The Preparation of Agar-chitosan Film from Gracilaria

M. Zulham Efendi Sinaga

1,3

, Saharman Gea

1

, Yuan Alfinsyah Sihombing

2,3

, Emma Zaidar

1,3

,

Rumondang Bulan

1

, Nami Panindia

1

, Hamdan Azhari

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, 20155,

Indonesia.

2

Department of Physics, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, 20155,

Indonesia.

3

Pusat Unggulan Inovasi (PUI) Green Chitosan dan Material Maju Universitas Sumatera, Indonesia.

ema3@usu.ac.idrumondang@usu.ac.idnamip14@gmail.com, and hamdanazhari91@gmail.com

Keywords: Chitosan, Agar, Gracilaria, Edible film, Food packaging.

Abstract: Packaging is one of the most important parts in maintaining the quality of food product. The film of agar-

glycerol-chitosan has been prepared fromthe isolated agar of Gracilaria. The objective of this study is to

investigate mechanical properties including the tensile strength, the young’s modulus, the elongation at

break,the functional groups by FTIR and the water solubility. The film was prepared by mixing agar, glycerol

(20 %) and chitosan (0 %, 1 %, 2 %, 3 % and 4 %) at 60

0

C and 600 rpm. FTIR showed that the interaction

occurred in the film agar-glycerol-chitosan was hydrogen bonding. From the result, the more chitosan added

to the agar-glycerol-chitosan film, the higher the tensile strength, the elongation at break, the young’s modulus

and the water solubulity.

1 INTRODUCTION

Packaging is one of the most important parts in

maintaining the quality of food products. The most

commonly used packaging is plastic, but the use of

plastic causes some problems such as difficult to

degradable in nature and environmentally unfriendly.

Similarly, there is a concern using plastic as

packaging which transfers plastic molecules to food.

Hence, edible film is considered as one of alternatives

for packaging food because it is environmentally

friendly and safe for consumption.

Some biopolymers used as edible film and coating

materials are polysaccharides, proteins and lipids

(Susanne and Gauri 2002; Paula et al., 2014; Kwang

et al., 2004). The biopolymers are available

abundantly in nature and they can be easily and

continuously obtained. Seaweed is one of potential

resources of polysaccharides. For example alginate,

agar, carrageenan, and vulvan. Agar is a derivative of

the polysaccharide present in the cell wall red algae

of Rhodophyceae class (Rafael,1995)which is widely

cultivated in Indonesia.

Chitin is the main componen of the exoskeleton

of crustacea like crabs and shrimps.Chitin is

composed of a monomer unit N-asetil-D-

glucosamine(2-acetamido-2-deoxy-Dglucopyranose)

linear bonding β-(1→4) (Maher and Entsar, 2013).

Chitin is white, hard, inelastic polysaccharide

whichhas much nitrogen, and it is the main resources

of pollutan in beach area.Chitosan is a derivative of

chitin and it is the second most abundant

polysaccharide after cellulose. Chitosan is a natural

polysaccharide resulting from the deacetylation

process (COCH

3

removal) of chitin. Generally,

chitosan is added to a film to produce excellent

biocompatibility film, forming ability and

antimicrobial activity. The other advantage of adding

chitosan is to decrease water sensitivity, increase

mechanical and barrier of film (Lili et al, 2017).

2 EXPERIMENTAL METHOD

2.1 Isolated Agar

Agar was prepared by soaking Gracilaria overnight

in a 200 ml NaOH 3%. After that, it was heated in a

water bath for 3 hours at 50 ºC and then washed with

deionized water. The process was followed by

Sinaga, M., Gea, S., Sihombing, Y., Zaidar, E., Bulan, R., Panindia, N. and Azhari, H.

The Preparation of Agar-chitosan Film from Gracilar ia.

DOI: 10.5220/0010096910471051

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1047-1051

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1047

soaking Gracilaria twice in a H

2

SO

4

0.025 % and

deionised water for 2 hours. After that it was washed

with 300 ml deionized water for 1.5 hours until pH 6-

6,5. It was frozen, melted and dried for 24 hours at 60

ºC. Agar yield was determined as the percentage of

dry weight by the following equation:

Agar yield =

𝑥 100 % (1)

2.2 Film Preparation

Chitosan powder (1,2,3 and 4 g) was dissolved in a

100 ml acetic acid 0.2 M solution at 60 ºC and 600

rpm to produce chitosan solution. Agar powder (5

g) was dissolved in a 100 ml deionized water at 95 ºC

and 600 rpm for 60 minutes. An amount of 20% of

glycerol was added to the agar and chitosan solution

as plasticizer. The agar-chitosan film was fabricated

by mixing chitosan solution (1,2,3 and 4 g /

100 ml) and agar solution (5 g/100 ml) with a ratio of

1:1. The mixture was stirred at 60 ºC and 600 rpm for

60 minutes. An amount of

film solution was distributed into the template for

drying and casting for 24 hours at 40 ºC. The films

were stored in a desiccator.

2.3 Characterization

2.3.1 Spectra of Fourier Transform Infrared

(FTIR)

Agar-chitosan films were measured by using an

IRPrestige-21 Shimadzu - Japan to investigate the

interactions of agar, glycerol and chitosan films. The

sample was prepared by mixing the film and KBr with

ratio of 100 : 1. The FTIR was operated with a

wavelength of 400 – 4000 cm

-1

, a resolution of 4 cm

-

1

and 100 scans.

2.3.2 Mechanical Properties

The tensile strength, the elongation at break and the

young’s modulus of the films (100 mm x 25 mm)

weredetermined using a RTF-1350 Tensilon- Japan.

2.3.3 Water Solubility (WS)

The solubility of films in water (WS) is defined as

the percentage of dry matter dissolved in water from

the film dissolved after soaking in distilled

water. The films were cut into a size of 25 mm ×

20 mm and stored in a desiccator to obtain a constant

weight. The specimen was weighed to determine the

initial dry weight and placed in a glass containing a

50 mL of deionized water. The sample

was maintained with a constant stirring for 2 hours,

a temperature of 80 ºC and dried at 105 ºC until

a constant weight was obtained. The percentage of

total dissolved material is calculated as follows:

WS=

𝑥 100 %(2)

3 RESULTS AND DISCUSSION

The agar yield from this research was 48 %. There are

some factors that influence the isolation of Gracilaria

including soaking time, temperature, extraction time

and temperature (Mahdieh et al., 2013).With

reference to Figure 1, the film was initially dark

brown. It becomes brighter after the addition of

glycerol 20% and chitosan 1, 2, 3 and 4%.

3.1 FTIR Spectroscopic Analysis of

Film

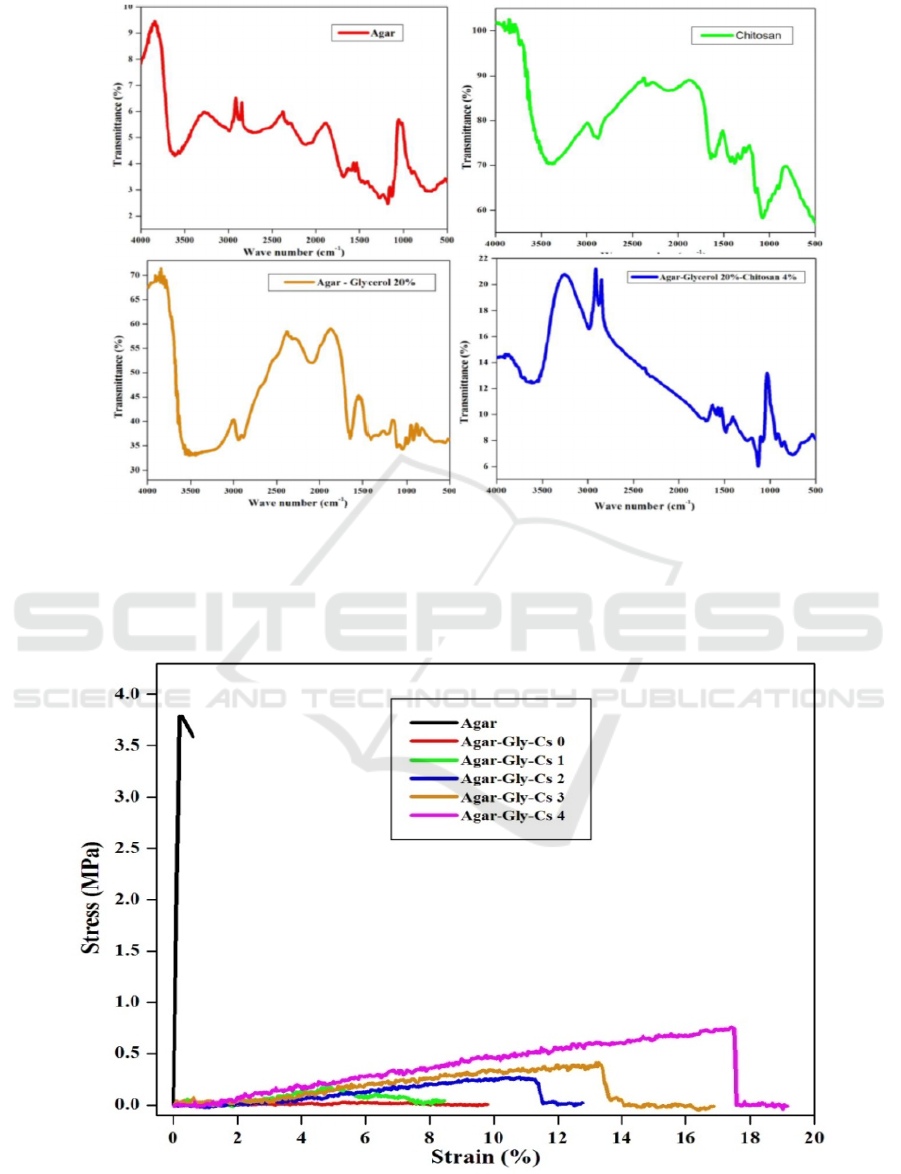

FTIR spectral analysis of the agar film was performed

to identify the nature of the functional groups present.

From Figure 2, the peak at at 3556 cm

-1

is attributed to

OH stretching from hidroxyl groups (Babak and

Fatemeh, 2012). The peak at 1184 cm

-1

is attributed

to stretching vibration C-O in C-O-H groups. The

absorption at 1130 cm

-1

represents stretching

vibration C-O in C-O-C groups (Mayur and Sonal,

2010). In the chitosan spectrum the peak at 3371 cm

-

1

isassociated withstretching vibration N-H bending

and hydrogen bonded hidroxyl groups

(Lili et al,

2017).The peak at 1643 cm

-1

and 1600 cm

-1

representto amide II (N-H) and amide I (C=O)

respectively (Lagaron et al.,2007).The wavenumber

of the FTIR spectral of the film agar changed after the

addition of 20% glycerol. It can be seen from 3603

cm

-1

to 3317 cm

-1

for OH stretching of the hydroxyl

group , 1184 cm

-1

to 1107 cm

-1

for C-O of C-OH

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1048

Figure 1 The Specimen of (a) Agar film, (b) agar-glycerol 20%, (c) agar-glycerol 20% – Chitosan1%, (d) agar-glycerol

20% - chitosan 2%, (e) agar-glycerol – chitosan 3% and (f) agar-glycerol – chitosan 4%.

1130 cm

-1

to 1045 cm

-1

for C-O in C-O-C. A new peak

was not appeared in the spectrum which indicated that

there was only hydrogen bonding between agar and

glycerol.Similarly, there is a shift of wavenumber

with the addition of 20% glycerol and chitosan

4%(Laura et al, 2016). They are from 3603 cm

-1

to

3317 cm

-1

indicating OH stretching of the hydroxyl

group, 1184 cm

-1

to 1107 cm

-1

for C-O of C-OH, 1130

cm

-1

to 1045 cm

-1

for C-O in C-O-C.There was

interaction between the functional group of O-H from

polysaccharides and N-H from chitosan (Emma et al,

2016).The agar film with glycerol 20 % and chitosan

4 % its known that the FTIR results show a

combination of the three constituent components

without forming a new functional groups. the

stretching OH of the hydroxyl group in film (3359

cm

-1

) was higher than agar (3556 cm

-1

) as well as

chitosan (3371 cm

-1

). This is due to inter and intra

molecular hydrogen bonding interactions of all

components

(Lili et al, 2017).

3.2 Mechanical Properties

The mechanical properties of edible film from this

research are show in Table 1.

Based on Table 1. film agar had the best mechanical

properties with the tensile strength of 3.785 MPa, but

the elongation at break was the lowest (0.199 %).

Table 1: Mechanical Properties of film agar, agar-glycerol

agar-glycerol-chitosan

Sample

Tensile

Strength

(

MPa

)

Young’s

Modulus

(

MPa

)

Elongation

atBreaks

(

%

)

Agar 3.785 1,993.31 0.199

Agar-glycerol

(20 %)

0.029 4.173 9.805

Agar-glycerol

(20%)-chitosan

(

1%

)

0.184 2.927 8.449

Agar-glycerol

(20%)-chitosan

(

2%

)

0.276 22.743 12.792

Agar-glycerol

(20%)-chitosan

(

3%

)

0.413 38.946 16.857

Agar-glycerol

(20%)-chitosan

(4%)

0.759 48.836 19.168

The addition of glycerol decreased the tensile strength

of film from 3.785 MPa to 0.029 MPa, increased the

value of elongation at break from 0.199 % to 9.805

%. The tensile strength and the elongation at break of

film increased after the addition of chitosan. The best

mechanical properties of the edible film were found

for agar-glycerol 20%-chitosan 4%.

a

b

c d

e

f

The Preparation of Agar-chitosan Film from Gracilaria

1049

Figure 2: FTIR spectra of agar, chitosan, agar-glycerol 20 % and agar-glycerol 20 %-chitosan 4 %

Figure 3:The tensile strength of agar, agar-glycerol 20 %, agar-glycerol 20 %-chitosan 4 %

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1050

3.3 Water Solubility (WS)

Based on Table 2,the solubility of film increased by

the addition of chitosan. This is due to chitosan highly

soluble in water. However, agar forms gel in water.

Table 2: Water solubility (WS) of agar, agar-glycerol, agar-

glycerol-chitosan

Sample

Water Solubility

(

%

)

Agar 9.84

Agar-glycerol 20 % 88.19

Agar-glycerol 20%-chitosan 1% 69.57

Agar-glycerol 20%-chitosan 2% 80.02

Agar-glycerol 20%-chitosan 3% 85.58

Agar-glycerol 20%-chitosan 4% 87.78

For food packaging application, low solubility

filmisneeded in order to maintain the integrity of

structures to cover vegetables andfruits. However,

high film solubility can be preferred for films to wrap

candy

(Lili et al, 2017)

4 CONCLUSIONS

In summary, it has been shown from this reseach that

the result from the isolation of Gracilaria is 48%.

FTIR spectral indicates that there is hydrogen

bonding in the film agar-glycerol-chitosan. The more

the concentration of chitosan added to the filmagar-

glycerol-chitosan, the tensile strength, the elongation

at break, the young's modulus and the water solubility

increase.

ACKNOWLEDGEMENTS

The authors thank to the Rector of Universitas

Sumatera Utara for the financial support towards this

research in the TALENTA Project 2018,

No.2590/UN5.1.R/PPM/2017 on March.16. 2018.

REFERENCES

Babak S., Fatemeh A., 2012.Adsorptive removal of

methylene blue by agar: effects of NaCl and

ethanol. Chemistry Central Journal (6), 1-13.

Emma Z., Rumondang B., Zul A., Jimmy, M. S. S.,

2016. Modification of Mango Extract with

Mixture of Chitosan, Glycerine and Tapioca to

Produce Edible Film. Chemistry and Materials

Research 8(6), 25-30.

Kwang Y. L., Jaeyong S., Hyeon G. L.,

2004.Mechanical Properties Of Gellan and

Gelatin CompositeFilms. Carbohydrate

Polymers56(2),251-254.

Lagaron,J. M., Fernandez-Saiz, P., Ocio, M. J., 2007.

Using ATR-FTIR spectroscopyto design active

antimicrobial food packaging structures based on

high molecular weight chitosan polysaccharide.

Journal of Agricultural and Food Chemistry55(7),

2554-2562.

Laura F. C., Marian M., Angela S., Leira A., M.,

Carmen V., Elena D. A., Angeles H., 2016. Films

Of Chitosan And Chitosan-Oligosaccharide

Neutralized And Thermally Treated: Effects on Its

Antibacterial and Other Activities. LWT - Food

Science and Technology73, 368-374.

Lili R., Xiaoxia Y., Jiang Z., Jin T., Xingguang S.,

2017. Influence of Chitosan Concentration On

Mechanical and Barrier Properties of Corn

Starch/Chitosan Films. International Journal of

Biological Macromolecules105, 1636–1643.

Mahdieh K. Y., Houman R. I., Yousef F., 2013.

Effect of Extraction Process on Agar Properties of

Gracilaria corticata (Rhodophyta) Collected from

the Persian Golf. Phycologia52(5), 1-9.

Maher Z. E., Entsar S. A., 2013. Chitosan Based

Edible Films And Coatings: A review. Materials

Science and Engineering C33, 1819–1841.

Mayur V.,Sonal T., 2010. Isocyanate Crosslinked

Reactive Starch Nanoparticles for Thermo-

ResponsiveConducting Applications,

Carbohydr345, 2354–2360.

Paula J. P. E., Wen-Xian D., Roberto J. A. B.,Nilda

F. F. S., Tara H.M., 2014. Edible Films From

Pectin: Physical-Mechanical and Antimicrobial

Properties - A Review. Food Hydrocolloids35,

287-296.

Rafael A.,1995. Word-wide Use and Importance of

Gracilaria.J. Appl. Phycol7, 231-243.

Susanne A., Gauri S. M., 2002. Comparative

Evaluation of EdibleCoatings to Reduce Fat

Uptake in a Deep-Fried Cereal Product. Food

Research International35, 445-458.

The Preparation of Agar-chitosan Film from Gracilaria

1051