Vitamin E Extraction from Red Palm Biodiesel by using

K

2

CO

3

based Deep Eutectic Solvent with 1,2-Propanediol

as Hydrogen Bond Donor

Renita Manurung

1

, Gilang Ramadhan

1

, Aulia Arief

1

and Halimatussa’diah Siregar

1

1

Chemical Engineering Department, Universitas Sumatera Utara, Jl. Dr. Mansur, No. 9, Medan, Indonesia

Keywords: Biodiesel, DES, Extraction, Vitamin E, 1,2-Propanediol.

Abstract: Deep Eutectic Solvent (DES) is the latest advancement in separation technology to extract vitamin E from its

source. In this research K

2

CO

3

based DES with hydrogen bond donor (HBD) of 1,2-propanediol was used to

extract vitamin E from red palm biodiesel. The DES was synthesized at temperature of 80

o

C for 1 hour by

stirring rate at 300 rpm and K

2

CO

3

to 1.,2-propanediol molar ratio variation of 1:7, 1:8 and 1:9. Red palm oil

was synthesized by degumming of CPO with 85% phosphate acid to obtain Degummed Palm Oil (DPO). The

extraction was performed by mixing between biodiesel and DES at 400 rpm for 3 hours in mass ratio of 1:2,

1:2,5. 1:3, 1:3,5 and 1:4. Based on molar ratio variation of of K

2

CO

3

:1,2-Propanediol and mass ratio of

biodiesel:DES, which effect to extracted vitamin E and biodiesel purity. The HPLC analysis was used to

showed concentration of extracted vitamin E while the GC analysis was used to showed that extraction using

K

2

CO

3

:1,2-propanediol based DES indeed can increase the purity. DES at K

2

CO

3

to 1,2-propanediol molar

ratio of 1:8 and biodiesel to DES mass ratio of 1:3.5 was the most effective in extracting vitamin E up to

392.16 ppm.

1 INTRODUCTION

Biodiesel is generally produced by transesterification

reaction. The palm oil transesterification is a gradual

reaction between palm oil and alcohol (methanol or

ethanol) producing methyl esters or ethyl seters

(Manurung, 2018a). Raw material requirements for

biodiesel production is the main consideration to

increase the economic value of biodiesel production

where waste cooking oil, crude palm oil (CPO) can

be an alternative choice that can replace the usage

palm oil. In Indonesia, palm oil is a raw material that

is quite potential to be used for biodiesel production

because it is available throughout the year in large

quantities (Manurung, 2018b). Crude palm oil is

converted to methyl ester that called biodiesel and

side product in the form of glycerol was obtained

from the reaction between raw materials in the form

of triglycerides using short chain alcohols such as

methanol and ethanol assisted by the presence of

alkaline catalysts. Biodiesel is ecofriendly diesel and

good performance (Manurung, 2018a).

One of the most prospective raw materials in

biodiesel production is obtained from palm oil. This

is due to the availability of palm oil is in large amount

in Indonesia, from September to October 2016, the

average production of palm oil reached 35 million

tons, and exports reached 26 million tons and

domestic consumption of 9.1 million tons in October

2016 (World Market and Trade, 2016). Indonesia as

one of the largest palm oil producer country in the

world has the potential to develop palm oil-based

biodiesel compared to fossil fuels.

One of minor component in CPO-based biodiesel

which can also be classified as an impurity is

carotenoids, and several other micronutrients such as

vitamin E, tocotrienol and sitosterol (β-sitosterol)

which are useful. Crude palm oil is a vegetable oil

containing minor components such as carotenoids

and vitamin E where the vitamin E content in the CPO

is approximately (600-1000 μg/ml) (Sinaga and

Donald, 2015). Among tocopherols, α-tocopherol is

the most important source of vitamin E in human

foods. The ability of antioxidants and their function

as anti-free radicals makes tocopherols become an

attractive molecule for the health and food industry.

Due to the function of tocopherol which is very

important for living things, it can be encourages the

338

Manurung, R., Ramadhan, G., Arief, A. and Siregar, H.

Vitamin E Extraction from Red Palm Biodiesel by using K2CO3 based Deep Eutectic Solvent with 1,2-Propanediol as Hydrogen Bond Donor.

DOI: 10.5220/0010094503380345

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

338-345

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

development of the separation of these compounds

from the sources. Several studies have been carried

out such as adsorption, membrane separation

technology, and the use of solvents extraction

(Bezold, 2017) (Dai, 2015).

To obtain these components from methyl esters, it

is necessary to maintain the components in the palm

oil methyl esters with certain techniques, it can be

performed using Deep Eutectic Solvent (DES). DES

is produced by mixing two components in certain

ratio to produce a mixture which has significantly

lower melting points than each of the components

singularly. Moreover DES has lower toxicity level

and most of them are biodegradable (Manurung,

2018b). As well as the usage of ChCl, in 2013,

potassium carbonate (K

2

CO

3

) and glycerol were used

in different molar ratio to create a new DES system

(Manurung, 2018b).

The development of the DES system is

increasingly in demand because it has been widely

applied as co-solven, liquid-liquid extraction and in

catalysis which can be used economically and

ecofriendly properties (Dai, 2015) (Manurung,

2018b). The use of 1,2-Propanediol as HBD was

carried out by (Manurung, 2018a) in the process of

purifying biodiesel in which biodiesel was purified up

to 99.88% (Manurung, 2018a). This research tried to

synthesize DES based on K

2

CO

3

with 1,2-

Propanediol as HBD to purifing red palm biodiesel

which expected that DES have ability to act in

extracting the oil components in the form of

tocopherols as vitamin E within CPO.

2 MATERIAL AND METHODS

2.1 Materials

Crude Palm Oil (CPO) was obtained from the palm

oil mill (PKS) PTPN IV. Phosphoric acid (85%) was

used to CPO pretreatment to obtained degummed

palm oil (DPO). Biodiesel based red palm oil was

conducted by ethanol (C

2

H

5

OH) as alcohol,

potassium hydroxide (KOH) as catalyst, and aquadest

used to biodiesel washing process. The DES synthesis

was used potassium carbonate (K

2

CO

3

) based 1,2-

Propanediol as HBD. The extraction process used n-

hexane to disperse biodiesel and used methanol to

disperse DES thus the liquid-liquid extraction could

create biphasic system. Recovery of vitamin E used

water-hexane method in 4:1 ratio, then concentrate

was obtained by using rotary evaporator.

2.2 Methods

The synthesis of deep eutectic solvent (DES) was

conducted at temperature of 80

o

C, stirring rate of 300

rpm for 1 hour (Manurung, 2018a), and molar ratio

variation of K

2

CO

3

to 1,2-Propanediol 1:7, 1:8 and

1:9. The transesterification reaction to synthesis

biodiesel was performed at temperature of 70

o

C for

1.5 hours by molar ratio of ethanol : DPO = 9:1, and

KOH concentration of 1.2 wt%. The extraction

process adopts the procedure by is based on a method

performed by (Manurung, 2018) (Manurung, 2018c),

n-hexane was used to disperse biodiesel and methanol

was used to disperse DES which then performed

liquid-liquid extraction by mixing biphasic system

between prepared CPO and DES. Mass ratio of

Biodiesel to DES was varied at 1:2, 1:2.5, 1:3, 1:3.5

and 1:4. Recovery of vitamin E was carried out by of

water-hexane method at ratio of 4:1 v/v. The

concentrate was obtained by using rotary evaporator

the vitamin E rich hexane product from water-hexane

recovery process

3 EXPERIMENTAL PROCEDURE

3.1 Synthesis of Deep Eutectic Solvent

(DES)

DES was performed by K

2

CO

3

and 1,2-Propanediol

with a certain molar ratio was introduced into the

erlenmeyer and sealed it with stopple. The mixture is

heated over hot plate until it reaches the reaction

temperature of 80 °C and then stirring at 300 rpm for

1 hour to obtained homogenous mixture (Manurung,

2018c).

3.2 Pretreatment of Crude Palm Oil

Crude palm oil in certain amount was put into beaker

glass. Palm oil was heated to 80 °C. 85% phosphoric

acid was added as much as 0.15% of the used palm

oil weight. The oil was then stirred at 300 rpm for 15

minutes. CPO was filtered using filter paper. The

filtrate was taken and called by Degummed Palm Oil

(DPO).

3.3 Synthesis of Biodiesel

DPO, ethanol, and KOH catalyst are prepared in a

certain weight. The equipped Three-neck flask with

magnetic stirrer, a thermometer, and condensation

system are heated by hot plate to temperature of 75

Vitamin E Extraction from Red Palm Biodiesel by using K2CO3 based Deep Eutectic Solvent with 1,2-Propanediol as Hydrogen Bond

Donor

339

o

C to remove water content. DPO in certain weight

was added to the three-neck flask and heated to

temperature of 70

o

C. Ethanol and KOH catalyst were

added to the three-neck flask and turned on the

magnetic stirrer, the stopwatch was run to calculate

the reaction time. After 1.5 hours, the hot plate was

turned off and the mixture cooled. The reaction

mixture was then introduced into the separating

funnel and waited for a few minutes to form 2 layers

so that the separation of the mixture can be

performed. The bottom layer which is a mixture of

glycerol, ethanol, and KOH was separated from the

top layer containing crude palm biodiesel which still

contained some impurities. The top layer then washed

using hot water until the bottom layer is clear to

remove any remaining impurities (Manurung,

2018d).

3.4 Extraction of Vitamin E

Prepared 10 grams of biodiesel was mixed with 100

ml n-hexane. DES with a certain mass ratio to

biodiesel was then mixed with 100 ml methanol.

Mixed both of those two mixtures and stirred at 400

rpm for 3 hours and then let it for 2 hours in the

separation funnel. The mixture will form two layers,

the bottom layer which is a mixture of DES,

methanol and vitamin E was then separated from the

top layer.

The bottom layer mixture was then mixed with

water-hexane by volume ratio of 4:1 v/v in separation

funnel and let it to form 2 layers. The lower layer

which is a mixture of DES, methanol and water was

separated from the top layer. The top layer was

condensed with rotary evaporator till there was no

more hexane remaining to obtained vitamin E, so that

the biodiesel purity can be analyzed (Hadi, 2014).

4 RESULTS AND DISCUSSION

4.1 Characteristic of DES

DES is produced by mixing two components in the

certain ratio to produce a mixture which has

significantly lower melting points than each of the

components singularly (Craveiro, 2016). In this study

used Potassium carbonate (K

2

CO

3

) and 1,2-

Propanediol in different molar ratios to create a new

DES system. The need development for green solvent

which can be used economically and applicable not

only just limited in gas absorption, liquid-liquid

extraction and catalysis (Setyawan, 2011).

4.1.1 Form and Appearance of DES

The goal in this part is to obtain DES with the best

characteristics as a solvent. The used DES was a

mixture of K

2

CO

3

and 1,2-propanediol as HBD with

various molar ratios can be explained in Table 1

below.

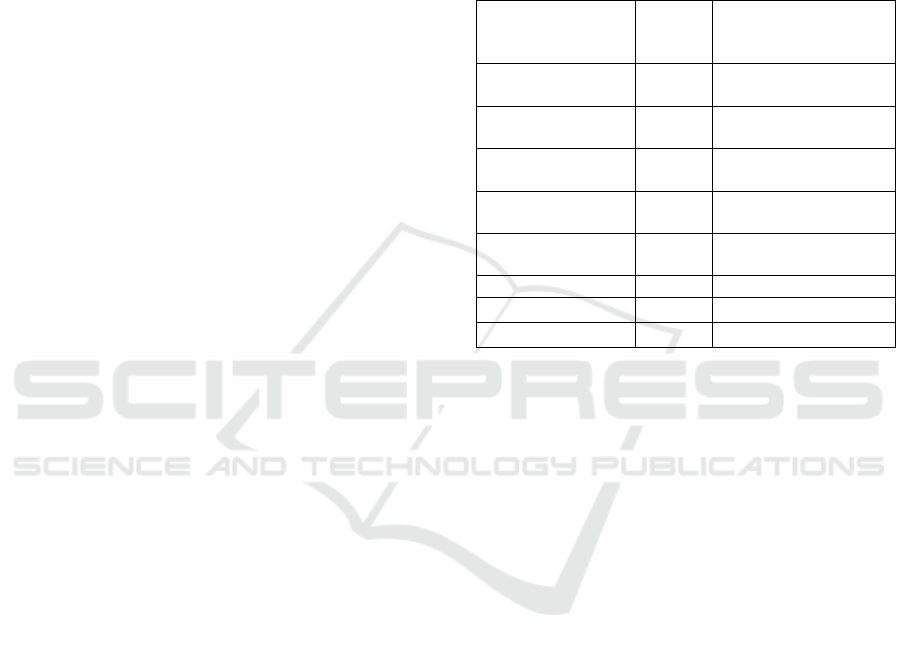

Table 1: Code and from of K

2

CO

3

based DES with 1.2

propanediol as HBD.

Ratio Molar of

K

2

CO

3

:1.2

Propanediol

Code

Form of DES

(RoomTemperature)

1 : 2 DES 1

White color, partial

Soli

d

1 : 3 DES 2

White color, partial

Soli

d

1 : 4 DES 3

Turbid, still there

soli

d

1 : 5 DES 4

Turbid, still there

soli

d

1 : 6 DES 5

Transparent, still

there soli

d

1 : 7 DES 6 Trans

p

arent, Li

q

ui

d

1 : 8 DES 7 Transparent, Liquid

1 : 9 DES 8 Transparent, Liquid

Based on Table 1 shows that DES at molar ratio

of 1:2, 1:3, 1:4, 1:5 and 1:6 (DES 1, DES 2, DES 3,

DES 4 and DES 5) visually were still produced poor

DES. The produced product was turbid, white and

freezing at room temperature. The phase of solid,

semi-solid, crystal, or liquid will be formed along and

after the preparation of DES synthesis with different

forming phase.

Important physical properties Characterization of

DES are viscosity, density, refraction index, pH, and

surface tension, (Dai, 2015). In this research, the

obtained DES Characterization were freezing point,

density, and viscosity.

4.1.2 Freezing Point of DES

DES is usually consisted of two or three cheap and

safe components, which can associate with each other

through hydrogen bond donor, to produce eutectic

mixture in the liquid phase when freezing point of

DES is much lower than it’s pure constituents. The

effect of molar ratio to freezing point of DES can be

explained in Figure 1 below.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

340

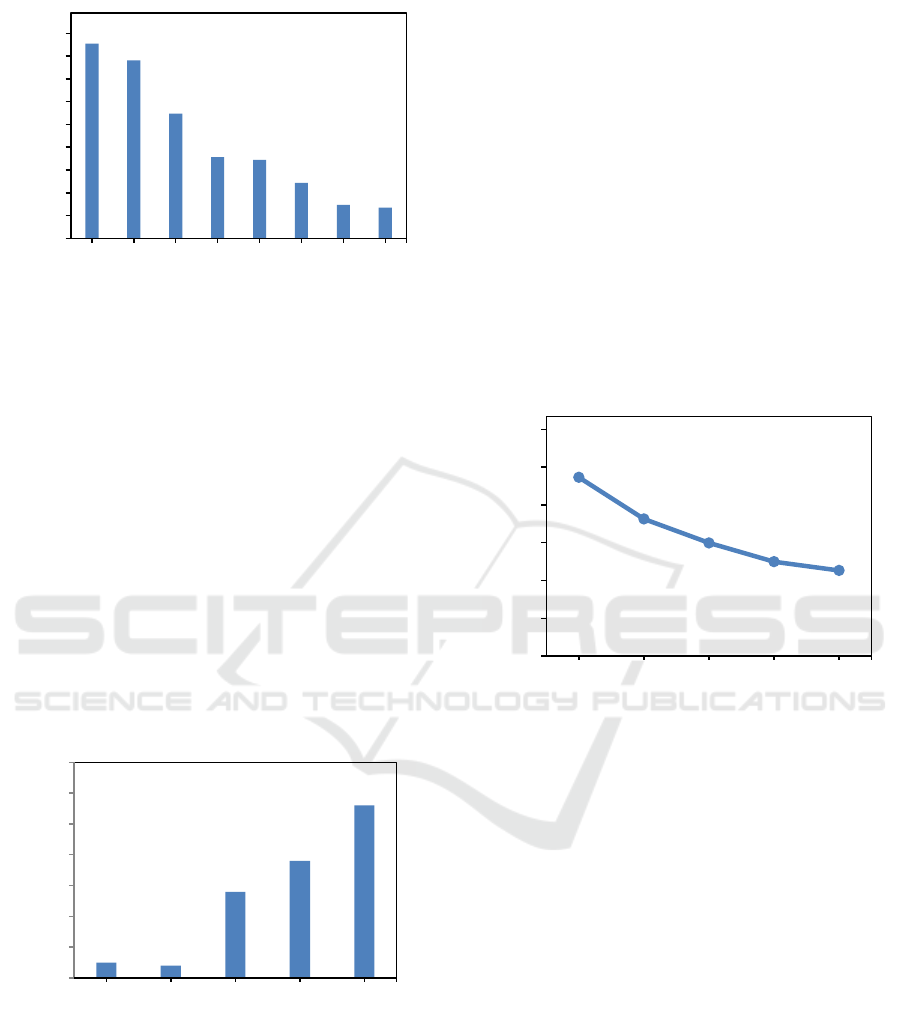

Figure 1: Molar ratio effect to DES freezing point.

Freezing point value is decreased by the increasing of

DES molar ratio. Freezing point value from DES 1

until DES 8 are 86.5, 79.1, 55.8, 36.7, 35.4, 25.4, 15.7

and 14.5

o

C. Mixing ammonium quarterner salt

(K

2

CO

3

) with hydrogen bond donor at a certain molar

ratio to form eutectic mixture forms the liquid phase

of DES. HBD forms a simple complex with anion

salts which leads to a reduction of the lattice energy

in the system and decrease of freezing point

(Manurung, 2018d). So it can be stated that the

suitable DES molar ratio to be used as a solvent are

1:6. 1:7 and 1:8 because these molar ratio produced

DES with the lowest freezing point.

4.1.3 Freezing Point of DES

Figure 2: Molar ratio effect to DES density.

Density is one of DES important physical properties.

The produced DES density also affected by different

molar ratios. It was found that by the increasing of

HBD mole fraction will also increase the DES density

(Manurung, 2018a). Figure 2 shows that the effect of

molar ratio of K

2

CO

3

: 1,2-propanediol to the DES

density value.

All of the DES density values were above 1.04

g/cm

3

. This value lies between the density of K

2

CO

3

and the density of 1,2-propanediol, where their

density are 2.43 g/cm

3

and 1.040 g/cm

3

respectively.

The density value of DES is higher than the density

of water and density of HBD constituent.

4.1.4 Viscosity of DES

Viscosity describes the internal friction forces which

occur in the moving fluid or in other words viscosity

is fluid resistance to each flow. Most reports about

DES show that DES has high viscosity value, usually

above 100 cP. Viscosity is an important characteristic

of DES (Manurung, 2018b,d). Figure 3 shows that the

effect of molar ratio of K

2

CO

3

: 1,2-propanediol to the

DES viscosity value.

Figure 3: Molar ratio effect to DES viscosity.

Based on Figure 3 shows that the viscosity values

for each DES4, DES5, DES6, DES7 and DES8

respectively are 15.18, 11.88, 9.98, 8.49 and 7.80 cSt,

where obtained DES viscosity is below 100 cP at

room temperature (Manurung, 2018b,d). Solid phase

can be seen at molar ratio of K

2

CO

3

to 1,2-

Propanediol of 1:2 and 1:3. In this case can not be

measured and not good choice to applicated as a green

solvent.

The highest of DES viscosity is believed due to

the presence of hydrogen-bonding excess between

combinations that limit the movement of free bonds

within the DES. Other interactions, such as Van Der

Waals and electrostatic interactions, can also affect

the highest viscosity in DES (Zainal, 2017).

4.2 Concentration of Vitamin E

In this part, the goal to be achieved is to know the

potential and effectiveness of K

2

CO

3

-based DES with

86.5

79.1

55.8

36.7

35.4

25.4

15.7

14.5

1

11

21

31

41

51

61

71

81

91

1 : 2 1 : 3 1 : 4 1 : 5 1 : 6 1 : 7 1 : 8 1 : 9

Freezing Point (

o

C)

Molar Ratio of K

2

CO

3

: 1,2-propanediol

1.05

1.04

1.28

1.38

1.56

1

1,1

1,2

1,3

1,4

1,5

1,6

1,7

1 : 5 1 : 6 1 : 7 1 : 8 1 : 9

Density (g/ml)

Molar Ratio of K

2

CO

3

: 1,2-propanediol

15.18

11.88

9.98

8.49

7.8

1

4

7

10

13

16

19

1 : 5 1 : 6 1 : 7 1 : 8 1 : 9

Viscosity (cSt)

Molar Ratio of K

2

CO

3

: 1,2-propanediol

Vitamin E Extraction from Red Palm Biodiesel by using K2CO3 based Deep Eutectic Solvent with 1,2-Propanediol as Hydrogen Bond

Donor

341

1,2-propanediol as HBD usage as solvent in vitamin

E extraction and biodiesel purification.

4.2.1 Pretreatment of Crude Palm Oil

The purpose of this part is to know the quality of the

used raw material in transesterification process to

produce biodiesel. The used raw material was Crude

Palm Oil (CPO), the compositions of used CPO fatty

acid are known from Gas Chromatography analysis

(Type 122-5711, Durabond-5HT; Length = 15 m,

inner diameter = 0.250 mm, film = 0.10 μm) with a

molecular weight of FFA is 271.8016 g/mol, while

the molecular weight of CPO (in the form of

triglycerides) is 853.4571 g/mol. From the analysis of

Gas Chromatography instrument, the composition of

CPO saturated fatty acids is 42.12%, while the

unsaturated fatty acid is 57.88% as shown in Table 2.

Biodiesel production that uses CPO as raw

materials is generally carried out by degumming

process at first. This step is the process of separating

unwanted gum which can usually interfere with the

stability of the oil at the next step. Degumming can

be done by treating CPO with phosphoric acid or

citric acid at certain concentrations (Manurung,

2018b), while in this research using phosphoric acid

85%.

Degumming acid with phosphoric acid is intended

to separate phosphatida which is a source of

unwanted taste and color. Gum contained in CPO

may block the activity of catalysts to accelerate

reaction equilibrium. Used DPO as raw material can

expected the purity and yield come to be higher

Manrung, 2018a,b).

4.2.2 Free Fatty Acid

Comparison of free fatty acid (FFA) levels of crude

palm oil (CPO) and degummed palm oil (DPO) is

presented in Figure 4. From Figure 4 it can be seen

that the FFA level in DPO is higher than FFA level in

CPO. FFA level in CPO is 4.52%, while the FFA

level in DPO is 4.77%. The increase of FFA level in

CPO after degumming process is 0.19%. This

increase in FFA level indicates a decrease in most

gum and impurities which can inhibit catalyst activity

and affects the produced product.

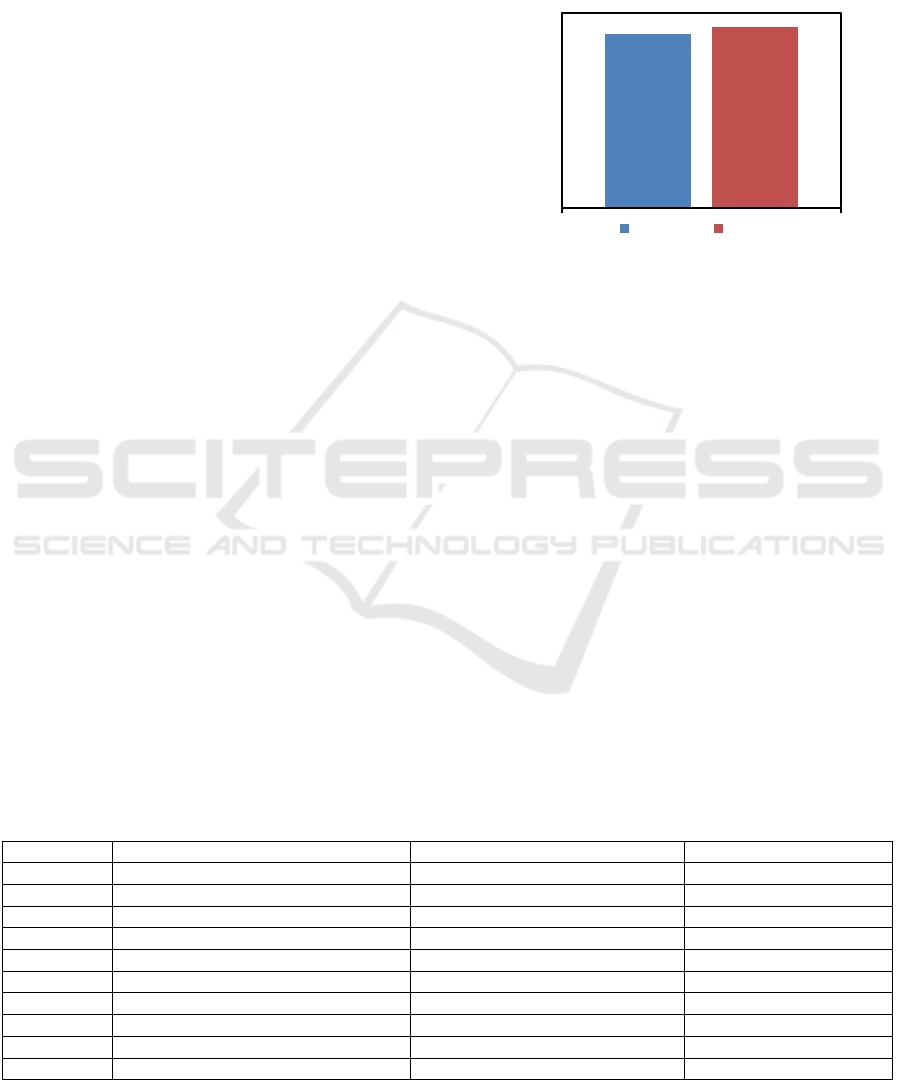

Figure 4: Analysis of FFA content in CPO and DPO.

Based on Figure 4 it can be seen that there is an

increase in FFA levels after degumming although not

significant. It is caused by the use of phosphoric acid

capable of hydrolyzing oil or trigliserida in the

presence of heat application (Manurung, 2018a, b).

To produce biodiesel, it is important to keep FFA

levels less than 6% to prevent unwanted

saponification reactions due to the presence of free

fatty acids that react with alkaline. In the presence of

highest FFA levels can reduce the yield of biodiesel.

4.3 Extraction of Vitamin E

The determination of extracted vitamin E content

from red palm biodiesel using instrument analysis.

The analytical instrument used to test the

Table 2: Compositions of fatty acid in CPO (Crude Palm Oil).

No. Retention Time

(

minute

)

Com

p

ounds Com

p

osition

(

%

)

(

w/w

)

1 10.357 Lau

r

ic Aci

d

(

C

12:0

)

0.08

2 12.794 Miristic Aci

d

(C

14:0

)0.61

3 15.213 Palmitic Aci

d

(C

16:0

) 36.37

4 15.464 Palmitoleic Aci

d

(C

16:1

)0.11

5 17.568 Stearic Aci

d

(

C

18:0

)

4.78

6 17.764 Oleic Aci

d

(

C

18:1

)

43.01

7 18.194 Linoleic Acid

(

C

18:2

)

14.49

8 18.760 Linolenic Aci

d

(C

18:3

)0.19

9 19.826 Arachidic Aci

d

(C

20:0

)0.28

10 20.023 Eikoseneic Acid

(

C

20:1

)

0.08

0

1

2

3

4

5

FFA (%)

CPO DPO

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

342

concentration of extracted vitamin E is High

Performance Liquid Chromatography (HPLC).

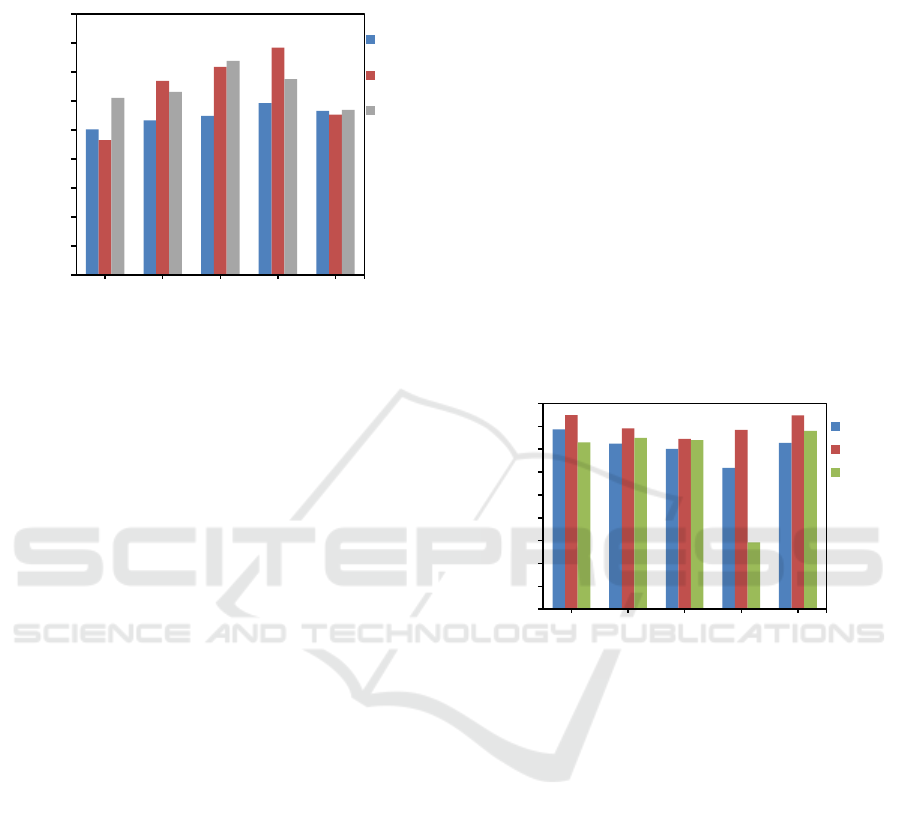

Figure 5: Concentration of extracted vitamin E vs ratio of

biodiesel : DES.

Figure 5 shows an increased in extracted vitamin E

concentration by the DES6, DES7 and DES8 until

mass ratio of 1:3.5 and continued to decrease by

usage of DES with biodiesel to DES mass ratio of 1:4

and at that point DES6, DES7 and DES8 reached the

lowest concentration of vitamin E which can be

extracted by K2CO3 based DES with 1,2-propanediol

as HBD.

Vitamin E concentration which can be extracted

by DES6 with biodiesel to DES mass ratio of 1:2,

1:2.5, 1:3, 1:3.5 and 1:4 respectively are 251.30,

266.62, 274.44, 296.23 and 282.87 ppm, by DES 7

with biodiesel to DES mass ratio of 1:2, 1:2.5, 1:3,

1:3.5 and 1:4 respectively are 232.62, 334.87, 358.80,

392.16 and 276.87 ppm and by DES8 with biodiesel

to DES mass ratio of 1:2, 1:2.5, 1:3, 1:3.5 and 1:4

respectively are 305.47, 315.75, 369.19, 337.19 and

248.61 ppm.

The polarity of the DES is an important factor in

determining separation efficiency which is influenced

by the interactions between the solute (vitamin E) and

the DES. In this research used water to get vitamin E

concentrate from DES-methanol by using water-

hexane method in the volume ratio of 4:1 v/v in the

funnel separation. The result in this research is fit

with the conducted study by (Dai, 2015). DES

containing high percentage of water will result in high

yield at polar bond, while DES containing low

percentage of water will result in low yield at non-

polar bond in the water-hexane system to recover

vitamin E. So the usage of water is to bind DES and

release Vitamin E from DES into n-hexane (Setyawa,

2011) (Tang, 2015).

The highest concentration of extracted vitamin E

from biodiesel using K

2

CO

3

based DES with 1,2-

Propanediol as HBD is resulted by DES 7. Extraction

using DES 6 and DES 7 resulted the highest

concentration of extracted vitamin E by biodiesel to

DES mass ratio of :3.5 at 296.23 ppm and 392.16

ppm, While on DES 8, the concentration of vitamin E

at biodiesel to DES mass ratio of 1:3 is 369.19 ppm.

This shows that the extraction process using K

2

CO

3

-

based DES with 1,2-propanediol as HBD can ended

extract vitamin E from palm biodiesel under certain

conditions.

4.4 Purity of Biodiesel

Purity of biodiesel is determined by the ester content

in produced biodiesel. Determination of ester content

from red palm biodiesel used Gas Chromatography

(GC) instrument. Figure 6 shows the effect of

Biodiesel : DES mass ratio to ester content.

Figure 6: Ester content (%) vs. mass ratio of biodiesel: DES.

The resulted ester content by DES6 at biodiesel : DES

mass ratio of 1:2, 1:2.5, 1:3, 1:3.5 and 1:4

respectively are 97.74%, 96.5%, 96.02%, 94.38% and

96.55% , by DES7 at biodiesel to DES mass ratio of

1:2, 1:2.5, 1:3, 1:3.5 and 1:4 respectively are 99.01%,

97.83%, 96.91%, 97.69% and 98.97% and by DES 8

at biodiesel to DES mass ratio of 1:2, 1:2.5, 1:3, 1:3.5

and 1:4 respectively are 96.60%, 97.01%, 96.79%,

87.85% and 97.61%. The higher ester content in

biodiesel means the higher purity of biodiesel. The

purity of biodiesel before extraction and after

extraction can be compared in Figure 7 below.

0

50

100

150

200

250

300

350

400

450

1:2 1:2.5 1:3 1:3.5 1:4

Concentration (ppm)

Mass Ratio of Ester : DES

DES 6

DES 7

DES 8

82

84

86

88

90

92

94

96

98

100

1:2 1:2.5 1:3 1:3.5 1:4

Ester Content (%)

Mass Ratio of Biodiesel : DES

DES 6

DES 7

DES 8

Vitamin E Extraction from Red Palm Biodiesel by using K2CO3 based Deep Eutectic Solvent with 1,2-Propanediol as Hydrogen Bond

Donor

343

Figure 7: Comparison of biodiesel purity before and after

extraction.

Biodiesel has presence of emulsions or major

impurities such as glycerol, catalyst, alcohol,

triglycerides, diglycerides and monoglyaccharides

and minor impuritives such as carotenoids, vitamin E,

tootrienol and sitosterol (β-sitosterol) (Hamilton,

1995) will affect the purity of the esters produced.

One of minor component in biodiesel that is the

trapped vitamin E, because Vitamin E (tocopherol) is

an antioxidant that is non-polar (hydrophobic)

(Khanum and Thevanayagam, 2017). Besides that

ethyl ester is a compound that has a long carbon chain

that is also hydrophobic (Hadi, 2014), then large

amounts of vitamin E will be bound to ethyl esters

which are both non-polar and stable. In the process of

refining biodiesel with washing method using water

is not enough to increase the purity of palm biodiesel.

So it takes a solvent like DES in the purification

process to bind vitamin E and increase the purity of

palm biodiesel.

It can be seen that the purity of biodiesel before it

was extracted by potassium carbonate based DES

with glycerol as HBD, the obtained ester content was

72.53%, the low purity of produced ethyl ester is due

to contaminant component which is not efficiently

washed by water. Compared to the biodiesel after

extraction using K

2

CO

3

based DES with glycerol as

HBD where the purity of produced biodiesel

increased untill above 96.5% averagely, although

there were some results which have under the avarage

purity value but Figure 7 shows that K

2

CO

3

based

DES with glycerol as HBD not only able to extract

vitamin E but also can improve purify of the palm

ethyl ester into high purity as a biodiesel. The

addition of DES in amounts less than 5% (w/w) was

able to increase the yield of biodiesel produced

(Manurung, 2018c).

5 CONCLUSIONS

K

2

CO

3

based DES with 1.2-propanediol as HBD

which has god characteristics as solvent was obtained

by K

2

CO

3

to glycerol molar ratio of 1:7, 1:8 and 1:9

based on the characteristics of freezing point, density,

and viscosity. The used CPO had 4.52%

concentration of free fatty acid (FFA) and after

pretreatment process the concentration of FFA

increased to 4.77%. DES8 with K

2

CO

3

to 1.2-

propanediol molar ratio of 1:8 was the most effective

DES in extracting vitamin E from palm biodiesel with

biodiesel to DES mass ratio of 1:3.5 by vitamin E

concentration of 392.16 ppm. The highest palm

biodiesel purification ability was performed by using

DES8 with K

2

CO

3

to 1.2-propanediol molar ratio of

1:8 at biodiesel to DES mass ratio of 1: 2 resulted

biodiesel purity of 99.01%.

ACKNOWLEDGEMENTS

The authors are grateful to DRPM DIKTI which has

accomodated the authors in completing this paper.

REFERENCES

Bezold, F., Weinberger, M. E. and Minceva, M. 2017

Computational Solvent System Screening for The

Separation of Tocopherols with Centrifugal Partition

Chromatography Using Deep Eutectic Solvent-Based

Biphasic System. In Journal of Chromatography A,

Volume 1491, 153-158.

Craveiro, R., Aroso, I., Flammia, V., Carvalho, T., Viciosa,

M. T., Dionisio, M., Barreiros, S., Reis, R. L, Duarte,

A. R. C. and Paiva, A. 2016. Properties and Thermal

Behavior of Natural Deep Eutectic Solvents. In Journal

of Molecular Liquids, Elsevier, Volume 215, 0167-

7322.

Dai, Y., Witkamp, G. J., Verpoorte, R. and Choi, Y. H.

2015. Tailoring Properties of Natural Deep Eutectic

Solvent With Water to Facilitate Their Applications. In

Food Chemistry, Volume 187, 14-19.

Hadi, N.A., Ng, M. H., Choo, Y. M., Hashim, M. A. and

Jayakumarz, N. M. 2014. Performance of Choline‑

Based Deep Eutectic Solvents in the Extraction of

Tocols from Crude Palm OiL. In Journal of the

American Oil Chemists' Society, Volume 92(11), 1709-

1716.

Hamilton, R. J. 1995. Developments In Oils and Fats.

Chapman & Hall. London, 1

st

edition.

Khanum, R. and Thevanayagam, H. Lipid Peroxidation: Its

Effects on Formulation and Use of Pharmaceutical

Emulsions. In Asian Journal of Pharmaceutical

Sciences, Volume 12(5), 401–411.

72.3

97.74

99.01

97.61

0

10

20

30

40

50

60

70

80

90

100

BIODIESEL

Ester Content (%)

Before Extraction

Extraction Using

DES 6 ( 1 : 2 )

Extraction Using

DES 7 ( 1 : 2 )

Extraction Using

DES 8 ( 1 : 4 )

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

344

Manurung, R., Syahputra, A. and Alhamdi, M. A. 2018a.

Purification of Palm Biodisel Using Deep Eutectic

Solvent (DES) Based Choline Chloride (ChCl) and 1,2-

Propanediol (C

3

H

8

O

2

). In IOP Conference Series,

Journal of Physics: Conference Series, Volume

1028(1), 1-8.

Manurung, R., Arief, A. and G. R Hutahuruk. 2018b.

Purification of Red Palm Biodiesel by Using K

2

CO

3

Based Deep Eutectic Solvent (DES) with Glycerol as

Hydrogen Bond Donor (HBD). In AIP Conference

Proceedings, Volume 1977(1), 1-8.

Manurung, R., Hutauruk, G. R. and Arief, A. 2018c.

Vitamin E Extraction from Red Palm Biodiesel by

Using K

2

CO

3

Based Deep Eutectic Solvent with

Glycerol as Hydrogen Bond Donor. In AIP Conference

Proceedings, Volume 1977(1), 1-8.

Manurung, R., Alhamdi, M. A. and Syahputra, A. 2018d.

Palm Ethyl Ester Purification By Using Choline

Chloride-1,2 Propanediol as Deep Eutectic Solvent. In

IOP Conference Series: Materials Science and

Engineering, Volume 309, 1-8.

Sinaga, A. G. S. and Siahaan, D. 2015. Characterization and

Antioxidant Activity of Non Polar Extract from Crude

Palm Oil and Palm Methyl Ester. In International

Journal of ChemTech Research, Volume 8(4), 1810-

1816.

Setyawan, H. Y., Hambali, E., Suryani, A. and

Setyaningsih, D. 2011. Separation of Tocopherol from

Crude Palm Oil Biodiesel. In Journal of Basic and

Applied Scientific Research, TextRoad Publication,

Volume 1(9), 1169-1172.

Tang, B., Zhang, H. and Row, K. H. 2015. Application Of

Deep Eutectic Solvents In the Extraction and

Separation of Target Compounds From Various

Sample. In Journal of Separation Science, Volume

38(6), 1053-1064.

United States Department of Agriculture (2016) Oilseeds.

World Markets and Trade.

Abidin, M. H. Z., Hayyan, M., Hayyan, A. and Jayakumar,

S. M. 2017. New Horizon in The Extraction of

Bioactive Compounds Using Deep Eutectic Solvents: A

Review. In Analytica Chimica Acta, Elsevier, Volume

979, 1-23.

Vitamin E Extraction from Red Palm Biodiesel by using K2CO3 based Deep Eutectic Solvent with 1,2-Propanediol as Hydrogen Bond

Donor

345