Taguchi Loss Function to Minimize Variance and Optimize a Flexible

Manufacturing System (FMS): A Six Sigma Approach Framework

Wa-Muzemba Anselm Tshibangu

Morgan State University, Department of Industrial and Systems Engineering,

1701 E Cold Spring Lane, Baltimore, MD 21251, U.S.A.

Keywords: Robust Design, Optimization, DOE, FMS, Taguchi Loss Function, Simulation, Six Sigma.

Abstract: This paper analyzes a flexible manufacturing system (FMS) and presents a new scheme to find the optimal

operational parameters settings of two of the mostly used performance measures in assessing manufacturing

and production systems, namely the throughput rate (TR) and the mean flow time (MFT). The scheme uses

an off-line model that combines discrete-event simulation, robust design principles and mathematical analysis

to uncover the optimal settings. The research suggests a two-level optimization procedure that uses an

empirical process followed by an analytical technique. In a first level, the empirical approach serves to derive

the near-optimal values of the two individual performance measures of interest. These values are then used

as targets in the second level of the optimization procedure in which, a Taguchi quality loss function (QLF)

is applied to the FMS mathematical model derived through simulation-meta-modeling to find the optimal

parameter settings. As advocated in Six Sigma Methodology the optimization of the modeled system is

implemented and achieved through a minimization of the performance variation followed by an optimal

adjustment of the performance’s mean if necessary, in order to minimize the overall loss incurred due to the

deviation of the mean from target.

1 INTRODUCTION

A high reliability is one of the most desired features

in operating a production system in general and a

Flexible Manufacturing System (FMS) in particular.

For this reason, there has been a highly increasing

need in the manufacturing sector to seek for both

flexibility and robustness under optimal settings of

main operating parameters.

The present research analyzes a hypothetical FMS

and presents a unique scheme in designing, modeling

and optimizing robust systems. The reader is referred

to Tshibangu 2017 for a detailed description of the

hypothetical FMS under study. A discrete-event

simulation and typical data collection plan are used

for the study. Data collected during simulation are

subsequently fed into a non-linear regression model

to generate meta-model that will characterize the

FMS from the performance measures point of view.

The optimization procedure as subsequently

developed in this paper is performed at two levels.

First an empirical technique is used to find near-to-

optimal values for each individual performance

criterion of interest. These values are subsequently

used as target goals in the second level of the

optimization procedure in which a Taguchi Quality

Loss Function (QLF) is applied to the meta-models to

uncover the optimal setting of the system parameters

while minimizing the loss incurred to the overall

systems for possibly missing the targets as set.

Specifically, the analytical optimization is applied to

a regression model equation (meta-model) derived

from the simulation output results.

The approach used in this study takes advantage

of a robust design methodology as it renders the

system insensitive to uncontrollable factors (noise)

and hence, guarantees the system stability required

before any improvement and /or optimization

attempt. The research is also motivated by both the

Six Sigma governing principle, that seeks

performance improvement through a reduction of

variability and the Six Sigma methodology that

advocates the use of DMAIC as roadmap to seek and

implement the best solution while reducing defects,

and thus, improving quality. The different steps in

this study will identify the Six Sigma roadmap phases

as well.

592

Tshibangu, W-M.

Taguchi Loss Function to Minimize Variance and Optimize a Flexible Manufacturing System (FMS): A Six Sigma Approach Framework.

DOI: 10.5220/0006868705920599

In Proceedings of the 15th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2018) - Volume 2, pages 592-599

ISBN: 978-989-758-321-6

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 LITERATURE REVIEW

The Six Sigma philosophy maintains that reducing

‘variation’ will help solve process and business

problems (Pojasek, 2003). This quality management

methodology is extensively used to improve

processes, products and/or services by discovering

and eliminating defects. The goal is to streamline

quality control in manufacturing or business

processes so there is little to no variance throughout.

The strategic use of Six Sigma principles and

practices ensures that process improvements

generated in one area can be leveraged elsewhere to a

maximum advantage, resulting in quantum increasing

product quality, continuous process improvement

resulting in corporate earnings performance (Sharma

2003).

There is still a limited number of reported flexible

manufacturing system optimization using Six Sigma

or a combination of both Lean principles and Six

Sigma. Moreover, there is virtually no documentation

on the merge of Six Sigma and Taguchi Quality Loss

Function in attempt to optimize a process and or

system. Sharma (2003) also mentions that there are

many advantages of using strategic Six Sigma

principles in tandem with lean enterprise techniques,

which can lead to quick process improvement and/or

optimization. More than 95% of plants closest to

world-class indicated that they have an established

improvement methodology in place, mainly

translated into Lean, Six Sigma or the combination of

both. Valles et. al 2009 use a Six Sigma methodology

(variation reduction) to achieve a 50% reduction in

the electrical failures in a semi-conductor company

dedicated to the manufacturing of cartridges for ink

jet printers. Han et al. 2008 also use Six Sigma

technique to optimize the performance and improve

quality in construction operations. Hansda et. al

(2014) use a Taguchi QLF in a multi-characteristics

optimization scheme to optimize the response in

drilling of GFR composites. Tsui (1996) proposes a

two-step procedure to identify optimal factor settings

that minimize the variance and adjust to target using

a robust design inspired from Taguchi methodology.

Zhanga et. al (2013) use a QLF to adjust a process in

an experimental silicon ingot growing process.

3 THE ROBUST

DESIGN - (DEFINE)

Being part of what is known today as the Taguchi

Methods, Robust Design includes both design of

experiments concepts, and a particular philosophy for

design in a more general sense (e.g. manufacturing

design). Taguchi sought to improve the quality of

manufactured goods, and advocated the notion that

“quality” should correspond to low variance, which is

also the backbone of the Six Sigma methodology

today as it seeks a reduction of variance as a means to

stabilize a process and, hence, improve “quality”. The

present study uses a robust design configuration

inspired by Taguchi robust design methodology.

However, because of the high amount of criticism

against Taguchi’s experimental design tools such as

orthogonal arrays, linear graphs, and signal-to-noise

ratios, the robust design formulation adopted here

avoids the use of Taguchi’s statistical methods and

rather uses an empirical technique developed by

Tshibangu (2003). Overall, implementing a robust

design methodology or formulation requires the

following steps:

• Define the performance measures of interest, the

controllable factors, and the uncontrollable factors or

source of noise.

• Plan the experiment by specifying how the

control parameter settings will be varied and how the

effect of noise will be measured.

• Carry out the experiment and use the results to

predict improved control parameter settings (e.g., by

using the optimization procedure developed in this

study).

• Run a confirmation experiment to check the

validity of the prediction.

In a robust design experiment, the settings of

control parameters are varied simultaneously in few

experimental runs, and for each run, multiple

measurements of the main performance criteria are

carried out in order to evaluate the system sensitivity

to noise.

This study investigates the FMS performance

with respect to the mean flow time (MFT) and

throughput rate (TR) separately by considering 5

variables Xi as controllable parameters, namely: i) the

number of AGVs (X

1

), ii) the speed of AGV (X

2

), iii)

the queue discipline (X

3

), iv) the AGV dispatching

rule (X

4

), v) and the buffer size (X

5

). These

parameters are not the only variables susceptible to

affect the performance of the FMS under study.

However, because one objective of the research is to

design a robust FMS, the parameters considered here

are those related to the performances of the most

costly and vulnerable components of the system, also

potential sources of disturbances, namely: machines

and material handling (AGVs). The controllable

Taguchi Loss Function to Minimize Variance and Optimize a Flexible Manufacturing System (FMS): A Six Sigma Approach Framework

593

parameters are tested at two settings (min and max)

as displayed in Table 1.

The principal sources of noise tested in this study

and commonly investigated and documented in the

reported literature (Tshibangu 2014) are: i) the arrival

rate between parts or orders in the manufacturing

environment (X

6

), ii) the mean time between failures

of the machines (X

7

), and iii) the associated mean

time to repair (X

8

).

These noise factors are also tested at two setting

levels in combination with each control factor at all

setting levels. Table 2 depicts settings and natural

values for noise factors. For both controllable and

noise factors, the coded levels are (-1) and (+1) for

the low and high level, respectively.

3.1 Planning the Experiment

Planning the experiment is a two-part step that

involves deciding how to vary the parameter settings

and how to measure the effect of noise. In the case of

a full factorial experimental design, with the 5

variables X1, X2, X3, X4, and X5, identified as the

control parameters to be evaluated at two settings, the

experiment will require 2

5

= 32 experimental runs.

The research also investigates three noise factors X

6

,

X

7

, and X

8

, varied at two settings each, resulting in

measuring a total of 2

3

= 8 noise combination settings

for each experimental run.

Therefore, the total number of experimental runs

to be conducted in a full factorial configuration would

therefore be equal to 32 x 8 = 256 simulation

experiments.

Two-level, full factorial or fractional factorial

designs are the most common structures used in

constructing experimental design plans for system

design variables. Tshibangu (2003) recommends

appropriate fractional factorial designs of resolution

IV or V in the design of robust manufacturing

systems. This research decides to use a two-level

fractional design of resolution V, denoted 2v

5-1

requiring only 16 runs, instead of the 32 needed for a

full factorial design. Across the full set of noise

factors, the design leads to a total of 16 x 8 =128

simulation runs (instead of 256 as required for a full

factorial design). The study uses a design of

resolution V to allow an estimation of both main

factors and two-way interactions effects, necessary

for the empirical optimization technique

implemented in this research study.

Normally, a standard, statistical experimental

design, also known as a data collection plan, should

be used when conducting simulation experiments.

Table 1: Natural Values and Setting of Controllable

Factors.

Designation

Noise Factor

Low Level (-1)

High Level(+1)

X

6

Inter-arrival

EXPO(15)

EXPO(5)

X

7

MTBF

EXPO(300)

EXPO(800)

X

8

MTTR

EXPO(50)

EXPO(90)

Table 2: Natural Values and Setting of Noise Factors.

Designation

Control Factor

Low

Level (-1)

High

Level(+1)

X

1

Number of AGVs

2

9

X

2

Speed of AGV

100

200

X

3

Queue Discipline

FIFO

SPT

X

4

AGV Dispatching Rule

FCFS

SDT

X

5

Buffer Size

8

40

The data collection plan used in this research is

inspired from Genichi Taguchi’s strategy for

improving product and process quality in

manufacturing. The proposed design strategy

includes simultaneous changing of input parameter

values. Therefore, the uncertainty (noise) associated

with not knowing the effect of shifts in actual

parameter values such as shifts in mean inter-arrival

times, mean service times, or the effect of not

knowing the accuracy of the estimates of the input

parameter values, is introduced into the experimental

design itself. Tshibangu (2003) gives detailed

information about this specific data collection plan

used in this study to run the simulation experiments

and collect the statistics thereof.

3.2 Level 1 Optimization Procedure:

Four-Step Single Response

Optimization for Robust Design

Because flexible manufacturing systems are subject

to various uncontrollable factors that may adversely

affect their performance, a robust design of such

systems is crucial and unavoidable. In order to

improve the expected value of the function estimate

or performance measure, Tshibangu (2003) has

developed a four-step optimization procedure to be

used simultaneously with the robust design in an

empirical fashion as follows:

Let

i

y

represent the average performance measure

across all the set of noise factors combination,

averaged across all the simulation replications for

each treatment combination (or design configuration)

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

594

i. Let log

2

wrtnf(i)

be the associated logarithm of the

variance with respect to noise for that particular

treatment i. The author recommends to use the

logarithm of the variance in order to improve

statistical properties of the analysis.

Employ the effects values and or graphs in

association with normal probability plots and or

ANOVA procedures to identify and partition the

following three categories of control factor vectors:

(i) X

v

T

the vector of controllable factors that have a

major (significant) effect on the variance with

respect to noise factors

2

wrtnf

(represented by

log

2

wrtnf

) of the performance measure of

interest y.

(ii) X

m

T

the vector of controllable factors that have a

significant effect on the mean

y

. The group X

m

T

is further partitioned into two sub-groups:

a. (X

m

T

)

1

including factors having a significant

effect on the mean

y

, with their main and

interaction effects with members of X

v

T

having

no or less significance on the variance

2

wrtnf

.

The main idea here is: since these factors or any

of their interaction with the controllable factors

members of X

v

T

do not have a significant effect

on the variance, but have a large effect on the

mean, they can be used as “tuning” factors to

adjust the mean on the target without altering the

variability.

b. (X

m

T

)

2

including factors having a significant

effect on mean

y

and on the variance

2

wrtnf

simultaneously. That is, (X

m

T

)

2

is a subset of X

v

T

,

or is totally confounded to the X

v

T

set. (X

m

T

)

2

is

further categorized in (X

m

T

)

2

A

that includes

factors with effect on variance and mean acting

in the same direction, and (X

m

T

)

2

B

containing

factors with effects on variance and mean acting

in opposition. Because these settings affect

inversely (in relation with the experiment’s

goal), there is a need for trade-off.

(iii) X

0

T

the vector of controllable factors that affect

neither the variance

2

wrtnf

nor the mean

y

, and

whose interactions with members of set X

v

T

has

no effect on the variance

2

wrtnf

.

Note that controllable factors members of set X

v

T

may also affect the mean

y

, i.e., they can also be

members of X

m

T

. Such factors affect both the variance

2

wrtnf

and the mean

y

. Thus, a compromise between

variance and mean might be required if necessary.

However, a controllable factor member of X

0

T

cannot

be simultaneously a member of X

v

T

and or X

m

T

. Also,

the robust design configuration should have enough

resolution (at least resolution IV) to allow

identification of the two-way interaction effects.

This study assumes that X

v

T

, X

m

T

, and X

0

T

, are not

empty sets and subsequently implements the four-

step optimization procedure as developed and

proposed by the author (Tshibangu 2003). Using the

related plots and tables, and applying it to the Mean

Flow Time (MFT) and Throughput Rate (TR)

performance measures, the following coded results

are obtained: MFT = 0.3666 units time /part and TR =

3000 parts/month (100 parts/day). These values will

be considered as the optimal target values to be

achieved in the second level of the optimization

procedure (multi-criteria optimization).

3.3 Simulation Meta-modeling -

(Measure)

Kleijnen (1977) defines the purposes of meta-

modeling as the method by which to measure the

sensitivity of the simulation response to various

factors that may be either decision (controllable)

variables or environmental (non-controllable)

variables. Meta-models are usually constructed by

running a special RSM (Response Surface

Methodology) experiment and fitting a regression

equation that relates the responses to the independent

variables or factors.

Let us assume that, for each objective

performance of the FMS under study a model has

been developed, representing the relationship

between the system objective performances and the

operating parameters X

1

, X

2

,…, X

p

, in the form of:

12

ˆ

( , ,..., )

jp

y f x x x

(1)

where

ˆ

j

y

is an estimate of the performance measure

of interest obtained through regression meta-

modeling, and

12

, ,...,

p

x x x

are the coded units of

operating variables X

1

, X

2

,…, X

P

. The FMS simulation

statistics collected were subsequently fed into a non-

linear regression meta-model. Applying the meta-

modeling technique to the FMS under study leads to

the estimate-equations

ˆ

TR

y

and

ˆ

MTF

y

for the

responses of interest, i.e., for the throughput rate (TR),

and for the mean flow time (MFT). The simulation

results, not displayed here, but available upon

request, yield the following equations for the

performance measures of interest,

ˆ

TR

y

and

ˆ

MTF

y

.

Taguchi Loss Function to Minimize Variance and Optimize a Flexible Manufacturing System (FMS): A Six Sigma Approach Framework

595

(2)

where

54321

,,,, xxxxx

are the coded units for the

operating variables X

1

, X

2

, X

3

, X

4

, and X

5

,

respectively.

(3)

3.4 Variance Metamodels – (Measure)

The same methodology used to derive the

metamodels for the means of performance measures

in equations (2) and (3) is applied to TR and MFT

logarithmic variances to derive a regression model

able to predict the variance with respect to noise at

any treatment combination of the controllable factors

(equations 4 and 5). Tables 3 displays an example of

outputs from SPSS

®

, from which the metamodels of

the TR log variances are generated as follows:

(4)

(5)

For all the equations generated in this paper, i.e.,

(Equations 2, 3, 4 and 5) the R-squared values of all

the prediction models are very high (e.g., 0.999+),

indicating a good approximation of the prediction

models. The accuracy of these prediction models

have been verified and confirmed through simulation

runs of all 21 designs followed by a subsequent

residuals calculation and comparison of the observed

values to the predicted values. The magnitude of

residuals (not shown here) was less than 5% overall.

Table 3: Non Linear Regression Analysis and ANOVA for

Var TR.

Nonlinear

Regression

Summary Statistics

Dependent Variable

VARTR

Source

DF Sum of Squares

Mean Square

Regression

21 1903372.42116

90636.78196

Residual

0 525.76464

Uncorrected Total

21 1903898.18580

(Corrected Total)

20 1162541.93246

R squared = 1 - Residual SS / Corrected SS = .99955

4 TAGUCHI QUALITY LOSS

FUNCTION ANALYSIS –

(ANALYZE)

This section overviews the basic features of the

Quality Loss Function (QLF). Taguchi’s approach in

Quality Engineering is explained in the following

steps:

Each engineering output has an ideal target

value.

Any deviation from target incurs a loss.

These losses include tolerance stack-up,

performance degradation, and life reduction.

The more the loss increases the more the

output response deviates from the target.

The goal of Robust Design (RD) is to reduce

deviation of performance measure(s) from

the target(s).

Performance begins to gradually deteriorate as the

quality characteristic of interest and/or performance

criterion deviates from its optimum value. Therefore,

Taguchi proposed that the loss function be measured

by the deviation from the ideal value.

A variety of loss functions have been discussed in

the literature. However, a simple Quadratic Loss

Function (QFL) may be appropriate in many

situations (Tshibangu 2003). These quality loss

functions, especially the nominal-the-best type

function, are widely used in process adjustment. Most

existing literature developed the algorithm by

minimizing the expected mean sum of squared error,

which is consistent with the nominal-the-best loss

function (Tshibangu 2015).

In this research the Taguchi QLF is used to

measure the loss of performance as compared to

target value(s). The optimal values found during the

implementation of the proposed empirical

optimization procedure will be used as target values

in the subsequent analytical optimization approach.

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

596

The two primary objective performances involved in

separate and single optimization procedures as

developed in this study are the Throughput Rate (TR)

and the Mean Flow Time (MFT).

Tshibangu (2003) shows that Taguchi QLF for a

single objective criterion can be extended to the case

of multiple quality characteristics or objective

performances, and then referred to as a “multivariate

quality loss function”. The purpose is to capture the

overall system performance when addressing a set of

performance objectives. This study addresses the

single objective optimization for the MTF and TR

using Taguchi QLF.

Let y

j

, and Tj be the performance measures of

interest (j =1 to Q, where Q is the total number of

performance measures), and the target for objective

performance y

j

respectively, and be denoted by y =

(y1, y2,…, yQ)

T

and T = (T1, T2,…, TQ)

T

under the

assumption that L(y) is a twice-differentiable function

in the neighborhood of T.

Assuming that each objective performance has a

mean μ(x)i and a variance σ(x)i

2

, then, after some

mathematical developments and manipulations

(Tshibangu 2003) the expected value of the quadratic

loss function can be written as follows:

2

2

1

1

21

Q

i i i i

i

Q

i

ij ij i i j j

ij

E L y T

TT

(6)

where

2

2

1

2

ij

i

L

ij

y

(7)

and

2

1

2

ij

ij

L

ij

yy

(8)

and σ

ij

represents the covariance between yi and y

j

.

Equation (6) reveals that several terms, such as the

bias and variance generated by each objective

performance, the covariance σ

ij

between objective

performance, and the cross products between biases,

must be reduced in order to minimize the expected

loss. Assuming that all the objective performances of

interest are statistically independent, then,

0

ij

and

equation (6) reduces to:

2

2

1

1

21

()

Q

i i i i

i

Q

i

ij i i j j

ij

E L y T

TT

(9)

As pointed out in Tshibangu (2015), there are

three aspects of interest in formulating robust design

systems: (i) deviation from targets; (ii) robustness to

noise; (iii) robustness to process parameters

fluctuations. A weighted sum of mean squares is

appropriate to capture (i) and (ii), while gradient

information is necessary to capture (iii). This research

is particularly interested in deviation from target and

robustness to noise. Therefore, only the first term of

Equation (9) is needed.

The next step consists of applying the derived

QLF to the FMS meta-models obtained from

simulation outputs and expressed in Equations (4) and

(5). In order to determine the optimal input

parameters, an objective function is developed from

Equation (9) following a framework adopted by

Tshibangu (2014).

Because of the robust design configuration

adopted during the experiments and assuming a Six

Sigma methodology is in use, it can be assumed that

the variability of the system due to fluctuations of the

operating parameters is negligible, then, for a given

treatment, the loss incurred to a system as the result

of a departure of the system performance from the

target T

j

can be estimated as:

(10)

where L(i) is the loss at treatment i; w

j

is a weight

to take into account to consider the relative

importance of an individual performance measure

j

y

(j=1,2,…Q), especially in the case of a multiple

optimization procedure;

ˆ

,

j yj

y

are respectively the

predicted (estimate) mean and standard deviation of

the performance measures of interest y

j

; T

j

is the

target for the system performance measure y

j

. L(i) is

the objective function to be minimized. In this

particular form, the objective function has two terms.

The first term of the objective function,

2

ˆ

jj

yT

accounts for deviations from target values. The

second term,

2

ˆ

yj

accounts for the source of

variability due to non-controllable (noise) factors.

Because this study is addressing a single criterion

optimization separately for each performance

measure and because the determination of goal’s

weights is beyond the scope of this research study, it

has been assumed that both performance measures of

interest are equally important, and most importantly,

as the study is trying to set up a proof of concept by

optimizing separately the performance measures

before attempting any multivariate optimization

procedure , a normalized weight value of 1 is applied

to for both the throughput rate TR and the mean flow

Taguchi Loss Function to Minimize Variance and Optimize a Flexible Manufacturing System (FMS): A Six Sigma Approach Framework

597

time MFT, respectively. Throughput Rate (TR) and

Mean Flow Time (MFT) data means and their

variances are also normalized.

It worth it to say that R-squared values should be

associated to residual analysis to check if the

assumption about the normality in the data is valid

and therefore, to justify any valid statistical analysis

and subsequent conclusions. When the effects of the

various control factors have been computed, they can

subsequently be plotted to normal probability paper

by adjusting the probability p as:

100* 0.5 /

k

p k n

(11)

where k is the order number; k = 1, 2, …(n-1), n is the

total number of runs, and p

k

is the probability of k.

Residual analysis is also conducted to verify the

conclusion on predicted significant effects.

The residuals obtained from a fractional factorial

design by the regression model should then be plotted

against the predicted values, against the levels of the

factors, and normal probability paper to assess the

validity of the embedded model assumptions and gain

additional insight into the experimental situation. The

various residual plots required for this research are

not displayed here for economy of space. These plots

are used to check if the assumptions presumed

embedded in the model are met.

The most common assumptions are that errors are

(Normally, Independently Distributed) NID (0,

2

).

When these assumptions are met, the residuals are

normally distributed, have equal variances, and are

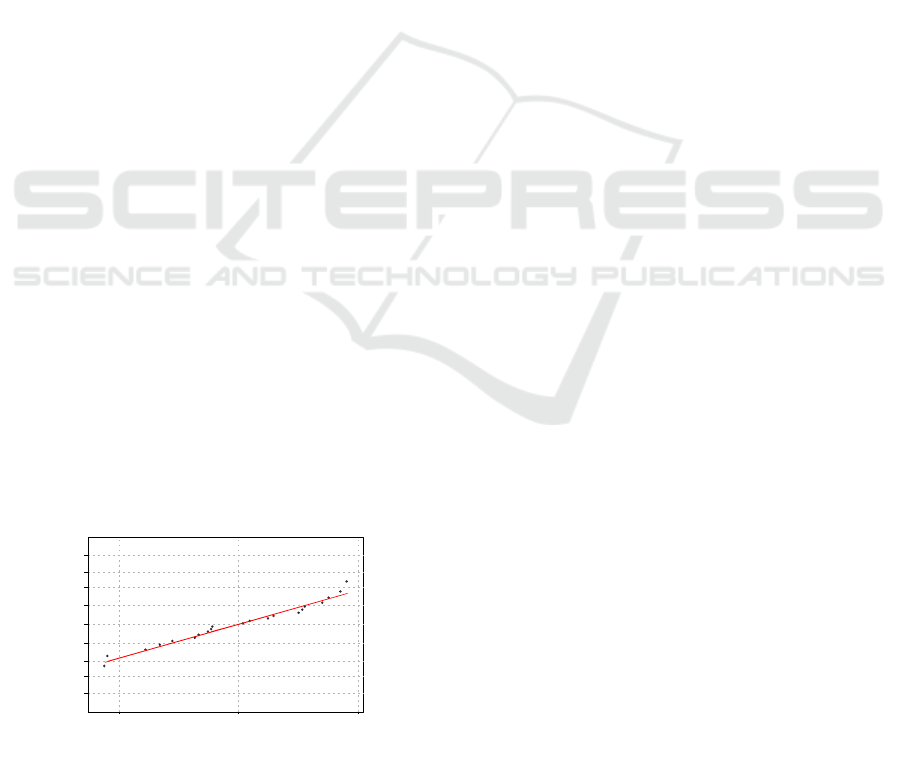

not independent. The normal probability plots of TR

residuals shown in Figure 1 for illustration purpose

lie approximately along a straight line. As a result,

there is no reason to suspect any severe non-normality

in the data (p=0.15). Hence, residuals are NID(0,

2

).

The same conclusion is also drawn for the MFT

whose plots are not displayed here for economy of

space.

Approximate P-Value > 0.15

D+: 0.108 D-: 0.125 D : 0.125

Kolmogorov-Smirnov Normality Test

N: 21

StDev: 0.313635

Average: -0.0000094

0.50.0-0.5

.999

.99

.95

.80

.50

.20

.05

.01

.001

Probability

TR Residuals

Normal Probability Plot

Figure 1: Normal Probability plots for TR Residuals.

5 LEVEL 2 OPTIMIZATION

USING TAGUCHI QLF AND

METAMODELS

(IMPROVE-CONTROL)

Analysis of Equation (10) reveals that a minimal loss

will be incurred to a performance measure when both

terms of the equation are minimized. Let

and

be the treatment level with the lowest

2

ˆ

jj

yT

and

2

ˆ

yj

value, respectively among all 21 treatment

combinations simulated. The minimization of the

second term

2

ˆ

yj

of Equation (10) is key to the

proposed approach as it is most critical term for the

quality of the product as it guarantees less variation

among the various products delivered under a specific

combination of operational parameters. Therefore,

the second level of the proposed optimization scheme

will first start with the minimization of the variance

(second) term

2

ˆ

yj

in Equation (10).

Step 1. A mathematical manipulation using basic

Linear Programing, of the metamodels derived in

Equation (4) and (5), expressed in the form of

objective functions as illustrated in Tshibangu 2014

will lead to the determination of the treatment

combination

that yields the minimal value for

the second term

2

ˆ

yj

.

Step 2. The minimum of the first term

2

ˆ

jj

yT

is obtained by computing

2

ˆ

jj

yT

for each treatment

(i) of the 21 designs simulated across the noise level

combination using TR and MFT metamodels found in

Equations (2) and (3) in combination with the target

values

j

T

derived from the empirical approach for

both TR and MTF, respectively at each treatment

level. The treatment combination yielding the

minimum value is considered as the optimal

combination for the first term of Equation (10). This

treatment combination level will not necessarily be

the same as the one derived through mathematical

minimization of the second term

2

ˆ

yj

.

Also, it worth it to say that because this research

has used a fractional design of experiments the

treatment combinations

and

do not

necessary have to be among the 21 simulated

combinations. However, because one of the

objectives of robust design is to reduce the

performance measure variance,

will be first

consider as the basic optimal treatment combination

level leading to the most robust (less variation) and

ICINCO 2018 - 15th International Conference on Informatics in Control, Automation and Robotics

598

optimal setting of operational parameters.

Confirmatory runs will be carried out to validate the

results while possible fine-tuning adjustments may be

necessary to compensate for any possible mean loss.

6 RESULTS AND CONCLUSIONS

This research first addresses a robust design

formulation and simulation data collection plan for a

hypothetical FMS and implements in a first level, an

empirical optimization procedure to use in order to

avoid the controversial Taguchi statistical tools. Then

the research derives a metamodel from the simulation

outputs. The study also derives a QLF from the

traditional Taguchi loss function in order to capture

the loss incurred to the overall FMS when addressing

a specific objective performance (TR or MFT). Next

(second level of the optimization scheme), the QLF is

analytically applied to the metamodels to optimize the

FMS with respect to an objective performance.

Target/optimum values of 100 parts/day and 0.3666

units time/part (in coded data) obtained in the first

level of the empirical optimization procedure have

been fixed for the TR, and MFT, respectively. This

two-level optimization procedure leads to a solution

that yields the least cost incurred to the overall FMS

as a penalty for missing the objective targets. The

values of 98 parts/day (-2% from target) and 0.3459

units time/part (+5.6% from target) are obtained as

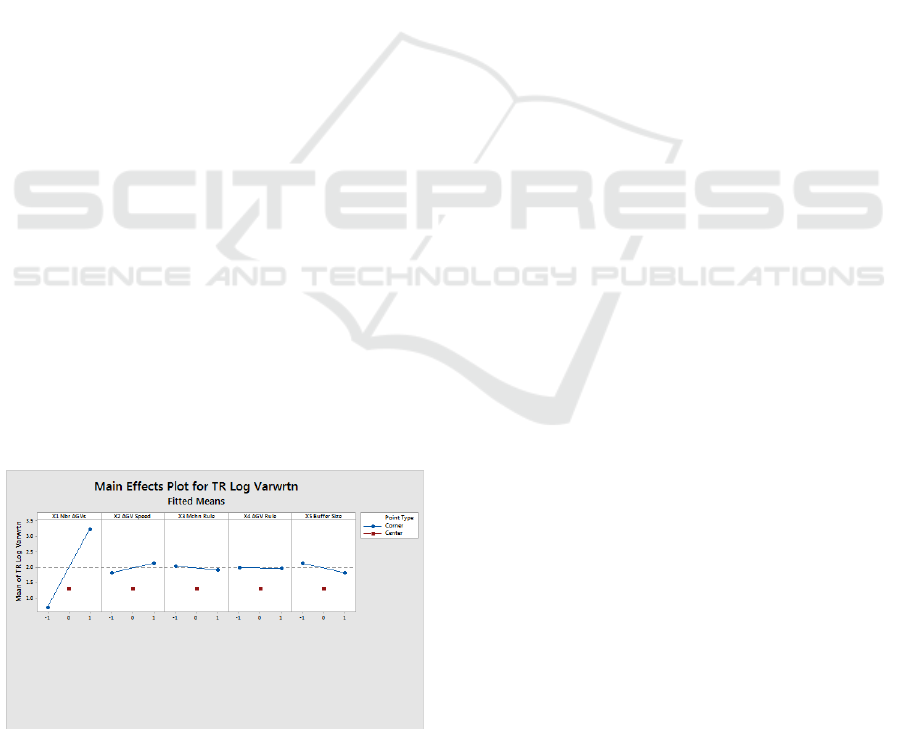

optima, for TR and MFT, respectively. Figure 2 is a

Minitab output depicting the effects of control factors

for TR. When using TR as performance measure the

most robust and optimal FMS configuration would be

at the following settings in natural values: Number of

AGVs (X

1

): 6; Speed of AGV (X

2

): 150 feet/min;

Queue discipline (machine rule) (X

3

): SPT; AGV

dispatching rule (X

4

): STD; Buffer size: (X

5

): 24.

Figure 2: Effects of Control Factors on Log

2

(wrtnf)

TR.

REFERENCES

Jun Zhanga,Wei Li a, Kaibo Wang b, Ran Jin Process

adjustment with an asymmetric quality loss function,

2013. Journal of Manufacturing Systems 33 (2014)

159–165.

Kleijnen, J.P.C., Design and Analysis of Simulations:

Practical Statistical Techniques, SIMULATION,

Volume 28, no.3, 81-90, 1977.

Kwok-Leung Tsui, 1996. A Multi-Step Analysis Procedure

For Robust. Statistica Sinica 6(1996), 631-648

Pojasek, RB., 2003. Lean Six Sigma, and the Systems

Approach: Management Initiatives for Process

Improvement. Environmental Quality Management, pp

85-92.

Seung, Heon Han, Myung Jim Chae, Keon Soom Im, Ho

Dong Ryu, 2008. Six Sigma-Based Approach to

Improve Performance in Construction Operations.

Journal of Management in Engineering, 21-31, ASCE.

Sharma, U., 2003. Implementing Lean Principles with Six

Sigma Advantage: How a Battery Company Realized

Significant Improvements. Journal of Organizational

Excellence, pp. 43-52.

Sunil Hansda and Simul Banerjee, Multi-characteristics

Optimization Using Taguchi Loss Function, 5th

International & 26th All India Manufacturing

Technology, Design and Research Conference

(AIMTDR 2014) December 12th–14th, 2014, IIT

Guwahati, Assam, India.

Tshibangu, WM Anselm, 2013. A Two-Step Empirical –

Analytical Optimization Scheme. A DOE-Simulation

Metamodeling. Proceedings of the 10th International

Conference on Informatics in Control, Automation and

Robotics, Reykjavik, Iceland, July 28-31, 2013,

ICINCO 2013.

Tshibangu, WM. A., Design and Modeling of a Robust and

Optimal Flexible Manufacturing System Using a

Multivariate Quadratic Loss Function: A Simulation

Metamodeling Approach. Ph.D. Dissertation, Morgan

State University, Baltimore, MD., Library of Congress,

2003.

Vales, Jaime Sanchez, Salvador Noriega and Bernice

Gomez Nunez, 2009. Implementation of Six Sigma in

Manufacturing Process: A Case Study. International

Journal of Industrial Engineering, 16(3), 171-181.

Taguchi Loss Function to Minimize Variance and Optimize a Flexible Manufacturing System (FMS): A Six Sigma Approach Framework

599