Synthesis and Characterization of Carboxymethyl Cellulose using

Solvents Variations

Sri Yuliasmi

1

, Henny Sri Wahyuni

1

, Hanifah Siti Aisyah

1

and Devi Riati

1

1

Department of Pharmaceutical Chemistry, Faculty of Pharmacy, Universitas Sumatera Utara, Medan, Indonesia

Sriyuliasmi@usu. ac.id , henny@usu. ac.id

Keywords: Carboxymethyl cellulose, degree of substitution, organic solvent.

Abstract: Carboxymethyl cellulose (CMC) is a cellulose derivative which is widely used in pharmaceutical and non-

pharmaceutical industries. One of the important parameters in CMC synthesis is the variation of solvent

medium. Solvents can affect the quality of CMC. The present study was conducted to synthesize and

characterize of CMC with the best organic solvent mixture. CMC was obtained from microcrystalline

cellulose by three stages, including alkalization between cellulose and sodium hydroxide with solvent;

carboxymethylation using sodium monochloroacetate; neutralization and purification using glacial acetic

acid-methanol. The solvent medium used were isopropanol-n butanol; benzene-ethanol-air; isopropanol-

benzene; isopropanol-ethanol-air, and isopropanol-isobutanol by each variety of comparisons. CMC was

characterized by Infrared Spectrophotometry. Degree of substitution and organoleptic test were then

determined. The optimum condition of CMC synthesis which provided highest degree of substitution of 0.9

was found on isopropanol-ethanol solvents in ratio of 50:50. Organoleptic test showed that CMC powdered

was colourless, rough, odorless and tasteless. Infrared analysis revealed the presence of carboxyl and ether

functional groups in the 1600-1000 cm

-1

region. It can be concluded that CMC has been succesfully

synthesized using isopropanol-ethanol as the best solvent.

1 INTRODUCTION

One of cellulose derivatives that the most widely

used is CMC. Many industries such as food,

pharmaceutical, detergent, textile, cosmetic, and

ceramic industries have used CMC as excipient

(Koh, 2013). The study of Technavio London shows

that the needs of CMC in the world will increase

rapidly by 5% in 2017-2021 (Maida, 2017).

The increasing variety of CMC usage encourages

the production of good quality CMC synthesis.

CMC synthesis involves the conversion of cellulose

into alkaline cellulose which then hydroxyl groups

of cellulose are substituted by carboxymethyl groups

by reacting them to sodium monchloracetate (Na-

MCA) (Heinze and Pfeiiffer, 1999).

The process of CMC synthesis consists of

several steps, namely alkalization,

carboximethylation, purification, and neutralization.

Alkalization and carboxymethylation reactions are

steps that determine the value of the DS. The

alkalization process aims to stretch the

intramolecular and intermolecular hydrogen bonds

of cellulose so easily substituted into carboxymethyl

groups using NaOH in a suitable solvent. The

number of substituted hydroxyl groups is called

degree of substitution (DS) (Cash and Caputo,

2010). The solvent is used should be inert. It

facilitates NaOH to penetrate well in reaction

cellulose. The addition of NaOH is important in

producing alkaline cellulose. The solvent also

provides in sodium mono chloro acetic acid

accessibility to AGU (anhydroglucose unit) cellulose

reaction that occurs during CMC synthesis

(Stigsson, 2006).

The quality of CMC can be obtained from

several parameters. DS is the main parameter in

determining quality of CMC, the DS value also

states the solubility of CMC in water. The maximum

degree of substitution for CMC is average value

between 0.4 to 1.5. The higher degree of substitution

of CMC, the easier solubility in water

(Aambjornsson, 2015).

DS values are influenced by several factors, one

of which is the type and composition of the solvent

medium in alkalization step. The purpose of this

research is conducted to synthesize and characterize

of CMC with the best organic solvent mixture

.

Yuliasmi, S., Wahyuni, H., Aisyah, H. and Riati, D.

Synthesis and Characterization of Carboxymethyl Cellulose using Solvents Variations.

DOI: 10.5220/0010093410151020

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1015-1020

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1015

2 METHODS

This research was conducted in two stages. First

stage includes synthesis carboxymethyl cellulose

using some solvents in different ratio. The second

stage includes characterization of the syntesized

carboxymethyl cellulose by Infra Red

Spectrophotometry, degree of substitution, and

organoleptic test.

2.1 Material

The materials used in the research were

microcrystalline cellulose, distilled water, sodium

hydroxide, sodium monochloroacetate (NaMCA),

isobutyl alcohol, N-butanol, isopropyl alcohol,

ethanol, methanol, benzene, glacial acetic acid.

2.2 Synthesis of Carboxymethyl

Cellulose

This procedures followed the method of Safitri

(2017) and Mulyatno (2017). 5 grams of cellulose

was added to 100 ml of isopropyl alcohol, and 20 ml

of NaOH while it was stirred in a temperature of

25°C for 1 hour. Then, added sodium chloroacetate

to the mixture. The mixture was then heated while

stirring at a temperature of 55

o

C for 3 hours.

Afterwards the mixture was filtered and the residue

soaked using 100 ml of methanol for 24 hours. The

mixture was neutralized using glacial acetic acid

solution and then filtered. The residue was dried in

an oven with a temperature of 60° C to a constant

weight. The formula of CMC synthesis can be seen

on Table 1.

Table 1: Design of formula synthesis of CMC.

Formula Solvents NaOH NaMCA

Isopropanol: N-

Butanol

10% 4 grams

F1 80:20

F2 50.50

F3 30:70

Benzene:Ethanol:Wat

er

F4 70:20:10

F5 50:30:20

F6 50:50:0

Benzene:Isopropanol

F7 30:70

F8 50:50

F9 70:30

Isopropanol:Isobutano

l

F10 70:30

F11 50:50

F12 30:70

Isopropanol:Ethanol:

Water

F13 70:20:10

F14 50:50:0

2.3 Characterization of Carboxymehyl

Cellulose

2.3.1 The Organoleptic Properties Test

It included colour, taste, texture and odor.

2.3.2 Degree of Substitution Determination

(DS)

Relative values of degree of substitution of carboxyl

group in CMC could be analysed by IR spectra. By

comparing absorbance of carboxyl group stretching

vibration and methine stretching vibration (Rrel

=A

1605

/A

2920

), we could evaluate the relative amount

of carboxyl group in the sample. DSrel was

calculated by the following equation (Singh and

Khatri, 2012):

DSrel = Rrel

(

CMC

)

– Rrel

(

cellulose

)

(1)

2.3.3 Infrared Spectrophotometry Analysis

All measurements were carried out using the KBr

method. The samples were dried in an oven at 60◦C.

Sample and KBr were mixed (1:100) then ground

until homogenous. Afterwards the mixture was

compressed to a form a transparent disk. The

infrared spectra of these samples were recorded with

a FT-IR Shimadzu Spectrophotometer between 400

and 4000 cm

−1

.

3 RESULT AND DICUSSION

Synthesis of CMC was began by suspending the

cellulose in a solvent using a mechanical stirrer at

room temperature. The effect of solvent which is

related to the ability of the reaction to dissolve the

etherifying agents (NaMCA) and swell the cellulose

to improve the accessibility NaMCA into cellulose

structure. The right solvent ratio will increase the

substitution of reaction, and if the ratio is not

appropriate the reaction will be inhibited (Ismail,

2010).

The next process was carboxymethylation

namely the addition of sodium monochloroacetic

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1016

(ClCH

2

COONa) with stirring for 3 hours at a

temperature of 55ºC. Resulting by products such as

sodium glycolate and sodium chloride at this stage.

Separating CMC from the side product with added

methanol and mixed. Neutralization of product was

conducted because the reaction process running on

alkaline conditions used acetic acid. CMC had been

cleaned and then dried using an oven at a

temperature of 60ºC (Musfiroh, 2013).

The influence of the type of solvent can be

explained in terms of polarity and stereochemistry.

Based on these properties, it is known that the

smaller the value of the polarity of the

solvent/reaction medium would increase the

effectiveness carboxymethylation (etherification)

and a smaller polarity solvent would also help keep

the cellulose molecules were less decomposed by

alkali. The formation of this layer makes the amount

of NaOH were distributed in the cellulose phase

enough to turn cellulose into cellulose-defined

shapes (Stigsson, 2006) (Pitaloka, 2017).

In other words, the polarity of the smaller

reaction medium would help the formation of alkali

cellulose with a uniform distribution. This uniform

distribution can be achieved because of low

solubility in the alkaline solution non-polar system

so that the hydroxyl group (OH) is not reactive with

the Na+. Decreased reactivity of hydroxyl groups

followed by a longer carbon chain (C) in alcohol.

Larger methyl group can make the low reactivity of

hydroxyl groups (Zhang, 1993). Polarity index of

some organic solvent is showed on Table 2.

Table 2: Data polarity index from some solvent.

Solvent Polarity Index

benzene 2.7

isopropanol 3.9

N-butanol 4

isobutanol 4

ethanol 5.2

water 9

3.1 The Organoleptic Properties

The results of the organoleptic synthesized CMC is

show in Table 3. Table 3 shows that synthesized

CMC has organoleptic with color is ivory, rough

powder, odorless, and tasteless. Overall the

synthesized CMC had similar organoleptic

caracteritics except F6 until F9. From the table it can

be seen that CMC produced using a solvent mixture

of benzene has organoleptic with lump hard and

colors are yellow to brown whereas the synthesized

CMC using a solvent mixture of water has a white

color and the form of a fine powder.

Table 3: The organoleptic properties of synthesized CMC.

Formula

Organoleptic

Colour Texture Odor Taste

F1 Ivory

Rough

powder

No No

F2 Wheat

Rough

powder

No No

F3 Ivory

Rough

powder

No No

F4 White

Fine

powder

No No

F5 White

Fine

powder

No No

F6 Ivory

Lump

hard

No No

F7 Burlywood

Lump

hard

No No

F8 Ivory

Lump

hard

No No

F9 Burlywood

Lump

hard

No No

F10 Ivory

Rough

powder

No No

F11 Ivory

Rough

powder

No No

F12 Ivory

Rough

powder

No No

F13 White

Rough

powder

No No

F14 Ivory

Rough

powder

No No

3.2 Degree of Substitution Analysis

(DS)

The maximum degree of substitution for CMC is 3

with an average value between 0.4 to 1.5. The higher

degree of substitution of CMC, the more increase

solubility in water (Aambjornsson, 2015). The

results of DS analysis of CMC which have been

synthesized are shown in Table 4.

As it is known, using a mixed of solvents in

various composition ratio could affect the value of

DS. From the table 4 below, it can be seen that CMC

were synthesized using isopropanol solvent mixture

has a higher DS compared to using a solvent mixture

of benzene. It can be explained by the increasing

composition of the solvent mixture of isopropanol,

the rising of the polarity of a solution (Kalem and

Johangir, 2007; Pitaloka, 2017).

Synthesis and Characterization of Carboxymethyl Cellulose using Solvents Variations

1017

Table 4: Degree of Substitution of CMC.

Formula Solvents DS

Isopropanol: N-Butanol

F1 80:20

0.523

F2 50.50

0.522

F3 30:70

0.561

Benzene:Ethanol:Water

F4 70:20:10

0.412

F5 50:30:20

0.382

F6 50:50:0

0.751

Benzene:Isopropanol

F7 30:70

0.694

F8 50:50

0.628

F9 70:30

0.623

Isopropanol:Isobutanol

F10 70:30

0.797

F11 50:50

0.890

F12 30:70

0.757

Isopropanol:Ethanol: Water

F13 70:20:10

0.887

F14 50:50:0

0.906

Microcrystalline cellulose was used as the main

ingredient of CMC manufacture had polar

properties, wherein the cellulose will be easier to

expand with more polar solvents. In addition, the use

of isopropanol during synthesis CMC was known to

produce fewer side reactions such as sodium

glycolate (Im, 2018).

Based on Table 2, the polarity index of water

was higher than ethanol, but the value of DS

decreased with increasing the ratio of water used in

the solvent mixture. This is due to the small

molecular weight of water, while the

microcrystalline cellulose has a large molecular

weight. So that cellulose can not mix with the water

because of differences in molecular weight which

quite large

.

At high water content also maked the cellulose

was more decomposed by alkali and could damage

the destruction of the cellulose crystal structure,

which inhibits the diffusion of small reagent

molecules into it. It caused more NaOH

and NaMCA were remained in the solvent. In

addition, the CMC product thus obtained had fewer

degree of substitution and could be easily

decomposed by alkali. The solvent with high water

content were more polar than low moisture

content. These factors lead to more side reactions,

thus decreasing the availability of NaMCA and

the degree of substitution for CMC (Zhang,

1993). This applies also to the mixture of

isopropanol mixed solvents or benzene mixed

solvents having a lower DS value compared to a

mixture of waterless solvents.

The synthesized CMC using a solvent mixture of

isobutanol obtained a higher DS value than using a

solvent mixture of n-butanol. Although the polarity

index value of isobutanol and n-butanol is the same,

but the solvent mixture is influenced by the

composition of its chemical structure.

In this study, using a solvent with a mixture of

benzene and isopropanol was obtained a higher DS

value compared with a mixture of benzene and

ethanol. This shows that the solvent mixture has a

high polarity index difference will cause a decrease

in the value of DS. According to Zhao (2003)

benzene would adjust the polarity of the solvent

system. The lower polarity was achieved by

increased the percentage of benzene, which tends to

decreased solvent accessibility and NaOH to the

cellulose chain. The CMC structure showed the

crystal structure of the CMC synthesized with

benzene completely destroyed and the CMC chain is

cleary expands by the solvent.

Of the various types and compositions of solvent

were used in this study, the maximum DS value was

obtained on Isopropanol: Ethanol solvents (50:50),

by 0.9. Increased accessibility of solvents and

etherification reactants into the cellulose can

increase of the rate of reaction, thereby increasing

the DS and viscosity of the CMC solution.

When the solvent contains high levels of

alcohols, cellulose will be more easily alkalized. The

alkalized cellulose possesses less crystalline

aggregation. This causes the reaction to be faster and

to result a higher DS value. The molecular weight of

the product has a relationship to alcohol content as

well as to the other caracteristics (Zhang, et, al,

1993).

On the other hand, the microcrystalline cellulose

has a smaller particle size so it has a large surface

area. This will affect cellulose swelling in the

solvent, which will affect the quality of the CMC

produced.

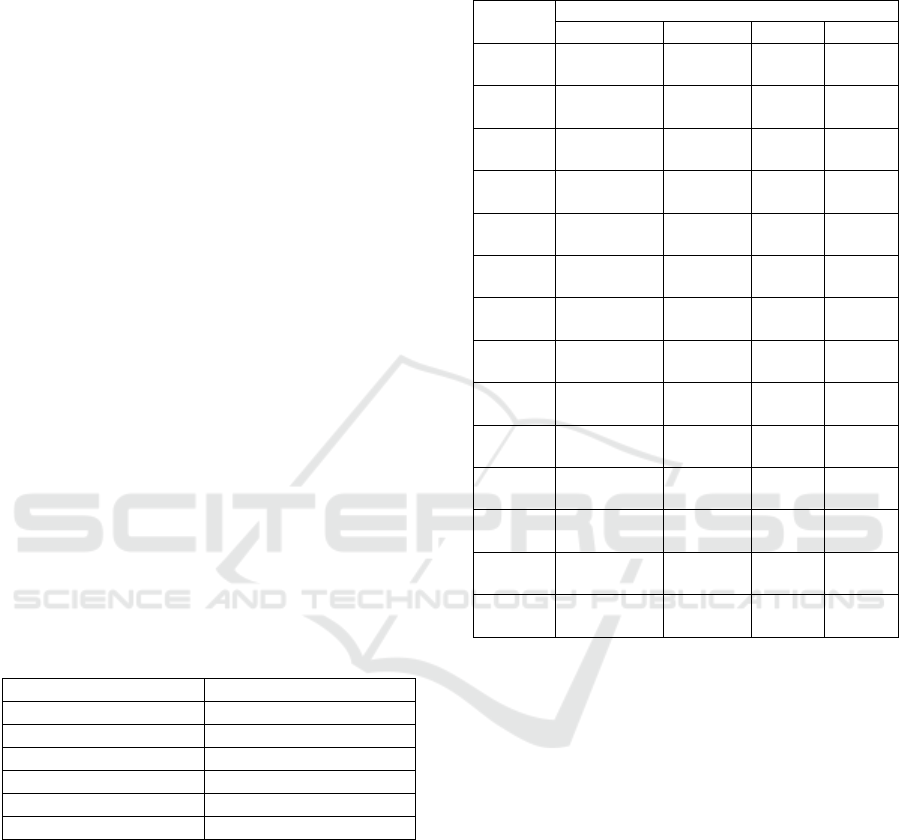

3.3 Analysis of FTIR

FTIR analysis is carried out by comparing the

commercial microcrystalline cellulose and CMC

which can be seen in Figure 1. From the figure can

be seen the differences between the spectrum of

microcrystalline cellulose and carboxymethyl

cellulose. In the area of wave number 3000 – 2850

cm

-1

and 1200-1000 cm

-1

, a commercial CMC had a

slighter spectra than microcrystalline cellulose.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1018

Figure 1: IR spectrum between CMC commercial and

microcrystal cellulose.

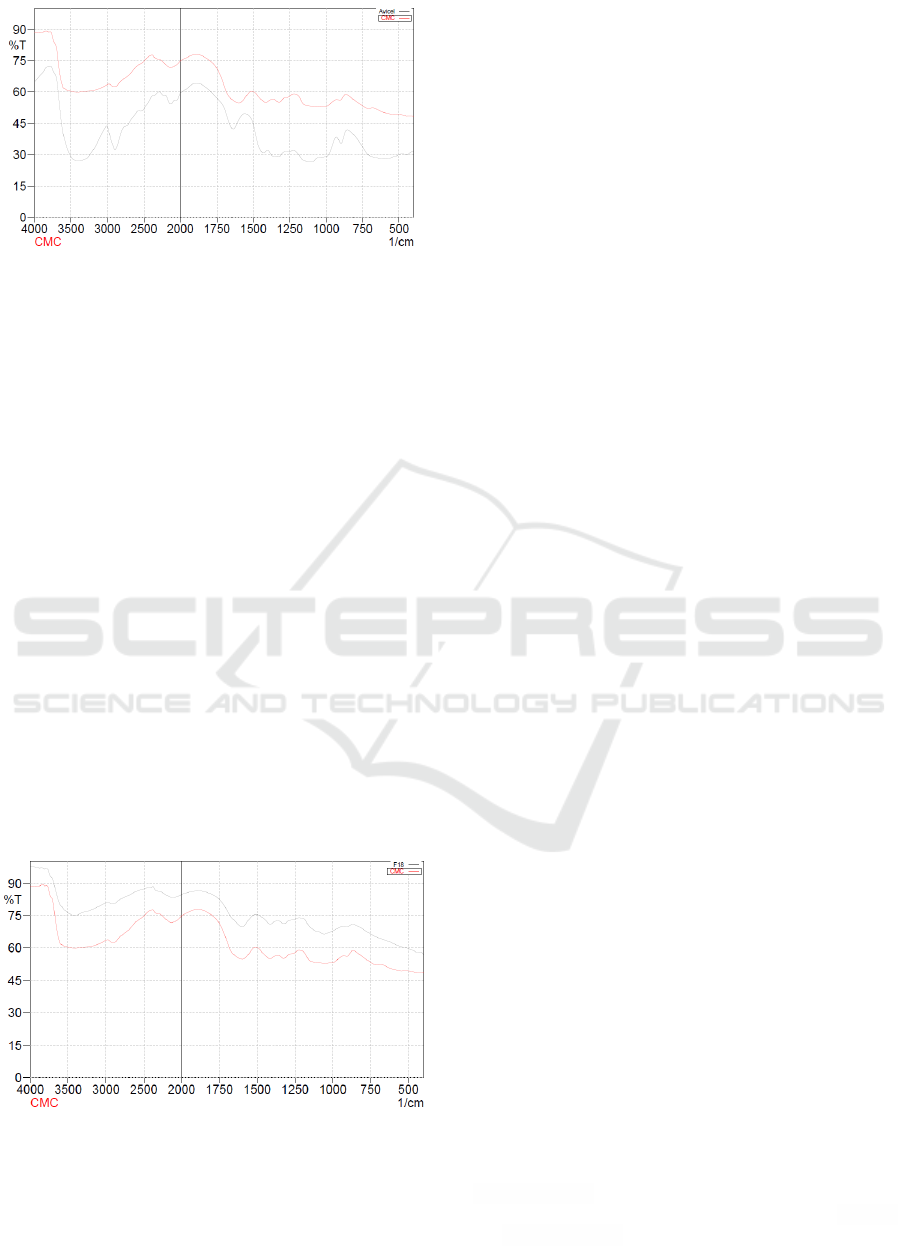

In addition, FTIR analysis of synthesized CMC

which had a maximum DS value with solvent

Isopropanol: Ethanol (50:50) is shown in Figure 2. It

indicated some point absorption at 1600.92 cm

-1

and

1415.75 cm

-1

. The highlights of the spectrum at a

wave number of 1600.92 cm

-1

with strong

absorption indicates the presence of carbonyl group

(COO), and at 1415.75 cm

-1

indicates methyl (-CH

2

).

It demonstrated a carboxymethyl had been

substituted in structure of the synthesized Na-CMC.

Carboxyl group as salt structures had a range of

waves ranging between 1600-1640 cm

-1

to 1400 to

1450 cm

-1

.

Furthermore, based on the analysis of FTIR of

synthesized CMC were obtained the stretching

vibration in some wave numbers, namely at 3421.72

cm

-1

indicated the -OH group, 2893.22 cm

-1

to

2927.94 cm

-1

showed -CH aliphatic. Figure 2

illustrated the comparison of the infrared spectrum

of commercial CMC and synthesized CMC. It

showed similar spectrum and functional groups in

both of them.

Figure 2: IR spectrum between commercial CMC and

synthesized CMC by Isopropanol: Ethanol (50:50)

4 CONCLUSIONS

Quality of the synthesized CMC is affected by the

solvent used. This study found that synthesis CMC

using mixed solvents content of water and solvent

with high polarity distinction would produce CMC

with a low degree of substitution values. In this

work, CMC was successfully synthesized using the

best solvent consisting of a mixture of Isopropanol:

Ethanol (50:50) with a DS value of 0.9 on the

addition of 10% NaOH at 55

o

C for 3 hours, and 4

grams NaMCA.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge that the present

research is supported by Universitas Sumatera Utara.

The support is under the research grant TALENTA

USU of Year 2018 Contract Number

2590/UN.5.1.R/PPM/2017 on 16

th

March 2018

REFERENCES

Aambjornsson, H., A., Schenzel, K., Germgard, U., 2015.

Carboxymethyl cellulose produced at different

mercerization condition and characterized by NIR FT

Raman spectroscopy in combination with multivariate

analytical methods. Bioresources. 8. 1918-1932.

Cash, M., J., Caputo, S., J., 2010. Cellulose derivatives. In

A Food stabilizer, thickener, and gelling agents.

Willey-Blackwell. United Kingdom. 94-115.

Heinze, T., Pfeiiffer, K., 1999. Studies on the synthesis

and characterization of carboxymethylcellulose. Die

Angewandte Makromolekulare Chemie. 266 (1), 37-

45.

Im, W., Lee, S., Abhari, A., R., Youn, H., J., Lee, H., L.,

2018. Optimization of carboxymethylation reaction as

a pretreatment for production of cellulose nanofibrils.

Cellulose. Springer Science+Business Media B V part

of Springer Nature.

Ismail, N., M., Bono, A., Valintinus, A., C., R., Nilus, S.,

Chng, L., M., 2010. Optimization of reaction condition

for preparing carboxymethyl cellulose. Journal of

Applied Sciences. 10 (21). 2530-2536.

Kamel, S., Jahangir, K., 2007. Optimization of

carboxymethylation of starch in organic solvent.

International Journal of Polymeric Materials. 56. 511-

519.

Koh, M., H., 2013. Preparation and characterization of

carboxymethyl cellulose from sugarcane

bagasse (Doctoral dissertation, UTAR).

Maida, J., 2017. Global Carboxymethyl Cellulose Market -

Drivers and Forecasts by Technavio (London:

Bussiness Wire).

Synthesis and Characterization of Carboxymethyl Cellulose using Solvents Variations

1019

Mulyatno, H., A., Pratama, O., I., Inayati, I., 2017.

Synthesis of carboxymethyl cellulose (CMC) from

banana tree stem: influence of ratio of cellulose with

sodium chloroacetate to properties of carboxymethyl

cellulose EQUILIBRIUM Journal of Chemical

Engineering. 16 (2).

Musfiroh, I., Hasanah, A., N., Budiman, I., 2013. The

Optimmization of sodium carboxymethyl cellulose

(NaCMC) synthesized from water hyacinth

(Eichhornia crassipes (Mart.) Solm) cellulose.

RJPBCS. 4. 1092-1099.

Pitaloka, A., B., Saputra, A., H., Nasikin, M., 2017. The

effect of isopropyl alcohol-2-butanol mixed solvent on

degree of substitution of carboxymethl cellulose from

water hyacinth (Eichhornia crassipes) cellulose.

International Journal of Applied Engineering

Research. 12 (22). 12546-12553.

Safitri, D., Rahim, E., A., Prismawiryanti, P., Sikanna, R.,

2017. Synthesis of carboxymethyl cellulose (CMC) of

durian peel (Durio zibethinus) cellulose. KOVALEN.

3. 58-68.

Singh, R., K., Khatri, O., P., 2012. A scanning

electronmicrocope based new method for determining

degree of subttution of sodium carboxymethy

cellulose. Journal of Microscopy. 246 (1). 43–52

Stigsson, V., Kloow, G., Germga, U., 2006. The influence

of the solvent system used duringmanufacturing of

CMC. Cellulose. 13 (6). 705 -712.

Zhang, J., Li, D., Hong, X., Yu, Z., Shi, Q., 1993. Solvent

effect on carboxymethylation of cellulose. Journal of

Applied Polymer Science 49. 741-746.

Zhao, H., Cheng, F., Li, G., Zhang, J., 2003. Optimization

of a process for carboxymethyl cellulose (CMC)

preparation in mixed solvents. International Journal of

Polymeric Materials. 52. 749-759.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1020