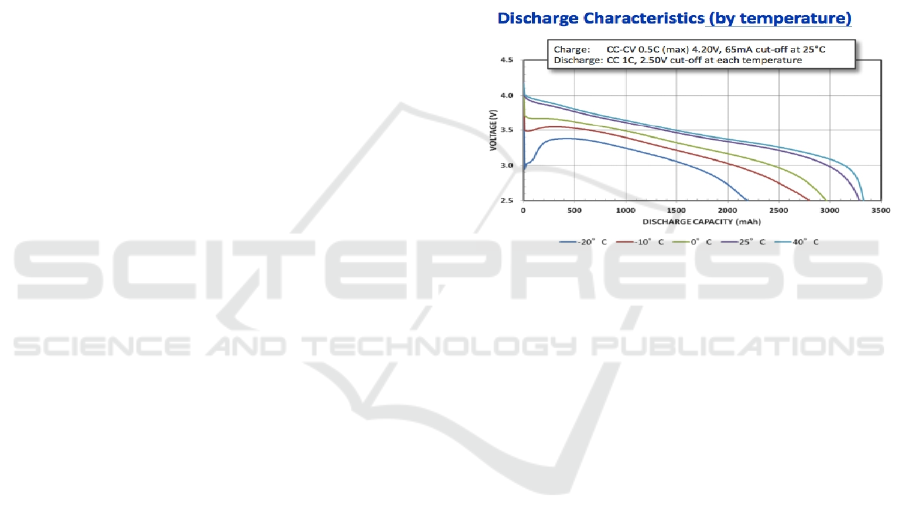

The relationship between battery voltage and

capacity is shown in Figure 1.

Figure 1: Voltage vs. Discharge capacity.

2.4 Assemble of Sensors

Take Connectors. Snip off the ends of the wires and

then strip the wires.

Grab four Light Sensitive Resistors. The legs are

way too long. Remove 2/3rds of their legs.Push one

Light Sensitive Resistor into each of the four

Connectors. The should go in easily.Thread one

Female JST Connector through each of the four

holes around the Sensor Divider.

Now have 8 wires handing down through the

Top around the Sensor Divider.

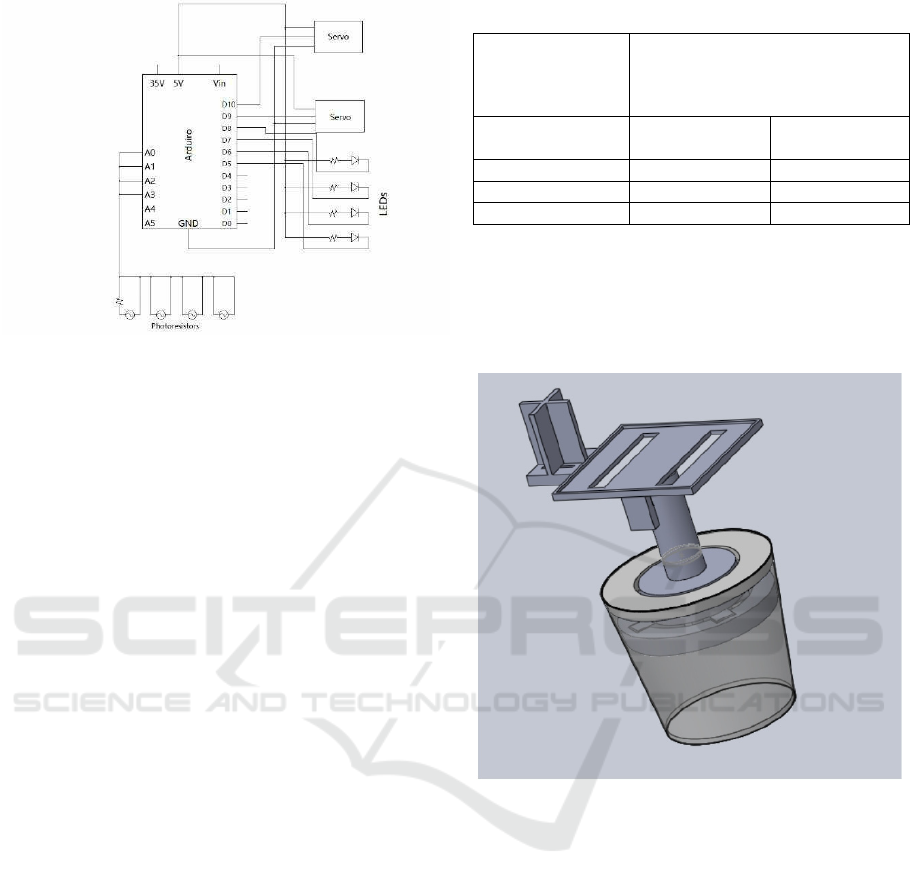

A diagram of the full circuit with the battery

indicators is shown in Figure 2.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

24

Figure 2:The full circuit with the battery indicators.

3 MATERIALS

Breadboard, Photoresistors, Ardunino, Jumper,

Servo Motor, Resistor (10k ohm), Tactile Switch,

Diode,LED,Voltage regulator switch,Porttermind

Block 2x5,Porttermind Block 2x4,

Cable Wraps,Screws.

4 RESULTS

The theoretical output voltage of the circuit to the

USB boost converters, which powers the Arduino

board and the phone, is 5V. The battery capacity is

3400mAh.

The tracking system is very sensitive as it is

capable of responding to small changes in angle of

light in high speed.

The functionality of the device makes it useful

when one is travelling long distances, or to places

where access to the power socket is limited. The

device can also double as both a house ornament and

renewable power supply. It can also be useful for

outdoor events, such as an outdoor party.

The values of the voltages of the battery at its

corresponding power remaining in the battery used

for the coding of the battery indicator may be very

slightly inaccurate. These values changes as the

temperature of the battery changes, and in the code

only the values at temperature of 25 degrees is used.

Table 1:Table of results

Length of Time Needed to Fully

Charge a Running Samsung Galaxy

S5 with 73% Battery

(minutes)

DU Battery

Save

r

Battery Doctor

(

Batter

y

Saver

)

Char

g

in

g

circuit 35 40

Power socket 35 40

Laptop 40 61

5 SOLIDWORK DRAWING

The Solidwork Drawing is shown in Figure 3.

Figure 3: a sample design of solidworks.

6 DISCUSSION

The solar tracking system is able to rotate 180

degrees horizontally and vertically and its

effectiveness in tracking the light is limited to this.

The solar tracking system will not be able to follow

the light after it reaches its maximum.

The speed of the charging circuit in charging the

cell phone, according to two phone battery saving

applications; the DU Battery Saver and Battery

Doctor (Batter Saver), is as fast as the power socket,

and faster than charging by connecting the phone to

the laptop. According to DU Battery Saver, when

the phone battery is at 73%, charging the phone

using the power socket, the charging circuit and the

by connecting it to the laptop takes 35 minutes, 35

Solar-Tracking Phone Charger

25

minutes and 40 minutes, respectively. According to

Battery Doctor (Battery Saver), it takes 40 minutes,

40 minutes and 61 minutes to charge the phone

using the power socket, the charging circuit and the

by connecting it to the laptop, respectively, when the

phone battery is at 73%.

7 CONCLUSION AND FUTURE

APPLICATION

One of the most important features of this project is

that it is able to track the source of energy. It

incorporates a solar tracking system that is able to

turn 360 degrees in both vertical and horizontal

direction. This helps to get a great amount of solar

energy. The solar energy is converted to chemical

energy and stored in the battery. In this project not

only can charge the electronics but also can indicate

the remaining amount of the battery. This prevent to

overcharging the electronics thus protect the

electronics. In the future study, improvement of the

shape can be made to increase the efficiency of the

converting process.

ACKNOWLEDGEMENTS

Our team would like to express their appreciation to

Dr. Ray Tehari, school of engineering, The

University of British Columbia Okanagan campus

for his valuable and high professional support. Our

Team also wish to acknowledge the TAs and

professor from Electrical and engineering

department from their valuable help.

REFERENCES

Awingot, A. R. (2016). A solar radiation tracker for solar

energy optimisation. British Journal of Applied

Science & Technology, 14(4), 1.

Juang, J., Radharamanan, R., & Beaver, J. (2013). A low

cost solar tracker design for renewable energy.

Journal of Management & Engineering Integration,

6(2), 15.

Wei, W., & Shaoyuan, L. (2012). Model predictive control

of 2-axis solar tracker for solar energy system. Paper

presented at the 4177-4182.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

26