Preliminary Study on Forging Planting Media with Variation of Raw

Materials by Manual Press Tool

Bode Haryanto

1

, Ahmad Perwira M. Tarigan

2

, Rina Br Bukit

3

, Sarjana

4

and Muhammad Arifin

4

1

Department of Chemical Engineering, Universitas Sumatera Utara, Padang Bulan, Medan, Indonesia

2

Department of Civil Engineering, Universitas Sumatera Utara, Padang Bulan, Medan, Indonesia

3

Department of Accounting, Universitas Sumatera Utara, Padang Bulan, Medan, Indonesia

4

Graduate School, Department of Mechanical Engineering, Universitas Sumatera Utara, Padang Bulan, Medan, Indonesia

Keywords: Forging, Planting-media, Press Tool.

Abstract: This idea to introduce the ability of a mechanical press tool manually. Tree types of raw materials were used

100% clay, 100% sand and mixture of both 50% plus 50%. This is done in order to measure the time needed

to produce the planting media using the press tool machines. The time needed for every different raw material,

which are clay, sand and mixed materials are 3 minutes, 0.4 minutes and 1.2 minutes, respectively. The

wetness of clay increases the time needed to form it into a growing medium because it becomes more muddy.

It has a higher strength value compared to sand and a mixture of both ingredients. Sand and mixture materials

are definitely need a binding compound to increase the bond of mixture raw of material.

1 INTRODUCTION

Sand has natural macro-porous and meso-porous

structures [Chen et al, 2017]. Porosity of soil is

mostly influenced by particle size, uniformity, and

rock type and assortment [Fetter, 1994]. The porosity

in solid materials can be more classified into intra-

particle and inter-particle porosities. Inter-particle

porosity is the porosity present between particle sand.

Intra-particle porosity is the porosity within a sand

particle. Pores have not only a greater surface area,

but also a higher selectivity for reaction and

adsorption [Kaneko, 1994]. On the other hand, the

porous characteristics of sand surface could be a

kinetic limitation to material desorption from porous

sites [Casas et al., 2006].

Clay is a finely-grained natural rock or soil

material. This material combines one or more clay

minerals with possible traces of quartz (SiO2), metal

oxides (Al2O3, MgO etc.) and organic matter.

Geologic clay deposits are mostly composed of

phyllosilicate minerals containing variable amounts

of water trapped in the mineral structure. Clays are

like plastic due to particle size and geometry as well

as water content. Clays become hard, brittle and non–

plastic upon drying or firing [Guggenheim and Martin

1995; London's Geology, 2016]. Clay is depending

on the soil's content in which it is found, clay can

appear in various colours from white to dull grey or

brown to deep orange-red [Wikipedia, 2018]

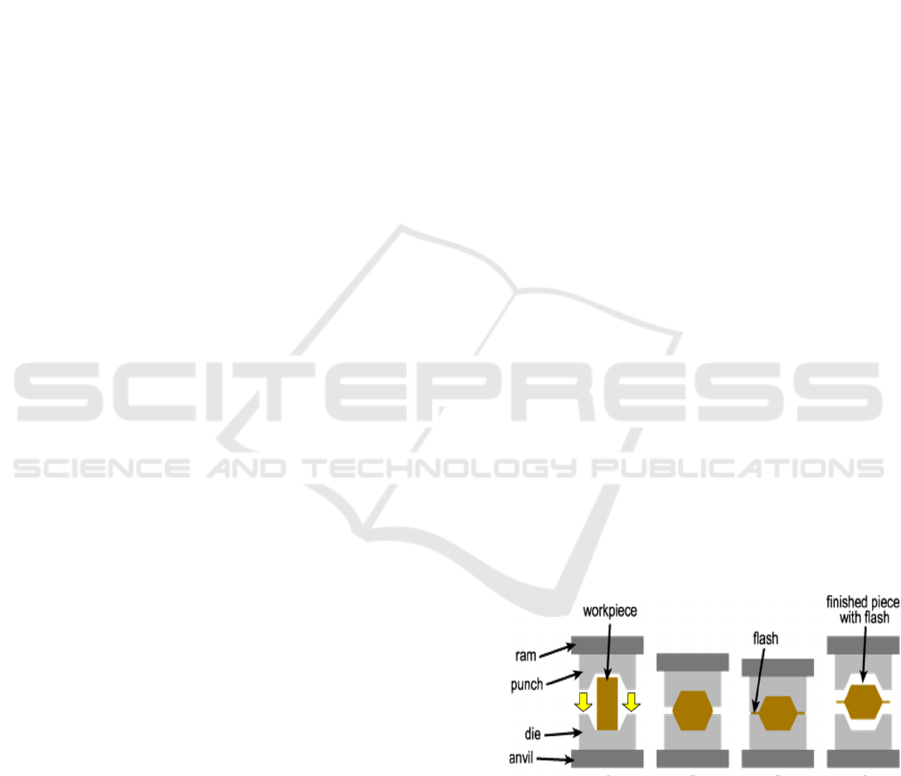

Press tools are often used in hydraulic, pneumatic,

and mechanical presses to produce the sheet solid

components in large volumes. Generally press tools

are categorized by the types of operation performed

using the tool, such as blanking, bending, forming,

forging (Figure 1.), etc (Cyril et al, 1972).

Figure 1. Machine Forging (https://www.quora.com/).

The purpose of this study is an introduction in

analyzing the performance of manual press tool

operation in producing planting media base on

composition variations of material. The time needed

to produce the planting media with its physical

properties was then investigated. This is as

preliminary study before a study using the raw

Haryanto, B., Tarigan, A., Bukit, R., Sarjana, . and Arifin, M.

Preliminary Study on Forging Planting Media with Variation of Raw Materials by Manual Press Tool.

DOI: 10.5220/0010100203750377

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

375-377

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

375

material of sand from mount Sinabung eruption, Karo

highland, Sumatera Utara.

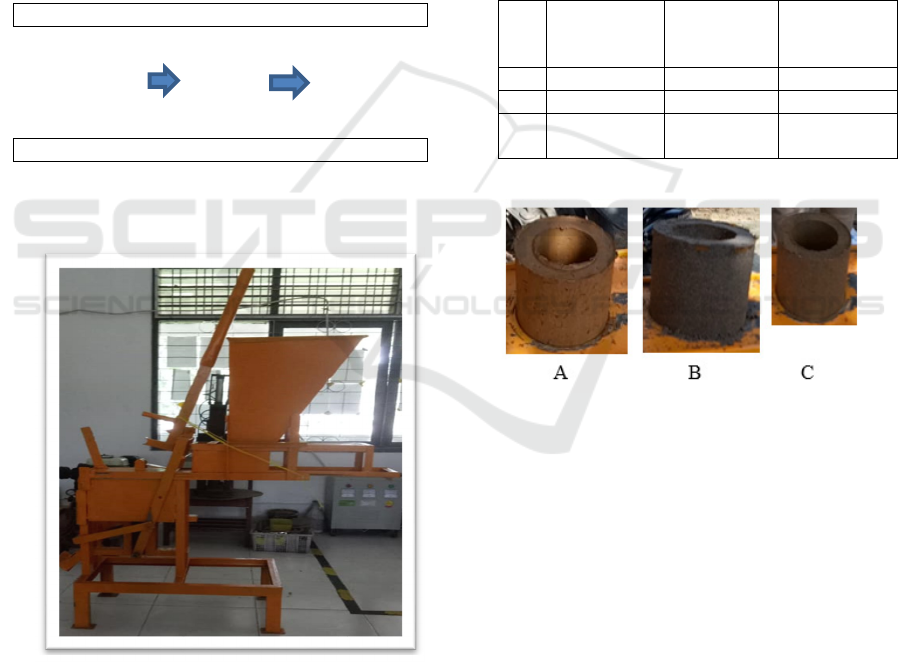

2 METHODOLOGY

In this study the material used was from clay and

sand around Medan city. The component of raw

material was originally used as raw materials and

mixed 50% : 50% of the sand and clay. The step

activities are shown in Figure 2. The activities were

started by preparing the raw materials then by using

the mechanical press tool manually. The press tool is

as shown in Figure 3. The strenght measurement is at

the removing step of the tool to dry step. The result

was shown as in the camea photos and timer.

Production Steps

Preparing

Raw

Materials

Mechanical

Press Tool

Planting

Media

Product

Operation Time

Figure 2. Operation steps to produce planting media

from sand.

Figure 3. Press tool manual.

After preparing the raw materials, it has four steps

in operating the mechanical oress tool. The fist is

loading the raw material (1) then (2) adjusting to

molding space (3) pressing and (4) flow out of the

product. Then the next step is to put the planting

media to dryer place.

3 RESULTS

The ability of a mechanical press tool manually is

as follow. Tree types of raw materials were used

100% clay, 100% sand and mixture of both 50% plus

50%. Then we measure the time needed to form

molds in planting media machines. The time for each

different raw material is 3 minutes, 0.4 minutes and

1.2 minutes, respectively. The wetness of clay

increases the time needed to form into a growing

medium because it becomes more clay. But it has a

higher strength value compared to sand and a mixture

of both ingredients. Sand and mixture materials are

definitely needed a binding compound to increase the

bond of raw material mixture.

Table1. The Operation Time.

No. Raw Type Percentage

Operation

time

(minutes)

1. Clay 100% 3

2. Sand 100% 0,4

3. Mixed Clay

and Sand

50% + 50% 1.2

Figure 4. The planting product: A. Clay, B. Sand, C.

Mixed 50% and 50%.

Using mechanical press tool manually, tree types

of raw materials were used 100% clay, 100% sand

and mixture of both 50% plus 50% (Figure 4). In

order to measure the time needed to form molds in

planting media machines. The each different raw

material is 3 minutes, 0.4 minutes and 1.2 minutes,

respectively. The wetness of clay increases the time

needed to form into a growing medium because it

becomes more clay. But it has a higher strength value

compared to sand and a mixture of both ingredients.

Sand and mixture materials are definitely needed a

binding compound to increase the bond of raw

material mixture.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

376

Figure 5. Drying steps.

Figure 5 shows the step to dry clay planting media

product. The drying is still using the natural sun light

energy. The comparison study related to drying step

will be done in the next study. Sand from Mount

Sinabung eruption will be the raw material used in the

next investigation.

4 CONCLUSIONS

Chemical compound type of a raw material

impacted the operational activities in producing

planting media. The clay needed longger time to mold

because the wettening impacted the material control

time to operate the mechanical pressure until pack as

product. Using 100% clay need time about 3 minutes

in compare to sand 100% about 0,4 menite and

mixture of both 50% plus 50% was about 1,2 minutes.

The strength structure of clay product is better than

sand and mixed material. More future study is needed

to get the suit composition of clay and sand to produce

the sand materials.

ACKNOWLEDGMENTS

The The authors wish to express sincere gratitude

to Lembaga Pengabdian Kepada Masyarakat,

Universitas Sumatera Utara on the DRPM

KEMENRISTEKDIKTI Project 2018, No:

154/UN5.2.3.2.1/PPM/2018, for the financial support

for this research project; also to Professor Robison

Tarigan to help and for providing comments on this

manuscript.

REFERENCES

Casas, CLDS, Bishop, KG, Bercik, LM, Johnson, M,

Potzler, M, Ela, WP, Sáez, AE, Huling, SG, &

Arnold, R G 2006, Remediation of Hazardous

Waste in the Subsurface: In-place regeneration of

granular activated carbon using fenton's

reagents, American Chemical Society, vol. 940,

Chapter 4, pp. 43-65.

Chen, H, Wang, J , Rahman, Z ,Worden, J , Liu, X ,

Dai, Q, Huo, & Q 2007, ‘Beach sand from Cancun

Mexico: a natural macro- and meso-porous

material’, J. Mater. Sci., vol. 42, pp. 6018 – 6026.

Cyril, D, George LC, Goold V C 1973, Tool design,

Tata McGraw-Hill Education, New Delhi, 3rd

edition.

Fetter, CW 1994, Applied hydrogeology, Maxwell

Macmillan International, New York. 3

rd

edition.

Guggenheim, S, & Martin, R T 1995, ‘Definition of

clay and clay mineral: Journal report of the

AIPEA nomenclature and CMS nomenclature

committees’, Clays and Clay Minerals, vol. 43,

no. 2, pp. 255–256.

Kaneko, K 1994, ‘Determination of poresizeand

poresized istribution: 1.Adsorbents and catalysts’,

J. Membrane Sci., vol. 96, pp. 59–89.

https://en.wikipedia.org/wiki/Clay

https://www.quora.com/What-is-the-difference

between-roll-forging-and-rolling

Preliminary Study on Forging Planting Media with Variation of Raw Materials by Manual Press Tool

377