The Effect of the Mixture Variation and Holding Time to the Porous

Ceramics based from Clay and Active Charcoal as a Filter of Water

Vapour

Susilawati

1,2

, Anwar Dharma Sembiring

1

, Fransiskus Waruwu

1

, and Siti Khanifah

1

1

Department of Physics, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan, 20155,

Indonesia

2

Pusat Unggulan Inovasi Green Chitosan dan Material Maju, Universitas Sumatera Utara, Medan, 20155, Indonesia

Keywords: Clay, Active Charcoal, Porous Ceramic, and Water Vapour Filter.

Abstract: Have made a porous ceramic which was formed by clay and active charcoal with casting technique. The clay

which was used comes from the village Iraonogeba regency of Moroó in West of Nias. The active charcoal

which is used is active Aquasorb® 1000. The clay and active charcoal sifted with the sieve mesh 200. Then

the clay wa activated chemically using the solution H

2

SO

4

6% and physically can be activated at a temperature

of 300

0

C. Ceramic was formed by the technique of slip casting with comparison of variation of clay: charcoal

active 100% : 0 percent ; 90% : 10% ; 80% : 20% ; 70% : 30% and 60% : 40%. The ceramics was sintering

with sintering temperature 1000

0

C with variation of holding time 2 hours ; 3 hours and 4 hours. Ceramics

characterized to get the value of mechanical properties (pressure and hardness); the size of the diameter of the

pores, womb elements (SEM-EDX) and the value of the water vapour adsorption. The results of this

characterization shows that the optimum variations there are on the mixtures of clay and active charcoal 80%

: 20% with a holding time of 2 hours with pressure = 9.8 MPa and hardness = 184,73 MPa ; the size of the

diameter of the pores on average = 8,606 µm and womb elements (EDX) namely elements O = 58,11% ; Si

= 24,04% ; Al = 12,33% ; Na = 3,06% ; K = 2.51% ; Ca = 2.22 % ; Fe = 2.01% ; Mg = 1.60 percent and C =

1.54%. water vapour adsorption test shows the value of the maximum hydrogen concentration passed =

61,87% on minutes- 77 with maximum output voltage = 3.09 Volts on minutes 98.

1 INTRODUCTION

Has been widely known that the pottery is one of the

first artificial material made by human beings as a

result of burning the clay in the fire to produce

artificial stone (Buys and Oakley, 2014) clay that

burned in the fire was then known as ceramics.

Ceramics have some attractive properties compared

to metals and poymers, is make them useful for

specific applications. Their physical properties have

been utilized for many applications. In other

applications their mechanical properties acres

Washington (Munz and Fett, 2013). Now ceramic

products has been expanded and has a wide range of

variation one of the porous ceramic. Porous Ceramic

is a component of the glomerular filtration which is

very useful in various applications and is designed to

eliminate concentrate grade which has the size of the

micrometer to nanometer from various fluid. Whereas

total and the distribution of the size of the pores is the

most important aspect of the porous media and

effected on most of the characteristics of the porous

media such as elasticity and mechanical properties,

the movement and the flow of the fluid (Kuila and

Prasad, 2013). Whereas the total important to

improve permeability and high surface area provided

for the adsorption of the vapour of gas (Prenzel et al,

2014). The way of filtering can be consist of the

surface filtration and the inside filtration (cake

filtration) ) (Hammel et al, 2014).

Adsorption as surface filtration occurs when a

solid surface left open to gas or fluid, which is defined

as material enrichment or a rise in the density of the

liquid in the region around the interface (Rouquerol

et al, 2013). Ceramic Adsorption to gas occurs on the

pores of the ceramic surface until the condition where

1062

Susilawati, ., Sembiring, A., Waruwu, F. and Khanifah, S.

The Effect of the Mixture Variation and Holding Time to the Porous Ceramics based from Clay and Active Charcoal as a Filter of Water Vapour.

DOI: 10.5220/0010098410621069

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1062-1069

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the pores is fully charged by the gas or in other words

is on the state of the saturated.

Mechanical characteristics such as a pressure and

hardness is one of the nature of the material that is

very important. Various studies have previously

using the mixture of clay with carbon (active carbon/

active charcoal) (Phonpuak, 2012; Sarkar, 2012; Shen

et al., 2014; Wang, 2013; Yates, 2012). (Susilawati

et. al., 2017) has studied the use of natural zeolite with

cocoa skin filler as a water vapor filter in the

electrolysis process

In this experiment a porous ceramic as water

vapour filter characterised the nature of the

mechanism made from clay and active charcoal that

have pores of that very much spread in all parts of the

ceramics, which eventually produce ceramic that is

weak with the mechanical nature of the weak. This is

the main problem of this experiment. Porous ceramic

needed not only have the nature of a good physic but

must also have a good mechanical nature. Mechanical

nature which is tested in this experiment is a pressure

and hardness. The pressure of ceramics tested using

Maekawa Testing Machine Tokyo Japan Type MR-

20-CT while hardness of ceramics tested using

Hardness Tester Matsuzawa Seiki Co,LTD No, 71C4.

After strong mechanics characterised, ceramics

porous structure will further be observed morphology

surface.

The size of the pores and elements analysis using

SEM EDX Zeiss types. For applications, ceramics

will be tested for filtering the water vapor using the

filter KIT is equipped with a hydrogen sensors

TGS821.

2 EXPERIMENTAL METHOD

Porous Ceramic is made from clay and active

charcoal. Clay which is used comes from the village

Iraonogeba, Regency of Moroó in West of Nias and

the active charcoal which is used is active Aquasorb®

1000 charcoal. The clay and active charcoal sifted

with the sieve mesh 200. The clay activated

chemically using the solution H

2

SO

4

6% and

continued with the activation of physics at a

temperature of 300

0

C. Ceramic is formed with the

technique of slip casting with comparison of

variation of clay mixtures : active charcoal 100% : 0%

; 90% : 10% ; 80% : 20% ; 70% : 30% and 60% : 40%.

Ceramics were sintering with sintering temperature

1000

0

C with variation of holding time 2 hours ; 3

hours and 4 hours. Ceramics characterised to get the

value of mechanical properties (pressure and

hardness); the size of the diameter of the pores,

unsure elements (SEM-EDX) and the value of the

water vapor adsorption.

3 RESULTS AND DISCUSSION

3.1 Mechanical Test

The results of the mechanical test of porous ceramic

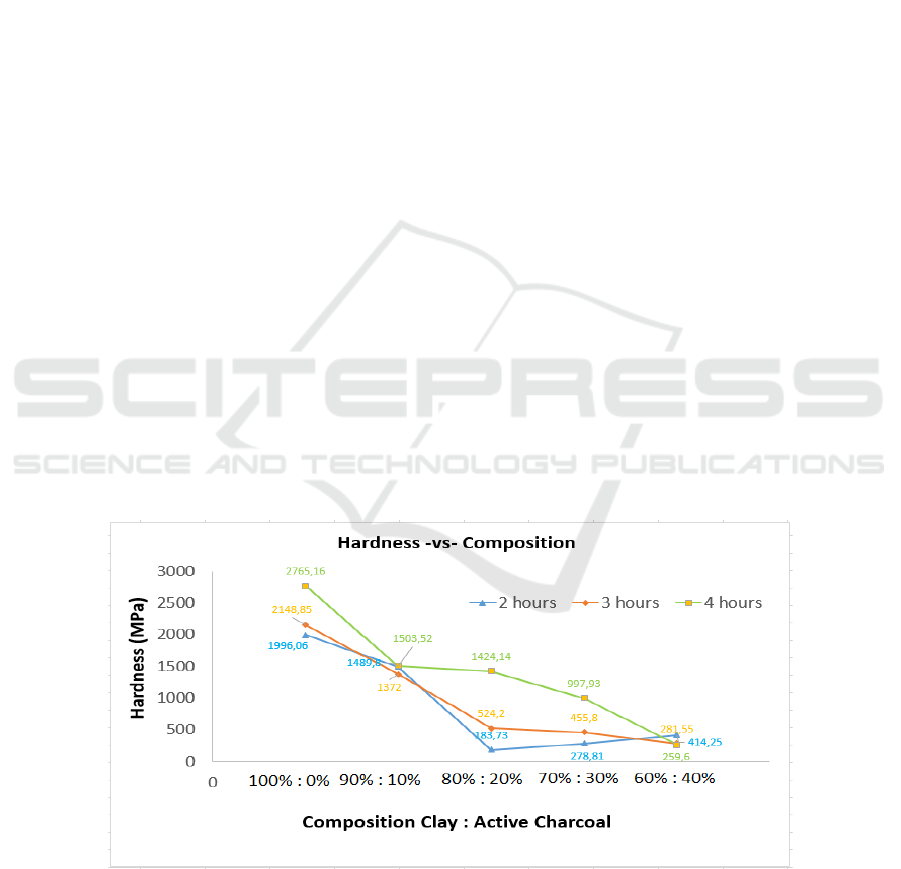

is shown in the Figure 1 and Figure 2.

Figure 1 : Chart of Hardness VS Composition.

The Effect of the Mixture Variation and Holding Time to the Porous Ceramics based from Clay and Active Charcoal as a Filter of Water

Vapour

1063

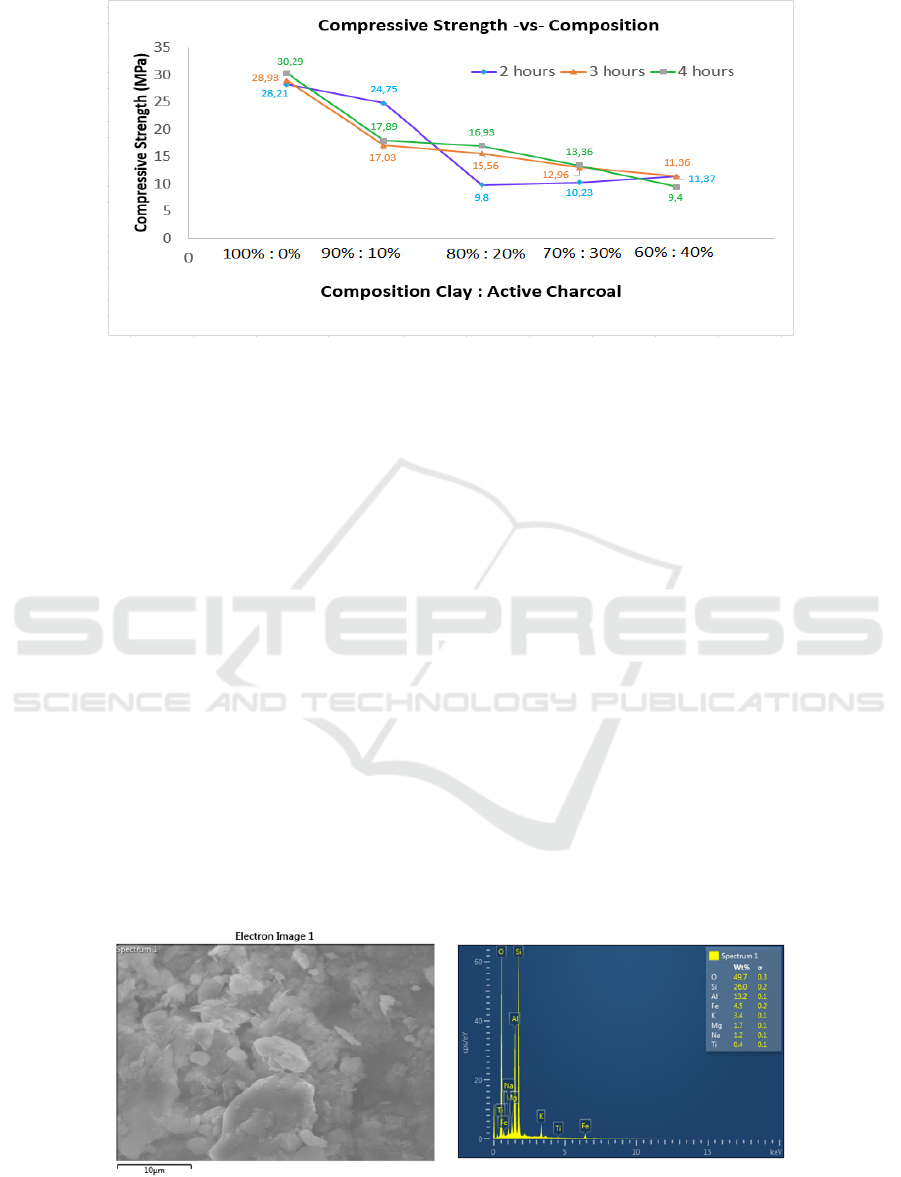

Figure 2 : Chart of Compresive Strength VS Composition.

From the results of compressive strength and

hardness test can be taken from the following

conclusion that ceramics which is form by clay and

active charcoal have strong value of compressive

strength and hardness that maximum at mixed

variations 90% : 10 % with holding time 4 hours (due

to the variation of a mixture of 100% : 0% do not have

a mixture of active charcoal in it) while the lowest

value is on the variation of a mixture of 80%:20%

with holding time 2 hours. But the desired porous

ceramic is ceramic that have many pores to be able to

accommodate the water vapor when doing the

filtration rate or in other words due to the porous

ceramic required have pores then by itself the value

of mechanical nature compressive strength and

hardness) will be low (Yuan, et al, 2016).

Therefore, then the optimum ceramic on this trial is

on ceramics mixed variations 80% : 20% with a

mixture of holding time 2 hours with pressure value

= 9.8 MPa (Figure 1) and value of violence = 184,73

MPa (Figure 2) while for comparison taken ceramics

with the value of the mechanical properties that high

on the variation of a mixture of 90% : 10% with a

holding time of 4 hours with strong value press =

17.89 MPa and the value of hardness = 1503,52 MPa

or 1,50352 GPa. In the Figure can also be seen that

the addition of active charcoal is on a mixture of

ceramic coating will reduce the value of mechanical

properties (either hardness or compressive strength)

where the value of the best mechanical properties of

ceramics found in a mixture of 100% : 0% without

adding active charcoal and the value of the lowest

mechanical nature there is on a mixture of 60% : 40%.

Based on previous research reference (Yuan, et al,

2016) can be seen that the ceramic that is produced

has a worth compressive strength between 13,72±2.2

- 43.5±3.3 MPa and also on the research (Yalcin and

Sevinc, 2000) hardness of ceramics has a value

between 0.79±0.02 - 8.25±0.09 GPa. So when

compared to the ceramic coating on this research is

worthy said as a porous ceramic.

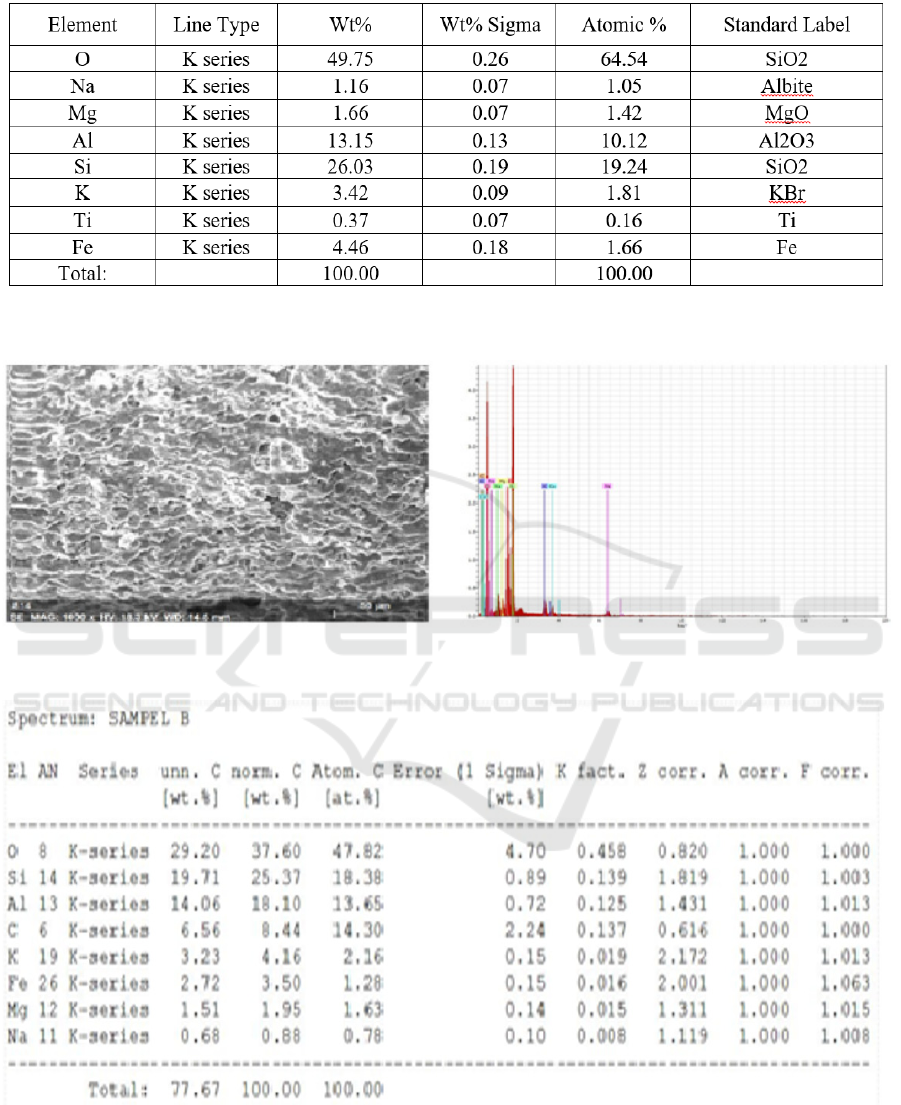

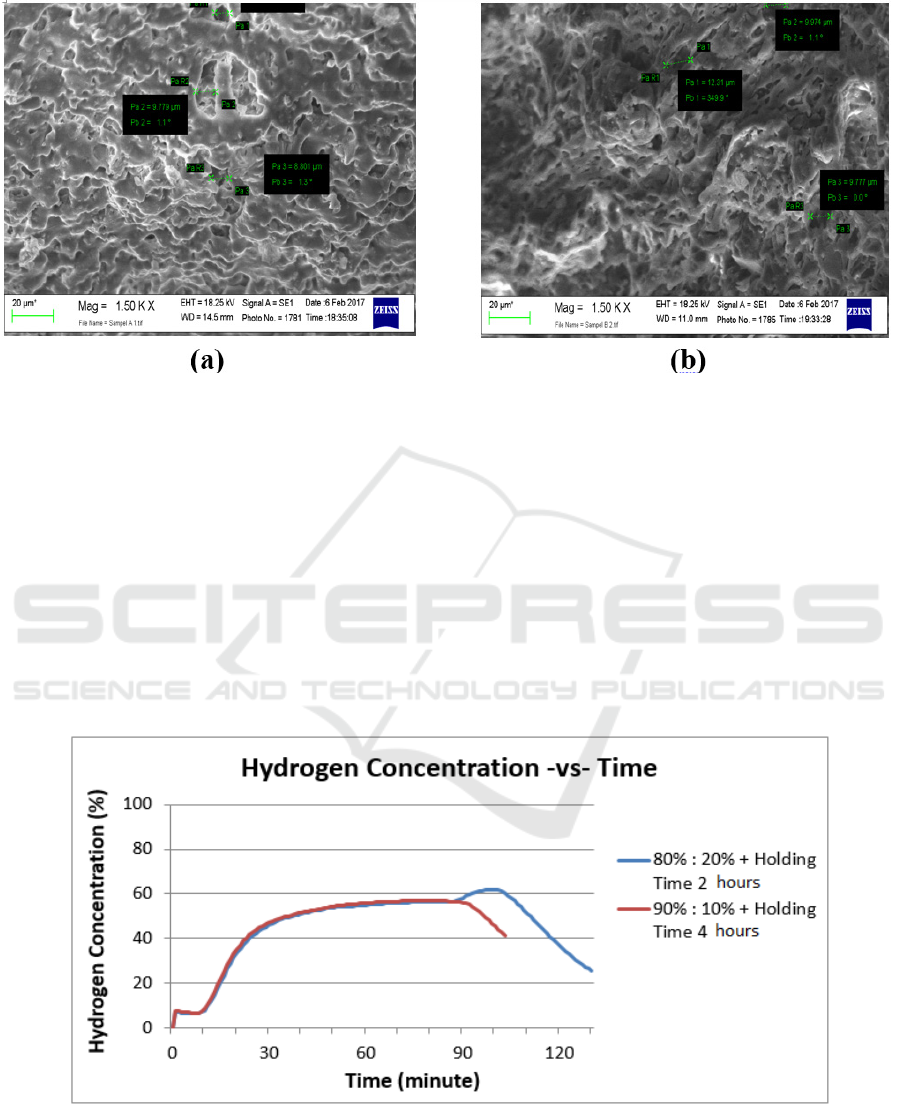

3.2 SEM-EDX

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1064

(a)

(b)

The Effect of the Mixture Variation and Holding Time to the Porous Ceramics based from Clay and Active Charcoal as a Filter of Water

Vapour

1065

(c)

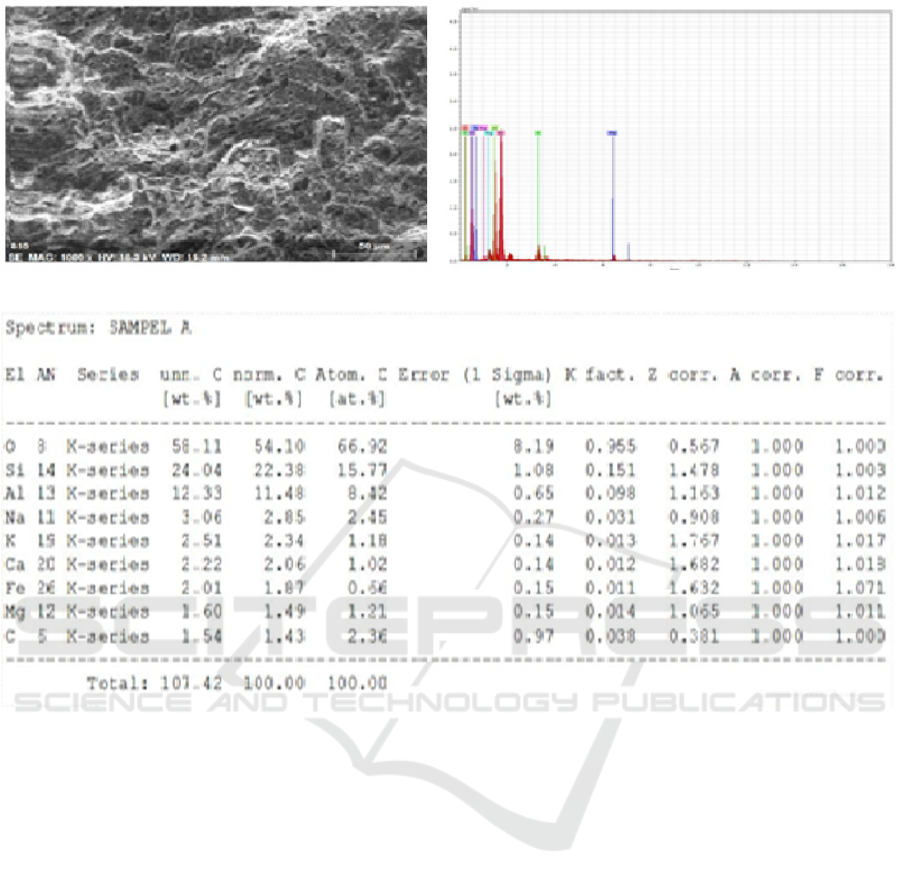

Figure 3 : SEM - EDX test results (a) clay without charcoal (b) clay: activated charcoal with 80%: 20% mixed variation, with

a holding time of 2 hours (c) clay: activated charcoal with 90%: 10% mixed variation, with a holding time of 4 hours.

From the observations of the morphology of the

ceramic surface can be used as an example of 80%:

20% mixture with a holding time of 2 hours has larger

and more pores compared to 90%: 10% mixture with

a 4 hour holding time which has pores which is far

less and not evenly distributed.

While the results of the analysis using EDX can

be used to mix 80%: 20% with a holding time of 2

hours which is equal to = 58.11% compared to a

mixture of 90%: 10% with a 4 hour holding time of =

29, 20% where oxygen indicates that the porosity (eg

oxygen from free air trapped in

the pores) in the

80%: 20% Mixture with 2 hours holding time is far

more than the 90%: 10% mixture with a 4 hour

holding time. When compared to the concentration of

oxygen in clay soil that has not been activated it can

be seen the amount of oxygen in the mixture of 80%:

20% with a holding time of 2 hours compared to

before the mixed clay is 90%: 10% with holding time

4 hours before clay is activated.

This reinforces that the 80%: 20% mixture with a 2

hour holding time is a better mixture.

From the reading of EDX elements, it can also be

seen that the content of Ti in clay that was previously

read by 0.37% was no longer found in 80%: 20%

mixture with a holding time of 2 hours and a mixture

of 90%: 10% with a holding time of 4 hours. This

shows that chemical activation and technology can

eliminate impurities but can also increase the surface

area and porosity of raw clay (Toor et al, 2015). In

addition, SEM-EDX also measured pore diameters at

3 different pores . Pore diameter measurements using

SEM EDX are shown in the following figure with

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1066

Figure 4 : Results of SEM observations for pore diameters with 1500 times magnification (a) samples with a mixture of 80%:

20%, 2-hour holding time, and (b) samples with a mixture of 90%: 10% 4-hour holding time.

From the results of the diameter size measurement

of the pores using SEM can be seen that the plates

with a mixture of variations 80% : 20% with holding

time 2 hours have the size of the diameter of the pores

average = 8,606 µm.

While ceramics with mixed variations 90% : 10%

with holding time 4 hours have the size of the

diameter of the pores on average = 10.

Have no evidence that the depiction of the

multitude of pores which is actually on the ceramic

coating is complex because of the extent of the

spreading of the size and shape of the pores and the

complexity of the network of pores .

From the measurement result proved both

variation of these ceramics including ceramic coating

type of macroporous ceramic due to the ceramic has

the size of the pores greater than 50 nm (d >50 nm).

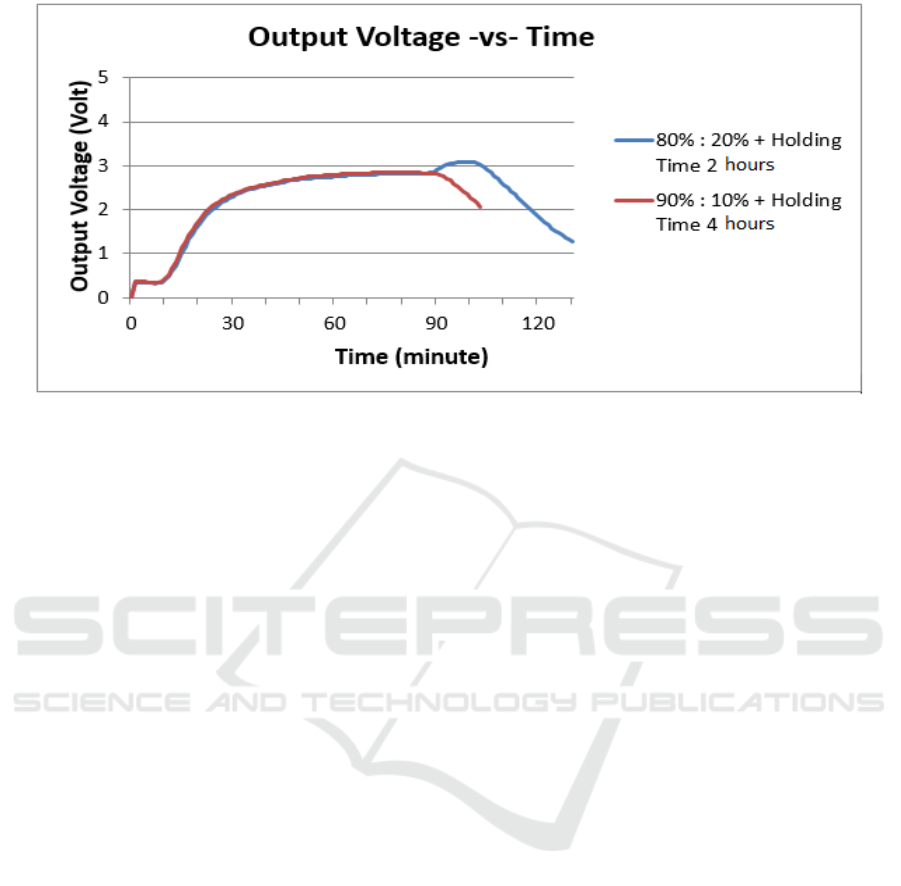

3.3 Water Vapour Adsorption Test

(a)

The Effect of the Mixture Variation and Holding Time to the Porous Ceramics based from Clay and Active Charcoal as a Filter of Water

Vapour

1067

(b)

Figure 5 : Charts of The Water Vapour Adsorption based on (a) Hydrogen Concentration (b) Output Voltage.

Based on the results of the water vapor adsorption test

can be seen that the variation of a mixture of 80% :

20% with holding time 2 hours that the hydrogen

concentration which is read by the censorship is

61,87% with output voltage 3.09 Volts on minutes to

98 while on the variation of a mixture of 90% : 10%

with holding time 4 hours the test results shows that

the concentration of hydrogen which is read by the

censorship is 57,08% on minutes to 77 with output

voltage of 3.09 Volts on minutes to 98 . From the

results of this test, it can be concluded that the

application of the water vapour filter turns to

ceramics with the basic materials of clay and active

charcoal variation by a mixture of 80% : 20% with

holding time 2 hours better in filtering the water

vapour.

4 CONCLUSIONS

Ceramics with the basic materials of clay and active

charcoal can be used as a water vapor filter with the

optimum mixture variations 80% : 20% with a

holding time of 2 hours is supported by mechanical

data test (pressure and hardness), observation SHEM-

EDX (morphology surface, the size of the diameter of

the pores and the analysis of unsures elements). From

the test of the water vapour adsorption also proves

that a mixture of 80% : 20% with a holding time of 2

hours is the optimum variations that can be filtering

the water vapour.

ACKNOWLEDGEMENTS

The authors are very grateful to Universitas Sumatera

Utara for its funding according to TALENTA

research contract 2018 with number

2590/UN5.1.R/PPM/2017 on March 16

th

, 2018.

REFERENCES

Buys, S. and Oakley, V., 2014. Conservation and

restoration of ceramics. Routledge.

Hammel, E.C., Ighodaro, O.R. and Okoli, O.I., 2014.

Processing and properties of advanced porous

ceramics: an application based review. Ceramics

International, 40(10), pp.15351-15370.

Kuila, U. and Prasad, M., 2013. Specific surface area and

pore size distribution in clays and shales. Geophysical

Prospecting, 61(2), pp.341-362.

Munz, D., & Fett, T. 2013. Ceramics: mechanical

properties, failure behaviour, materials selection (Vol.

36). Springer Science & Business Media.

Phonphuak, N. and Thiansem, S., 2012. Using charcoal to

increase properties and durability of fired test

briquettes. Construction and Building Materials, 29,

pp.612-618.

Prenzel, T., Guedes, T.L.M., Schlüter, F., Wilhelm, M. and

Rezwan, K., 2014. Tailoring surfaces of hybrid

ceramics for gas adsorption–From alkanes to CO 2.

Separation and Purification Technology, 129, pp.80-

89.

Rouquerol, J., Rouquerol, F., Llewellyn, P., Maurin, G., &

Sing, K. S. 2013. Adsorption by powders and porous

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1068

solids: principles, methodology and applications.

Academic press.

Sarkar, S., Bandyopadhyay, S., Larbot, A. and Cerneaux,

S., 2012. New clay–alumina porous capillary supports

for filtration application. Journal of membrane science,

392, pp.130-136.

Shen, Y., Zhao, P. and Shao, Q., 2014. Porous silica and

carbon derived materials from rice husk pyrolysis char.

Microporous and Mesoporous Materials, 188, pp.46-

76.

Susilawati, Tulus I. N., Fynnisa Z., and Hamonangan N.

2017. Hydrogen purification using natural pahae zeolit

and cocoa rind based filter. International Journal of

Applied Engineering Research 12 (13), 3914-3918.

Toor, M., Jin, B., Dai, S., & Vimonses, V. 2015. Activating

natural bentonite as a cost-effective adsorbent for

removal of Congo-red in wastewater. Journal of

Industrial and Engineering Chemistry, 21, 653-661.

Wang, A., Gao, X., Giese, R.F. and Chung, D.D.L., 2013.

A ceramic–carbon hybrid as a high-temperature

structural monolith and reinforcing filler and binder for

carbon/carbon composites. Carbon, 59, pp.76-92.

Yalçın, N., & Sevinc, V. 2000. Studies of the surface area

and porosity of activated carbons prepared from rice

husks. Carbon, 38(14), 1943-1945.

Yates, M., Martín-Luengo, M.A., Argomaniz, L.V. and

Velasco, S.N., 2012. Design of activated carbon–clay

composites for effluent decontamination. Microporous

and Mesoporous Materials, 154, pp.87-92.

Yuan, B, Li, H. X, Wang, G., Yu, J. B., Ma, W. K, filter.

Journal of Alloys and Compunds, 684, 613-615

Yuan, B., Li, H. X., Wang, G., Yu, J. B., Ma, W. K., Liu,

L. F., ... & Shen, Z. J. 2016. Preparation and properties

of porous silicon carbide based ceramic

The Effect of the Mixture Variation and Holding Time to the Porous Ceramics based from Clay and Active Charcoal as a Filter of Water

Vapour

1069