Optimization of Polymer and Cross-linker Combination on the

Formation of Pectin Film Containing Metformin Hydrochloride

Mariadi

1,2

*, Bayu Eko Prasetyo

1,2

and Yade Metri Permata

3

1

Departement of Pharmaceutical Technology, Faculty of Pharmacy, Universitas Sumatera Utara, Medan, 20155, Indonesia

2

Nanomedicine Centre of Innovation, Universitas Sumatera Utara, Medan, 20155, Indonesia

3

Departement of Pharmaceutical Chemistry, Faculty of Pharmacy, Universitas Sumatera Utara, Medan, 20155, indonesia

Keywords: Pectin film, combination of polymers, cross-linker, metformin hydrochloride.

Abstract: Pectin has been developed as an edible film in drug delivery systems, however pectin has some disadvantages

such as rapid drug release, low mechanical strength, and low drug infusion efficiency. The purpose of this

study was to optimize the polymer and cross-linker combination on the formation of pectin film containing

metformin hydrochloride. The films were prepared using a single or combination of polymer as a matrix and

glycerin as a plasticizer. The homogenous mixture of pectin mucilage, alginate mucilage, hydroxyl-propyl

methylcellulose (HPMC) mucilage, ethyl-cellulose, glycerin, and metformin hydrochloride was flattened on

an object glass (2 cm x 5 cm) and then allowed to dry at room temperature. The all formula were evaluated

the capability of forming the membrane or film and elasticity properties. The pectin, alginate, HPMC, and

ethyl-cellulose polymer in single or two polymer combination cannot form a film with the addition of

metformin hydrochloride. The combination of three polymers of pectin, alginate, and ethyl-cellulose can form

a finer, smoother surface, more elastic, rolled and folded membrane/film. The combination of three polymers

of pectin, alginate, ethyl-cellulose and the addition of cross-linkers to a combination of pectin, alginate,

HPMC provides an optimal film for Drug Delivery System.

1 INTRODUCTION

Pectin is widely used in the pharmaceutical as an

ingredient for applications of Drug Delivery System

(DDS). Pectin has advantages as a non-toxic nature

polymers, low production cost, and high availability

(

Mishra, 2012). Edible films can be distinguished in

three categories based on the raw materials used i.e.

hydrocolloids, fats and mixtures of both. The

hydrocolloid groups can be prepared from

polysaccharides (cellulose, modified cellulose,

starch, agar, alginate, pectin, dextrin), proteins

(collagen, gelatin, egg white), and also lipids

(Omidian and Kinam, 2012).

Drug release from high methoxy pectin has been

studied in terms acrylamide grafted pectin was

characterized by FTIR, DSC and X-ray diffraction.

The polymer was cross-linked with glutaral dehyde

and tested for salicylic acid release using a Franz

diffusion cell. A grafted hydrogel displayed better

film-forming properties than pectin (Sutar, 2008).

Hydrogel membrane based on pectin and

polyvinylpyrrolidone have been prepared by physical

blending and conventional solution casting methods.

The release of salicylic acid was monitored at

different aqueous media using a UV Vis

spectrophotometer at 294 nm wavelength. The

presence of secondary amide, decrease in crystallinity

at higher PVP ratio (Mishra, 2008). Amidated pectin

complexes with calcium were used in preparation of

a multipar-ticulate system with the potential for site-

specific colon delivery (Munjeri, 1997).

In the manufacture of edible film from pectin as a

drug delivery system, pectin has several

disadvantages such as rapid drug release, low

mechanical strength, and low drug infusion

efficiency. The purpose of this study is the optimize

of polymer and cross-linker combination on the

formation of pectin film containing metformin

hydrochloride.

Mariadi, ., Prasetyo, B. and Permata, Y.

Optimization of Polymer and Cross-linker Combination on the Formation of Pectin Film Containing Metformin Hydrochloride.

DOI: 10.5220/0010093608450851

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

845-851

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

845

2 METHODS

2.1 Materials

Metformin hydrochloride was obtained from Iol

Chemicals and Pharmaceuticals Ltd India. Sodium

Alginate 500~600 cP was the products of Wako Pure

Chemical Industries, Ltd Japan. Pectin was obtained

from Cargill Deutschland GmbH Germany, ethyl

cellulose was the products of Shanghai Honest Chem

Co., Ltd. China, and hydroxypropyl methylcel lulose

(HPMC) was the products of Wuhan Senwayer

Century Chemical Co., Ltd., China.

2.2 Preparation of Films Containing

Metformin Hydrochloride

The films were prepared using the single or

combination of polymer as a matrix and glycerin as a

plasticizer. The homogenous mixture of mucillage of

4% sodium alginate in water, mucillage of 10% pectin

in water, mucillage of 8% HPMC in water,

ethylcellulose, glycerin, and metformin

hydrochloride (Table 1) was flattened on a object

glass (2 cm x 5 cm) and then allowed to dry at room

temperature for 48 hours. The films formed were

removed carefully, and placed in desiccator.

3 EVALUATION

The formulas designed with various combinations of

polymers containing metformin hydrochloride (Table

1), the capability of the polymer in each formula to

form the membrane/film was observed visually and

the elasticity properties was evaluated by rolling or

folding the membrane/film.

4 RESULT AND DISCUSSION

4.1 The Film Properties of Single

Polymers without Metformin

Hydrochloride

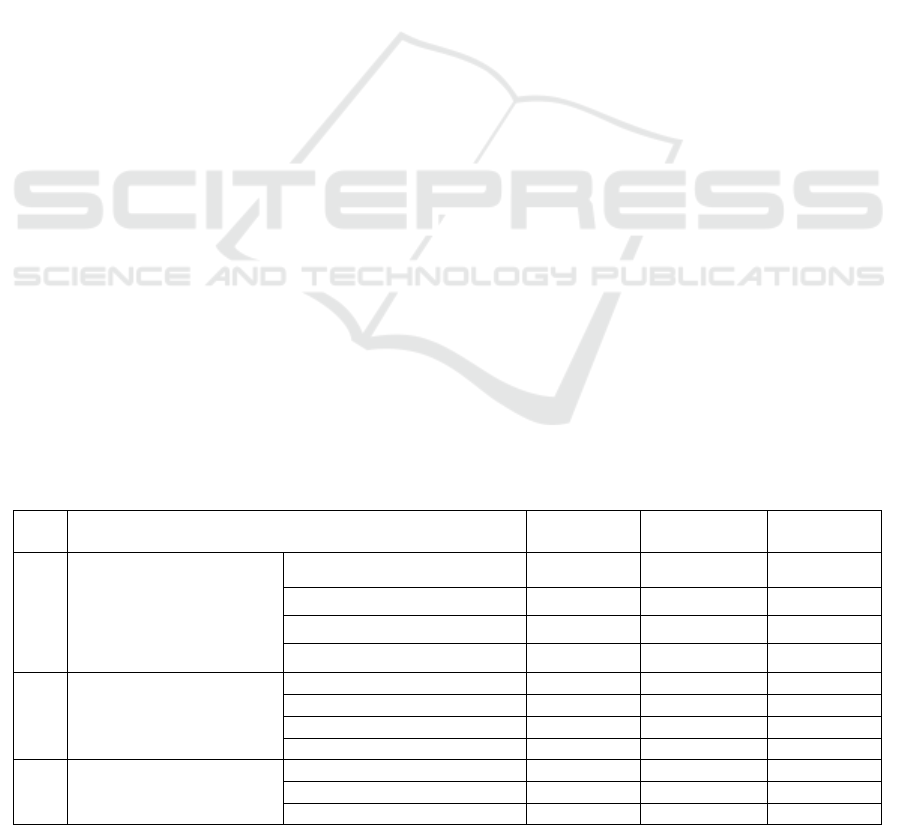

The membrane/films of single polymers and

combinations without containing metformin

hydrochloride were prepared by dissolving the

polymers at concentrations which may form a gel.

The gel solution is then placed on the mold and dried

at room temperature. The gel solutions of the pectin,

alginate, HPMC and ethyl cellulose polymers all

demonstrate to form a films. The generally obtained

films have properties such as plastic, transparent,

thin, elastic to be rolled or folded, except for the films

of ethyl cellulose showed yellowish white film as

shown in Table 2 and Figure 1.

Based on the data in table 2, all of the polymers

have the ability to form a good film. Edible film

preparations can be distinguished based on the raw

materials used namely hydrocolloids, fats and

mixtures of both. Edible hydrocolloid group films can

be made from polysaccharides such as cellulose,

cellulose modification, starch, agar, alginate, pectin,

and dextrin (Omidian and Kinam, 2012).

The ability of these polymers to form films and

applications as matrices in drug delivery systems has

been reported in several studies i.e. combinations of

chitosan-alginic films containing antacids as the

gastroretentive drug delivery system (Mariadi, 2015),

the characterization of pectin/PVP hydrogel

membranes containing salicylic acid for drug

delivery system (Mishra, 2008), pectin-based

biodegradable hydrogels with potential biomedical

application as drug delivery system (Sadeghi, 2011),

and chitosan-alginate films prepared with chitosan of

different molecular weights (Yan, 2001).

Table 1: Formula of films containing metformin hydrochloride

No Polymers

Polymers

Ratio

Metformin

h

y

drochloride

Glycerin

1

Single of polymer without

containing metformin

hydrochloride

Pectin 10%

- - 2 drops

HPMC 8%

- - 2 drops

Etil Selulosa 8%

- - 2 drops

Alginate 4%

- - 2 drops

2

Single of polymer

containing metformin

hydrochloride

Pectin 10% - 500 mg 4 drops

HPMC 8% - 500 m

g

4 dro

p

s

Eth

y

l cellulose 8% - 500 m

g

4 dro

p

s

Sodium Al

g

inate 4% - 500 m

g

4 dro

p

s

3

Combination of two

polymer containing

metformin hydrochloride

Pectin + HPMC 1:1 500 mg 4 drops

Pectin + Ethyl cellulose 1:1 500 mg 4 drops

Pectin + Sodium Al

g

inate 1:1 500 m

g

4 dro

p

s

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

846

Table 1: Formula of films containing metformin hydrochloride(cont.)

No Polymers

Polymers

Ratio

Metformin

hydrochloride

Glycerin

4

Combination of three

polymers containing

metformin hydrochloride

Pectin + Sodium Alginate +

Eth

y

l cellulose

1:1:1 500 mg 4 drops

Pectin + Sodium Algintae +

HPMC

1:1:1 500 mg 4 drops

Pectin + Ethyl cellulose +

HPMC

1:1:1 500 mg 4 drops

5

Combination of two and

three polymers with the

addition of Crosslinker

(CaCl

2

) containing

Metformin hydrochloride

Pectin + Alginate + CaCl

2

1%

+ metformin HCl

1:1 500 mg 4 drops

Pectin + Alginate + CaCl

2

2%

+ metformin HCl

1:1 500 mg 4 drops

Pectin+ Alginate + CaCl

2

3%

+ metformin HCl

1:1 500 mg 4 drops

Pectin + Alginate + Ethyl

cellulose + CaCl

2

1% +

Metformin HCl

1:1:1 500 mg 4 drops

Pectin + Alginate + HPMC +

CaCl

2

1% + Metformin HCl

1:1:1 500 mg 4 drops

Table 2: The properties of single polymer membrane/film

No Polymer

Thickness of the

membrane/fil

m

(

mm

)

Properties of Film

1 Pectin 10% 0.27±0.05 Transparent fil

m

: thin, elastic and roll able/foldable

2 HPMC 8% 0.14±0.01

Transparent film: thin, elastic and roll able/foldable

3

Ethyl Cellulose

8%

0.34±0.02

Yellowish white film: thin, elastic and roll able/foldable

4 Alginat 4 % 0.75±0.17

Transparent fil

m

: thin, elastic and roll able

/

foldable

Pectin HPMC Al

g

inate

Ethylcellulose

Figure 1: The Films of pectin, alginate, HPMC and ethyl cellulose polymer

4.2 The Membrane Properties of Single

Polymer Contains Metformin

Hydrochloride

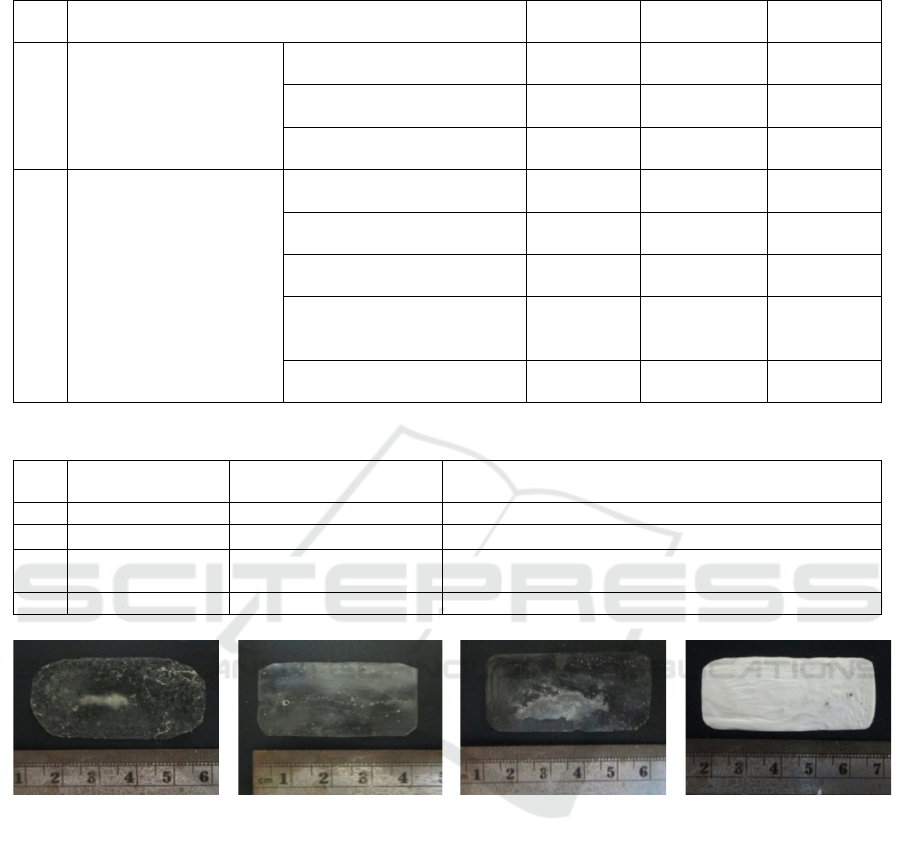

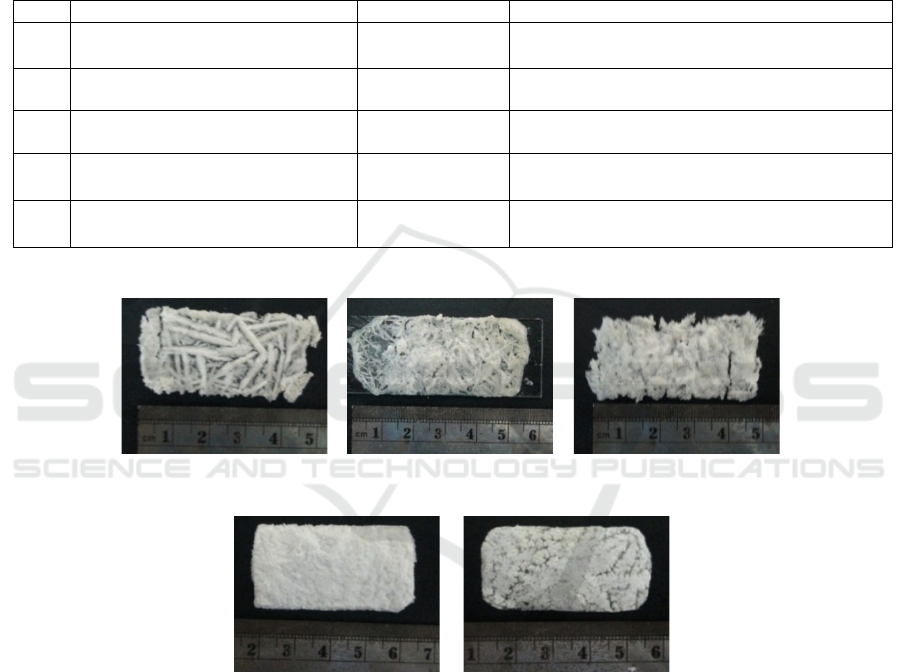

The gel solution of the pectin, alginate, HPMC and

ethylcellulose polymers added with metformin HCl

respectively, indicates that this mixture can not form

the membrane/ film, but produces crystalline particles

of metformine HCl-coated polymer as shown in Table

3 and Figure 2.

From the obtained data, the membrane/film can not

be formed suspected that it is related to the water-

soluble nature of metformin HCl, so that when mixed

with the polymer gel solution dissolves between the

gel and metformin HCl. The gel solution breaks into

liquid and dilute, this is because the dissolved

metformin HCl can break the crosslinks in the

polymer chains of the gel. The breaking of crosslinks

of the gel preparations of these polymers results in the

loss of the gel properties, so that when the mixture is

dried it can not form membrane /films. In physical

gels, the nature of the crosslinking process is

physical. This is normally achieved via utilizing

physical processes such as association, aggregation,

crystal lization, complexation, and hydrogen

bonding. While physical hydrogels are reversible due

Optimization of Polymer and Cross-linker Combination on the Formation of Pectin Film Containing Metformin Hydrochloride

847

Table 3: The membrane properties of single polymer contains metformin hydrochloride

No Polymer

The resultin

g

film membrane

The result Pro

p

erties of membrane

1 Pectin 10% + Metformin HCl

Could not formed films Produce irregular crystals

2 HPMC 8% + Metformin HCl

Could not formed films Produce rod-shaped crystals

3 Alginate 4% + Metformin HCl

Could not formed films Produce irregular crystals

4 Ethyl cellulose 10% + Metformin HCl

Could not formed films Produce powder

Pectin + Metformin HCl HPMC + Metformin HCl

Alginate + Metformin

HCl

Ethylcellulose

+ Metformin HCl

Figure 2: Single polymer (pectin, alginate, HPMC and ethyl cellulose) can not form a film membranes with Metformin HCl

to the conformational changes. Hydrogels are also

classified as hydrogels responsive to changes in terms

of their interaction with the surrounding environment,

i.e., responses to the changes in pH, temperature, and

the composition of the surrounding liquid. Depending

on its structure, hydrogel can respond to

environmental changes by changing its size or shape

(Omidian and Kinam, 2012).

4.3 The Memran/Film Properties of

Pectin (two polymer combination)

That Contain Metformin HCl

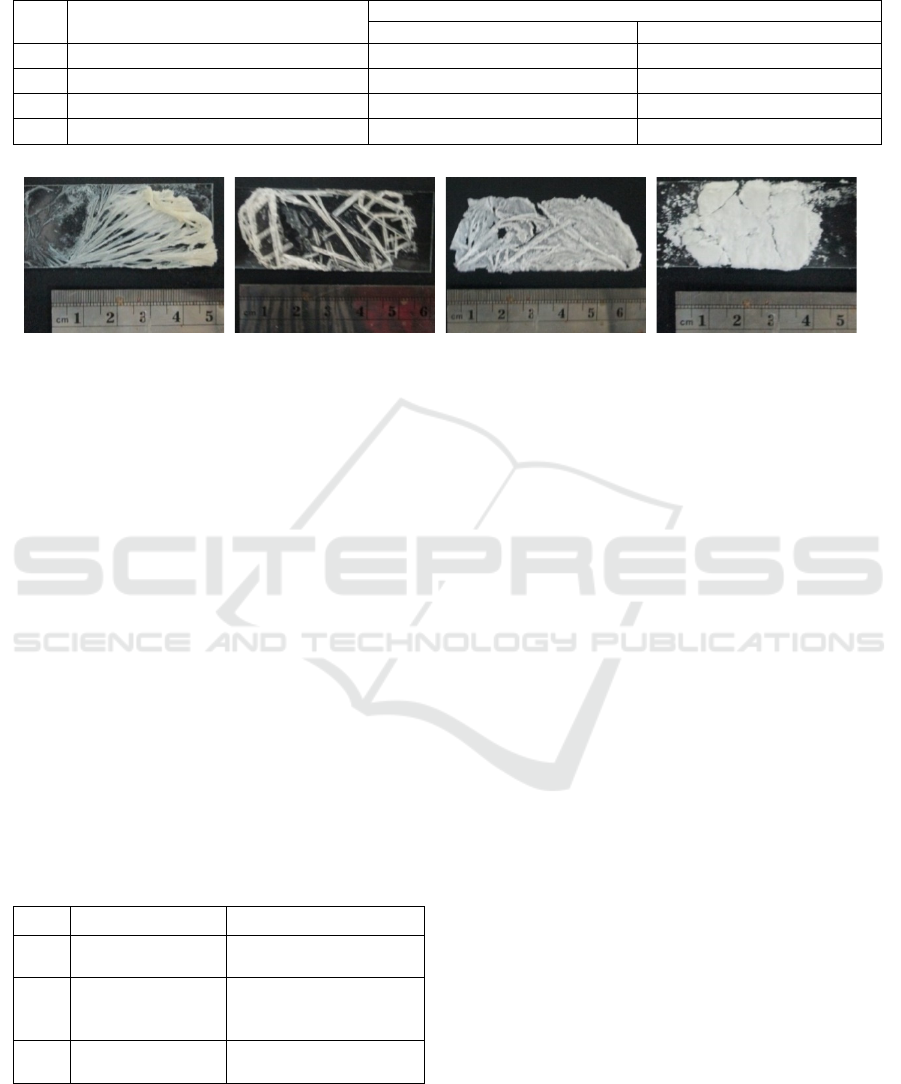

The membrane/film properties of pectin (two

polymer combination) that contain metformin HCl

shows the same results as a single polymer that can

not form a film, as in the Table 4 and Figure 3.

Table 4: The film membrane properties of polymer (two

polymer combination) containing Metformin HCl

No Polymer The result

1

Pectin + HPMC

+ Metformin HCl

Could not formed films

2

Pectin

+ Ethylcellulose

+ Metformin HCl

Could not formed films

3

Pectin + Alginate

+ Metformin HCl

Could not formed films

4.4. The Membrane/Film Properties of

Pectin (three polymer combination)

Containing Metformin HCl

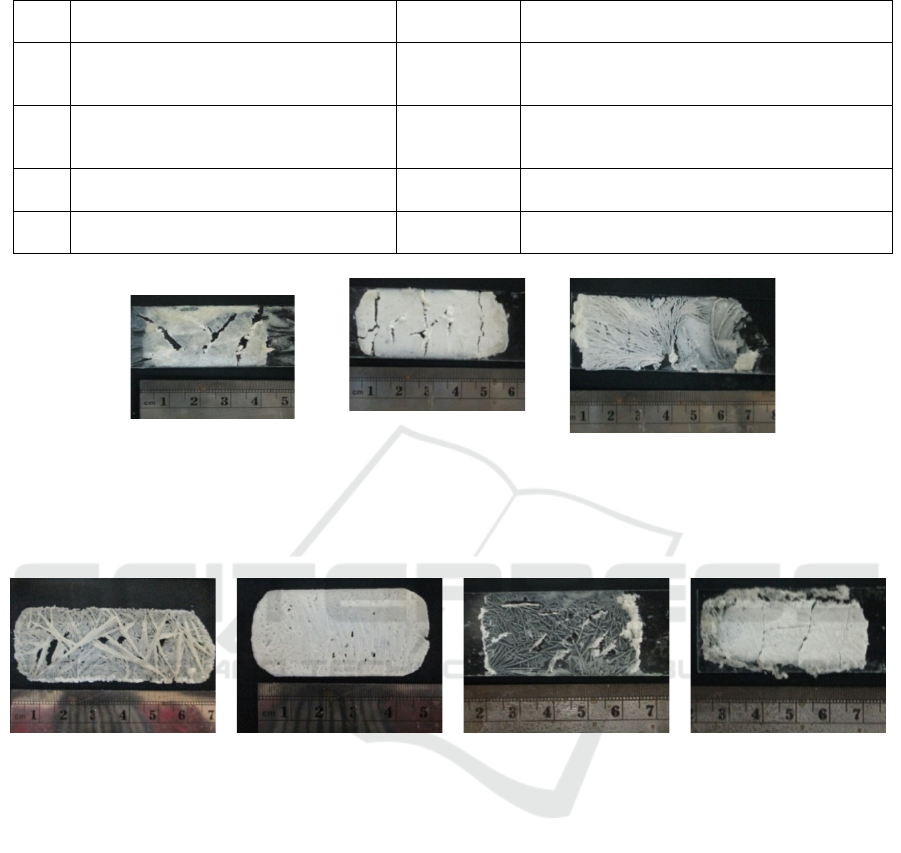

The properties of the pectin membranes/films (three

polymer combination) containing metformin HCl can

be seen in Table 5 and Figure 4, that the combination

of three polymers gives different results, some

formulas may form membranes/films and some other

can not. It will be dependent on combination of the

polymer from the formula.

The combination of pectin, alginate and

ethylcellulose polymer can form membran/film, but

combination with ethylcellulose powder provides

better membrane/film than mucilago ethyl cellulose,

which is obtained more smooth and flat surface

membrane, elastic, easily rolled and folded. It is

assumed that the ethyl cellulose powder as a

hydrophobic polymer covers/coats the metformin

HCl so it is not disturb the stability of the gel solution

of the hydrophilic pectin and alginate polymers and

capable to form a membrane/film.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

848

Table 5: The membrane film of polymer (three polymer combination) that contain metformin HCl

No Polymer

Thickness

(mm)

Properties of film

1

Pectin + Alginate + mucillage of ethyl

cellulose + Metformin HCl

0.96±0.02

Retrieved membranes/films with a rough surface

containing metformin HCl, uneven, and

p

erforated crystals

2

Pectin + Alginate + powder of ethyl

cellulose + Metformin HCl

0.71±0.04

Retrieved membranes /films with a smoother

and flat surface, elastic, easily rolled and folde

d

3

Pectin + Alginate + HPMC + Metformin

HCl

- Could not formed films

4

Pectin + HPMC + Ethyl cellulose

+ Metformin HCl

- Could not formed films

Figure 3: Polymers of pectin, alginate, HPMC and ethyl cellulose (two polymers combination) can not form film membranes

with Metformin HCl

Pectin + Alginate

+ mucillage of Ethyl

cellulose + Metformin HCl

Pectin + Alginate

+ powder of Ethyl cellulose

+MetforminHCl

Pectin + Alginate

+ HPMC + Metformin HCl

Pectin + HPMC

+ Ethylcellulose

+ Metformin HCl

Figure 4: Polymers of pectin, alginate, HPMC and ethyl cellulose (three polymer combination) containing Metformin HCl:

only a combination of pectin + alginate and powder of Ethyl cellulose are capable of forming a good film.

4.5 The Membrane/Film Properties of

Pectin (three polymer combination)

with the Addition of CaCl

2

Containing Metformin HCl

Interestingly, the addition of crosslinkers (CaCl

2

) to a

combination of polymers containing metformin HCl

is a combination of the polymer pectin, alginate and

HPMC in the previous data can not form

membrane/film, but the addition of CaCl

2

showed

different results, it is capable to form a thin films,

elastic, easily rolled and folded, as shown in Table 6

and Figure 5. It can be explained that one of the

properties of sodium alginate is having the ability to

form a gel by addition of a calcium salts and caused

by the occurrence of chelating between the L-

guluronic of alginate chains with calcium ions. This

gel is a cross link network composed of the calcium

alginate forming egg box conformation (

Morris,,

1978)

.

5 CONCLUSIONS

A single and combination of the polymers containing

metformin hydrochloride could not formed films. The

combination of pektin, alginat, and ethylcellulose

pectin and the addition of crosslinker (CaCl

2

) in

Pectin + HPMC

+ Metformin HCl

Pectin + Ethylcellulose

+ Metformin HCl

Pectin + Alginate +

Metformin HCl

Optimization of Polymer and Cross-linker Combination on the Formation of Pectin Film Containing Metformin Hydrochloride

849

pectin alginate and HPMC polymer combination

capable to form an optimum membrane/film and

potential for drug delivery system.

ACKNOWLEDMENTS

This research is funded by Universitas Sumatera

Utara in accordance with the contract of TALENTA

research implementation of Universitas Sumatera

Utara for 2018 No: 2590 / UN.5.1.R / PPM / 2018

dated 16

th

March 2018.

Table 6: The membrane/film of pectin (three polymer combination) with the addition of CaCl

2

containing Metformin HCl

No Polyme

r

Thickness (mm) Properties of film

1

Pectin + Alginate + CaCl

2

1% +

metformin HCl

- Could not formed films

2

Pectin+ Alginate + CaCl

2

2% +

metformin HCl

- Could not formed films

3

Pectin+ Alginate + CaCl

2

3%

metformin HC

- Could not formed films

4

Pectin + Alginate + Ethyl cellulose

+ CaCl2 1 % Metformin HCl

1.32 ±0.03

Retrieved thin, rigid, non-rolled and folded film

membranes.

5

Pectin+Alginate + HPMC+ CaCl

2

1% + Metformin HCl

0.87±0.03

Retrieved thin, elastic, transparent, irregularly

shaped, easily rolled or folded film membranes.

Pectin + Alginate

+ CaCl

2

1%

+ metformin HCl

Pectin + Alginate

+ CaCl

2

2%

+ metformin HCl

Pectin + Alginate + CaCl

2

3% + metformin HCl

Pectin + Alginate Pectin + Alginate + HPMC

+ Ethyl cellulose + CaCl

2

1%

+ CaCl

2

1% + metformin HCl + metformin HCl

Figure 5: Pectin Membrane Film (three polymers combination) with addition (CaCl

2

) Containing Metformin HCl:

combination of pectin + alginate + powder of Ethyl cellulose and combination of pectin + alginate + HPMC capable to form

a film membrane.

REFERENCES

Mariadi, Bangun, H., and Karsono, 2015. Formulation and

In Vitro Evaluation of Gastroretentive Drug Delivery

System of Antacids Using Alginate-Chitosan Films.

International Journal of Pharm Tech Research. Vol.8,

No.9, pp 01-12.

Mishra, R.K., Banthia, A.K., Majeed, A.B.A., 2012. Pectin

Based Formulations for Biomedical Applications: A

Review, Asian Journal of Pharmaceutical and Clinical

Research. Volume 5, 1-7.

Mishra, R.K., Datt M., Banthia, AK., 2008. Synthesis and

characterization of pectin/PVP hydrogel membranes for

drug delivery system. AAPS PharmSciTech 9(2):395–

403.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

850

Morris, E.R., Rees, D.A., and Thom, D., 1978. Chiroptical

and Stoichiometry Evidence of a Specific Primary

Dimerisation in Alginat Gelation. Carbohydrate

Research. 11(2): 272-277.

Munjeri O., Collett J.H., Fell J.T., 1997. Hydrogel beads

based on amidated pectins for colon-specific drug

delivery: the role of chitosan in modifying drug release.

J Control Release. 46 (3):273–278.

Omidian, H and Kinam P., 2012. Hydrogels. In: Siepmann,

J., Ronald, A., Michael J (Editors), Fundamentals and

Applications of Controlled Release Drug Delivery.

Springer New York Dordrecht Heidelberg. London. P.

76-78.

Sadeghi, M., 2011. Pectin-Based Biodegradable Hydrogels

with Potential Biomedical Application as Drug

Delivery System. Biomaterials and

Nanobiotechnology, 2, 36-40.

Sutar, P.B., 2008. Development of pH sensitive

polyacrylamide grafted pectin hydrogel for controlled

drug delivery system. J Mater Sci Mater Med

19(6):2247–2253.

Yan, X.L., Khor, E., Lim, L-Y., 2001. Chitosan-Alginate

Films Prepared With Chitosan Of Different Molecular

Weights. Journal of Biomedical Materials Research:

Applied Biomaterials. (4): 358-365.

Optimization of Polymer and Cross-linker Combination on the Formation of Pectin Film Containing Metformin Hydrochloride

851