Demand Response of Medical Freezers in a Business Park Microgrid

Rosa Morales Gonz

´

alez

1

, Madeleine Gibescu

1

, Sjef Cobben

1,2

,

Martijn Bongaerts

2

, Marcel de Nes-Koedam

2

and Wouter Vermeiden

2

1

Electrical Energy Systems Group, Department of Electrical Engineering, Eindhoven University of Technology,

5612AP Eindhoven, The Netherlands

2

Alliander N.V., 6812AH Arnhem, The Netherlands

{martijn.bongaerts, marcel.de.nes.koedam}@alliander.com, wouter.vermeiden@zown.eu

Keywords:

Demand Response, Genetic Algorithm, Local RES Integration, Physical System Modeling, Smart Grid.

Abstract:

This paper presents a demand response (DR) framework that utilizes the flexibility inherent to the thermo-

dynamic behavior of four groups of independently-controlled medical freezers in a privately-owned business

park microgrid that contains rooftop photovoltaics (PV). The optimization objectives may be chosen from the

following 3 options: minimizing electricity exchanges with the public grid; minimizing costs by considering

prices and RES availability; and minimizing peak load. The proposed DR framework combines thermody-

namic models with automated, genetic-algorithm-based optimization, resulting in demonstrable benefits in

terms of cost, energy efficiency, and peak power reduction for the consumer, local energy producer, and grid

operator. The resulting optimal DR schedules of the freezers are compared against unoptimized, business-as-

usual scenarios with- and without PV. Results show that flexibility can be harnessed from the thermal mass of

the freezers and their contents, improving the cost- and energy performance of the system with respect to the

business-as-usual scenarios.

1 INTRODUCTION

Increasing distributed generation from renewable

energy sources (DG-RES), such as solar and wind,

into electricity networks poses several challenges due

to the resources’ stochastic nature (Hewicker et al.,

2012). This variability brings about a loss of flexi-

bility in the generation side of the power system va-

lue chain, since the electricity generation profile can

no longer ramp up or down to adapt to the load pro-

file. Within the evolution of power systems, the con-

cept of smart grids proposes different technical solu-

tions that can harness flexibility from other sources

to compensate for the loss of flexibility from the ge-

neration side: e.g., enhanced monitoring and control

functionalities, electrical and/or thermal storage, no-

vel electricity market designs, and increased demand-

side flexibility through demand response (DR) pro-

grams (Huber et al., 2014; Alizadeh et al., 2016). De-

mand response is defined as the set of “actions vo-

luntarily taken by consumers [and/or prosumers] to

change their energy usage —either in terms of quan-

tity or timing— in response to an external control sig-

nal” (Morales Gonz

´

alez et al., 2016), e.g., price or a

direct command from the aggregator or system opera-

tor.

Thermostatically-controlled loads have become a

valuable flexible resource of DR programs in the resi-

dential sector, where water heaters (Gela

ˇ

zanskas and

Gamage, 2016), refrigerators (Liu et al., 2014), and

HVAC systems (Yoon et al., 2014) have been targe-

ted for the implementation of DR programs in the

residential sector. However, in order to unlock their

full potential, the (small) loads have to be aggregated

in large numbers. This is not always possible in pi-

lot programs involving residential consumers, due to

low participation of the customer base, limited resour-

ces and large investment requirements, as discussed in

(He et al., 2013; Klaassen et al., 2014; D’hulst et al.,

2015; Labeeuw et al., 2015).

Commercial and industrial (C&I) consumers, on

the other hand, have an overall higher consumption

footprint and a higher peak demand (European En-

vironment Agency, 2017). Furthermore, C&I consu-

mers are usually located in concentrated areas such

as business/industrial parks, which facilitates aggre-

gation and makes this type of end-users interesting for

applying DR programs (Ashok and Banerjee, 2000;

Gr

¨

unewald and Torriti, 2013). Several strategies have

been proposed for different types of heavy industry

120

Morales González, R., Gibescu, M., Cobben, S., Bongaerts, M., de Nes-Koedam, M. and Vermeiden, W.

Demand Response of Medical Freezers in a Business Park Microgrid.

DOI: 10.5220/0006801001200129

In Proceedings of the 7th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2018), pages 120-129

ISBN: 978-989-758-292-9

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

in works such as (Matthews and Craig, 2013; Mitra

et al., 2013; Finn and Fitzpatrick, 2014), but DR is

still not implemented systematically in this sector be-

cause industrial consumers’ energy needs vary gre-

atly from one another and applications for DR can be

restricted in scope due to the nature or sensitivity to

changes of the processes inherent to the industry (Sa-

mad and Kiliccote, 2012; Ton and Smith, 2012).

Authors such as the ones from (Zavala, 2013; Ma

et al., 2015; Yin et al., 2016; Hurtado et al., 2017)

have written extensively on the flexibility of commer-

cial buildings in cities through buildings’ passive ther-

mal capacitance and HVAC controls. Their findings

on the DR potential of commercial buildings are es-

pecially relevant to the case of the Netherlands, where

the service industry is the second largest energy con-

sumer behind heavy industry (Centraal Bureau voor

de Statistiek, 2017a). This sector has seen steady

and rapid growth in the past twenty years and contri-

butes to the highest added value and employment in

the Dutch economy (Compendium voor de Leefom-

geving, 2017).

In this work, we focus on the DR potential of the

health services sector, ranked in the top three sectors

of the Dutch economy (Centraal Bureau voor de Sta-

tistiek, 2017b). We propose and test a DR framework

with a case study of a business park microgrid with

local PV generation in which the flexible load is a me-

dical freezing warehouse. Freezer loads are shifted in

time by automated DR actions, controlling the medi-

cal freezers in four independent clusters, while trea-

ting PV production as a curtailable/reparameterizable

resource. The case study evaluates the benefits of the

DR program over a 48-hour time window with a reso-

lution of 15-minutes. We study a 48-hour optimiza-

tion window in order to observe the temperature dyn-

amics of the freezers on a longer term than day-ahead,

and to solve a more complex problem that can test the

robustness of our framework.

Our main contributions are the iterative embed-

ding of the thermodynamic freezer model into an op-

timization algorithm to form a single DR framework,

and its application to a real-world situation. This

work explores 1) how flexibility can be harnessed

from the freezer contents’ thermal mass, and 2) what

the resulting benefits are in terms of cost, energy effi-

ciency and peak load reduction for the consumer, the

local DG-RES producer, and the operator of the busi-

ness park microgrid.

The rest of the paper is organized as follows:

Section 2 describes the mathematical models, and

Section 3 describes the case study used for this work.

In Sections 4 and 5, results are presented and dis-

cussed. Finally, conclusions and directions for future

Freezer Enclosure

Indoor environment

Ambient

R

ic-in

R

e,1,1

R

e,1,2

R

e,1,3

R

e,1,4

R

e,2,1

R

e,2,2

R

e,2,3

R

e,2,4

R

e,n,1

R

e,n,2

R

e,n,3

R

e,n,4

R

in-sup

Q˙

sup

T

amb

T

in

T

sup

T

ic

(mc

p

)

ic

(mc

p

)

e,2

(mc

p

)

e,n

(mc

p

)

e,1

(mc

p

)

in

Figure 1: Equivalent RC circuit of the medical freezers.

work are stated in Section 6.

2 METHODOLOGY

This section describes the mathematical models and

algorithms that make up the physical models, in com-

bination with our optimization-based DR framework.

2.1 Thermodynamic Modeling

The thermodynamics of the medical freezers in the

research facility can be described by a first-order dy-

namic system, as described in works such as (Za-

paroli and de Lemos, 1996; Lampropoulos et al.,

2013; Kalsi et al., 2011; Hurtado et al., 2015; Wil-

son et al., 2015). The generic, lumped parameter

resistance/capacitance (RC) circuit model, shown in

Figure 1, is used to achieve a better understanding

of how the thermal mass of buildings can unlock

demand-side flexibility in terms of available shifting

power and duration and possible energy/cost savings.

This simplified representation of end-user premises

allows us to 1) capture first-order transients without

having to perform a heavily-detailed simulation, and

2) facilitate the real-time implementation of the opti-

mization framework we use in our DR program. The

system of equations describing the thermodynamic

behavior of the medical freezers is given in equation

(1):

(mc

p

)

ic

dT

ic

(t)/dt = −(T

ic

− T

in

)/R

ic−in

(1a)

(mc

p

)

in

dT

in

(t)

dt

=

T

ic

− T

in

R

ic−in

−

T

in

− T

sup

R

in−sup

−

N

∑

n=1

T

in

− T

e,n

R

e,n,1

+ R

e,n,2

(1b)

(mc

p

)

e,n

dT

e,n

(t)

dt

=

T

in

− T

e,n

R

e,n,1

+ R

e,n,2

−

T

e,n

− T

amb

R

e,n,3

+ R

e,n,4

∀n ∈ [1,N]

(1c)

0 = (T

in

− T

sup

)/R

conv

+

˙

Q

sup

(1d)

Demand Response of Medical Freezers in a Business Park Microgrid

121

where (mc

p

)

x

denotes heat capacity in J/K; dT

x

(t)/dt,

is the rate of change temperature with respect to time

in K/s; and R

x

denotes thermal resistance in K/W. The

subscript x is a stand-in for the subscripts ic, in, sup

and e,n, (see corresponding blocks in Figure 1) which

denote the freezer’s interior contents, indoor air, heat

supply system (evaporator coil), and n number of en-

closure elements out of a total N (e.g., freezer roof,

walls, floor), respectively. T

amb

is the ambient tem-

perature (i.e. temperature of the conditioned space in

which the freezers are kept) as a function of time in

degrees Kelvin (K),

˙

Q

sup

is the heat extracted by the

freezer’s mechanical cooling system in watts, and T

sup

is the supply temperature of the mechanical cooling

system in K.

Mechanical heat extracted is related to electrical

power consumption,

˙

W

el

, through the coefficient of

performance (COP) of the freezers’ mechanical cool-

ing system, defined by (2):

COP =

˙

Q

sup

/

˙

W

el

(2)

Assuming that the conditioned space in which the

freezers are kept is maintained at a constant tempera-

ture to ensure the optimal operation of the mechanical

refrigeration system, we may assume a constant COP;

hence, mechanical heat extracted is given by (3):

˙

Q

sup

= COP ×

˙

W

el

(3)

Finally, assuming we can independently control

the operation of the medical freezer in i clusters, the

electricity consumption of each cluster at time t is gi-

ven by (4):

E(i,t) =

Z

t

t−1

˙

W

el

(i,t)dt

(4)

2.2 Optimization Problem Formulation

Let us consider that the ON/OFF signal of the medical

freezers of cluster i at time t is defined by the binary

variable β(i,t). The net energy imported from the

grid of all I freezers at the research facility, E

net

(t),

after combining the predicted contribution of local

DG-RES in the microgrid E

RES

(t) and the electricity

consumption of the independently-controlled freezer

clusters i at time t, E(i,t), is expressed by (5):

E

net

(t) =

I

∑

i=1

β(i,t)E(i,t) − E

RES

(t)

(5)

The optimization problem (6a) signifies choosing

the ON/OFF switching schedules (β(i,t)) and the PV

production schedule E

RES

(t) over the whole time ho-

rizon, with the objective of minimizing energy ex-

changes with the regional grid (7), peak power con-

sumption (8), or overall energy cost (12). Each of

these optimization problems is analyzed separately.

The freezer temperatures (T

in

(i,t)) must not exceed

the critical values required by the end-users (6b). Phy-

sical constraints of local DG-RES production (6c) are

considered. Finally, the rated capacity of the con-

nection, P

max

, should not be exceeded (6d). The opti-

mization problem takes on the form (6):

min

β,E

RES

Ω = Φ (6a)

s.t. T

min

(i,t) ≤ T

in

(i,t) ≤ T

max

(i,t) ∀i,t (6b)

0 ≤ E

RES

(t) ≤ E

max

RES

(t) ∀t (6c)

|P

net

| ≤ P

max

(6d)

with P

net

(t) =

∑

I

i=1

β(i,t)

˙

W

el

(i,t) −P

RES

(t). Φ stands

in for Φ

e

(7) in the energy consumption minimization-

, Φ

p

(8) in the peak load reduction- , and Φ

c

(12) in

the energy cost minimization problem variants:

Φ = Φ

e

=

T

∑

t=1

|E

net

(t)| (7)

Φ = Φ

p

= max(|P

net

|) (8)

For the cost optimization problem, let λ

RES

be

the price per kilowatt-hour the local consumer pays

for buying locally-produced energy in the microgrid,

λ

grid

the price for buying electricity from the regio-

nal electricity supplier, and λ

f eedin

the tariff the local

DG-RES producer gets for exporting PV to the regio-

nal distribution network. Let us assume that the DG-

RES producer sells its electricity at a lower price than

the consumer would pay for electricity from the regi-

onal electricity supplier, and that the feed-in tariff it

gets for feeding the electricity back into the regional

network is considerably less than that it receives for

selling electricity locally within the microgrid (9):

λ

f eedin

λ

RES

(t) < λ

grid

(t) ∀t (9)

The total cost for the consumer is given by (10):

T

∑

t=1

(λ

RES

(t)E

RES

(t) + λ

grid

(t)E

imports

(t)) (10)

where E

RES

(t) is energy consumed from local DG-

RES, and E

imports

(t) is energy consumed from grid

imports in the microgrid —i.e., when E

net

> 0— at

time t. The total revenue for the DG-RES producer

from feeding in energy back into the grid —i.e., when

E

net

> 0— is denoted E

exports

(t) and defined as (11):

T

∑

t=1

(λ

RES

(t)E

RES

(t) + λ

f eedin

(t)E

exports

(t)) (11)

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

122

Maximizing producer revenue and minimizing

consumer costs, we have:

Φ = Φ

c

=

T

∑

t=1

(λ

grid

(t)E

imports

(t)

− λ

f eedin

(t)E

exports

(t))

(12)

Constraint (6b) determines the flexibility of the

freezer and enforces the critical temperature ranges

for each freezer cluster i: T

min

(i,t) and T

max

(i,t). The

values of T

in

(i,t) are obtained from the thermodyna-

mic freezer submodels. Constraint (6c) enforces the

physical upper and lower bounds of local DG-RES

production. The resulting non-linear, mixed-integer

optimization problem is too complex to be solved by

traditional methods in reasonable time. From the fa-

mily of heuristic search techniques, we opted for the

genetic algorithm (GA) for its ability to efficiently

deal with both continuous and discrete decision va-

riables.

2.3 Interaction Between Models

While conventional freezer temperature controls have

a fixed set-point temperature and fixed temperature

trip points based on indoor air temperature measure-

ments, our multiphysics DR framework couples and

iteratively intertwines the thermodynamic freezer mo-

dels with the GA-based optimization framework to:

1) calculate temperature limits based on the freezer

contents instead of the indoor air to gain extra flexi-

bility from the products’ inherent thermal mass; and

2) to devise optimal on/off strategies for all freezer

clusters in the building, such that the objectives of

minimal cost, maximal energy self-sufficiency or mi-

nimum peak load are achieved. Note that the opti-

mization problem will determine the entire 48-hour

switching schedule in advance of real-time, assuming

perfect knowledge and/or accurate forecasts of all in-

fluencing factors: feed-in tarrifs, wholesale and local

market prices, and short-term PV production.

3 CASE STUDY

This section describes the case study for which the

simulation experiments were performed, as well as all

relevant technical characteristics.

Our DR framework is applied to a freezing ware-

house used for medical research in the Netherlands.

The medical freezing facility is located in a busi-

ness park that operates as a local, private microgrid

interconnected to the regional grid via a consumer

substation. Grid constraints are not an issue in this

case, since all network assets have been overdimensi-

oned. A 250-kWp photovoltaic installation consisting

of 1700 m

2

of crystalline PV panels is also coupled

to the business park microgrid through the consumer

substation. The PV modules are made of crystalline

silicone, and have a 15% efficiency. The energy con-

version efficiency of the PV modules is 80%. Overall,

the PV system efficiency is thus 12%. Electricity ge-

nerated locally by the PV installation is 157 MWh/y.

The medical freezing facility consumes approxima-

tely 1.4 GWh/y. It stores blood samples at a tempera-

ture of -80

◦

C in 120 freezer units. The freezer units

consume approximately 500 MWh/y in total, repre-

senting 35% of the total energy consumption in the

medical freezing facility.

The blood samples are preserved in a glycerol so-

lution for long-term storage. In setting our flexibility

thresholds for the freezer temperatures, we refer to in-

dustry best practices. These dictate that the tempera-

ture of the glycerolized red blood cells during storage

should not exceed -60

◦

C in order to avoid the de-

terioration of the samples (Maharashtra State Blood

Transfusion Council, 2014; Eftekhar, 1989; Wessling

and Blackshear, 1973). We set a conservative flexibi-

lity temperature upper limit of -70

◦

C to remain well

within the limits for sample quality preservation. The

temperature of the blood samples, (i.e., the tempera-

ture of the freezers’ internal contents, T

ic

in Figure 1

and eq. (1) will be used for the constraints formu-

lation of the optimization problem. This means that

T

ic

will be allowed to oscillate between -80 and -70

◦

C

with a tolerance of ±0.3

◦

C to account for system de-

lay in our GA-based controller.

The density and specific heat capacity of glycer-

olized red blood cells for the freezer working tempe-

ratures are compiled from (Eftekhar, 1989; Wessling

and Blackshear, 1973), and are shown in Table 1, and

compared against values for whole blood, as a refe-

rence. The values for glycerolized red blood cells will

be used in our DR framework’s building models to re-

present the internal contents of the medical freezers.

In this work, we assume that 1) the internal con-

tents of the freezer are already “at temperature”, and

2) there is no in- or outflow of samples during the 48h

time horizon of the DR optimization problem. In ot-

her words, the mechanical refrigeration system of the

freezers are only used to maintain the product tem-

perature. We contend this is a reasonable assumption

given that the medical freezing warehouse is a long-

term research facility in which samples are kept in

storage in the order of years, even decades.

In our energy calculations for the medical research

freezing facility, we neglect the base electricity load

Demand Response of Medical Freezers in a Business Park Microgrid

123

Table 1: Thermophysical properties of blood components.

Blood component ρ [kg/m

3

] c

p

[kJ/(kgK)]

Glycerolized red blood cells 1063 1.5

Whole blood 980 3.6

Time [h]

0 5 10 15 20 25 30 35 40 45

0

0.02

0.04

λ

grid

λ

RES

λ

feedin

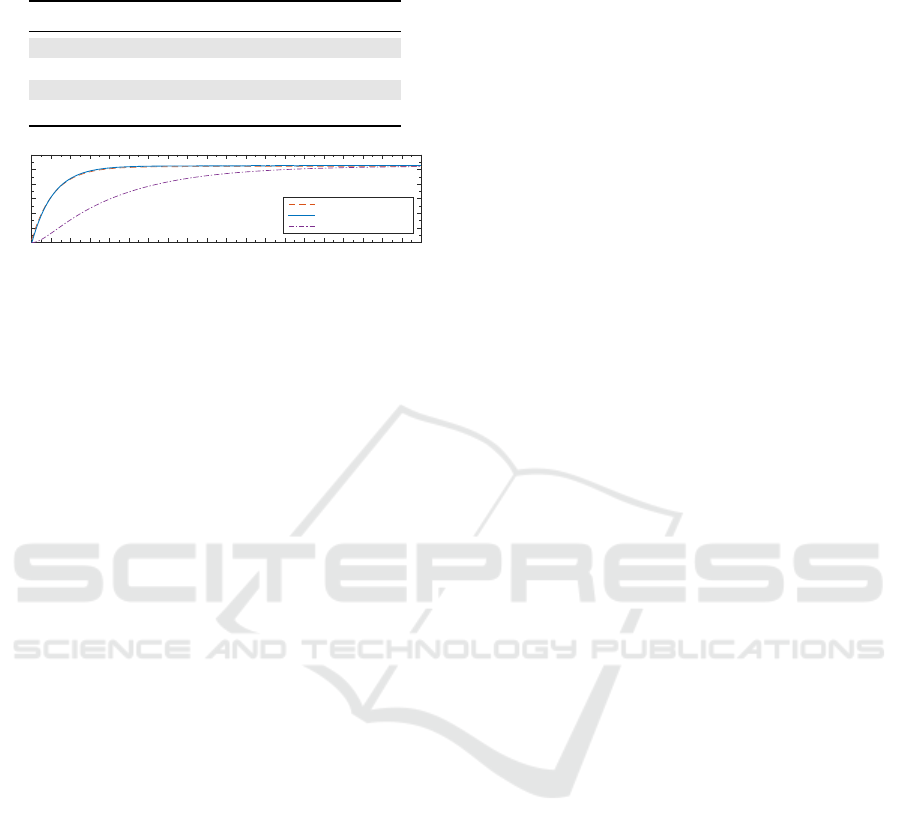

Figure 2: Dynamic electricity prices for the end-users of the

microgrid.

and any loads triggered by human interaction. Hea-

ting or cooling loads required to balance ventilation

and internal heat gains/losses from lighting, people,

and equipment could be additional sources of flexibi-

lity in the building, but are not taken into considera-

tion in the present case study.

We assume that all end-users are subjected to the

same hourly electricity prices; and that electricity pri-

ces and PV generation for the optimization horizon

can be forecasted with a reasonable degree of accu-

racy. Expected day-ahead electricity prices

1

and PV

generation values for average irradiation days

2

used

in the simulations are shown in Figure 2 and Figure 3.

Three optimization objectives are considered se-

parately: 1) energy minimization (i.e., reducing

energy exchanges with the regional grid), 2) cost mi-

nimization, and 3) peak load minimization. The op-

timization results are compared against a Business-

As-Usual (BAU) scenario, where temperature con-

trol in the freezers is driven by their conventional,

continuously-operating thermostats with a fixed set-

point and deadband. We compare results of switching

all 120 freezers at the same time in the BAU scena-

rio (worst-case scenario for peak load) against having

four clusters of 30 freezers each that can be indepen-

dently controlled. Because grid constraints are not

an issue in the present case study, we set P

max

to the

1

Based on data from https://transparency.entsoe.eu/

2

Based on data from http://www.soda-pro.com/web-

services#radiation

Time [h]

0 5 10 15 20 25 30 35 40 45

Power [W]

× 10

4

0

5

10

15

Figure 3: PV production profiles for two consecutive

average solar irradiation days in the Netherlands (1700m

2

,

system efficiency 12%).

worst-case scenario for peak load, or 132 kW, in con-

straint (6d).

The design variables of the optimization problem

are the 15-minute switching schedules of the mecha-

nical refrigeration system for all freezer clusters, bi-

nary variable β(i,t), and the 15-minute DG-RES pro-

duction schedules, E

RES

(t). E

RES

is a continuous non-

negative variable on the interval [0,1] based on the

maximum forecasted production for that 48-hour time

horizon. For the 48-hour time window of the case

study, β has a length of 193 elements per i cluster

of freezers, and the microgrid-aggregated E

RES

has a

length of 193, resulting in a phenotype of 965 ele-

ments. Results were obtained by parallelizing the

GA computations into twenty-eight pools of workers

using MATLAB’s Parallel Computing Toolbox. The

simulations were carried out using an Intel Xeon CPU

with two processors running at 2.6 GHz.

3.1 Freezer Model

Each of the ultra-low temperature freezers used in the

medical research facility have a rated capacity of 1.1

kW and a COP of 0.575 at T

amb

= 25

◦

C. Their elec-

tricity consumption under no-load conditions —i.e.,

with an empty freezer— at a setpoint of -80

◦

C is 11.5

kWh/day. The peak load when all freezers are on at

the same time is 132 kW.

The freezers’ external and internal dimensions are

1030 × 882 × 1993 mm and 870 × 600 × 1400 mm,

respectively. The freezer enclosures are 80 mm-

thick, and consist of vacuum-insulated panels sand-

wiched between painted AISI type 304 stainless steel

sheets, which are commonly used in the manufactu-

ring of cryogenic vessels and refrigeration equipment.

Thermophysical properties of the freezer enclosure

were calculated with data from (ASM Aerospace Spe-

cification Metals Inc., ; MatWeb, 2017), and are given

in Table 2.

The heat transfer mechanisms we consider in the

freezer model are conduction and convection. The

low emissivity values of the freezer enclosure materi-

als make the magnitude of radiative heat transfer neg-

ligible compared to the magnitudes of the conductive

heat transfer from the evaporator coils to the inner

chamber of the freezer, and the convective heat trans-

fer due to the forced air distribution system inside the

freezer chamber.

The internal volume of each freezer is 729 liters,

which can fit 576 vial storage boxes, each containing

one hundred 1-ml samples. This means that the total

volume of blood samples contained in each freezer is

57.6 liters, or approximately 8% of the total volume

of the freezer chamber.

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

124

Table 2: Thermophysical properties of the freezer enclo-

sure.

Value Unit

Thermal conductivity, k 0.01 W/(mK)

Heat transfer coefficient, h 8 W/(m

2

K)

Specific heat capacity, c

p

650 J/(kgK)

Density, ρ 186 kg/m

3

Time [h]

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200

Temperature [°C]

-80

-60

-40

-20

0

20

40

Manufacturer pull-up curve

Simulation, no load

Simulation, with load

Figure 4: Pull-up system response comparison.

3.2 Freezer Model Validation

In order to validate our model, we compared a simu-

lation of the freezer response without any load nor

contributions from the refrigeration system with the

freezer pull-up curve from the manufacturer. The sy-

stem response simulation in Figure 4 is shown in a

solid blue line against the manufacturer data, plotted

as a dashed red line. There is a very good match be-

tween the manufacturer data and simulation results,

which means that the model is sufficiently accurate

for our purposes. The figure shows that the time con-

stant of the system is approximately 70 hours with an

empty freezer. Our results are also in the same order

of magnitude, but comparatively higher than those in

refrigerators for residential applications, where a time

constant of approximately 20-30 hours is found (Ver-

zijlbergh and Lukszo, 2013). Figure 4 also compares

the pull-up system response under no-load conditions

(solid blue line) against the fully-loaded freezer with

blood samples described in the previous subsection

(purple dash-dotted line). It can be seen from the fi-

gure that the time constant of the system increases al-

most threefold, going from 70 hours in the no-load

case to 200 hours in the fully-loaded case, which is as

expected.

We also simulated the performance of the free-

zer under no-load conditions and compared it against

the electricity consumption given by the manufactu-

rer. Simulation results under no-load conditions show

that the daily electricity consumption of the freezer is

12.4 kWh/day. This represents a 7% error difference,

but is nevertheless a good, if conservative, approxi-

mation of the freezer’s cooling capacity that will take

into account future degradation of the freezer’s me-

chanical refrigeration system that comes with normal

use.

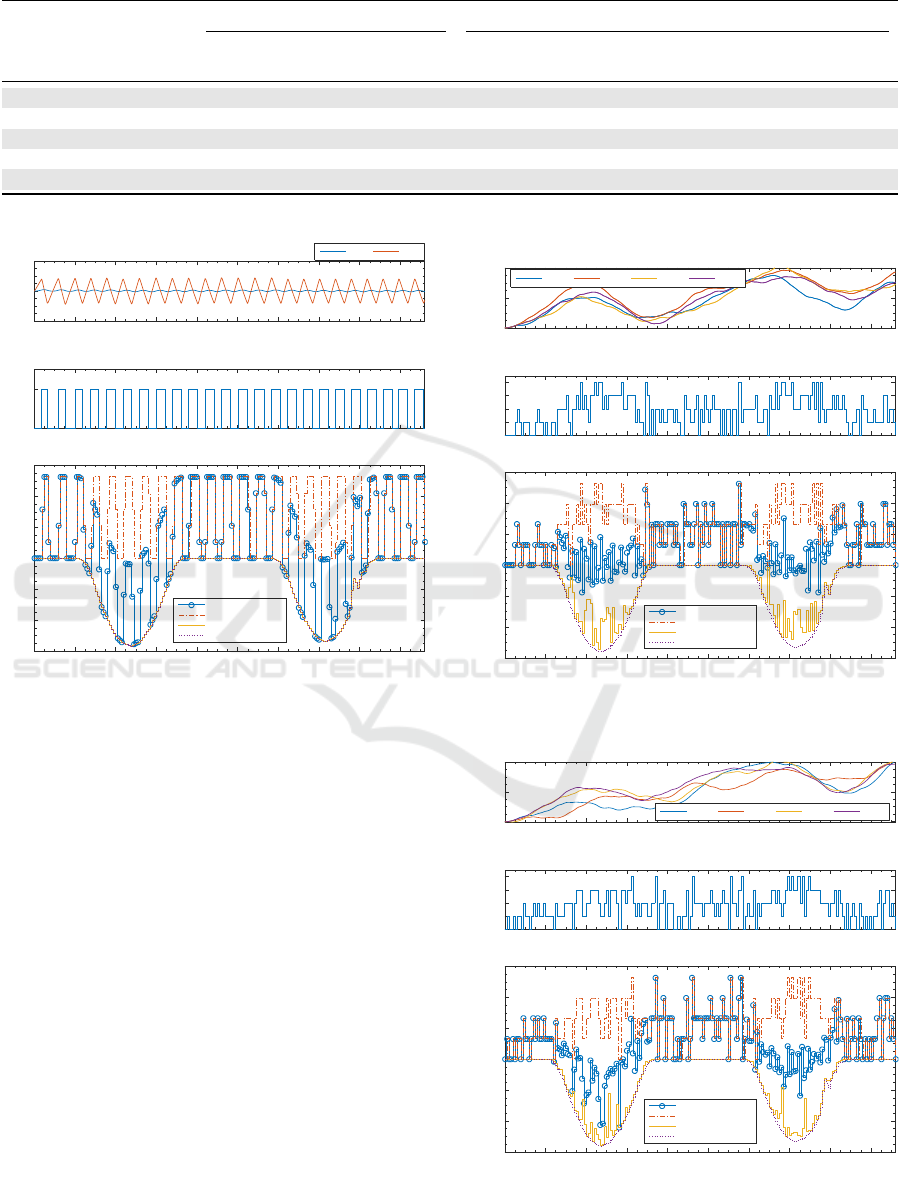

4 RESULTS

This section presents the simulation results for the

BAU scenario, plus the energy amount, energy cost,

and peak reduction optimizations. Due to the heuris-

tic nature of the GA, a number of local minima were

found in successive runs, and the best results are re-

ported graphically in Figs. 5-8, and are summarized

and compared against each other in Table 3.

4.1 BAU Scenario

Simulation results for the BAU scenario are shown

in Figure 5, which contains three subplots. The top-

most subplot (a) shows freezer contents (blue solid

line) and indoor temperatures (red solid line) with re-

spect to time. The middle subplot (b) shows whether

the mechanical refrigeration system is switched on at

every time step. Finally, the bottom subplot (c) shows

the electrical power consumption with respect to time

in a scenario with local PV generation, with positive

values denoting consumption and negative values de-

noting generation.

Results show that local PV generation by itself has

a beneficial effect on cost and energy reduction. Ho-

wever, it is possible to see from Figure 5(c) and Table

3 that an uncontrolled PV production has an adverse

effect in the system, in the form of a 5% increase in

the peak load from 132 to 139 kW.

4.2 Optimization Results

Optimization results are shown in Figure 6, Figure 7

and Figure 8 for the energy, cost, peak power mini-

mization objectives, respectively. The subplots and

legends for all optimization results are analogous to

those of Figure 5. In subplot (a), Ti

blood

denotes the

temperature of the blood samples of cluster i of inde-

pendently controllable freezers. The DR scheduling

process took approximately one and a half hours to

converge for each run in the MATLAB/Simulink si-

mulation environment.

The energy minimization objective is apparent in

Figure 6(b), since net energy exchanges with the elec-

tricity grid during times of solar energy production

are kept as close to zero as possible. The ability to

reduce the cooling load without infringing upon the

thermal safety boundaries is due to the freezers’ ther-

mal mass; i.e., the summation of the heat capacities

of the different freezer enclosure elements and their

contents: term (mc

p

)

x

in (1). Because of this need to

keep grid imports and exports to a minimum, the PV

utilization rate goes down to 77% with respect to the

uncontrolled BAU scenario with PV. Energy and cost

Demand Response of Medical Freezers in a Business Park Microgrid

125

Table 3: Optimization results vs BAU scenario.

Energy [kWh] [AC] [%]

Scenario Imports Exports

Total

exchange

Social

cost

Cost

savings

Energy

savings

Peak

reduction

PV

utilization

BAU, no PV 3369.3 0 3369.3 92.89 — — — 0

BAU + PV, no DR 2235.1 793.2 3028.3 59.15 36 10 -5 100

Energy optimization 1482.1 35.1 1517.2 40.11 57 55 0 77

Cost optimization 1423.8 280.6 1704.4 36.92 60 49 0 88

Peak load optimization 2158.7 138.5 2297.2 58.37 37 32 25 50

0 5 10 15 20 25 30 35 40 45

Temperature [°C]

-85

-80

-75

(a) Temperatures

T

blood

T

in, air

0 5 10 15 20 25 30 35 40 45

β

0

1

(b) Mechanical heating/cooling switch

Time [h]

0 5 10 15 20 25 30 35 40 45

Power [W]

× 10

5

-1.5

-1

-0.5

0

0.5

1

1.5

(c) Electrical Power Consumption and Generation

Net power

Consumption

Local generation

Max. available DG-RES

Figure 5: Results for the BAU scenario + DG-RES, no DR.

savings are 55% and 57% respectively; however, this

optimization objective does not have any noticeable

effect on peak reduction.

From Table 3, although net energy consumption

is higher in the cost optimization scenario, cost per-

formance slightly improves, signifying a reduction of

60% with respect to the BAU scenario. Results in

Figure 7(c) show that consumption concentrates not

only on the times where the electricity prices are low,

but also where PV production is highest. As can be

seen in Table 3, the PV utilization rate is 12% less

than in the BAU case with uncontrolled PV genera-

tion and no DR.

The peak power minimization objective does pre-

cisely what it is supposed to do, keeping at most three

freezer clusters on at the same time or having all four

clusters on at times where PV is being produced to

keep peak power as low as possible. This scenario had

the lowest energy and cost savings performance of

the three optimization objectives studied in this work.

However, the results obtained for the peak minimiza-

0 5 10 15 20 25 30 35 40 45

Temperature [°C]

-80

-75

-70

(a) Temperatures

T1

blood

T2

blood

T3

blood

T4

blood

0 5 10 15 20 25 30 35 40 45

β

0

1

2

3

4

(b) Mechanical heating/cooling switch

Time [h]

0 5 10 15 20 25 30 35 40 45

Power [W]

× 10

5

-1.5

-1

-0.5

0

0.5

1

1.5

(c) Electrical Power Consumption and Generation

Net power

Consumption

Local generation

Max. available DG-RES

Figure 6: Results for energy minimization.

0 5 10 15 20 25 30 35 40 45

Temperature [°C]

-80

-75

-70

(a) Temperatures

T1

blood

T2

blood

T3

blood

T4

blood

0 5 10 15 20 25 30 35 40 45

β

0

1

2

3

4

(b) Mechanical heating/cooling switch

Time [h]

0 5 10 15 20 25 30 35 40 45

Power [W]

× 10

5

-1.5

-1

-0.5

0

0.5

1

1.5

(c) Electrical Power Consumption and Generation

Net power

Consumption

Local generation

Max. available DG-RES

Figure 7: Results for cost minimization.

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

126

0 5 10 15 20 25 30 35 40 45

Temperature [°C]

-80

-75

-70

(a) Temperatures

T1

blood

T2

blood

T3

blood

T4

blood

0 5 10 15 20 25 30 35 40 45

β

0

1

2

3

4

(b) Mechanical heating/cooling switch

Time [h]

0 5 10 15 20 25 30 35 40 45

Power [W]

× 10

5

-1.5

-1

-0.5

0

0.5

1

1.5

(c) Electrical Power Consumption and Generation

Net power

Consumption

Local generation

Max. available DG-RES

Figure 8: Results for peak minimization.

tion objective still outperform those for the BAU with

uncontrolled PV scenario, with the added benefit of

reducing net peak power by 25%: a benefit that is ex-

tended not only for the microgrid consumers’ capacity

connection fees but also to the network operator, as

network reinforcements due to increased loads can be

delayed (although in this case study it is not a critical

problem).

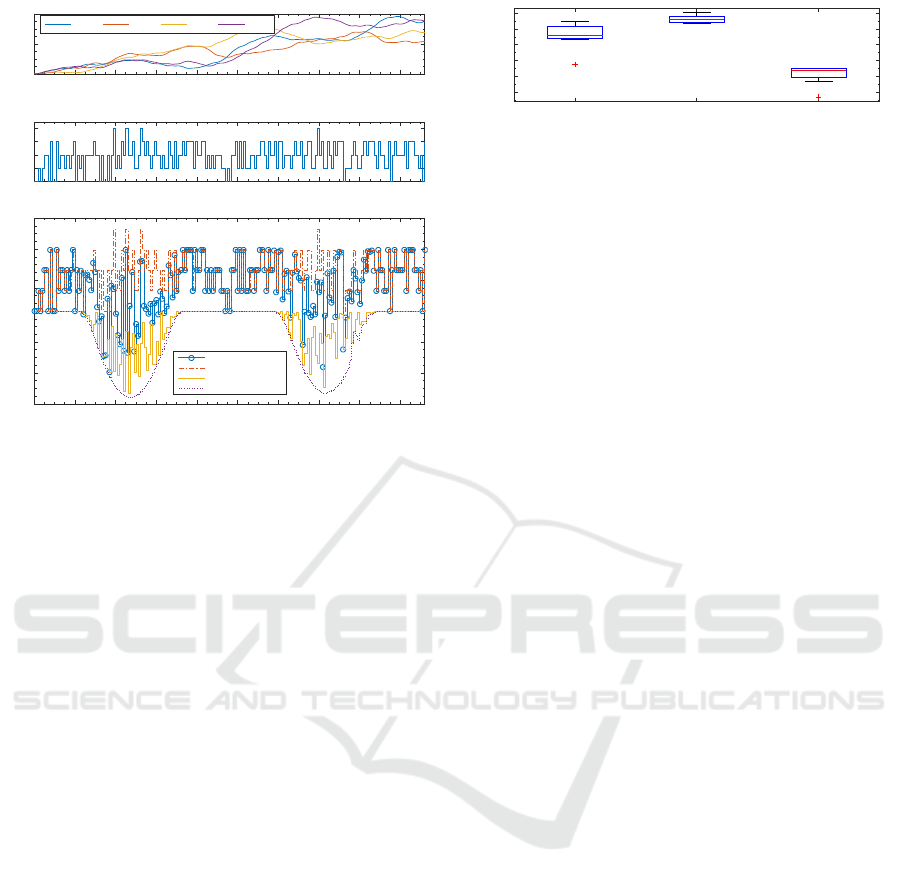

Figure 9 shows the distribution of fitness function

values from all the successive simulation runs for each

optimization variant. They are expressed as the diffe-

rence with respect to the results from the BAU scena-

rio. Mean values for the simulation successions per-

formed for this work were (46 ± 8)% for the energy-,

(56 ± 2)% for the cost minimization, and (21 ± 6)%

for the peak reduction variants.

5 DISCUSSION

The results presented in the previous section show

the potential of implementing both price-responsive

(cost minimization) and direct control (peak load mi-

nimization) DR programs to harness flexibility from

C&I customers’ thermostatic loads. The benefits of

harnessing this flexibility are clear and attractive, in

terms of reductions in the amount and overall cost of

electricity demand for the end-users connected to the

microgrid. In the case of peak load reduction, pos-

sible deferrals in network reinforcement investments

and/or lower connection costs are also present. This

assertion holds for comparisons against both the BAU

scenario with no DG-RES and the BAU scenario with

Energy optimization Cost optimization Peak reduction

Difference vs. BAU [%]

10

20

30

40

50

60

Figure 9: Distribution of fitness function values for each

optimization variant.

DG-RES but no demand response. The benefits of

combining DR with customer thermostatic loads and

local DG-RES available in the microgrid is especially

evident when comparing results in terms of peak load

mitigation with respect to the BAU scenario with un-

controlled PV.

To put things in a realistic perspective, it is im-

portant to mention that the 55% energy savings in the

freezers’ operation translates overall to 19% energy

savings in the total electricity consumption of the me-

dical research facility. This number could be increa-

sed if, apart from the freezers, we could harness flex-

ibility from other thermostatic loads such as heating

and air conditioning systems in the rest of the medi-

cal research facility.

However, while achieving these targets, the ther-

mal inertia of the freezers is depleted at the end of the

48-hour window, since the freezer temperatures are

all at or near the temperature upper bounds of -70

◦

C

(see Figures 6(a) and 7(a)). This means that some re-

covery time is required immediately after the 48-hour

window where DR was implemented, during which

the freezers can recharge their thermal buffers (i.e.,

cool down to -80

◦

C). In order to overcome this limi-

tation, we will add end-of-horizon temperature targets

in the problem formulation in future versions of this

work to limit the state of charge of the thermal buffers.

Another limitation of our model is that the gre-

ater energy efficiency and lower demand/generation

peaks in the C&I microgrid —while being in the in-

terest of the microgrid as a whole— come at a loss

for the local PV producer. This is because PV uti-

lization rates become lower in the energy- and peak

load minimization objectives due to PV curtailment.

Since the two aforementioned optimization objectives

do not take price into account, a way to increase PV

utilization in these scenarios would be to add utiliza-

tion constraints linked to the target payback time or

return on investment for the PV producer. Similarly,

in order to decrease peak load, we could include peak

capacity tariffs in the objective function for the energy

and cost minimization variants.

We decided to study a 48-hour window to observe

the long-term temperature dynamics of the medical

freezers, given the high time constant of the system.

Additionally, we tested the robustness of our DR fra-

Demand Response of Medical Freezers in a Business Park Microgrid

127

mework with this expanded time window, since the

optimization problem increases in complexity given

the doubled number of design variables with respect

to observing a 24-hour window.

However, in practice it makes more sense to cre-

ate schedules on a day-ahead basis because electricity

prices would be known to the aggregator 24-hours in

advance and the performance of PV production fo-

recasting models improves the closer they are used

to the period of interest. More local DG-RES can

be installed in the business park if additional hea-

ting/cooling systems in the buildings located there can

be harnessed in the same way we have presented in

this paper without changing the network infrastruc-

ture. Scaling up or down our thermodynamic models

and DR framework —depending on the size of the

window, the time granularity, and the number of con-

trollable devices— should therefore present no signi-

ficant challenges when performing simulations.

Additional work is needed in order to surmount

some of the assumptions made when computing the

optimal schedules, especially with regards to dealing

with errors in the PV forecasting data. Further steps

are required in order to move out of the simulation

environment and into the practical implementation of

the proposed DR framework in the actual customer

site, especially considering that the current conver-

gence time is quite long. Optimizing the GA imple-

mentation in MATLAB in future versions of our work

will be essential to maintain the computation time be-

low the 24-hour window in which the DR scheduling

has to be made, especially when more sources of flex-

ibility are harnessed from the microgrid customers.

Because of the non-linear, combinatorial nature of the

optimization problems that make up our DR frame-

work, the heuristic methods used to solve them re-

quire multiple successive simulation runs from which

the best local optima can be selected. That is, de-

pending on the number of flexible sources/consumers

in the microgrid, it would be necessary to curtail the

computation time so as not to take longer than the

available scheduling window, at the expense of fin-

ding a better solution (see Figure 9).

6 CONCLUSIONS

This work modeled and optimized the thermodyna-

mic behavior of medical freezers in a research facility

in order to quantify their potential for DR programs.

In summary, the results presented show that flexibility

can be harnessed from the thermal mass of the free-

zers’ enclosure and contents, resulting in significant

benefits in terms of cost and energy efficiency for the

end-user. Although uncontrolled DG-RES is already

a significant benefit in terms of energy efficiency and

cost with respect to the BAU scenario, adding DR has

the following benefits: 1) reduces the coincidence of

the loads, 2) improves cost and energy performance

for the consumer; and 3) mitigates increased peak

loads due to uncontrolled in-feed of DG-RES at the

point of common coupling between the local business

park microgrid and the regional distribution grid.

Future work will extend the scope of our proposed

DR framework to the rest of the business park where

the medical freezing warehouse is located, in order

to combine the flexibility of the freezers in the medi-

cal research facility with other sources of flexibility

available: other buildings and their heating/cooling

systems, thermal buffers, and eventually electric vehi-

cles.

ACKNOWLEDGMENTS

Rosa Morales Gonz

´

alez would like to thank Julian

Croker for providing information on the case study,

and Cees Jan Dronkers for his constructive insight on

the interpretation of results.

REFERENCES

Alizadeh, M. I., Parsa Moghaddam, M., Amjady, N., Siano,

P., and Sheikh-El-Eslami, M. K. (2016). Flexibility

in future power systems with high renewable penetra-

tion: A review.

Ashok, S. and Banerjee, R. (2000). Load-management

applications for the industrial sector. Appl. Energy,

66(2):105–111.

ASM Aerospace Specification Metals Inc. AISI Type 304

Stainless Steel.

Centraal Bureau voor de Statistiek (2017a). Energiever-

bruik; opbouw, bedrijfstak.

Centraal Bureau voor de Statistiek (2017b). Monitor top-

sectoren 2017.

Compendium voor de Leefomgeving (2017). Bruto toege-

voegde waarde en werkgelegenheid, 1995-2016.

D’hulst, R., Labeeuw, W., Beusen, B., Claessens, S., De-

coninck, G., and Vanthournout, K. (2015). Demand

response flexibility and flexibility potential of residen-

tial smart appliances: Experiences from large pilot test

in Belgium. Appl. Energy, 155:79–90.

Eftekhar, J. G. (1989). Some Thermophysical Properties of

Blood Components and Coolants for D5U. Technical

report, University of Texas San Antonio, San Antonio.

European Environment Agency (2017). Final energy con-

sumption by sector and fuel.

Finn, P. and Fitzpatrick, C. (2014). Demand side manage-

ment of industrial electricity consumption: Promoting

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

128

the use of renewable energy through real-time pricing.

Appl. Energy, 113:11–21.

Gela

ˇ

zanskas, L. and Gamage, K. A. A. (2016). Distributed

Energy Storage Using Residential Hot Water Heaters.

Energies, 9(3):127.

Gr

¨

unewald, P. and Torriti, J. (2013). Demand response from

the non-domestic sector: Early UK experiences and

future opportunities. Energy Policy, 61:423–429.

He, X., Keyaerts, N., Azevedo, I., Meeus, L., Hancher,

L., and Glachant, J.-M. (2013). How to engage con-

sumers in demand response: A contract perspective.

Util. Policy, 27:108–122.

Hewicker, C., Hogan, M., and Mogren, A. (2012). Po-

wer Perspectives 2030: On the road to a decarbonised

power sector. Technical report, Roadmap 2050, Den

Haag.

Huber, M., Dimkova, D., and Hamacher, T. (2014). Integra-

tion of wind and solar power in Europe: Assessment

of flexibility requirements. Energy, 69:236–246.

Hurtado, L., Mocanu, E., Nguyen, P., and Kling, W. (2015).

Comfort-constrained demand flexibility management

for building aggregations using a decentralized appro-

ach. In SmartGreens 2015 - 4th Int. Conf. Smart Cities

Green ICT Syst., pages 157–166, Lisbon.

Hurtado, L. A., Mocanu, E., Nguyen, P. H., Gibescu, M.,

and Kamphuis, I. G. (2017). Enabling cooperative be-

havior for building demand response based on exten-

ded joint action learning. IEEE Trans. Ind. Informa-

tics, PP(99):1.

Kalsi, K., Chassin, F., and Chassin, D. (2011). Aggregated

modeling of thermostatic loads in demand response:

A systems and control perspective. In Decis. Cont-

rol Eur. Control Conf. (CDC-ECC), 2011 50th IEEE

Conf., pages 15–20, Orlando. IEEE.

Klaassen, E., Frunt, J., and Slootweg, J. (2014). Method for

Evaluating Smart Grid Concepts and Pilots. In IEEE

Young Res. Symp. 2014 (YRS 2014), pages 1–6, Ghent.

EESA.

Labeeuw, W., Stragier, J., and Deconinck, G. (2015). Po-

tential of Active Demand Reduction With Residential

Wet Appliances: A Case Study for Belgium. IEEE

Trans. Smart Grid, 6(1):315–323.

Lampropoulos, I., Kling, W. L., Ribeiro, P. F., and van den

Berg, J. (2013). History of demand side management

and classification of demand response control sche-

mes. 2013 IEEE Power Energy Soc. Gen. Meet., pages

1–5.

Liu, W., Wu, Q., Wen, F., and Ostergaard, J. (2014). Day-

Ahead Congestion Management in Distribution Sys-

tems Through Household Demand Response and Dis-

tribution Congestion Prices. Smart Grid, IEEE Trans.,

5(6):2739–2747.

Ma, K., Hu, G., and Spanos, C. J. (2015). A Coope-

rative Demand Response Scheme Using Punishment

Mechanism and Application to Industrial Refrige-

rated Warehouses. IEEE Trans. Ind. Informatics,

11(6):1520–1531.

Maharashtra State Blood Transfusion Council (2014). Pre-

servation and Storage of Blood.

Matthews, B. and Craig, I. (2013). Demand side mana-

gement of a run-of-mine ore milling circuit. Control

Eng. Pract., 21(6):759–768.

MatWeb (2017). Unifrax Excelfrax 200 VIP Vacuum Insu-

lation Panel.

Mitra, S., Sun, L., and Grossmann, I. E. (2013). Opti-

mal scheduling of industrial combined heat and power

plants under time-sensitive electricity prices. Energy,

54:194–211.

Morales Gonz

´

alez, R., Shariat Torbaghan, S., Gibescu, M.,

and Cobben, S. (2016). Harnessing the Flexibility of

Thermostatic Loads in Microgrids with Solar Power

Generation. Energies, 9(7):547.

Samad, T. and Kiliccote, S. (2012). Smart grid technolo-

gies and applications for the industrial sector. Comput.

Chem. Eng., 47:76–84.

Ton, D. and Smith, M. (2012). The U.S. Department of

Energy’s Microgrid Initiative. Electr. J., 25(8):84–94.

Verzijlbergh, R. and Lukszo, Z. (2013). Conceptual model

of a cold storage warehouse with PV generation in a

smart grid setting. In 2013 10th IEEE Int. Conf. Net-

working, Sens. Control. ICNSC 2013, pages 889–894,

Evry. IEEE.

Wessling, F. and Blackshear, P. (1973). The Thermal Pro-

perties of Human Blood During the Freezing Process.

Heat Transf., 95(2):246–249.

Wilson, M. B., Luck, R., and Mago, P. J. (2015). A

First-Order Study of Reduced Energy Consumption

via Increased Thermal Capacitance with Thermal

Storage Management in a Micro-Building. Energies,

8:12266–12282.

Yin, R., Kara, E. C., Li, Y., DeForest, N., Wang, K., Yong,

T., and Stadler, M. (2016). Quantifying flexibility of

commercial and residential loads for demand response

using setpoint changes. Appl. Energy, 177:149–164.

Yoon, J. H., Baldick, R., and Novoselac, A. (2014). Dy-

namic Demand Response Controller Based on Real-

Time Retail Price for Residential Buildings. IEEE

Trans. Smart Grid, 5(1):121–129.

Zaparoli, E. L. and de Lemos, M. (1996). Simulation of

Transient Response of Domestic Refrigeration Sys-

tems. In Int. Refrig. Air Cond. Conf., pages 495–500,

West Lafayette. Purdue University.

Zavala, V. M. (2013). Real-time optimization strategies for

building systems. Ind. Eng. Chem. Res., 52(9):3137–

3150.

Demand Response of Medical Freezers in a Business Park Microgrid

129