Estimation of the Effect of 3D Grid Parameters on the Simulation

of the Working Process of Axial Turbines

Grigorii Popov, Valery Matveev, Oleg Baturin, Iuliia Novikova,

Daria Kolmakova and Vasilii Zubanov

Department of Aircraft Engine Theory, Samara National Research University, Samara, Russian Federation

Keywords: Component, Axial Turbine, CFD, Finite Volume Mesh, Settings, Simulation Accuracy, Error, Optimization.

Abstract: This article describes the second part of the global work done by the authors aimed at finding the best settings

for a numerical model for calculations of axial uncooled turbines using the RANS approach. The authors

studied more than 80 papers published over the past 5 years in the examined field. Their analysis did not allow

to identify unified recommendations for the creation of numerical models. The selection of model parameters

is usually motivated by general considerations of numerical simulation, which follow from the method. In

none of the papers the selection of parameters is correlated with the structure of the flow in the turbine. Many

specific simulation issues were not covered at all. For the research, more than 1000 models of full-size axial

turbines (including multistage turbines) and their elements were created. They differed in the number, size,

parameters of the elements of finite volume meshes, in turbulence models, in the degree of simplification.

The results were compared with the experimental data. As a result, the following was obtained: 1. A method

for developing and optimizing the working process of turbines using numerical simulation based on the RANS

approach is proposed. The search for the optimal turbine configuration is carried out using light computational

models, which are based on the simplified channel geometry and the finite volume mesh. Their application

makes it possible to reliably find the optimal turbine configuration 2.8 times faster. The characteristics of the

selected variants are verified with the help of verification models that consider the real geometry of the

channels and have a minimum error. 2. Recommendations are given on the selection of parameters for finite

volume meshes and the selection of turbulence models for numerical models of the working process of axial

turbines designed to perform optimization and verification calculations.

NOMENCLATURE

GTU – gas turbine unit

GTE – gas turbine engine

LPT – Low pressure turbine

FT – free turbine

y+ – dimensionless distance

RANS - Reynolds-averaged Navier–Stokes equations

=

- cell expansion ratio of the finite

volume mesh

=

- maximum cell aspect ratio of the

finite volume mesh

y

FP1

–size of the element of the finite volume mesh

closest to the endwall.

y

B2B1

- size of the element of the finite volume mesh

closest to the blade surface

CIAM – Central Institute of Aviation Motors

ζ

PR

– profile losses

λ – specific velocity

β

1

– inlet flow angle of the cascade, degree

β

2

– outlet flow angle of the cascade, degree

–residual dispersion

F – F-ratio test

qMSE – mean square error

– mean relative square errors

ζ

EXP

mean

– mean experimental value of profile losses

S – calculation speed up

η

PR

– cascade efficiency

Т

∗

- gas expansion ration in turbine

Popov, G., Matveev, V., Baturin, O., Novikova, I., Kolmakova, D. and Zubanov, V.

Estimation of the Effect of 3D Grid Parameters on the Simulation of the Working Process of Axial Turbines.

DOI: 10.5220/0006890203710377

In Proceedings of 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2018), pages 371-377

ISBN: 978-989-758-323-0

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

371

α

OUT

– outlet flow angle of the turbine, degree

Т

∗

- throughflow capacity of the turbine, m

.

n – rotational speed, rpm

∗

- isentropic rate of gas expansion in a turbine, m/s

E – efficiency of parallelization of a computational

task

B2B – two-dimensional blade passage

FV – finite volumes.

1 MOTIVATION AND

STATEMENT OF THE

RESEARCH PROBLEM

This paper is an integral part and a continuation of the

paper (Popov, 2018) in which it was shown that axial

uncooled turbine is widely used in aviation and

industrial gas turbine propulsion engineering.

Turbines are the components that significantly

determine the reliability, efficiency and cost of gas

turbine engines (Inozemcev, 2015). For this reason,

the problem of increasing the efficiency of turbines is

important and relevant. It is also important to develop

methods for designing and developing such turbines,

and primarily the methods for their numerical

simulation that is the most advanced calculation

method available to a modern engineer for evaluation

of the characteristics.

It was shown in (Popov, 2018) that the available

publications do not contain universal recommenda-

tions for numerical modeling of turbines. In (Popov,

2018), an approach was suggested, according to

which the selection of finite volume mesh should be

differentiated in accordance with the flow structure in

the blade row.

The selection of the values for 2D mesh

parameters must be carried out by the profile losses

determined during the simulation for individual blade

rows or by integral parameters of the turbines. The

paper (Popov, 2018) contains the results of the study

to substantiate this choice. Secondary losses have a

complex distribution along the height of the blade and

have effect only near the end surfaces of the flow

path. Therefore, when selecting the values of

and

, it is necessary to evaluate the distribution

of the flow parameters (for example, loss coefficients,

flow angle, total pressure) along the height of the flow

path. Below the development of recommendations for

the selection of the distribution of parameters along

the height of the turbine cascade and the results of

testing the received recommendations during the

simulation are described.

2 INVESTIGATION OF EFFECT

OF THE DISTRIBUTION OF

FINITE-VOLUME MESH

ELEMENTS ALONG THE

HEIGHT OF THE FLOW PART

TO THE SIMULATION

EFFICIENCY OF THE

WORKING PROCESS OF

TURBINE CASCADES

In the framework of the research, 9 meshes were

created for each cascade, the values of

and

parameters in which ranged from 1.2 to 1.7 and

from 250 to 4000, respectively. Each mesh was

simulated using 6 turbulence models. In total, 216

numerical models were created.

and

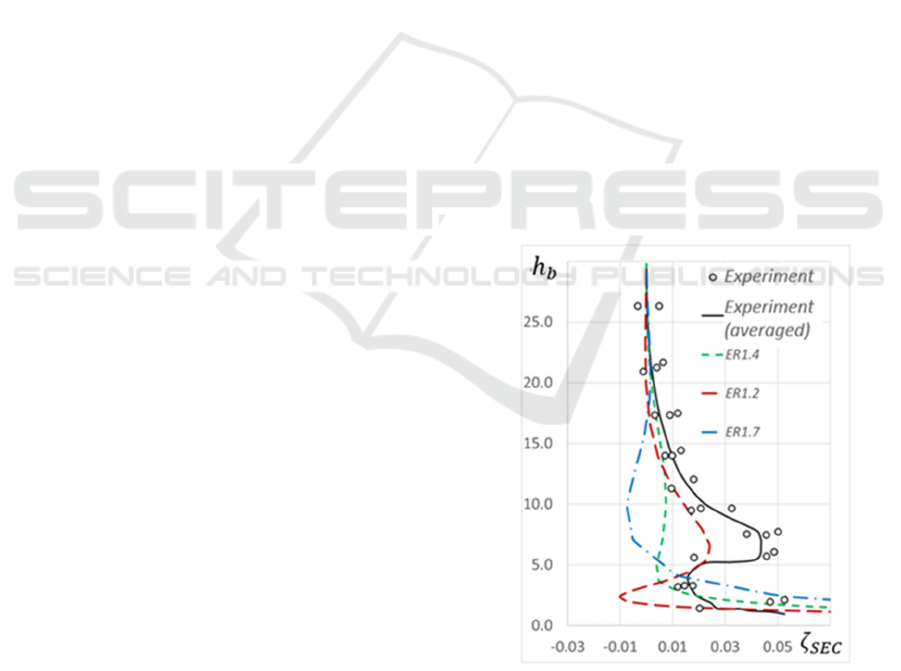

parameters have a qualitative and

quantitative effect on the calculated distribution of

secondary losses along the height of the flow part

=

. The increase in the

and

parameters leads to a decrease in the characteristic

loss peak on the distribution of secondary losses

along the height of the flow part (Figure 1), which is

also confirmed by the patterns of the flow structure in

the blade passages (Figure 2).

Figure 1: Influence of the

parameter at

=1.2

on the simulation of secondary losses (on the example of

cascade No. 34 (Venediktov, 1990).

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

372

a)

=1.2;

=250

b)

=1.7;

= 4000

Figure 2: Influence of the

and

parameters on

the computed fields of turbulent viscosity at the outlet from

the cascade No. 34 (Venediktov etc., 1990).

Acceptable combinations of the

and

parameters that allow to describe the distribution of

secondary losses in blade height adequately to the

experimental data are:

=1.2,

=

250 … 2000, and

=1.2…1.7,

= 250.

The

and

parameters have a negligible

effect on the total loss coefficient

in the

cascades (the change in the calculated value of

with changing

and

parameters in the

indicated ranges does not exceed 0.002), but they

significantly decrease the value of the speed up

parameter S in the range of

<1.4 and

<

1000, reaching the value S = 0.46 for

<1.2 и

= 250.

Based on the performed studies, it was concluded

that rational combinations of the parameters

and

for simulation of the secondary flows of

turbine cascades are:

=1.2,

=

1000 … 2000.

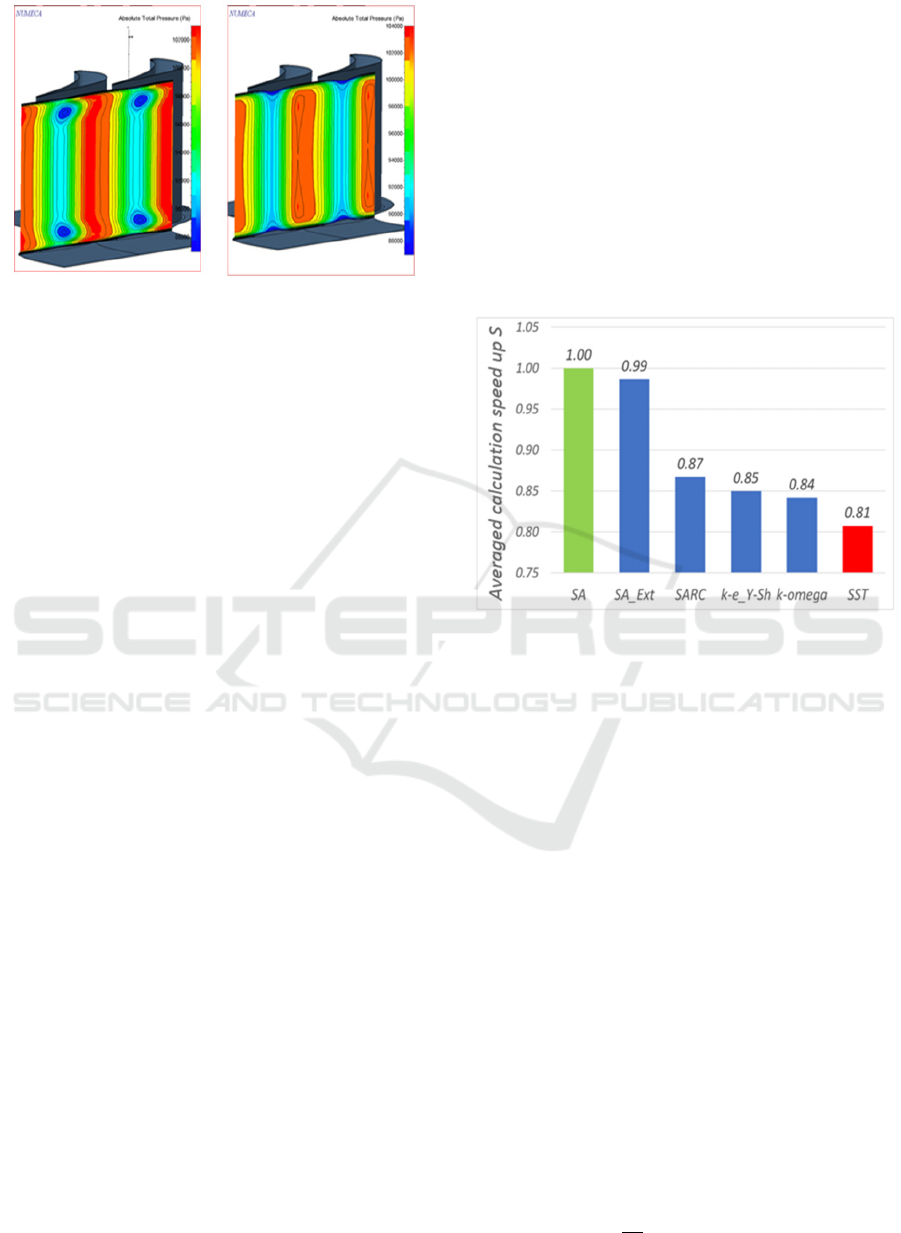

Then, the influence of the turbulence model on the

efficiency of simulation of the secondary losses in

axial turbine cascades was studied. When conducting

the mesh studies, it was found that the selection of the

turbulence model has only a quantitative effect on the

characteristics of the cascades in the form of

=

, and, consequently, on the error in

determining the coefficients of profile losses and the

efficiency of the cascades. The smallest errors in the

calculation of the cascade characteristics are provided

by using SST and k-ω turbulence models. It was also

found that the selection of the turbulence model has a

certain effect on the speed up of the calculations S.

Figure 3 shows a histogram of the relative speed up

averaged over all cascade and meshes

. The

relative speed up

was defined as the ratio of

the calculation time of one iteration

,

of the

numerical model with the i-th mesh and the Spalart-

Allmaras turbulence model to the time of calculation

of one iteration

,

of the numerical model

with the i-th mesh and the j-th turbulence model:

=

,

/

,

. The greatest value

of speed up

is achieved using the Spalart-

Allmaras turbulence model. Thus, to perform

optimization calculations, it is advisable to use the

Spalart-Allmaras model, and SST and k-ω turbulence

models for the verification, since the least error in

determining the losses is achieved.

Figure 3: The averaged (over all meshes) calculation speed

up for various turbulence models.

3 INVESTIGATION OF THE

INFLUENCE OF VARIOUS

PARAMETERS OF FINITE

ELEMENT MESHES ON THE

SIMULATION EFFICIENCY OF

THE WORKING PROCESS OF

FULL-SIZE GAS TURBINES

One of the features of numerical simulation of the

working process of full-size axial uncooled turbines

is the need to determine three characteristics for them:

the dependences of throughflow capacity, efficiency

and the flow angle in absolute motion at the outlet of

the turbine from the expansion ratio to the total

pressure (

Т

∗

=

Т

∗

,

Т

∗

=

Т

∗

и

=

Т

∗

,

respectively). Other features of simulation of the

working process of turbines is the variety of structural

elements of stage, such as, for example, shroud

platform, as well as the need to determine the

characteristics for different modes of operation with

respect to the

∗

⁄

parameter.

Estimation of the Effect of 3D Grid Parameters on the Simulation of the Working Process of Axial Turbines

373

Therefore, in addition to checking the results of

studies for turbine cascades on the simulation

efficiency of the turbine working process as a whole

while varying the number of 2D B2B mesh elements,

parameter, the

and

parameters, the

turbulence models obtained earlier, additional studies

on the effect of the accounting the parietal cavities

over the shroud platforms on simulation efficiency,

and also on the evaluation of the simulation efficiency

for various values of the parameter

∗

⁄

were

carried out.

In total, ten uncooled axial turbines with

aerodynamically long blades were examined. The

number of stages in the selected turbines ranged from

1 to 4, the throughflow capacity

Т

∗

was in the range

from 0.3 m

.

to 3.0 m

.

, the value

of the loading parameter

∗

⁄

was up to 0.66.

In the beginning, the computational models of

turbines were created using the parameters of the

basic numerical models of the working process. They

did not contain the parietal cavities. The simulation

was performed using three turbulence models:

Spalart-Allmaras, k -ε Low Re Yang-Shih and k-ω (in

total 30 numerical models).

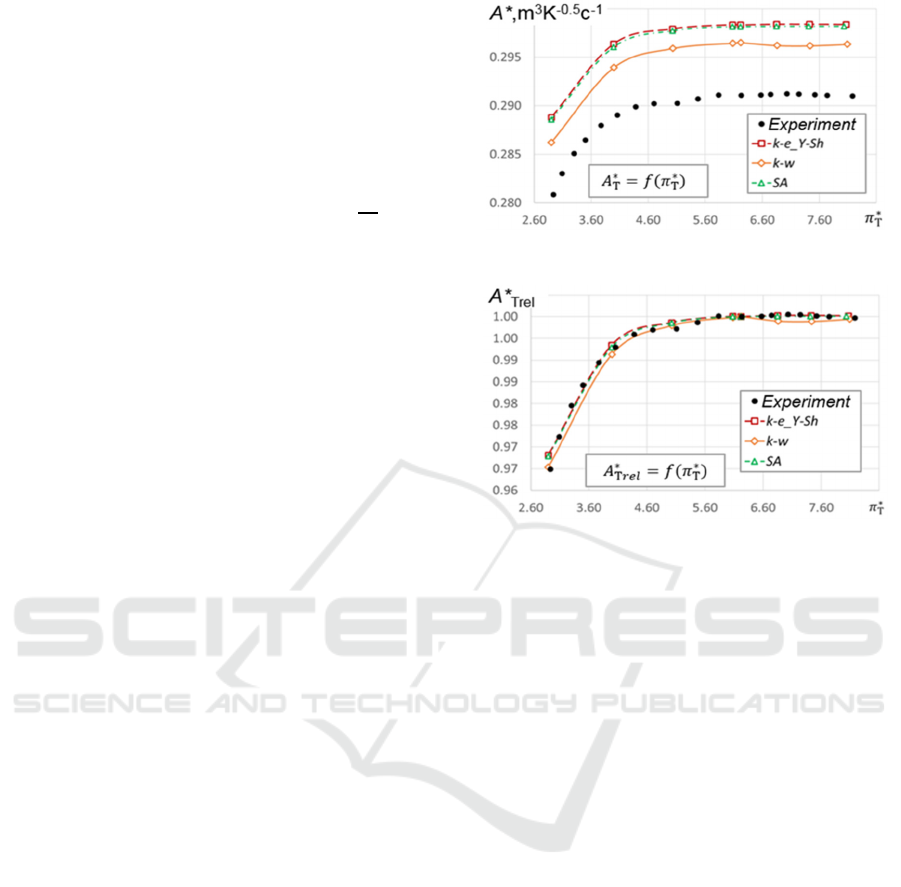

As a result of the conducted studies, it was

established that all the obtained calculation

characteristics are adequate to the available

characteristics of turbines obtained experimentally or

using verified mathematical models. At the same

time, the discrepancy between the existing and the

numerical values of the integral parameters of

turbines at the design point reached 4% (abs.)

(Figure 4, a). For this reason, the existing and

resultant numerical simulation data were recalculated

into a relative form:

=

Т

∗

.. The

relative values of the integral parameters of turbines

Т

∗

,

Т

∗

and

were determined using

expression:

=

,

where is the parameter value at an

arbitrary point of the characteristic curve,

is the parameter value at the design

point. All the relative characteristics obtained during

numerical simulation are adequate to the available

experimental characteristics (Figure 4, b). Thus, it

was concluded that all the basic numerical models of

the working process of turbines allow to determine

the behavior of the characteristics of turbines.

a) absolute characteristics

b) relative characteristics

Figure 4: Comparison of the calculated and experimental

characteristics of the NASA 4.5 turbine stage (Whitney,

1977), obtained using various turbulence models and basic

meshes.

Then, a study of the effect of the number of 2D

B2B mesh elements on the simulation efficiency of

the working process of axial uncooled turbines was

performed. Within the framework of the research

based on the basic meshes, 3 additional

computational meshes were created for each turbine

with 2D meshes B2B-2, B2B1 and B2B2, the number

of B2B elements varied from 6000 to 34000. The

calculation of each mesh was carried out using three

turbulence models. In total, 120 numerical models

were created. The studies confirmed the conclusions

made for the cascades about only the quantitative

influence of the number of B2B elements on the

calculation absolute characteristics; about a small

quantitative effect on the calculated parameters for

the number of elements 2 21000 (2D mesh

B2B1); about the insignificant influence of the

number of B2B elements on the absolute and relative

errors in determining the integral parameters of

turbines (Figure 5), as well as on increasing the

calculation speed up S to 2, while reducing the

number of 2D mesh elements to 6000 (corresponds to

B2B0 mesh). At the same time, the relative

characteristics of turbines when changing the number

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

374

of B2B elements practically do not change and are

adequate to the available relative characteristics.

Figure 5: The influence of the number of 2D mesh elements

on the absolute error in determining the efficiency of the

turbine.

Investigations on the effect of the

parameter

on the simulation efficiency performed in the range

of

from 0.2 to 5.0 using three turbulence

models also confirmed the conclusions drawn for the

cascades. The change in the

parameter does not

change the behavior of the calculation absolute

characteristics of turbines and only shifts them along

the ordinate axis. For

1, the influence of the

parameter on the calculated values of the integral

parameters of the turbines and on the error of their

determination is extremely insignificant. At the same

time, the relative characteristics of turbines with a

change in the

parameter practically do not

change and are adequate to the available relative

characteristics.

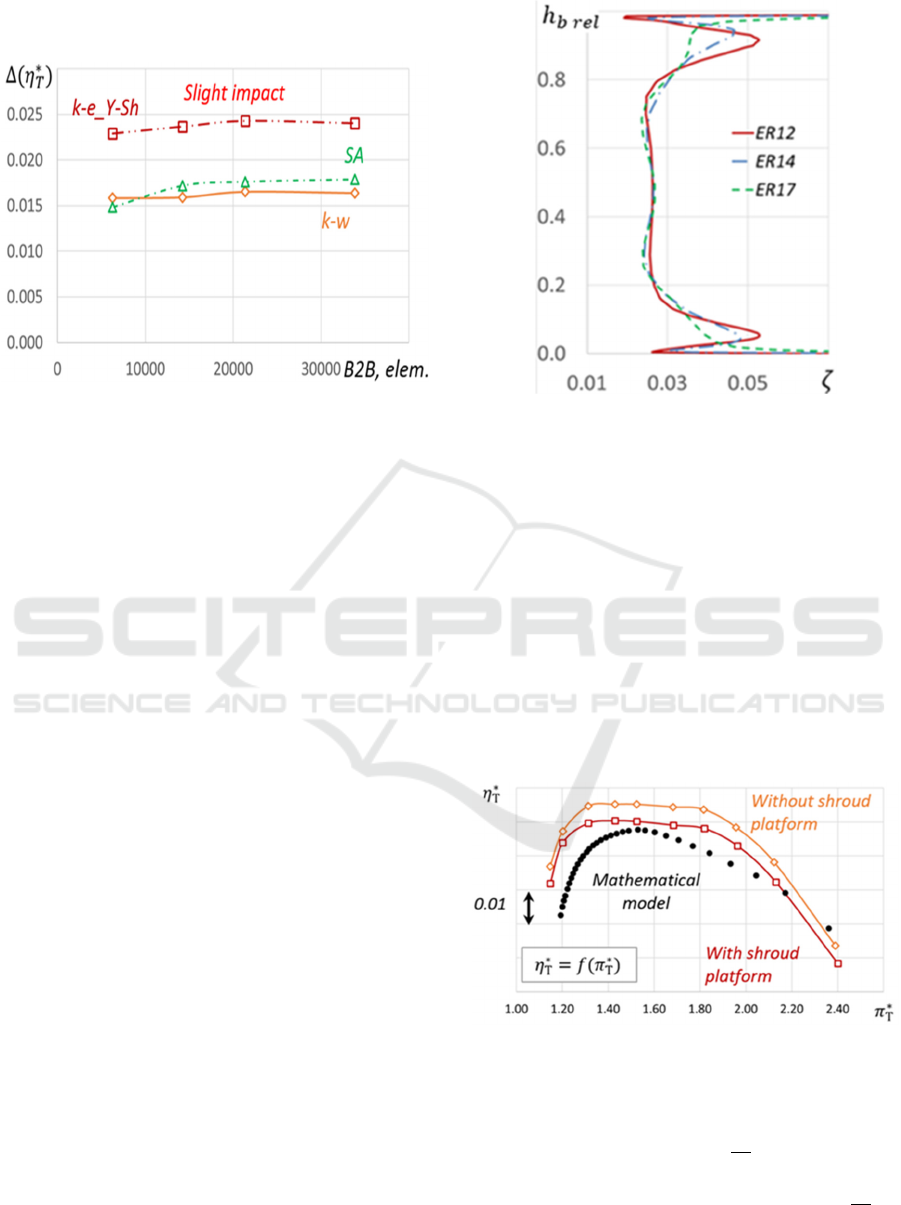

The next step was to investigate the effect of the

and

parameters on the simulation

efficiency of the turbine workflow. The range of

parameters during the study was:

=1.2…1.7,

= 1000 …4000.. Also, as for cascades, the

increase in

and

parameters lead to the

flattening of peaks due to secondary losses on the loss

distribution over the height of the flow part

(Figure 6). At the same time, permissible

combinations of the

and

parameters

allow adequately describing the distribution of losses

along the blade height:

1.4,

2000.

and

parameters in the permissible range

have practically no effect on the absolute and relative

characteristics of the turbines. At the same time, the

calculation speed up S significantly decreases with

decreasing the

and

parameters, reaching

the value S = 0.67 for

1.4,

2000.

Figure 6: The effect of the

parameter at

= 1000 on the simulated distribution of losses along

the blade height in a section behind first nozzle block of the

NASA turbine (Whitney, 1977).

Studies on the effect of accounting the cavities

over the shroud platforms on the simulation

efficiency showed that their presence does not

qualitatively affect the behavior of the characteristics,

but exerts a significant quantitative influence on

them, shifting the efficiency along the ordinate axis

by up to 1% (Figure 7), which leads to a significant

reduction in the error in the calculation of the

efficiency. At the same time, the calculation speed up

S is also significantly reduced (up to 0.74)

(J. Respondek, 2010).

Figure 7: The influence of the accounting of the shroud

platform on the calculation characteristics of the LPT.

Simulation of the turbine working process using

different meshes, turbulence models for various

values of the parameter

∗

⁄

showed that all

numerical models allow to estimate the

characteristics at off-design modes by

∗

⁄

in

Estimation of the Effect of 3D Grid Parameters on the Simulation of the Working Process of Axial Turbines

375

absolute and in a relative form without additional

errors.

At the final stage, the effect of the selection of

turbulence models on the simulation efficiency of the

working process of axial turbines was generalized.

All the described mesh studies for turbines were

performed using only three turbulence models and

allowed to establish that the selection of the

turbulence model does not change the behavior of the

characteristics, but only equidistantly shifts them

along the ordinate axis. Thus, all turbulence models

make it possible to evaluate trends in the turbine

parameters. The simulated workflow of some of the

turbines using the basic meshes and 7th turbulence

models only confirmed these conclusions. The

smallest errors in determining the integral parameters

of turbines are provided by using k-ω turbulence

model, and the greatest speed up S is when the

Spalart-Allmaras turbulence model is used.

4 GENERALIZATION OF THE

OBTAINED RESULTS:

RECOMMENDATIONS FOR

THE DEVELOPMENT OF

NUMERICAL MODELS OF

AXIAL UNCOOLED TURBINES

Based on the studies carried out, two methods were

developed for the creation of rational numerical

models for the working process of turbines with

aerodynamic long blades, designed to perform

optimization and verification calculations.

At the first stage of creating a rational numerical

model designed to perform optimization calculations,

the geometry of the computational domain is

constructed.

Then a mesh of finite volumes is constructed. For

optimization calculations it is necessary to use two-

dimensional meshes B2B-2 (6000 elem.), in which

the value of the dimensionless parameter

is 1.

The distribution of the elements along the height must

be specified using the

and

. parameters.

At the initial stages of optimization, it is advisable to

use meshes in which

<1.4,

< 2000.

When optimizing with a more accurate account of

secondary losses, meshes should be used in which

<1.2,

< 2000.

At the third stage of adjusting the parameters of

the numerical model, among other settings, it is

necessary to select the Spalart-Allmaras turbulence

model.

When configuring paralleling settings, it is

advisable to adhere to the approach that involves

running the maximum number of tasks

simultaneously on all processors.

This method allows to create rational optimization

numerical models that to estimate accurately the

trends in the integral parameters of turbines and have

high values of the speed up parameter up to 2.8.

The method of creating rational numerical models

intended for verification calculations differs from the

method for optimization models only by

recommendations on the selection of values of model

parameters.

For verification calculations, it is advisable to use

two-dimensional meshes B2B1 (21000 elem.). The

values of the parameters for the distribution of

elements along the height of the flow part should be

chosen from the interval:

<1.2,

= 1000 …2000. When carrying out the

verification calculations, it is necessary to consider

the parietal cavities over the shroud platforms. For

verifying calculations, the best results are shown by

the k - ω turbulence model.

Parallelization should be performed on the

maximum possible number of processors, but one

processor should account for at least 200 thousand

elements of the computational mesh.

This method allows the creation of rational

numerical models designed for verification

calculations, which determine the detailed flow

structure, which have minimal errors in determining

the integral parameters, but also a low value of the

speed up S (approximately 0.27...0.30).

5 CONCLUSIONS

This paper together with (Popov, 2018) describes the

main stages and results of the work aimed at

increasing the simulation efficiency (increasing

accuracy and reducing the calculation time) of the

workflow of uncooled axial turbines of aircraft

engines using the RANS approach.

To obtain the results, more than 80 papers by

different authors published over the last 5 years

related to numerical simulation of the working

process of axial turbines were studied. More than

1000 numerical models of axial turbines and their

elements were created, calculated and analyzed. The

obtained results were compared with the results of

experiments or calculations using verified methods.

All the results obtained during the study were

processed and generalized using the methods of

mathematical statistics.

SIMULTECH 2018 - 8th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

376

As a result of the work, the following results were

obtained:

1. A method for studying, improving and

optimizing the working process of axial turbines

using numerical simulation based on the RANS

approach is proposed. The essence of the method lies

in the fact that the search for the optimal

configuration of the turbine is carried out using light

computational models that are based on a simplified

channel geometry (neglecting the parasitic cavities,

fillets, etc.) and a light mesh of finite volumes. The

application of such models makes it possible to create

a rational optimization numerical models that allow

estimating the trends in the variation of the integral

parameters of turbines and having high values of the

speed up parameter (up to 2.8). The obtained results

should be checked with the help of verification

numerical models that consider the real geometry of

the channels and allow to determine the detailed flow

structure with minimal errors in calculating the

integral parameters.

2. A universal complex of parameters describing

the finite volume mesh of numerical models of axial

air turbines and based on the features of the flow

structure in the channels is proposed. The complex

includes: the number of elements along the

characteristic sides of 2D-mesh topological blocks;

dimensionless parameter y

, which determines the

values y

and y

, the cell expansion ratio along

the height of the flow part ER

, the maximum cell

aspect ratio along the height of the flow part MR

.

3. An original approach to the search for the best

parameters of a finite volume mesh was proposed and

implemented. In particular, the selection of the values

of the parameters of 2D mesh should be carried out

according to the calculated profile losses for

individual blade rows or by integral parameters of

turbines. The selection of ER

and MR

parameter

values must be performed based on the distribution of

flow parameters along the height of the flow part.

4. Recommendations were received on the setting

the parameters for finite volume meshes and the

selection of turbulence models for numerical models

of the working process of axial uncooled turbines

designed to perform optimization calculations. The

number of B2B mesh elements must contain more

than 6000 elements, the value of the y

parameter

is 1, the value of the MR

parameter is 2000, and the

ER

parameter value is less than 1.4. Simulation

should be performed using the Spalart-Allmaras

turbulence model.

5. Recommendations were received on the setting

the parameters for finite volume meshes and the

selection of turbulence models for numerical models

of the working process of axial uncooled turbines

designed to perform verification calculations. For

verification calculations it is advisable to use two-

dimensional B2B meshes with the number of

elements greater than 21000. The values of the

parameters for the distribution of the elements along

the height of the flow part should be chosen from the

interval: ER

<1.2, MR

= 1000 … 2000. When

carrying out verification calculations, parietal cavities

over the shroud platforms should be considered.

Simulation should be performed using k-ω turbulence

model.

ACKNOWLEDGEMENTS

This work was supported by the Ministry of

Education and scenes of the Russian Federation in the

framework of implementation of the Program of

increasing the competitiveness of Samara University

among the world's leading and educational centers for

2013-2020 years.

REFERENCES

Popov, G., Matveev, V., Baturin, O., Novikova, J., Volkov

A., 2018. Selection of parameters for blade-to-blade

finite-volume mesh for CFD simulation of axial

turbines. In press. Proceedings of International

Conference on Mechanical, System and Control

Engineering, ICMSC 2018.

Inozemcev, A. A., 2015. Development of a line of civil gas

turbine engines (Razvitie linejki grazhdanskih GTD).

Report, CIAM.

Venediktov, V. D., and Granovsky, A. V., 1990. The

Atlas of Experimental Performances of Cooled Gas

Turbine Blade Cascades (Atlas eksperimental'nykh

kharakteristik ploskikh reshetok okhlazhdaemykh

gazovykh turbin). CIAM.

Wilfert, G., Joerg, S., Rolt, A., Baker, N., and A. Touyeras,

2007. New Environmental Friendly Aero Engine Core

Concepts. Proceedings of the ISABE 2007, Paper 1120.

Whitney, W. J., Bebning, F. P., Moffit, T. P., Hotz, G. M.,

1977. Cold-air investigation of 4 ½ stage turbine with a

stage loading factor of 4.66 and high specific work

output. I – Overall Performance. NASA TM X-3498.

Respondek, J., 2010. Numerical simulation in the partial

differential equation controllability analysis with

physically meaningful constraints. Mathematics and

Computers in Simulation 81, P 120–132.

Estimation of the Effect of 3D Grid Parameters on the Simulation of the Working Process of Axial Turbines

377