Morphology of Composite Membranes based on Chitosan-Pahae

Natural Zeolite

Yuan Alfinsyah Sihombing

1,3

, Susilawati

1,3

, Irwana Nainggolan

2,3

, Adi Syahputra Purba

1

and Tulus

Ikhsan Nasution

1,3

1

Department of Physics, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan, 20155,

Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan, 20155,

Indonesia

3

Pusat Unggulan Inovasi Green Chitosan dan Material Maju, Universitas Sumatera Utara, Medan, 20155, Indonesia

Keywords: Chitosan, Pahae Natural Zeolite and solution casting method.

Abstract: Composite membranes based on Chitosan-Pahae Natural Zeolite have been fabricated by solution casting

method. The composite membranes are Chitosan and Chitosan with variation of composition zeolite relative

to the mass of chitosan. The composition of Pahae natural zeolite are 5%, 10%, 15%, 20% and 25%. The

samples were made by two step. The first step, the zeolite rock was crushed by mortar, and then zeolite was

sieved with particle size of 200 mesh. Zeolite was activated by soaking into Sulfuric acid for 2 hours, then

rinsed with distilled water until the pH about 7.0. Furthermore, the zeolite was sieved and burned in furnace

with temperature 100°C for 5 hours. The second step, chitosan was dissolved in the acetic acid solution and

stirred by using magnetic stirrer. Furthermore, zeolite was added into the solution. The resulting solution were

stirred for 24 hours and dried in atmosphere at room temperature. From FTIR spectra was confirmed the

existence of chitosan with stretching and bending at absorption wavenumber of 3250 cm

-1

, 2877 cm

-1

, 1640

cm

-1

, 1543 cm

-1

, 1401 cm

-1

and 1014 cm

-1

. The morphology of surfaces were obtained by using Scanning

Electron Microscope (SEM) and showed that zeolite was evenly distributed within chitosan.

1 INTRODUCTION

One of the polymer materials that is widely used in

making a membranes is chitosan. Chitosan is natural

polymers that has good characteristic such as

chemical inertness, hydrophilicity, biodegradability,

biocompatibility, good film formation properties and

more low cost (Liu et al, 2005 and Yavuz et al, 2009).

The membranes based on chitosan have received

considerable attention as membrane of polymer

electrolyte because the membranes have good

thermal and chemical stability, low conductivity,

good mechanical properties, etc. Low conductivity

properties caused by the absence of hydrogen ions

moving in the structure (Xiao et al, 2013). So, for

increase the efficient membranes based on chitosan,

various modification approaches are needed like

doping, blending and cross-linking.

The modification approaches based on chitosan

have been done by adding other materials such as

Carbon Nanotubes (CNTs), Polyaniline/Silica

(PAni/SiO

2

) and Sulfonated Graphene Oxide (SGO),

etc. CNTs were used to modify polymer electrolyte

membranes in energy conversion devices. The

addition of CNTs to chitosan matrix cause the

conductivity is increased (Wang et al, 2018). Ionic

cross-linked based on chitosan by using

nanocomposites of PAni/SiO

2

show increased

mechanical properties and improved the stability of

oxidation (Vijayalekshmi and Dipak, 2018).

Sulfonated chitosan (SCS) and SGO nanosheets are

fused into a membrane of chitosan have effect on the

electrochemical properties of the membrane such as

the increasing of conductivity, the reducing of

permeability and increasing of selectivity relative to

the pure chitosan. Furthermore, the addition of SCS

and SGO to chitosan leads more proton conductivity

than the individual additives due to the synergistic

effect of SCS and SGO (Shirdast et al, 2016).

Zeolite is alumino-silicate compound with

tetrahedral bound linked by oxygen. Aluminium

Atom is negative that can be neralized by cation. The

1052

Sihombing, Y., Susilawati, ., Nainggolan, I., Purba, A. and Nasution, T.

Morphology of Composite Membranes based on Chitosan-Pahae Natural Zeolite.

DOI: 10.5220/0010097010521056

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1052-1056

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

exchangeable cation affects the adsorption ability of

zeolite. For example, the zeolite was used as water

vapor filter to purify hydrogen gas (Susilawati et al,

2017). Besides that, Zeolite is inorganic materials that

has good mechanical properties and thermal stability.

It can be a great potential to modify chitosan. The

presence of hydrogen bonds between chitosan and

zeolite, the membranes shows the desired thermal and

mechanical stability (Wang et al, 2008).

In this study, chitosan was chosen as a matrix and

Pahae Natural zeolite as a filler. Pahae Natural Zeolite

was used because this mineral rock is widely

available in Indonesia, especially Tapanuli Utara,

Sumatera Utara. This study aims to fabricate

composite membranes and knowing the morphology

of membranes.

2 EXPERIMENTAL METHOD

2.1 Materials

There are two main materials in this study, Chitosan

and Zeolite. Chitosan medium molecular weight with

a degree of deacetylation about 85% was obtained

from Sigma Aldrich Chemical (Singapore) and

Natural Zeolite was obtained from Tarutung,

Tapanuli Utara, Sumatera Utara. Furthermore, some

of chemical materials needed to fabricate composite

membranes, such as acetic acid, sulfuric acid and

distilled water.

2.2 Membranes Preparation

The pure chitosan membrane and Chitosan-Zeolite

membranes were fabricated by using solution-casting

method. For the first, zeolite rock was crushed by

mortar and then this zeolite was sieved with particle

size of 200 mesh become zeolite powder. After that,

zeolite powder was activated by soaking into Sulfuric

acid 6% for 2 hours using magnetic stirrer and hot

plate. Then the zeolite powder was flushed with

distilled water until the pH of flushing solution is

reached normal pH about 7.0, which confirmed that

zeolite powder was completely free of sulfuric acid.

Furthermore, the zeolite powder was sieved by sieve

paper and then burned in furnace with temperature

100°C for 5 hours.

The second step, 1.5 g of chitosan was dissolved

in the 75 ml, 2wt% acetic acid solution. Then, this

solution of chitosan and acetic acid were stirred by

using magnetic stirrer and hot plate. After chitosan

and acetic acid were mixed, the zeolite powder was

added into this solution with variation zeolite com-

position of 5%, 10%, 15%, 20% and 25%. The resul-

ting solution were stirred for 24 hours and then this

mixtures were poured onto a glass mold and dried in

atmosphere pressure at room temperature. Finally, the

composite membranes were obtained. For pure chi-

tosan membrane, the chitosan was fabricated in same

way with others devoid adding of zeolite powder.

2.3 Characterization

2.3.1 Spectra of Fourier Transform Infrared

(FTIR)

The spectra of Fourier Transform Infrared were

measured by Agilent/Cary 630 in transmittance

mode. This instrument has resolution of 16 cm

-1

and

spectra of every sample was measured in the

wavenumber range between 4050 cm

-1

and 650 cm

-1

at room temperature.

2.3.2 Scanning Electron Microscope (SEM)

For scan of the surface morphology of composite

membranes were used by Zeiss/SEM EVO MA10

instrument with magnification 500 x. The SEM

morphology was obtained to show the existence of

zeolite in composite membranes.

3 RESULTS AND DISCUSSION

3.1 Spectra of Fourier Transform

Infrared (FTIR)

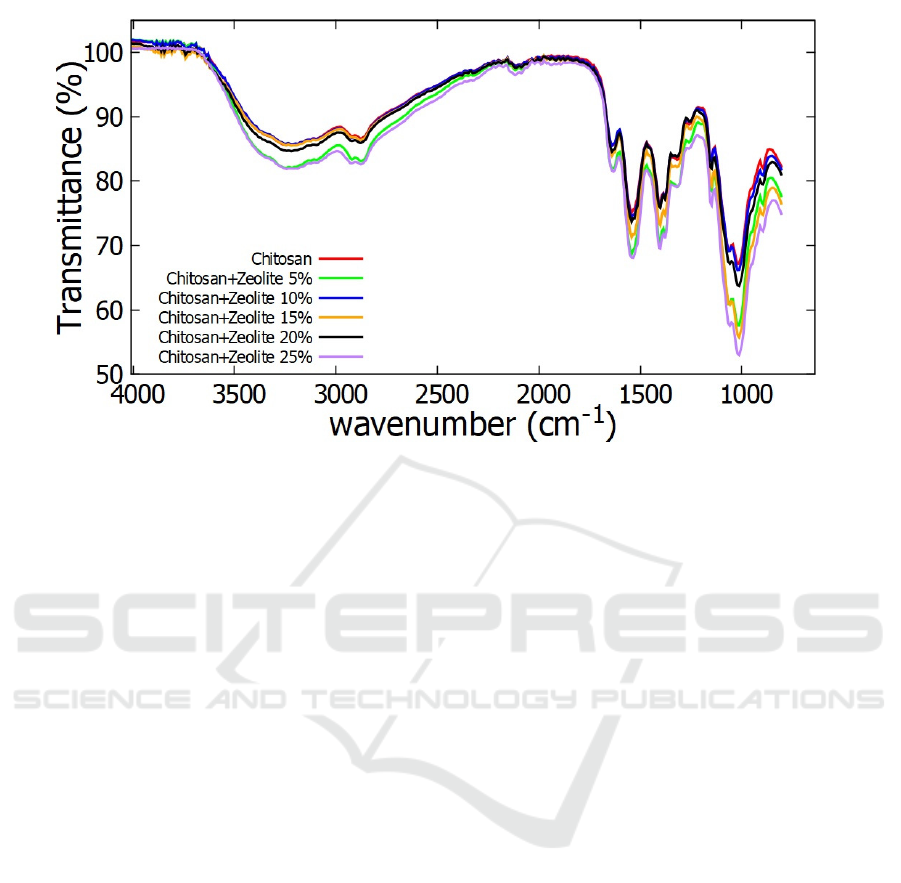

The spectra of FTIR ensured the existence of

hydrogen bonds. The hydrogen bonds occur between

chitosan and Pahae Natural zeolite in composite

membranes. Figure 1 showed the FTIR spectra of

chitosan and composite membranes with variation of

zeolite composition. The peak of absorption spectra

for all of membranes at around 3250 cm

-1

. This

wavenumber was confirmed to stretching of hydroxyl

groups (-OH).

Aliphatic groups (CH

2

and –CH

3

) could be

observed about 2877 cm

-1

. The absorption peaks

around 1640 and 1543 cm

-1

were confirmed to C=O

stretching (the band of Amide I) and –NH

2

Bending

(the band of Amide II), respectively (Yuan et al,

2007). The existence of C-O Stretching of Primary

alcohol was showed by absorption of wavenumber at

1401 cm

-1

and the last of absorption peak was showed

at 1014 cm

-1

. It was confirmed to glycosidic –C-O-C-

groups that connect between Monomer of Chitosan.

Morphology of Composite Membranes based on Chitosan-Pahae Natural Zeolite

1053

Figure 1: FTIR Spectra of Chitosan and composite membranes with variation of zeolite composition.

3.2 Scanning Electron Microscope

(SEM)

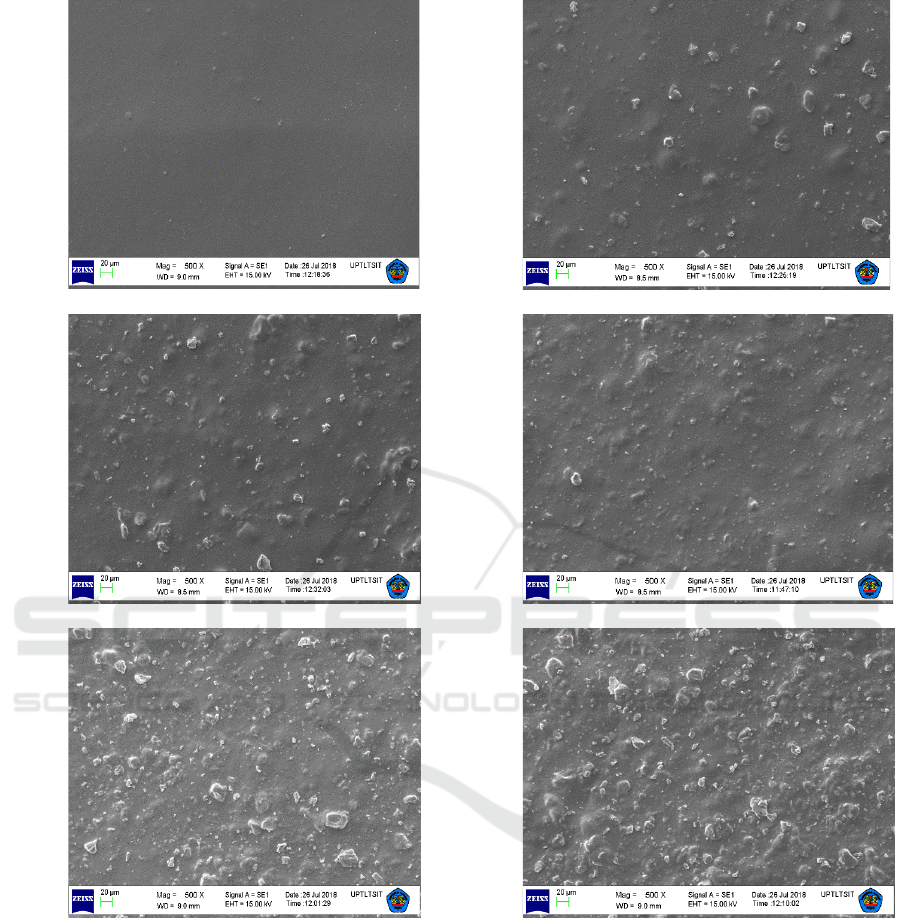

Morphological analysis in this research was

performed by using Scanning Electron Microscope

(SEM) with magnification 500 x. The surface of

membranes were scan by Zeiss/SEM. These surface

morphology could be seen from Figure 2 (a-f).

According to Figure 2, Pahae natural zeolite particles

distribution were relatively homogenous in the

chitosan phase because of its efficient dispersion.

Figure 2 also was confirmed that the increasing of

zeolite particles composition cause zeolite particles

more evenly distributed in chitosan. The surface of all

composite membranes were uniform and smooth

without tolerable defect. Finally, the composite

membranes from chitosan and zeolite was

successfully fabricated with no visible zeolite

aggregation existing in the membranes.

4 CONCLUSIONS

Composite membranes based on chitosan-zeolite

with variation of zeolite composition were obtained.

The variation of zeolite composition are 5%, 10%,

15%, 20% and 25% relative to mass of chitosan. From

FTIR spectra, the absorption peaks were occur at

wavenumber around 3250 cm

-1

, 2877 cm

-1

, 1640 cm

-

1

, 1543 cm

-1

, 1401 cm

-1

and 1014 cm

-1

. These

wavenumbers were confirmed to stretching of

hydroxyl groups, aliphatic groups. Amide I and II

band, C-O Stretching of Primary alcohol and

glycosidic –C-O-C- groups. All of this peaks related

to chitosan. Furthermore, the Pahae natural zeolite

could be evenly distributed in chitosan. It was

confirmed by scanning electron microscope

morphology. The surface of composite membranes

showed that membranes were uniform and smooth

without defect and aggregation.

ACKNOWLEDGEMENTS

The authors are very grateful to Universitas Sumatera

Utara for its funding according to TALENTA

research contract 2018 with number

2590/UN5.1.R/PPM/2017 on March 16

th

, 2018.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1054

(a) (b)

(c) (d)

(e) (f)

Figure 2: Morphology of composite membrane by using SEM; (a) pure Chitosan, (b) Chitosan/Zeolite 5%, (c)

Chitosan/Zeolite 10%, (d) Chitosan/Zeolite 15%, (e) Chitosan/Zeolite 20% and (f) Chitosan/Zeolite 25%.

REFERENCES

Liu Y. L., Hsu C. Y., Su Y. H., and Lai J. Y. 2005.

Chitosan-silica complex membranes from sulfonic acid

functionalized silica nanoparticles for pervaporation

dehydration of ethanol-water solutions.

Biomacromolecules. 6 (1), 368-373.

Shirdast, A., Alireza S., and Mahdi A. 2016. Effect of

incorporation of sulfonated chitosan/sulfonated

graphene oxide on the proton conductivity of chitosan

membranes. Journal of Power Sources, 306, 541-551.

Susilawati, Tulus I. N., Fynnisa Z., and Hamonangan N.

2017. Hydrogen purification using natural pahae zeolit

and cocoa rind based filter. International Journal of

Applied Engineering Research 12 (13), 3914-3918.

Morphology of Composite Membranes based on Chitosan-Pahae Natural Zeolite

1055

Vijayalekshmi, V., and Dipak Khastgir. 2018. Hybrid

composite membranes of chitosan/sulfonated

polyaniline/silica as polymer electrolyte membrane for

fuel cells. Carbohydrate Polymers, 179, 152-163.

Wang, Jie, Chunli Gong, Sheng Wen, Hai Liu, Caiqin Qin,

Chuanxi Xiong and Lijie Dong. 2018. Proton exchange

membrane based on chitosan and solvent-free carbon

nanotube fluids for fuel cells applications.

Carbohydrate Polymers, 186, 200-207.

Wang, J., Xiao hang Z., Hong W., Bin Z., Zhongyi J.,

Xiaopeng H., and Baoyi W. 2008. Effect of zeolites on

chitosan/zeolite hybrid membranes for direct methanol

fuel cell. Journal of Power Sources 178, 9-19. Xiao Y.,

Xiang Y., Xiu R., and Lu S. 2013. Development of

cesium phosphotungstate salt and chitosan composite

membrane for direct methanol fuel cells. Carbohydrate

Polymers, 98 (1), 233–240.

Yavuz A. G., Uygun A., and Bhethanabotla V. R. 2009.

Substituted polyaniline/chitosan composites: synthesis

and characterization. Carbohydrate Polymers, 75(3),

448–453.

Yuan, W., Hong Wu, Bin Zheng, Xiaohong Zheng,

Zhongyi Jiang, Xiaopeng Hao, and Baoyi Wang. 2007.

Sorbitol-plasticized chitosan/zeolite hybrid membrane

for direct methanol fuel cell. Journal of Power Sources

172, 604-612

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1056