Utilization of Volcanic Ash of Mount Sinabung as a Substitute for

Cement to Flexure Strength of Geopolymer Concrete

Rahmi Karolina

1

, Syahrizal

2

, M. A. P. Handana

2

, Billy Wijaya

2

1

Doctoral student of Civil Engineering Universitas Sumatera Utara

2

Department of Civil Engineering Universitas Sumatera Utara

Keywords: geopolymer concrete, sinabung ash, curing time, flexure strength.

Abstract: Concrete is one of the construction materials that have been commonly used for the construction of buildings,

bridges, roads and so forth. The need for concrete will increase in line with the increasing need of basic human

facilities and infrastructures. Therefore, the production of cement as a binder of concrete increases as well. In

the process of cement production occurs a process of a huge amount of CO2 release into the atmosphere and

then damage the environment which among them cause global warming. To overcome these problems, it’s

necessary to find another material as a substitute for cement. Geopolymer concrete is an alternative to

substitute concrete that uses cement. Geopolymer concrete is made without the use of cement as a concrete

binder, and instead, using sinabung ash which is rich in silica and alumina and can react with alkaline liquids

to produce a binder. In this research, the flexure strength of concrete is tested to a number of samples in the

form of 15x15x60 cm3 block with curing time variation of 4 hours, 8 hours, 12 hours and 24 hours at 60

o

C

temperature by using oven. From the results, it’s obtained that the graph of flexure strength value increases

with the length of curing time. Maximum flexure strength occurs at 24 hours curing time.

1 INTRODUCTION

(Davidovits, 1999) Geopolymer concrete is a

construction material that is developed and offers

many advantages compared to conventional concrete

where the making process of concrete does not use

cement. The advantages to be obtained from

geopolymer concrete are its ability to withstand fire,

corrosive resistance, reducing air pollution due to

excessive CO2 emissions at the time of cement

production. The base materials for the geopolymer

binder used to create geopolymer concrete can be

obtained from various sources where these materials

have high silica and aluminum content.

In this research the cement substitute binder

used is volcanic ash. Volcanic ash is a fine material

and very small in size, bursting from a erupting

volcano. Volcanic ash has some content that can

support reinforcement in concrete. One of the most

abundant types of material in volcanic ash is silica

(SiO2). This material can react chemically with

alkaline liquids at a certain temperature to form a

cement-like mixed material.

Based on the descriptions described above, the

author will conduct a test by using volcanic ash of

Mount Sinabung as a substitute of cement in concrete

mixture, to be able to know the result of flexure

strength of concrete produced with the base material

of volcanic ash.

2 MATERIALS

Sinabung Ash. Volcanic ash or volcanic sand is a

falling volcanic material that is ejected into the air

during an eruption. The ash and volcanic sand consist

of large to fine-sized rocks, large ones usually falling

around 5-7 km from the crater, while the fine ones can

fall at a distance of hundreds of kilometers or even

thousands of kilometers from the crater that caused

by the wind (Sudaryo dan Sucipto, 2009). The

characteristics of volcanic ash generally contain

major elements (AI, Si, Ca and Fe), minor (I, Mg, Mn,

Na, P, S and Ti), trace levels (Au, As, Ba, Co, Cr, Cu,

Mo, Ni, Pb, S, Sb, Sn, Sr, V and Zn), have broad uses

(AI, Si, Ca, Fe, Ti, V and Zn) and high values (Au).

Based on the content of AI, Ca and Si elements in

332

Karolina, R., Syahrizal, ., Handana, M. and Wijaya, B.

Utilization of Volcanic Ash of Mount Sinabung as a Substitute for Cement to Flexure Strength of Geopolymer Concrete.

DOI: 10.5220/0010094303320337

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

332-337

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

large ash (56%, 4% and 18% respectively), it is

possible to use the ash as a cement material or

cement-based goods (Wahyuni, 2012)

Table 1: Chemical Contents of Volcanic Ash of

Mount Sinabung Eruption

No Parameter Result (%) Method

1 Silika as

SiO₂

85,6 Gravimetri

2 Aluminium

as Al₂O₃

0,95 Perhitungan

3 Kalsium as

CaO

4,78 Gravimetri

4 Magnesium

as MgO

4,48 Gravimetri

5 Water

content

1,43 Gravimetri

(Source : Balai Riset dan Standarisasi Industri

Medan, Laboraturium Penguji, Kementerian

Perindustrian)

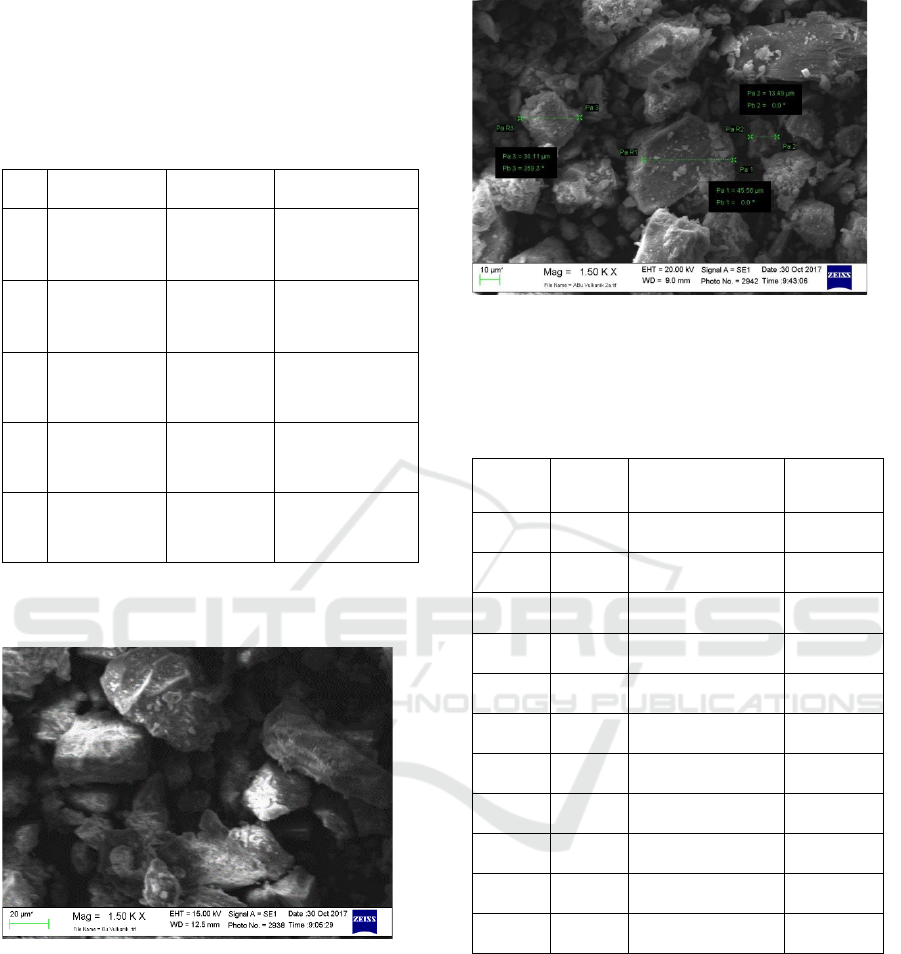

Figure 1: Magnification of Volcanic Ash Samples

with SEM Test

Figure 2: Magnification of Volcanic Ash Samples

with SEM Test

Table 2: Results of EDS Spectrum Analysis of

Volcanic Ash Samples of Mount Sinabung

EI An C Norm (wt%)

C atom

(at%)

Fe 26 37,96 16,72

O 8 33,28 51,16

Si 14 16,81 14,72

C 6 6,12 12,53

Al 13 4,26 3,88

K 19 0,89 0,56

Ca 20 0,69 0,42

Na 11 0,00 0,00

Mg 12 0,00 0,00

Br 35 0,00 0,00

Tl 81 0,00 0,00

(Source : Laboratorium Fisika Universitas Negeri

Medan)

Utilization of Volcanic Ash of Mount Sinabung as a Substitute for Cement to Flexure Strength of Geopolymer Concrete

333

Table 3: Results of X-ray Diffraction Analysis of

Activation Nature of Volcanic Ash

No

2 Theta

(deg)

d

(A)

I/II

FWH

M

(deg)

Intensi

ty

(Coun

ts)

Int

eg

rat

ed

Int

(C

ou

nt

s)

1

27,758

4

3,2

11

12

5

100

0,505

80

297

79

98

2 21,786

4,0

76

19

73 0,412 217

48

31

3

23,559

4

3,7

73

22

48

0,281

1

144

20

25

(Source : Laboratorium Fisika Universitas Negeri

Medan)

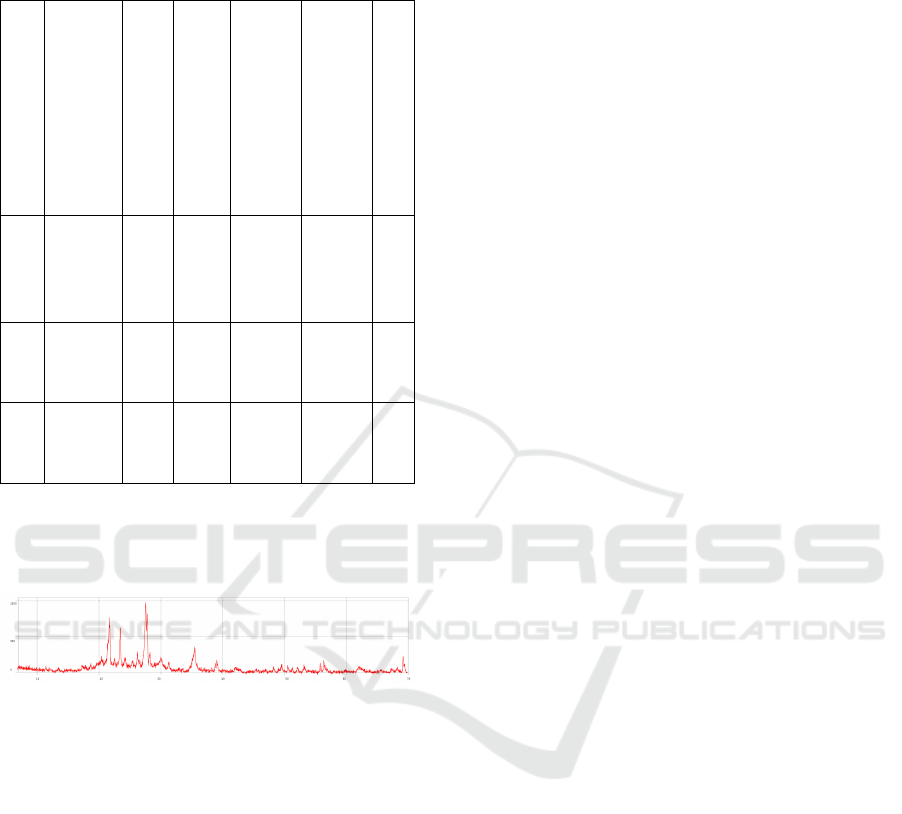

Figure 3: Diffraction Pattern of Activation Results of

Volcanic Ash

Figure 3 shows the pattern of X-ray diffraction

between intensities to the volcanic ash element

pattern of modified nature (chemical and physical

activation). The analysis of X-ray diffraction tool is

intended to know the dase and crystal structure, and

identification result crystallinity of a dominant

composition on volcanic ash (Bambang Nurdiansyah,

2017).

From table 3, it can be seen that the maximum

peak is at 2θ = 27.7584 with spacing of 3.21125A and

FWHM 0,50580.

From the results of chemical content

examination above, it is seen that sinabung ash has a

very high silica content. The percentage of this

content indicates that the ash can be used as a

substitute for cement in a concrete mixture.

From the SEM test of volcanic ash samples

above, it can be seen that the morphology of samples

is irregular with varying sizes. And the magnitude of

the volcanic ash particle distribution from the

eruption of Mount Sinabung is 13.49μm - 45.56μm

(Bambang Nurdiansyah, 2017).

Agregates. The fine aggregate (sand) used is sand

from Medan Sunggal with dry, SSD and apparent

specific gravity of 2460 kg / m3 and 2510 kg / m3

and 2590 kg / m3. Coarse aggregate (gravel) is split

with the maximum size of 20 mm with SSD and

apparent specific gravity of 2630 kg / m3, 2680 kg /

m3 and 2770 kg / m3

Admixtures. Admixtures are materials used in

concrete mixture other than water, aggregates (fine

and coarse aggregate), ashes, and alkaline activators

added in concrete mix. In this research is using

highrange water reducer admixture such as Master

Ease 3029 and Accelerator.

[2][3]

Alkaline Activators (Sodium Silicate dan

Sodium Hidroxyde). Alkaline activators to be used

in this research are sodium hydroxide and sodium

silicate. NaOH is a powder with a content of 98%.

Sodium hydroxide serves to react the Si and Al

elements contained in the volcanic ash so as to

produce a strong polymer bonds. Na

2

SiO

4

contains

96% gel-shaped sodium silicate. Sodium silicate

serves to speed up the polymerization reaction.

3 METHOD

(Mulyono, 2004) Research method is stages,

processes, sequences or workflows to get the purpose

of a research conducted. The method used in this

study is an experimental study conducted at the

Concrete Laboratory of Faculty of Engineering of

Department of Civil Engineering of University of

Sumatra Utara. A complete mix design calculation

can be seen in the attachment. From the mix design

results, it is obtained 1m³ concrete mixture proportion

among others are as follows :

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

334

Table 4: The proportion of concrete mixture per m

3

Material Weight

Sinabung Ash 553,57 kg/m³

Sodium Silicate 138,40 kg/m³

Sodium Hidroxyde 230,65 L/m³

Coarse Aggregate 900,16 kg/m³

Sand 808,46 kg/m³

Master Ease 3029 11,07 L/m³

Accelerator 5,54 L/m³

Concrete Flexure Strength. The loading system in

the flexure test, ie the specimen is loaded so that it

will only experience a failure caused by pure flexure

(two point loading system). The flexure strength of

concrete (modulus of rupture) is calculated as

follows:

If the failure occurs in the middle of the span:

[1]

If the collapse occurs in the drag outside of the center

of the span then the following formula is used:

[2]

Where :

Fr = modulus of rupture

P = the maximum load that occurs

L = the effective span length

b = average width of fault specimen

d = average height of fault specimen

a = the average distance from the failure line from

the nearest placement point measured at the

specimen's drag

4 RESULTS AND DISCCUSIONS

Visible Properties

Volume Weight of Geopolimer Concrete. The

volume weight of concrete is the ratio between the

weight of the concrete and its volume. The average

volume weight of the geopolymer concrete can be

seen in table 5 below :

Table 5: Table of average volume weight of

Geopolymer Concrete

No.

Curing

Time

(Hours)

Number

of

Samples

AverageVolume

Weight (kg/m

2

)

1 4 3 2329,04

2 8 3 2381,04

3 12 3 2386,00

4 24 3 2369,41

From the results obtained, the volume weight of

geopolymer concrete volume ranges between

2329,04 kg/m

2

– 2386,00 kg/m

2

. The examination

results of the geopolymer concrete volume weight, it

is included a normal weighted concrete (SNI 03-

2847-2002).

Flexture Strength of Geopolymer Concrete. In this

research, flexure strength test is performed on a beam

of geopolymer concrete with the size of 15 x 15 x 60

2

bd

PL

fr

2

3

bd

Pa

fr

Utilization of Volcanic Ash of Mount Sinabung as a Substitute for Cement to Flexure Strength of Geopolymer Concrete

335

cm at 7 days of age. The results of the average flexure

strength test can be seen in Table 6.

Table 6: Average Flexure Strength of Geopolymer

Concrete

N

o

Curing

Time

(Hours

)

Curing

Temperatur

e (

o

C)

Average

Flexure

Strength

(Mpa)

1 4 60 2,78

2 8 60 3,29

3 12 60 3,79

4 24 60 4,53

[6]

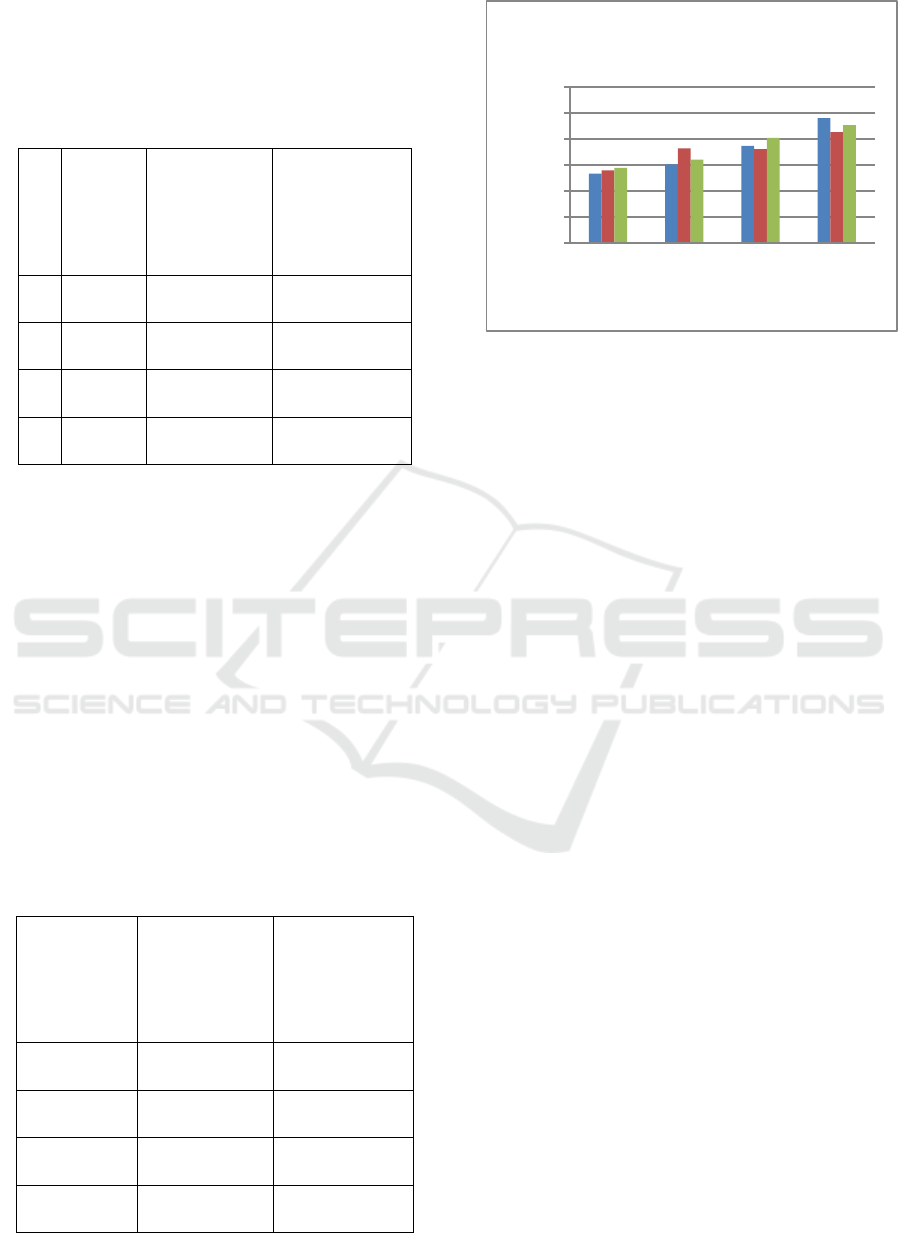

From the table and graph above, it can be seen that

there is an increase of flexural strength of geopolymer

concrete along with the length of treatment time in the

oven (Curing Time) at 60

o

C. The longer the curing

time on the concrete samples, the higher the strength

of the concrete flexure is. Maximum flexure strength

occurs at 24 hours curing time.

From the results of the research of flexure strength of

geopolymer concrete, it is obtained a concrete

conversion value at 4 hours, 8 hours, 12 hours, to 24

hours curing time.

Table 7: Conversion Table of Geopolymer Concrete

Flexure Strength

Curing

Time

(Hours)

Flexure

Strength

(Mpa)

Conversion

Value of

Flexure

Strength

4 2,78 0,61

8 3,29 0,73

12 3,79 0,84

24 4,53 1,00

Figure 5: Flexure Strength Comparison

5 CONCLUSIONS

From the test results, data processing and analysis, it

can be concluded as follows:

1. Based on the test results, it can be concluded that

the optimum variation is on the variation with

24 hours curing time because it has the highest

flexure strength. For 24 hours curing time

variation, the average flexure strength is 4.53

MPa.

2. Based on the discussion, it can be concluded that

the flexure strength value of geopolymer

concrete increases along with the length of

treatment time in the oven (Curing Time) at

60oC. The average flexure strength of 7days of

age concrete and being ovened for 24 hours has

a flexure strength of . The longer the curing

time on the concrete samples, the higher the

strength of the concrete flexure is. Maximum

flexure strength occurs at 24 hours curing time.

6 SUGGESTIONS

Based on the results obtained in this research, the

author provides some suggestions as follows :

1. Conducting variation of curing temperature

more than 60

o

C and more than 24 hours curing

time and more than 7 days of concrete age to

obtain an optimum flexure strength of concrete.

2,67

3,02

3,73

4,8

2,79

3,64

3,61

4,26

2,88

3,20

4,04

4,53

0

1

2

3

4

5

6

4 Hours 8 Hours 12 Hours 24 Hours

f'c (MPa)

Ovening Time (Hours)

Comparison of Geopolymer

Concrete Flexure Strength

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

336

2. Conducting further research by varying the

molarity of NaOH and the ratio between

Na2SiO3 and NaOH to obtain an optimum

value.

3. Noticing the use of vaseline for formwork of

samples because the incorrect use of vaseline

can cause a sticky samples when opening the

formwork.

4. Conducting research on the mechanism and

method of mixing of geopolymer concrete

materials connected with concrete workability.

ACKNOWLEDGEMENTS

Thank you to USU Research Institute and

TALENTA USU Research Program 2018 for

funding this research.

REFERENCES

Davidovits, J. (1999). Chemistry of Geopolymeric

Systems, Terminology In: Proceedings of 99

International Conference. eds. Joseph

Davidovits, R. Davidovits & C. James,

France.

Ekaputri, J. J., & Triwulan, T. (2013). Sodium

sebagai Aktivator Fly Ash, Trass dan Lumpur

Sidoarjo dalam Be

GEOPOLIMER, TERHADAP KUAT MEKANIK

BETON. "PENGARUH MOLARITAS

AKTIFATOR ALKALIN TERHADAP

KUAT MEKANIK BETON GEOPOLIMER

DENGAN TRAS SEBAGAI PENGISI."

Karolina, Rahmi, M. Agung Putra, and Tito Agung

Prasetyo. "Optimization of the use of volcanic

ash of Mount Sinabung eruption as the

substitution for fine aggregate." Procedia

Engineering 125 (2015): 669-674.

Mulyono, Tri. "Teknologi Beton." Yogyakarta:

Andi(2004).

Risdanareni, Puput, Adjib Karjanto, Januarti Jaya

Ekaputri, Poppy Puspitasari, and Febriano

Khakim. "Mechanical properties of volcanic

ash based geopolymer concrete." In Materials

Science Forum, vol. 857, pp. 377-381. Trans

Tech Publications, 201

Utilization of Volcanic Ash of Mount Sinabung as a Substitute for Cement to Flexure Strength of Geopolymer Concrete

337