Semantic Interoperability among Industrial Product Data Standards

using an Ontology Network

Alvaro Luis Fraga, Marcela Vegetti and Horacio Pascual Leone

Instituto de Desarrollo y Diseño (CONICET-UTN), Avellaneda 3657, Santa Fe, Argentina

Keywords: Interoperability, Ontology, Industrial Data.

Abstract: Globalization impacts on the competitive capacity of industries forcing them to integrate their productive

processes with other facilities geographically distributed. So, information systems supporting such processes

should interoperate. Standards have been seen for many years as a way to reach interoperability. In particular,

the committee 184 subcommittee 4 of the International Standard Organization (ISO) focus on the definition

of industrial product data standards. However, they still suffer from semantic inconsistencies when the

standards are put to work together. In this article, we propose an ontology network as a semantic bridge among

standards for product representation, as a solution to reach interoperability among information system in

manufacturing industries.

1 INTRODUCTION

Nowadays, the effects of globalization have changed

the scenarios in which manufacturing enterprises

develop their activities. Industrial companies were

reached by this phenomenon and saw as a competitive

advantage to seek partners abroad in distributed

industries to collaborate in their production processes.

Achieving this collaboration means that industrial

information systems can share their knowledge and

data models.

Information systems must be adapted or changed

to remain useful in these new scenarios where they

are likely to interact with other systems in different

areas. The ability of an information system (IS) to

exchange information with others is defined as

interoperability (Ray and Jones, 2006). David Chen

presents in his paper Enterprise Interoperability

Framework (Chen, 2015), part of the INTEROP

Network of Excellence, the following classification:

Technique: it tries to overcome the

incompatibilities between the different

information technologies.

Organizational: focuses on defining

responsibilities, authority, and structure.

Conceptual: concerning the syntactic and

semantic part of the information to be shared.

This position paper focuses on semantic interope-

rability. To achieve this interoperability level it is

necessary to know the formal conceptualization that

exists behind the terms used in each domain and then

integrate them. To reach this required integration is not

an easy task due to the different interpretations that

may exist for terms in the distinct domains involved.

Since many years the defintion of standards have

been accepted to promote interoperability. Among the

standards published to solve the problem of

interoperability between systems supporting product

life-cycle management in manufacturing industries, it

is possible to highlight those presented by the

Technical Committee 184 subcommittee 4 of the

International Standards Organization (ISO

TC184/SC) (Cutting-Decelle et al., 2007).

Although the mentioned committee seeks to solve

interoperability problems, when analyzing the

proposed standards simultaneously, potential

semantic issues in the terminology are detected

(Young et al., 2007). The terms that are defined in the

different standards may present ambiguities in their

conceptualization due to the lack of a solid consensus

among the experts who develop such standards. In

particular, some of the problems encountered

following an analysis of a set of standards from the

ISO TC184/SC are:

Lack of compatibility between the information

models and the vocabulary used by each one.

328

Fraga, A., Vegetti, M. and Leone, H.

Semantic Interoperability among Industrial Product Data Standards using an Ontology Network.

DOI: 10.5220/0006783303280335

In Proceedings of the 20th International Conference on Enterprise Information Systems (ICEIS 2018), pages 328-335

ISBN: 978-989-758-298-1

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Lack of formalization in the concepts that

prevents the automatic processing of

information.

Definitions of terms in different standards are

not consistent.

Tables I, II, III illustrate some of the problems

noted above. Table I displays the different definitions

specified for the term “Resource” presented in ISO

15531-1, ISO 18629-1, ISO 10303-239 and ISO

10303-232 standards. This term has multiple

definitions leading to ambiguities in their

interpretation. Also, this problem is getting worse

because the term “Resource” is involved in each

stage of the product life-cycle.

Table 1: Multiple Definitions for the term resource.

Resource

Any device, tool and means, except

raw material and final product, at the

disposal of the enterprise to produce

goods or services. ISO 15531-1, ISO

18629-1.

Result of a process. ISO 10303-239.

Recorded facts, concepts, or

instructions about a product. ISO

10303-232.

Table II shows the definitions of “Resource”,

“Process” and “Product” terms. These definitions

point out that both “Resource” and “Product” result

from a “Process”, while the term “Process” is a

particular procedure that can produce a “Product”, a

property or an aspect of it. Which would lead to

formalize that a “Resource” is a property or an aspect

of the product, or that a “Resource” is a “Product”.

Table III reveals, three different terms

(“Resource”, “Product” and “Product Information”)

having the same definition, and may cause actors to

infer that these terms are equivalent.

Therefore, getting heterogeneous information

systems that implement a set of standards belonging

to the ISO TC184/SC4 committee to interoperate,

represents a major challenge (Fortineau, Paviot and

Lamouri, 2013). As a first step to overcome this

challenge, the present paper proposes an ontology

network based on the mentioned standards that acts

as mediator between the heterogeneous systems that

implement different standards, data models, and

vocabularies.

Table 2: Definition of the terms: product, process, and

resource.

Process

A particular procedure for doing

something involving one or more

steps or operations. The process may

produce a product, a property of a

product, or an aspect of a product.

ISO 10303-49

Resource Result of a process. ISO 10303-239

Product

Thing or substance produced by a

natural or artificial process. ISO

10303-1, ISO 15531-32.

Table 3: Definition of the terms: resource, product, and

product information.

Resource

Recorded facts, concepts, or

instructions about a product. ISO

10303-232.

Product

Facts, concepts or instructions. ISO

13584-102.

Product

Information

Facts, concepts, or instructions

about a product. ISO 10303-1.

The work is organized as follows. Section 2

describes the proposed ontology network, specifying

the architecture, its levels, relations and interaction

between its components. Next, Section 3 presents a

proof of concept that shows how the ISO 10303-49

standard is added into the low level of the proposed

network. Finally, in section 4, conclusions and future

work are presented.

2 PROPOSED ONTOLOGY

NETWORK

This section introduces an ontology network that will

act as a semantic mediator between different

information systems supporting product life-cycle in

manufacturing companies.

The proposal is based on the formalization of a set

of standards published by the ISO TC184/SC4

committee. This approach allows, the re-use of

knowledge immersed in the definitions proposed in

the above-mentioned standards, so the proposal

covers a wide spectrum of action on different

Semantic Interoperability among Industrial Product Data Standards using an Ontology Network

329

application fields and across the different phases of

the product life-cycle. Likewise, the proposed

network can be extended to incorporate diverse

standards and others documents that implement a

certain data model into industrial information

systems.

2.1 General Description

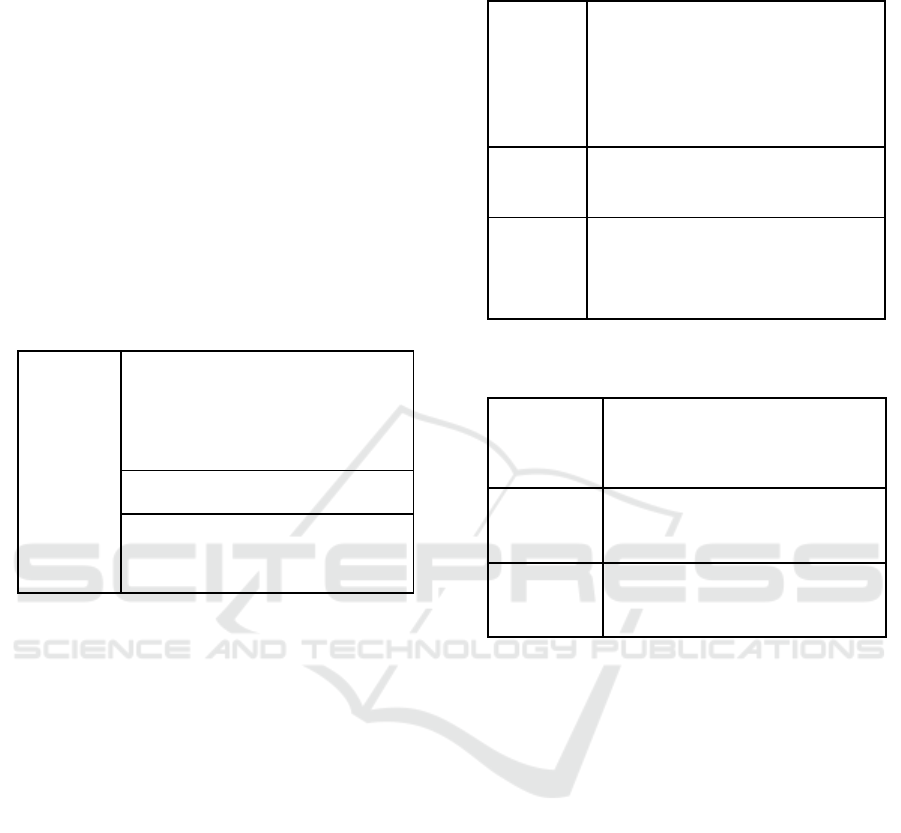

The proposed multilevel ontology network is

depicted in Figure 1. The core level is composed of

an ontology that specifies four key terms: "Process",

"Product", "Resource" and "Enterprise". These terms

are considered by Zhao et al. (1999), Lin and Harding

(2007), Chungoora et al. (2013) and Usman et al.

(2013) as the principal concepts of all manufacturing

information systems.

Figure 1: Proposed ontology network schema.

The refinement level has four modules, each of

which specifies a set of concepts that refine one of the

terms of the higher level. These modules have the

goal of specifying the terms that are strongly related

to the concepts introduced in the first level, thus

extending the definitions of them.

The standards level contains the ontologies that

formalize the standards and/or data models among

which it is necessary to establish semantic

interoperability. Some of them are mentioned in

Tables I, II and III. This level connects with the

refinement level through an alignment layer that

defines, by means of the SWRL (Semantic Web Rule

Language), a set of rules to match the terms defined

at refinement and standards levels.

2.2 Core Level

In Figure 2, the conceptual scheme of the Ontology

Network Core level is shown. This figure depicts the

relationships between the terms "Product", "Process",

"Resource" and "Enterprise". It also shows using

dotted line boxes which are the standards that have a

definition for each term.

It was decided to associate the terms "Product"

and "Process" because of the definition of "Process"

in ISO 10303-49, which states: "A particular

procedure for doing something involving one or more

steps or operations. The process can produce a

product, a property of a product or an aspect of a

product".

The term "Process" is related to "Enterprise" in

ISO 15531 and ISO 18629 standards. Both standards

describe "Process" as: "A set of activities involving

various business entities that are organized for one

purpose". In addition, "Enterprise" is defined in ISO

100303-239 as one or more organizations with a set

of goals and objectives to offer products and/or

services.

Figure 2: Core level conceptual schema.

2.3 Refinement Level

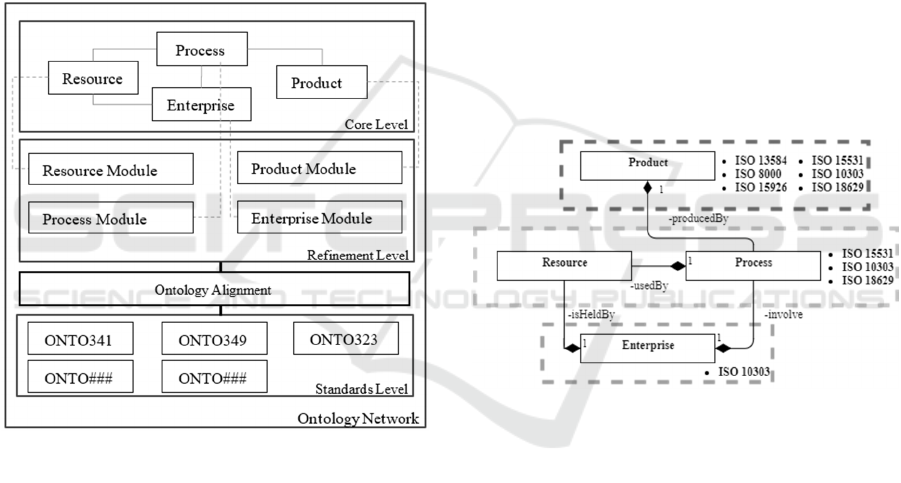

Figures 3, 4, 5 and 6 illustrate the diagrams that

correspond to each of the modules in the architecture

refinement level: “Process”, “Product”, “Resource”

and “Enterprise”.

The “Process” module, which is shown in Figure

3, includes the terms "Natural_Process" and,

"Artificial_Process". These two terms are part of the

definition of "Product" in ISO 8000, ISO 10303, ISO

13584, ISO 15531, ISO 15926, ISO 18629 standards.

Figure 3 shows that the term "Procedure" materializes

the term "Process" as defined in ISO 10303. A

"Process_Activity" is a step or operation that is part

of a "Process" and "Procedure_Activity" is a specific

execution of a "Process_Activity". Using the

associations that are explicitly shown in Fig. 3 linking

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

330

“Procedure”, “Process”, “Process_Activity” and

“Procedure_Activity” classes it is possible to infer the

relations that links an instance of “Procedure” with

the instances of “Procedure_Activity” that composed

it. A resource required to execute a

"Process_Activity" is called "Process_Material". The

set of processes required to manufacture a product are

linked by means of a "Process_Plan", which is

executed in a "Process_Plant".

Figure 3: Process module terms.

The diagram corresponding to the “Product”

module is shown in Figure 4. This figure shows the

terms "Instruction", "Fact", and "Concept" as

specializations of "Product_Information". The term

"Instruction" describes information on how to do or

how to use something, while "Fact" is the atomic

information of the product and "Concept" is the

notion or idea about it.

ISO 10303-1 standard gives two definitions for

the term "Product". As it is illustrated in Table 3 one

of this definition is equivalent to the one of

"Product_Information". The proposal introduces the

concept of "Product_Information" to the “Product”

module and associates it with the concept through the

relationship “definedBy”. Figure 4 also shows that

the terms "Substance" and "Thing" have been

introduced in “Product” module as a specialization of

the term "Product". This decision is based on the fact

that the ISO 8000, ISO 10303, ISO 13584, ISO

15531, ISO 15926 and ISO 18629 standards define

"Product" as “a thing or substance produced by a

natural or artificial process”.

Figure 4: Product module terms.

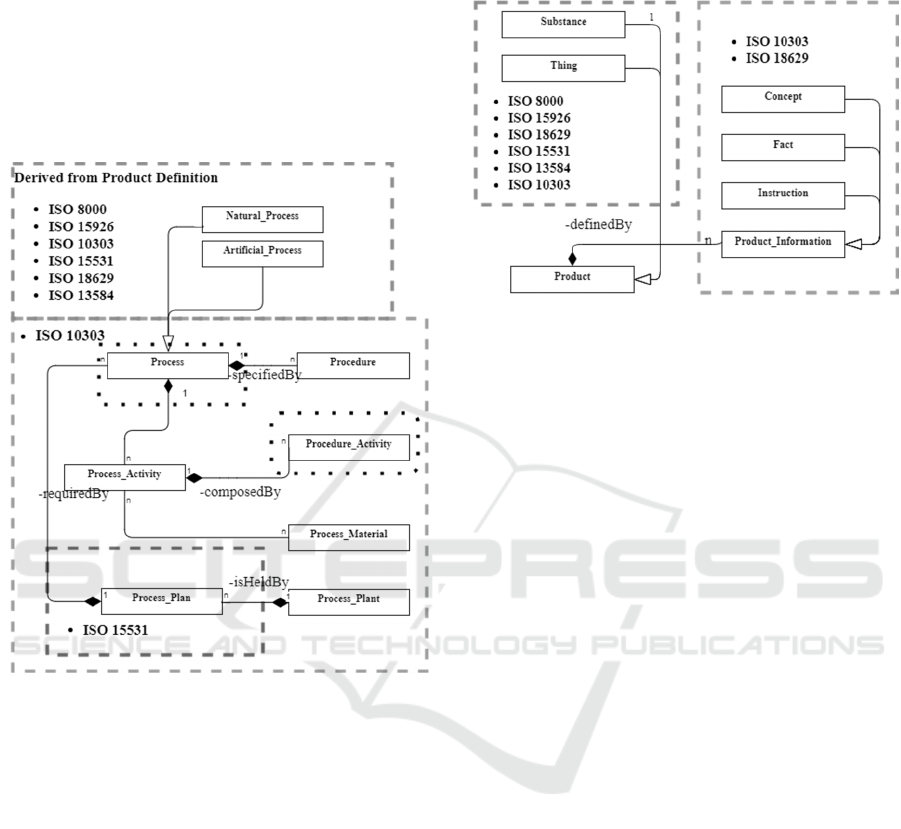

The module refining the term "Resource" is

introduced in Figure 5. According to ISO 10303-49,

a "Resource" is defined by its behaviours and

capabilities, hence it is associated with the terms

"Behaviour" and "Capability". This module also

includes the terms "Tool", "Equip", and "Device",

which are described as resources by ISO 15531 and

ISO 18629 standards. These standards do not

recognize, neither consider the term "Raw Material"

as a resource type.

Other standards specify other concepts as

different kind of “Resource”, such as

"Material_Procees" and "Product_Material". So, they

have been included in this module. According to ISO

10303-227, the first mentioned term defines material

used or transported by a process activity. The second

one, in accordance with ISO 10303-235, refers to the

physical object that was manufactured to a

specification and from which another product can be

manufactured. A subsumption relationship is defined

between "Material" and the terms

"Product_Material", "Process_Material" and

"Raw_Material".

Figure 6 introduces the Enterprise ontology

module, in which the corresponding term of the core

level is refined using the four-level manufacturing

model present in (Zhao, Cheung and Young, 1999).

This module represents the levels at which a process

or process plan can be executed. A workstation,

"Station", is where a particular job is performed. The

term "Cell" is a group of related operations in the

production flow, while "Shop" is the area where

production is carried out, and "Factory" is the place

where those production areas are located. The

"Factory" group is also a member of "Enterprise".

Semantic Interoperability among Industrial Product Data Standards using an Ontology Network

331

Figure 5: Resource module terms.

Figure 6: Enterprise module terms.

2.4 Standards Level

The standards level is proposed to group the different

ontologies that formalize the standards or model to be

interoperated. This proposal uses the process that is

introduced in Figure 7 to transform or reuse the

standard documentation, or different academic

contribution to adapt them into an OWL (Ontology

Web Language) ontology to add into the standards

level of the proposed network. It is important to

mention that the process can also be used to

incorporate other type of product data model that

need to interoperate with the standards.

The process begins selecting the standard,

language, vocabulary, or ontology that needs to be

integrated with other systems involved in the

production process supported by the network. Once

this selection is done, the process classifies the

information sources that will be used to develop the

ontology. These information sources can be

ontological or non-ontological. Within the

ontological ones, it is possible to emphasize diverse

works that contribute with ontologies based on

standards or models that interfere in the product life

cycle.

Figure 7: Standards level ontology network integration

workflow.

Non-ontological sources are documents that

describe the conceptualizations of terms,

relationships and restrictions between terms. ISO

TC186/SC4 standards are in this category.

Afterwards, sources are selected, the non-

ontological ones are studied to build a new ontology

from them. A semiautomatic process for this ontology

construction has been also proposed by the authors in

(Fraga, Vegetti and Leone, 2017), but its description

is out of the scope of the present article. The ontology

that is obtained as a result of the mentioned process

is, then merge with other ontologies that may

complete and enhance the definitions of the first one.

Once the ontology merging activity is done, the

evaluation of the ontology is executed. Two different

tools are proposed for this activity. The first one is the

OOPS! Scanner (Poveda-Villalón et al., 2014) that

finds common design mistakes and verifies ontology

consistency. The second one consists of using

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

332

competency questions, which have defined in natural

language at the beginning of the ontology

development and then formalized in SPARQL query

language, to verify the new ontology requirement.

If the ontology passes both tests, it is imported

into the ontology network as part of its standards level

and a set of SWRL rules are written to align the

imported new ontology with the concepts already

defined by the network. Subsequently, the updated

ontology network is tested using competency

questions to ensure its integrity and verify if the

ontology is fully functional to the interoperability

process.

Next section illustrates how the process

previously described is applied to add the ISO 10303-

49 standard to the low level of the proposed ontology

3 PROOF OF CONCEPT

The aim of this section is to illustrate how the ISO

10303 standard, part 49 has been added at the lowest

level of the proposed network using the process that

has been explained in section 2.4.

The specification of ISO 10303-49 is written

using natural language and EXPRESS code. To

generate an OWL ontology from such non-

ontological source the semi-automatic tool proposed

in (Fraga, Vegetti and Leone, 2017) is used. Such tool

handles both kind of content in different way. On one

hand, the content in natural language is interpreted

using a component based on lexicon syntactic rules

written on UIMA rule script language and supported

by the UIMA Ruta framework (Ferrucci and Lally,

2004). On the other hand, the EXPRESS code content

is handled using an implementation of the EXPRESS

to OWL strategies proposed by (Pauwels and Terkaj,

2016).

Once the ontology formalizing the standard is

obtained from such tool, it is validated using OOPS!

Scanner, competency questions and experts from the

area.

To add the new ontology to the Standards level of

the proposed network it is necessary to provide

different alignment rules to relate concepts of the new

generated ontology with terms of the ontology

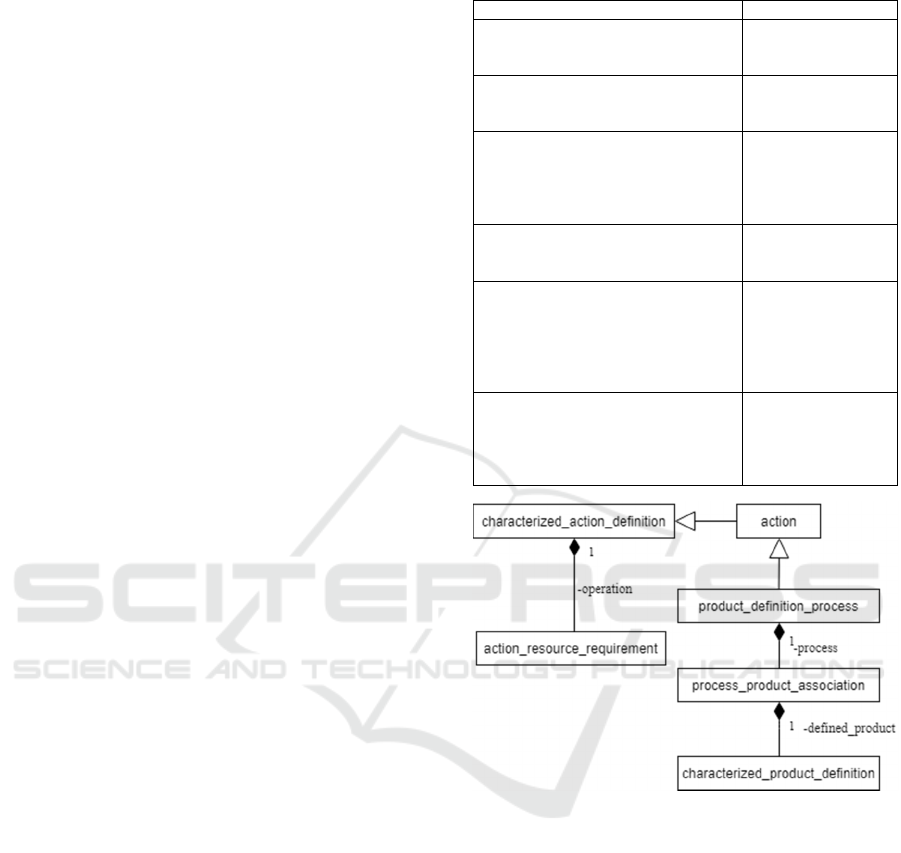

network. Table 4 and Figure 8 illustrate the definition

of some terms belonging to ISO 10303-49 and their

relations. The terms listed in such table are not all the

terms defined by the standard, but are the ones used

to test concepts in this paper.

Table 4: ISO 10303-49 Terms and definitions.

10303-49 terms Definition

Action_resource_requirement Defines the

resources required

for a process

Product_definition_process Represents a product

definition, a product,

or an aspect of it.

Process_product_association Specifies a certain

process to achieve a

specific

characteristic of the

product

Characterized_product_definition Defines the

characteristics of a

process

Characterized_action_definition

I

dentifies either an

a

ction, an action

m

ethod, an

a

ction_method_relatio

n

ship, or an

a

ction_relationship.

Action

I

dentifies an activity

t

hat has taken place, is

t

aking place, or is

e

xpected to take place

i

n the future.

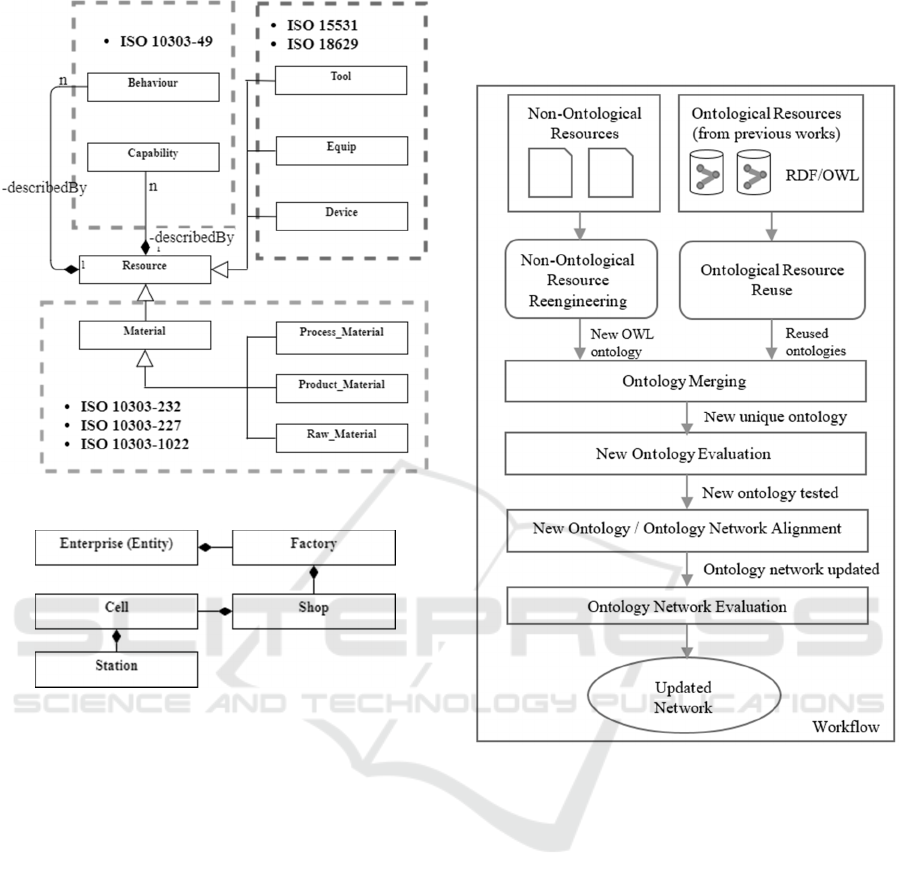

Figure 8: Extract of ISO 10303-49.

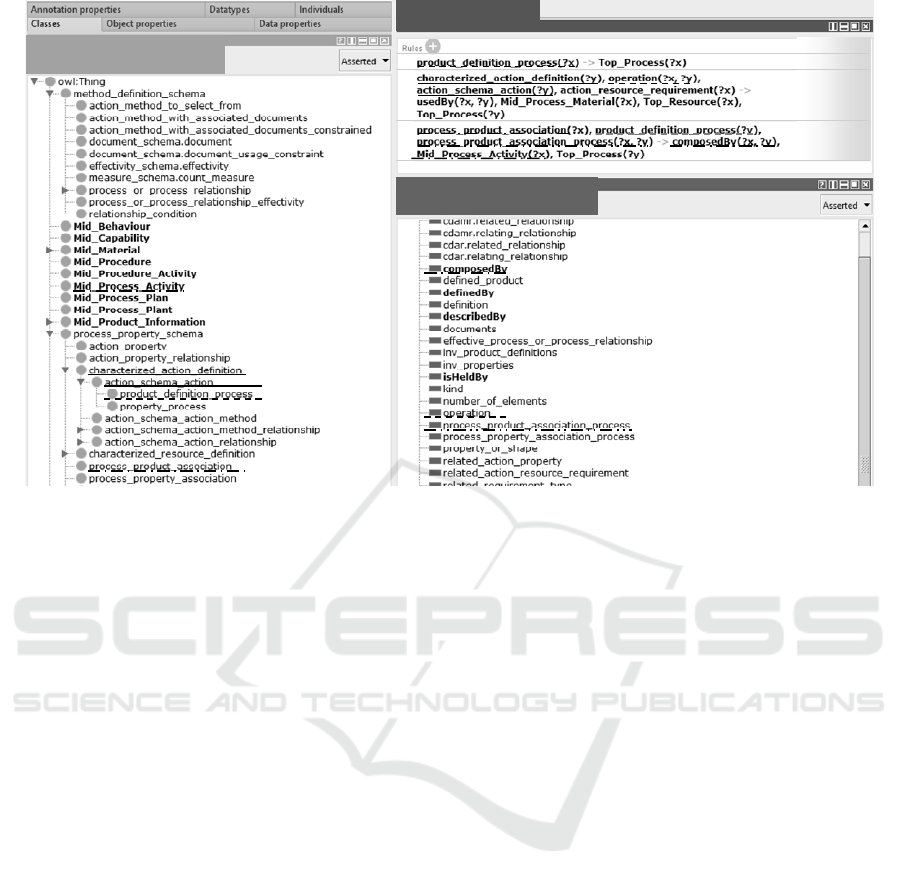

Figure 9 shows a screenshot of the Protegé

ontology editor, which has been used to specify the

mappings rules. At the left part and the bottom right

part of the image, the concepts taxonomy and the

property taxonomy are shown, respectively. At the

right top part of Fig. 9, the mapping rules, which.

describe how individuals in the ISO 10303-49 module

can be inferred as individuals from the refinement

level ontology network terms.

R_Process rule specifies that if X is an individual

in the population of the concept

"product_definition_process", then X is an individual

of the entity "Top_Process" in the core level.

R_Resource rule details that if X is an

"action_resource_requirement" and is related to Y

through the "operation" property, then X is a

Semantic Interoperability among Industrial Product Data Standards using an Ontology Network

333

Rules Description

Object Property Hierarchy

Class Hierarchy

Rules Names

R

_

Process

R

_

Resource

R

_

Process

_

Activity

Figure 9: Protege screenshot.

"Mid_Process_Material", a term present in the

refinement level and "Top_Resource", a term present

in the core level; individual Y from the entity

"characterized_action_definition" becomes a

"Top_Process" individual in the refinement level

related with the X individual through the “usedBy”

property. The R_Process_Activity rule

specifies that if X is a "process_product_association"

and is related to an individual Y from

"product_definition_process" entity by the property

"process_product_association_process", then X is a

"Mid_Process_Activity" individual and Y is the

equivalent of "Top_Process" in the ontology network

associated by the “composedBy” object property.

4 CONCLUSIONS

This paper presents a multilevel network of

ontologies as a solution to the problem of

interoperability of heterogeneous systems

implementing the standards of the 184 subcommittee

4 of the International Standards Organization. This

network can also be extended and used for other

standards, adding the necessary rules for the

alignment of participating ontologies. The division of

the structure into levels was shown. The core level

has four terms that represent key concepts in

manufacturing domain. The refinement level details

the conceptualization of the terms of the higher level

by making use of terms present in various standards

involved in this project. The refinement level through

rules and an inference engine achieves alignment with

the standards level. The standards level contains the

ontologies based on the standards imported to achieve

semantic interoperability between them. This

network promise to be very useful not only for the

specialized industrial systems to which it offers the

possibility of adapting the information models to the

standard that they require for representing their

information, but it can also provide interoperability

between non-specific standard based information

models, as well as, non-specific industrial

information systems and could provide information

models for areas that need only an overview or a

reduced data model with the information from the

upper layers of the network.

The next steps will be to continue with the

implementation of the modules of different parts and

standards, check the integrity of the proposal with

multiple case studies and applications.

ACKNOWLEDGEMENTS

This work has been supported by CONICET and

Universidad Tecnológica Nacional (

UTI3810TC and

UTI3803TC))

ICEIS 2018 - 20th International Conference on Enterprise Information Systems

334

REFERENCES

Chen, D. (2015) ‘Enterprise Interoperability’, Lecture

Notes in Business Information Processing,

213(MARCH), pp. 118–131. doi: 10.1007/978-3-662-

47157-9.

Chungoora, N. et al. (2013) ‘A model-driven ontology

approach for manufacturing system interoperability and

knowledge sharing’, Computers in Industry, 64(4), pp.

392–401. doi: 10.1016/j.compind.2013.01.003.

Cutting-Decelle, A. F. et al. (2007) ‘ISO 15531

MANDATE: A Product-process-resource based

Approach for Managing Modularity in Production

Management’, Concurrent Engineering, 15(2), pp.

217–235. doi: 10.1177/1063293X07079329.

Ferrucci, D. and Lally, A. (2004) ‘UIMA: An Architectural

Approach to Unstructured Information Processing in

the Corporate Research Environment’, Nat. Lang. Eng.

New York, NY, USA: Cambridge University Press,

10(3–4), pp. 327–348. doi: 10.1017/S135132490400

3523.

Fortineau, V., Paviot, T. and Lamouri, S. (2013)

‘Improving the interoperability of industrial

information systems with description logic-based

models-The state of the art’, Computers in Industry.

Elsevier B.V., 64(4), pp. 363–375. doi:

10.1016/j.compind.2013.01.001.

Fraga, A. L, Vegetti, M., Leone, H. P. (2017) ‘Semi-

Automated Ontology Generation Process from

Industrial Product Data Standards’, in 46

th

JAIIO, pp.

53-66. Available at: http://www.clei2017-46jaiio.sadio.

org.ar/sites/default/files/Mem/SAOA/SAOA-05.pdf.

Lin, H. K. and Harding, J. A. (2007) ‘A manufacturing

system engineering ontology model on the semantic

web for inter-enterprise collaboration’, Computers in

Industry. Elsevier Science Publishers B. V., 58(5), pp.

428–437. doi: 10.1016/j.compind.2006.09.015.

Pauwels, P. and Terkaj, W. (2016) ‘EXPRESS to OWL for

construction industry: Towards a recommendable and

usable ifcOWL ontology’, Automation in Construction.

Elsevier B. V., 63, pp. 100–133. doi: 10.1016/

j.autcon.2015.12.003.

Poveda-Villalón, M. et al. (2014) ‘OOPS! (OntOlogy Pitfall

Scanner!): supporting ontology evaluation on-line’,

International Journal on Semantic Web & Information

Systems, 10(2), pp. 7–34. doi: http://dx.doi.org/

10.4018/ijswis.2014040102.

Ray, S. R. and Jones, A. T. (2006) ‘Manufacturing

interoperability’, Journal of Intelligent Manufacturing,

17(6), pp. 681–688. doi: 10.1007/s10845-006-0037-x.

Usman, Z. et al. (2013) ‘Towards a formal manufacturing

reference ontology’, International Journal of

Production Research, 51(22), pp. 6553–6572. doi:

10.1080/00207543.2013.801570.

Young, R. I. M. et al. (2007) ‘Manufacturing knowledge

sharing in PLM: a progression towards the use of heavy

weight ontologies’, International Journal of

Production Research, 45(7), pp. 1505–1519. doi:

10.1080/00207540600942268.

Zhao, J., Cheung, W. M. and Young, R. I. M. (1999) ‘A

consistent manufacturing data model to support virtual

enterprises’, International Journal of Agile

Management Systems, 1(3), pp. 150–158. doi:

10.1108/14654659910296517.

Semantic Interoperability among Industrial Product Data Standards using an Ontology Network

335