Preliminary Results of Wood Plastics Composite: An Innovative

Eco-friendly Product

Arif Nuryawan

1

, Iwan Risnasari

1

, Rahmawaty

2

, Esra Y. S. Purba

1

and Nova O. Hutauruk

1

1

Department of Forest Products Technology, Faculty of Forestry, Universitas Sumatera Utara, Medan, Indonesia

2

Department of Forest Management, Faculty of Forestry, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Wood Plastics Composite, Grave Yard Test, Weight Loss.

Abstract: The eco-friendly wood plastics composite (WPC) made of low density polyethylene (LDPE) as the matrices

and 80-mesh wood powder as the filler have been produced in various percentage composition, namely 85/15;

90/10; and 95/5 (w/w) using compounding process with xylene as the solvent of the plastics. Physical and

mechanical properties have been investigated according to Japanese Industrial Standard (JIS) A 5908 for

particleboard. In this contribution, emphasizing on the WPC as the eco-friendly product has been discussed

through their capability to degrade after grave yard test. Even though the result of weight loss for the WPC’s

samples after buried in the soil for 50 days were very light, these results indicated that WPC has capability to

decompose. In other words, products of WPC were environmentally friendly because they will deteriote after

certain time buried in the soil although the composition of the plastics was majority.

1 INTRODUCTION

Wood plastics composite (WPC) is made by

thoroughly mixing hydrophobic plastics as the matrix

and hydrophilic wood as the filler (Suzuki, 2014).

The types of wood filler are consisted of wood

particle, wood flour, and wood pulp having different

dimensions (size and shape) and aspect ratio (Kim,

2014). Initially, application of WPC can be found in

automotive industry for interior parts such as door

inner panels and seatbacks (Ozdemir & Mengeloglu,

2008) but to date, the use of WPC are more expand

including in housing components such as decking,

fencing, flooring, railings, moldings, and roofing

(Caufield et al., 2005); and also infrastructure such as

marine and boardwalks (Homkhiew et al. 2015).

Numerous investigators have been studied the

manufacturing process of WPC (Ozdemir &

Mengeloglu, 2008; Rahman et al., 2013);

compatibility of hydrophobic plastics as the matrix

and hydrophilic wood as the filler (Bledzki et al.,

1998; Catto et al. 2014); properties of resulted WPC

(Rahman et al., 2013; Catto et al. 2014); but only

limited reports were found in durability of WPC

(Schrip et al., 2008). Therefore in this contribution,

investigation on degradation of WPC was reported.

The WPC was intended to be manufactured with

predominant plastics in their composition in order to

encapsulate the wood filler with the plastics. In this

circumstance, if an organism like termite attacks the

wood filler for feed, the matrices plastics should be

broken first either physically or biologically. Termite

will bite the surface of WPC to get the wood filler for

feed. Physically the WPC will be broken down and

biologically presumably the termite eats some part of

plastics accidentally.

In this report, weight loss of the WPC after buried

in the soil will be revealed. Others results such as

micro-morphology of the WPC after grave yard test,

spectroscopy test of termite’s guts after WPC’s

feeding, and physical and mechanical properties of

WPC will be declared elsewhere in upcoming

publications. Therefore, the aim of this study was to

observe step by step WPC alteration after

decomposing in the soil particularly from weight loss

point of view.

98

Nuryawan, A., Risnasari, I., Rahmawaty, ., Purba, E. and Hutauruk, N.

Preliminary Results of Wood Plastics Composite: An Innovative Eco-friendly Product.

DOI: 10.5220/0010097600980101

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

98-101

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MATERIALS AND METHODS

2.1 Preparation of Raw Materials

Commercial granule thermoplastics of LDPE (low

density polyethylene) with specific gravity of 0.93

g/cm

3

and the melting point of 110C, was used as the

matrix. Wood filler was obtained by sieving industrial

sawdust of durian-wood (Durio sp.) collected from

local mills to 80-mesh particle size. The wood particle

was then dried in an convection oven for 24 h at

(105+2)C. Xylene as the solvent of the plastics was

reagent grade and purchased in local chemical store

in Medan city.

2.2 Manufacturing Process

Here, compounding process was applied in this work.

The process can be described as blending process

which consists of mixing, kneading, and shearing,

respectively prior to manufacturing products (Kim,

2014). Hence, in WPC, the compounding process is

normally done to blend WPC compositions. Blended

and compounded ingredients are formed into pellets

for future processing. The compositions of the raw

materials were shown in Table 1.

Table 1. Compositions of the raw materials for making

WPC

Composition

LDPE:wood filler

Amount of

LDPE (g)

Amount of

wood filler (g)

85:15 186 33

90:10 197 22

95:5 208 11

In this regards, traditional method of dissolution

of the plastics was applied (Achilias et al., 2007). The

solvent was placed in the reactor and then the mantle

heater was heated up to 110C. Subsequently, a

certain amount of plastics were added and the mixture

was heated under reflux for 25-30 minutes until the

plastics had reached their melting temperature. After

all of the plastics dissolved, wood filler was added

and stirred gently approximately 10 minutes. The

mixture in the form of pellets then was conditioned in

fume hood for 24 h in order to evaporate the solvent.

The resulted pellets then was flat-pressed in

105C using laboratory hydraulic hot press for 6

minutes for converting into board with size dimension

of 25 cm x 25 cm and 0.5 cm in thickness with target

density of 0.7 g/cm

3

.

2.3 Durability Test

Prior to undergo test of durability, the WPC was cut

into samples with size dimension of 5 cm x 5 cm as

shown in Figure 1.

Figure 1. Specimen of respective WPC for durability testing

in various proportions of plastics and wood filler (85:15,

90:10, and 95:5)

The specimens were buried in the soil for 50 days

and they were weight every 10 days for measuring the

weight loss. The resulted data were tabulated and the

discussion regarding this data was presented. In order

to avoid the influence of moisture content, the

specimens were dried in convection oven for 24 h at

(105+2)C prior to balance. Observation of their

alteration in micro-morphology before and after

grave yard test will be reported in upcoming

publications.

3 RESULTS AND DISCUSSIONS

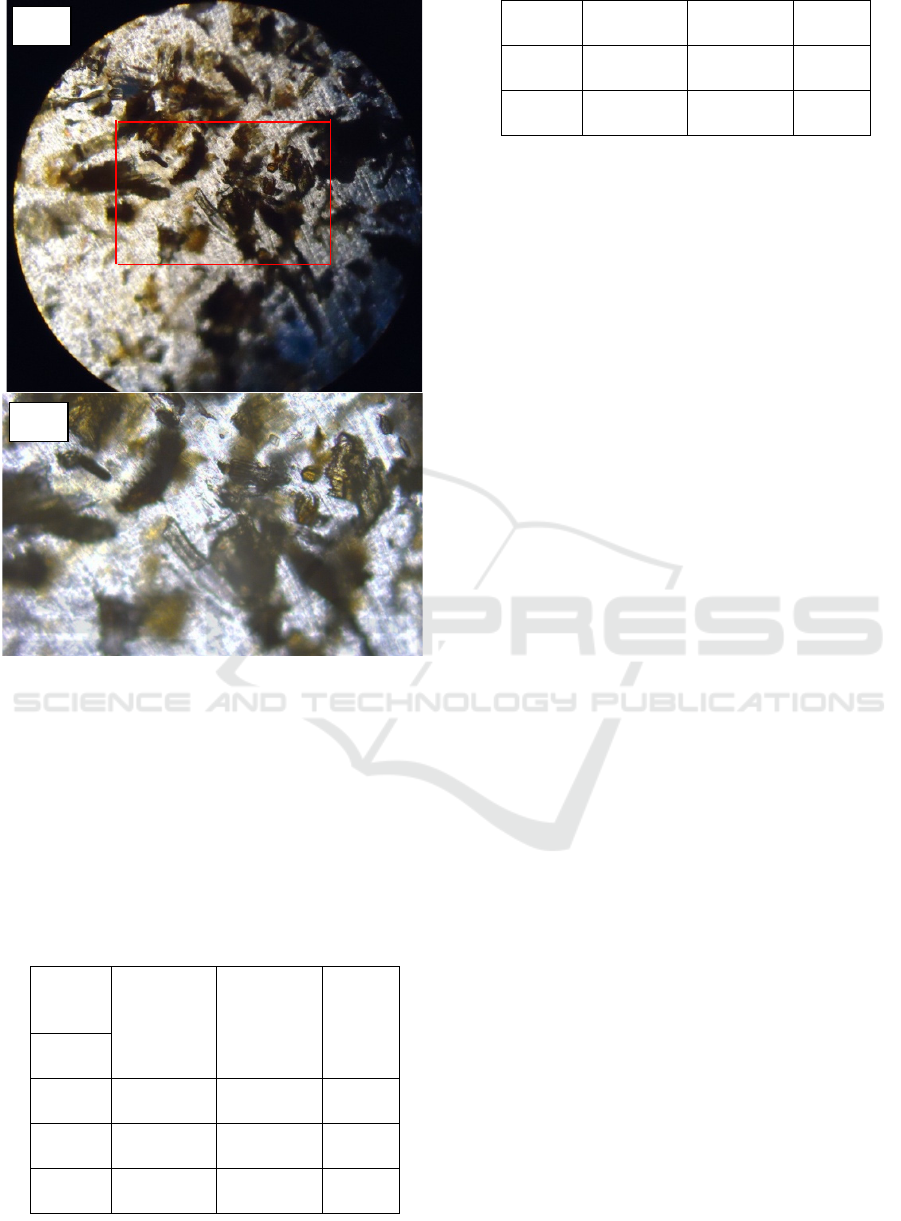

Typical WPC in this research was shown in Figure 2.

The WPC showed distinguish parts between LDPE

matrices and wood filler under bright field

microscope. Further advance micro-morphological

characterization is needed to ensure clearly identify

wood particle was encapsulated with the matrix in

the WPC system, for instance previous work of one

the author (Singh et al., 2013) in using FE-SEM (field

emission scanning electron microscope) for resolving

particle-matrix interfaces in the WPC.

In addition, wood filler appeared covered with

LDPE plastics thus wood degrading organisms like

termite will attack the plastics first before reach the

edible wood. This condition is very important for

investigating further such as behavior of termite in

reaching edible wood; spectroscopy of termite’s guts

whether it contains plastics or not, and description of

the micro-morphology of the WPC prior and after

durability test whether the changes occurs only on the

surface or into inner part of WPC.

Preliminary Results of Wood Plastics Composite: An Innovative Eco-friendly Product

99

Figure 2. Typical wood filler which was covering LDPE

matrices in specimen WPC with proportion of plastic and

wood of 85:15. (A) under bright field microscope with 4x

magnification and (B) with higher 10x magnification view

of the red box in Fig.A

The weight of the WPC samples prior and after

grave yard test in certain periods was shown in Table

2.

Table 2. Data of weight of the WPC samples before and

after buried in the soil in certain days

Type

of

WPC

WPC

85:15

WPC

90:10

WPC

95:5

Weight

(

g

)

Initial

8.67

(0.32)

8.36

(0.77)

8.48

(0.77)

10

th

da

y

8.62

(0.31)

8.31

(0.78)

8.46

(0.76)

20

th

da

y

8.56

(0.32)

8.25

(0.78)

8.42

(0.76)

30

th

da

y

8.52

(0.32)

8.21

(0.80)

8.39

(0.75)

40

th

da

y

8.47

(0.31)

8.16

(0.80)

8.35

(0.76)

50

th

da

y

8.42

(0.31)

8.11

(0.81)

8.30

(0.76)

Remarks: the parentheses is the standard deviation

From the data presented in Table 2, there was a

consistent tendency of the weight loss. The longer

buried in the soil, the weight of the WPCsample

decreased. Although plastics can hinder wood filler

from organisms attacks, the weight loss of the sample

were occurs and inevitable. According to the best

knowledge of the authors, wood can easily degrade

vice versa with the plastics; they are very difficult to

be decomposed. Therefore, they were factors made of

the WPC deteriorate and they need investigate

further, such as wood decaying fungi or symbioses

between mold and termite as the agent of degrading

wood.

4 CONCLUSIONS

Products of WPC were environmentally friendly

because they will deteriote after certain time buried in

the soil although the composition of the plastics was

majority

.

ACKNOWLEDGEMENTS

The authors thank to University of Sumatera Utara for

funding this research under scheme of Penelitian

Terapan TALENTA-USU year of 2018, contract

number 2590/UN5.1.R/PPM/2018 date March 16,

2018

REFERENCES

Achilias, D. S., Roupakias, C., Megalokonomos, P.,

Lappas, A. A., Antonakou, E. V., 2007. Chemical

recycling of plastic wastes made from polyethylene

(LDPE and HDPE) and polypropylene (PP).Journal of

Hazardous Materials 149: 536-542.

Bledzki, A. K., Reihmane, S., Gassan, J., 1998.

Thermoplastics reinforced with wood fillers: aliterature

review. Polymer Plastics Technology and Engineering

37(4): 451-468

Catto, A. L., Stefani, B. V., Ribeiro, V. F., Santana, R. M.

C., 2014. Wood plastic composites weathering: Effects

A

B

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

100

of compatibilization on biodegradation in soil and

fungal decay Materials Research 17: 203-209

Caufield, D. F., Clemons, C., Jacobson, R. E., Rowell, R.

M., 2005. Chapter 13 Wood Thermoplastics

CompositesIn Handbook of Wood Chemistry and Wood

Composites (Rowell RM, ed) (USA: CRC Press).

P.365-378.

Homkhiew, C., Ratanawilai, T., Thongruang, W., 2015.

Composites from recycled polypropylene and

rubberwood flour effects of composition on mechanical

properties.Journal of Thermoplastic Composite

Materials 28(2):179-194.

Kim, B. J., 2014. Overview of wood plastic composites:

focusing on use of bio-based plastics and co-extrusion

technique. Journal of the Korean Wood Science and

Technology 42(5):499-509.

Ozdemir, T., Mengeloglu, F., 2008. Some properties of

composite panels made from wood flour and recycled

polyethylene.International Journal of Molecular

Sciences 9: 2559-2569.

Rahman, K.-S., Islam, M. N., Rahman, M. M., Hannan, M.

O., Dungani, R., Khalil, H. P. S. A., 2013. Flat-pressed

wood plastic composites from sawdust and recycled

polyethylene terephthalate (PET): physical and

mechanical properties. SpringerPlus 2 269: 1-7

Schirp, A., Ibach, R. E., Pendleton, D. E., Wolcott, M. P.,

2008. Chapter 29 Biological Degradation of Wood-

Plastic Composites (WPC) and Strategies for

Improving the Resistance of WPC against Biological

Decay.InDevelopment of Commercial Wood

Preservatives (Schultz T. P., Militz, H., Freeman, M.

H., Goodell, B., and Nicholas, D. D, ed) (USA: ACS

Symposium Series Books)

Singh, A. P., Anderson, R., Park, B. D., Nuryawan, A.,

2013. A novel approach for FE-SEM imaging of wood-

matrix polymerinterface in a biocomposite. Micron 54–

55: 87-90.

Suzuki, S., 2014. Evolution of element in wood-based

products from lamina to nano. In Proc of The 6th

International Symposium of Indonesian Wood

Research Society (Medan: Indonesia) p.7-10.

Preliminary Results of Wood Plastics Composite: An Innovative Eco-friendly Product

101