A Stochastic Approach for Damage Modelling of Cast Alloys

Christian Mühlstätter

LKR Leichtmetallkompetenzzentrum Ranshofen GmbH,

Austrian Institute of Technology, Austria

Keywords: Damage Modelling, Triaxiality, Goodness-of-fit Test.

Abstract: The increasing interest of cast Aluminium alloys in structural application asks for appropriate simulation

approaches. Besides the constitutive behaviour, damage properties play an important role for this material.

The damage behaviour is significantly influenced by the microstructure. Due to the specific morphology of

cast microstructure and the random spatial deviation of voids, a novel concept of material modelling is

necessary. In this study, a concept for stochastic material characterisation and modelling in structural Finite

Element simulations is introduced. Therefore, a test matrix for experimental tests is discussed. Based on the

generated experimental data a stochastic evaluation is performed by a goodness-of-fit test. The achieved

characterisation knowledge is used to introduce the concept for stochastic material modelling of Aluminium

cast alloys.

1 INTRODUCTION

Since light weight demand raises in automotive

application, cast Aluminium alloys gain more

relevance for structural parts. Therefore, an accurate

capturing of material behaviour is necessary for

structural Finite Elemente (FE) simulations. Due to

the casting process the material gets its characteristic

morphology with certain small amounts of voids

which is substantially influenced by process

parameters, e.g. time dependent pressure distribution,

cooling rate, flow behaviour. Furthermore, the quality

of melted Aluminium is a sensitive parameter which

depends on air exhibition duration and accuracy of

designated mass fraction for each alloy component.

The set of these parameters causes a material with

varying microstructure which results in

inhomogeneous mechanical properties. In

conventional modelling approaches, e.g. (Gurson,

1978) or subsequent works (Tvergaard and

Needleman, 1984) the material is considered as

continuum with smoothed micromechanical

behaviour. These models capture the damage

behaviour by the evolution of void fractions within

the material due to ductile fracture mechanisms.

Furthermore, phenomenological approaches are

proposed by (Wilkins, et al., 1980) and (Johnson and

Cook, 1985) which describe the material damage by

a triaxiality dependent fracture strain. The standard

implementation of these models is as well smoothed

and does not consider the spatial variation of material

parameters.

In this paper, a phenomenological approach

combined with a concept of stochastic consideration

for cast material characterisation and modelling is

introduced.

2 DUCTILE FRACTURE

Structural materials are characterised by several

engineering parameters, e.g. yield stress and tensile

strength. Furthermore, the damage behaviour is a

characteristic of a material which is composed by

the evolution of certain micromechanical

phenomena. Essentially, two different failure modes

can be observed at metallic materials which appear

as brittle or ductile fracture. The characterisation of

the failure mode is basically done by monitoring the

plastic strain until fracture occurs. Aluminium die

cast alloys show a ductile fracture behaviour with

distinct plastic deformations (Fagerholt, et al., 2010;

Muehlstaetter and Hartmann, 2016). The evolution

of ductile fracture is based on micromechanical

mechanisms including nucleation, growth and

coalescence of micro voids within a material as

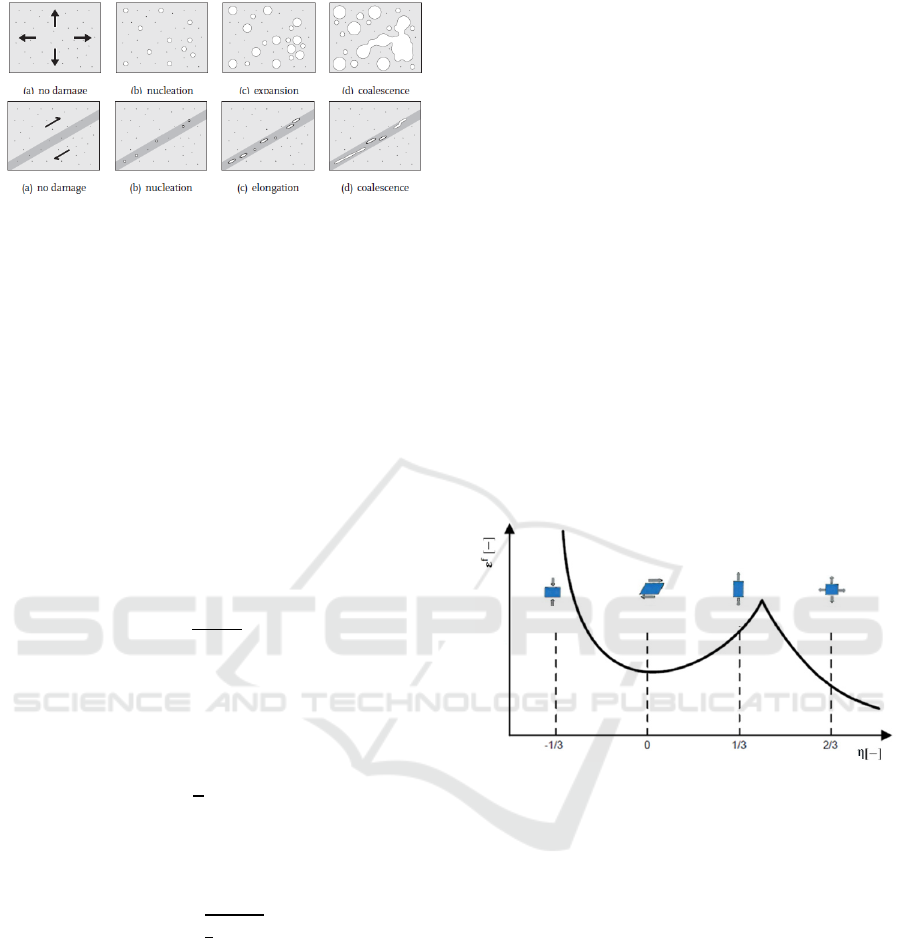

depicted in Figure 1.

Mühlstätter, C.

A Stochastic Approach for Damage Modelling of Cast Alloys.

DOI: 10.5220/0006909904670471

In Proceedings of 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2018), pages 467-471

ISBN: 978-989-758-323-0

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

467

Figure 1: Evolution of material damage by different stress

states (Engelen, 2005).

2.1 Solid Mechanics

A certain stress state, denoted by the stress tensor,

causes a characteristic damage mechanism after

exceeding yield strength. Normal stresses (Figure 1

top) lead to expansion and coalescence of voids.

Shear stresses (Figure 1, bottom) cause the formation

of shear bands. Therefore, an arbitrary stress state

needs to be evaluated regarding the damage effect of

the material. A well-established method is proposed

by (Bao and Wierzbicki, 2004) which consider the

fraction strain as function of the stress triaxiality,

defined as

η=

.

(1)

The triaxiality quantifies a stress state in terms of the

multiaxiality by the ratio between the hydrostatic

stress σ

, given by

σ

=

1

3

(

)

,

(2)

which is extracted from the stress tensor and the

von Mises equivalent stress σ

, calculated as

σ

=

,

(3)

composed by the stress deviator

in Einstein

notation which is formulated as residual of the stress

tensor with respect to the hydrostatic strain, therefore

=−

(4)

with the threedimensional unity matrix .

2.2 Characterisation of Damage

Behaviour

For structural mechanics, numerical simulation

software calculates displacements which appears due

to external loads and boundaries. Therefore, strains

are determined based on a defined constitutive law

which leads to a stress field. In addition, the induced

stresses cause certain micromechanical effects and

the evolution of damage. As already outlined in the

previous section, the damage mechanism depends on

the stress state. State of the art damage modelling is

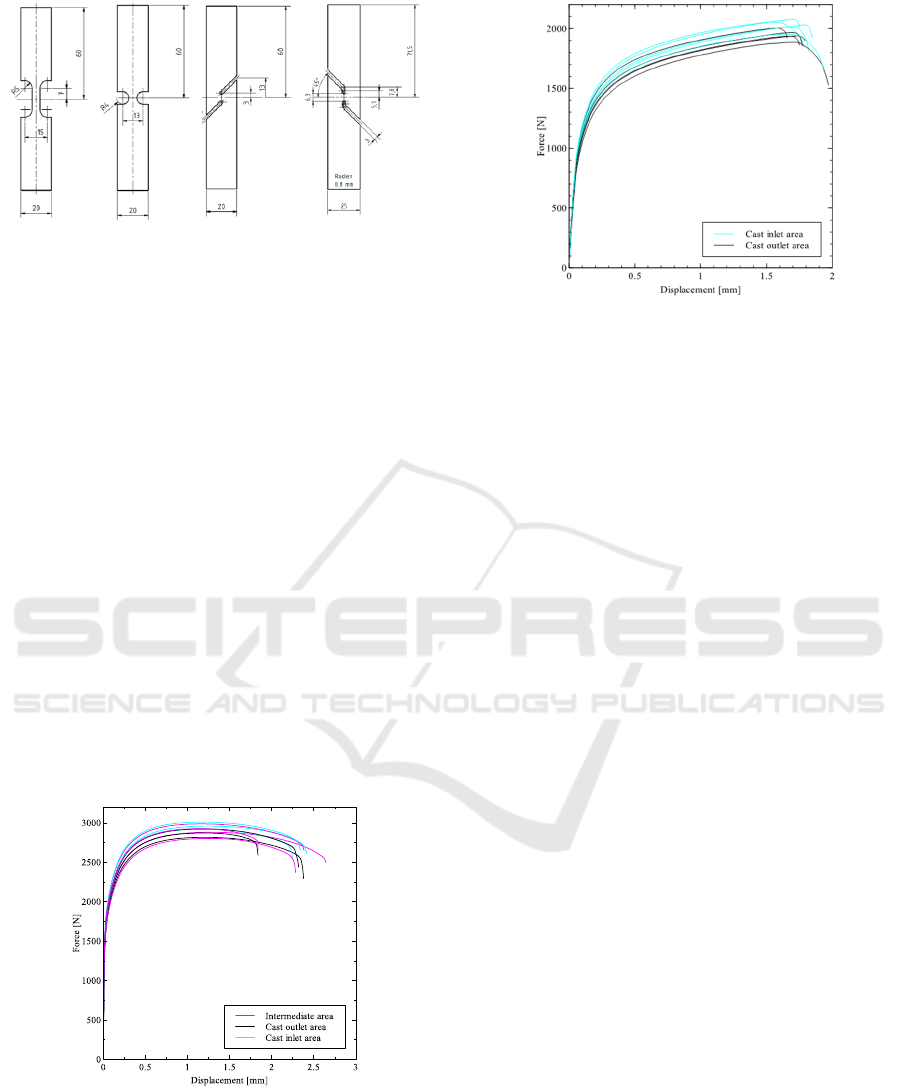

based on the approach of (Bao and Wierzbicki, 2004),

where a characteristic fracture strain is defined as

function of the stress triaxiality η (see Figure 2).

Based on this approach a damage variable D is

formulated as function of the plastic strain

and the

fracture strain function

(

η

)

:

D=

f

ε

,

(

η

)

(5)

Figure 2: Characteristic metal fracture strain curve as

function of the stress triaxiality (Bao and Wierzbicki,

2004).

Hence, for structural simulations including damage,

additional material characterisation effort is

necessary. Figure 3 shows a set of test coupons to

capture different stress states which cause various

damage mechanisms. Therefore, test geometries are

manufactured and tested under tension load. The

specific morphology within the gauge length, where

fracture occurs, leads to triaxiality regimes of 0, for

shear tensile and Merklein shear, to 0.33 for flat

tensile tests and 0.57 for notched test. The negative

triaxiality regime cannot be covered with this

characterisation strategy.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

468

Figure 3: Test geometries for characterisation of the

damage behaviour (from left: flat tensile, notched, shear

tensile and Merklein shear).

2.3 Experimental Results

The intention of this study is to characterise a cast

material which is produced by a stable and steady

state die casting process. Therefore, the process runs

a certain time to ensure constant process parameters,

e.g. temperature field within the casting plant. The

test specimens are extracted from casted hat profiles.

For the experimental characterisation, a test matrix

with at least 10 valid tests of each test geometry is

defined. Furthermore, the spatial location of

extraction with respect to the casting inlet is

documented.

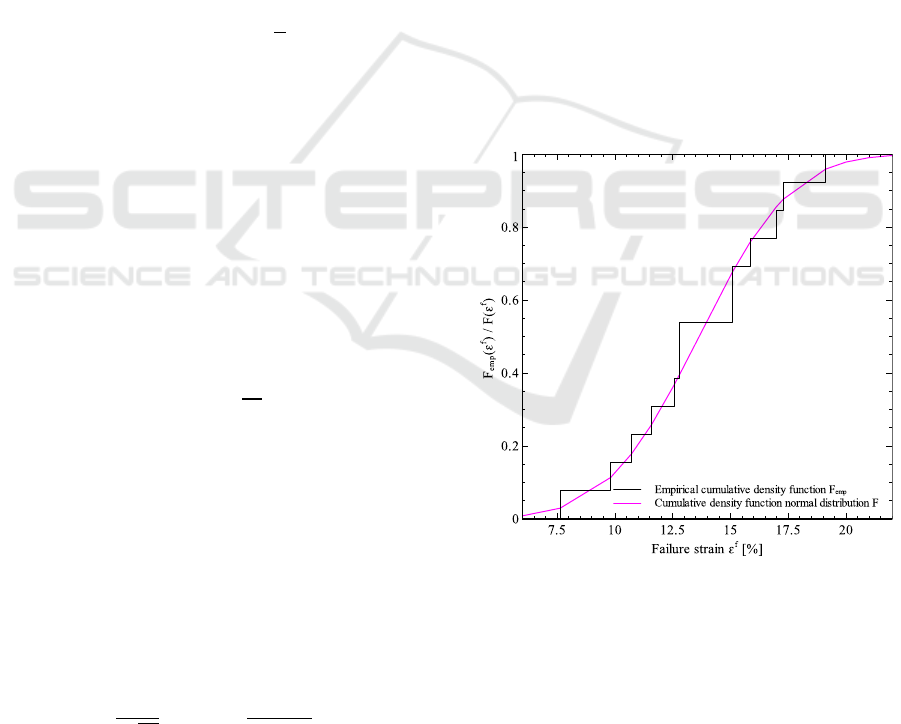

The output of these tests are force vs.

displacement curves. Figure 4 shows the results of the

flat tensile tests. The force-displacement curves show

a significant deviation for a pure tension load with

theoretical triaxiality of 0.33. A similar behaviour is

observed for the notched tension tests (Muehlstaetter,

2015).

Figure 4: Experimental force vs. displacement curves of flat

tensile tests for different regions within the casted part.

The test results of the Merklein tests are depicted in

Figure

5

. Deviation is also apparent in these results,

although it is lower than in the triaxiality regimes of

η0.33.

Figure 5: Experimental force vs. displacement curves of

Merklein test geometry for different regions within the

casted part.

3 STOCHASTIC EVALUATION

Based on the experimental data of the previous

chapter an evaluation regarding the stochastic

behaviour is performed.

3.1 Goodness-of-fit Test

In this section, a strategy for a stochastic

consideration of the experimental data is introduced.

The objective is to characterise the obtained

scattering of the force-displacement curves. The

scattering consists of the variation in the flow

behaviour and the failure displacement. This study

aims to consider only the failure displacement.

Hence, discrete failure displacement values are

extracted from the experiments.

By application of stochastic theory, the problem

appears as issue of seeking a formulation of a

potential underlying stochastic distribution.

Therefore, goodness-of-fit tests are available

(Schiefermayr and Weiß, 2014). These tests need an

initial estimation of a stochastic distribution including

their parameters, e.g. standard deviation for the

normal distribution, as input. Based on the

Cumulative Density Function (CDF) of this

stochastic distribution, the null hypothesis ʜ

is tested

against the alternative hypothesisʜ

.

ʜ

is defined as: The claim that the test data

follows the estimated stochastic distribution is true;

ʜ

has the opposite meaning. Several goodness-of-fit

tests are available in literature, e.g. (Schiefermayr and

Weiß, 2014). The application of each test depends on

the range of available data. In this study, the test data

is relatively low for a stochastic consideration.

A Stochastic Approach for Damage Modelling of Cast Alloys

469

Therefore, the Kolmogorov-Smirnov (KS) test which

delivers accurate results for low data is suitable.

This goodness-of-fit test is based on the steady

distribution proposed by Kolmogorov with the CDF

defined as

=1+2

(

−1

)

(

≥0

)

.

(6)

The random variable is the fracture strain

from the

experiments.

For the application of goodness-of-fit tests a

significance level α needs to be defined. The

significance level sets the probability, that the true

null hypothesis is rejected accidentally. A common

value for α is 5 %. Based on this parameter the

condition for the rejection of the null hypothesis is

formulated as

≥

(1−)/

√

(7)

whereas

is the Quantile of the Kolmogorov CDF

and is the amount of available test data for

. The

parameter is based on the experimental data and the

CDF of the estimated underlying distribution, defined

as

:=

(

)

−

(

)

. (8)

This parameter determines the maximum deviation,

or mathematically formulated as supremum between

the empirical CDF

(

)

, given by

(

)

=

,

(9)

and the estimated CDF.

in Equation 9 is the

number of data which fulfil the condition ≤

and

is the total number of test data. The second term in

Equation 8 is the CDF of the estimated stochastic

distribution. In applied sciences, many processes

succeed the normal distribution. Therefore, it is

reasonable to choose this distribution for the first

iteration of the KS test. The CDF of the normal

distribution is defined as

=

1

√

2π

exp−

(

−

)

2

.

(10)

The normal distribution has 2 parameters, the

expectation value and the variance which needs

to be defined by application of moment estimators.

Hence, and are calculated by the arithmetic mean

value and the standard deviation.

The introduced test of this chapter is applied on

the experimental data of the flat tensile test, depicted

in Figure 4. The determination of the condition for the

rejection of the null hypothesis from Equation 7

yields a value for T of 0.41. The determination of the

parameter T leads to a value of 0.139. Thus, the

condition of Equation 7 is not fulfilled, and the null

hypothesis is true. Furthermore, the tested data

follows the normal distribution.

If the first iteration leads to a rejection of the null

hypothesis, an alternative distribution needs to be

defined for the second KS test iteration. The concept

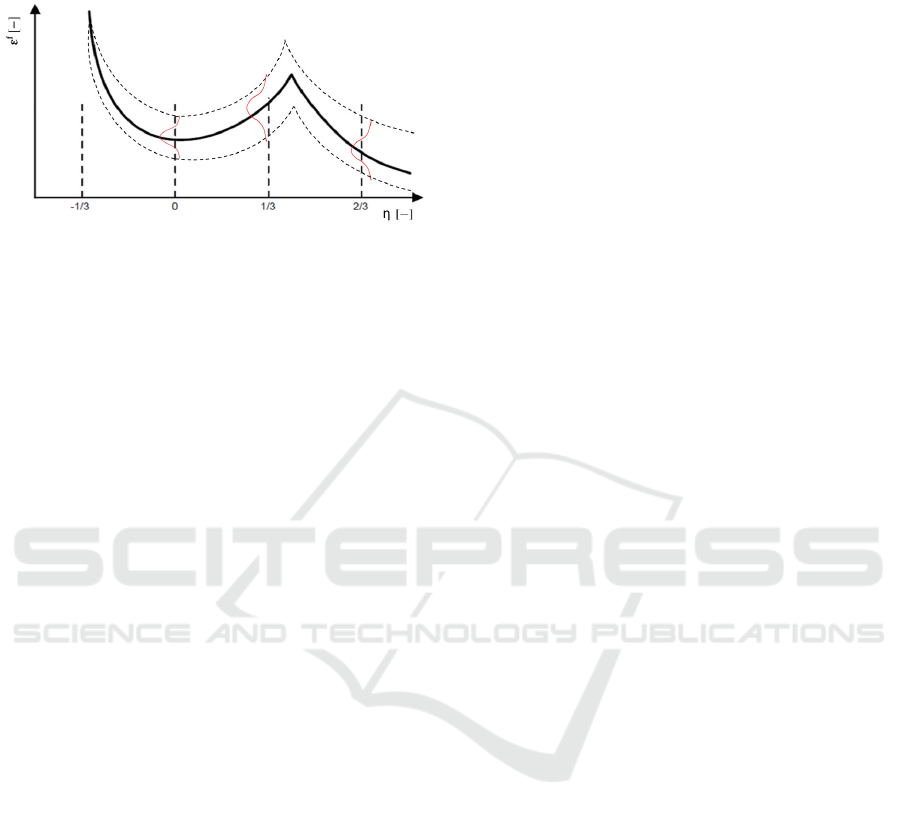

of the KS test is depicted in Figure 6 in graphical

representation. The empirical density function

appears as step function in black line and the CDF of

the normal distribution with estimated parameters in

magenta line. The CDF of the normal distribution

crosses every plateau of the empirical CDF, except

at

=17.5. This is the visual interpretation of

Equation 8 with the supremum between

(

)

and

(

)

.

Figure 6: Visual representation of the Kolmogorov-

Smirnov goodness-of-fit test with normal distribution and

empirical CDF for tensile test data.

The application of this strategy for each test data

set builds the concept for the development of an

innovative approach for damage modelling. The

fundament of this approach is the consideration of

material damage proposed by (Bao and Wierzbicki,

2004) which is implemented in several Finite Element

codes, e.g. LS-Dyna. In addition, the stochastic

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

470

behaviour of a material is added by the concept of this

study. Figure 7 depicts this combined approach.

Figure 7: Schematic concept for the stochastic damage

modelling (red and dashed line) based on the approach of

(Bao and Wierzbicki, 2004) (black, solid line).

The black solid line represents the well-

established approach of (Bao and Wierzbicki, 2004).

The red Gauss’ curve at =0.33 is introduced by the

concept in this chapter. The remaining Gauss’ curves

are schematic for any probability function which

needs to be establish by the KS test. Based on the

probability functions, the dashed bounds are defined.

This concept is intended as input for a random

variable generator which delivers fraction strain

curves as function of the triaxiality for each

integration point in a simulation model. Hence, a

random field of material property is generated

initially for structural Finite Element simulations.

4 CONCLUSIONS

Damage modelling under consideration of the

fracture strain as function of triaxiality is a well-

established method. However, for cast Aluminium

alloys the inhomogeneous material/damage

behaviour is neglected. The introduced concept can

overcome this drawback and builds a potential for

more accurate capturing of material scatter of cast

Aluminium alloys.

ACKNOWLEDGEMENTS

This work has been supported by the European

Regional Development Fund (EFRE) in the

framework of the EU-program "IWB Investition in

Wachstum und Beschäftigung Österreich 2014-

2020", and the federal state Upper Austria.

REFERENCES

Bao, Y., Wierzbicki, T., 2004. On fracture locus in the

equivalent strain and stress triaxiality space.

s.l.:International Journal of Mechanical Sciences.

Engelen, R., 2005. Plasitcity induced Damage in Metals:

nonlocal modelling at finite strains. s.l.:Habilitation

thesis.

Fagerholt, E.; et al., 2010. Experimental and numerical

investigation of fracture in a cast aluminium alloy.

s.l.:International Journal of Solids and Structures.

Gurson, A. L., 1978. Porous rigid-plastic materials

containing rigid inclusions-yield function, plastic

potential and void nucleation. s.l.:The Physical

Metallurgy of Fracture.

Johnson, G. R., Cook, W. H., 1985. Fracture

characteristics of three metals subjected to various

strains, strain rates, terperatures and pressures.

s.l.:Engineering Fracture Mechanics.

Muehlstaetter, C., 2015. Versagensmodellierung von Al-

Gusswerkstoffen. s.l.: Master Thesis, Upper Austrian

University of applied sciences.

Muehlstaetter, C., Hartmann, M., 2016. Material modelling

of cast Aluminium by application of the Wilkins

Damage Model. s.l.:ECCOMAS Congress Proceedia.

Schiefermayr, K., Weiß, P., 2014. Wahrscheinlichkeits-

rechnung und Statistik. s.l.:Course book, Upper

Austrian University of applied sciences.

Tvergaard, V., Needleman, A., 1984. An analysis of ductile

rupture in notched bars. s.l.:Journal of the Mechanics

and Physics of Solids.

Wilkins, M. L., Streit, R. D., Reaugh, J. E., 1980.

Cumulative-strain-damage model of ductile fracture:

Simulation and prediction of engineering fracture tests.

s.l.:s.n.

A Stochastic Approach for Damage Modelling of Cast Alloys

471