Inulin Extraction and Characterisation of Fresh and Chip Gembili

(Dioscorea Esculenta) Extract by Ultrasound-assisted Extraction

A Hilman

1

*, E. Harmayani

2

, M. N. Cahyanto

2

1

Postgraduate Program of Food Science and Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada,

Sleman 55281, Yogyakarta, Indonesia

2

Department of Food and Agricultural Products Technology, Faculty of Agricultural Technology, Universitas Gadjah

Mada, Sleman 55281, Yogyakarta, Indonesia

Keywords: Inulin, prebiotic, fresh gembili, chip gembili, ultrasound-assisted extraction.

Abstract: Inulin has the prebiotic component to improve health and reduce the risk of digestive tract disorders.

Gembili (Dioscorea esculenta) is one of inulin source found in Indonesia. Fresh Gembili has a relatively

short shelf-life so it needs to be drying into chips. Inulin extraction was the factor that can affect the

characteristics of gembili extract. The aim of this research was to determine the effect of ultrasound-assisted

extraction on the inulin extraction stage to the yield and the characteristics of fresh and chip gembili extract.

The study was conducted in two stages: (1) inulin extraction from fresh and chip gembili with ultrasound-

assisted extraction and compared by non-ultrasound extraction; (2) characterisation of physical and

chemical properties. The results showed that inulin extraction by ultrasound-assisted extraction was not

different significantly to the yield (30.78%-32.47%); degree of white (92.18-93.69); pH (6.55) and

solubility at 25

o

C (11.26%-12.75%), 60

o

C (22.50%-25.97%), 90

o

C (36.34%-37.71%) compared by non-

ultrasound extraction. Gembili extract from fresh and chip gembili by ultrasound-assisted extraction have

inulin content was about 10.00%-21.13%; inulin purity was about 61.57-119.22 mg/kg; and viscosity

becomes smaller as the temperature increases. It could be concluded that inulin can be extracted from fresh

and chip gembili.

1 INTRODUCTION

Inulin is a prebiotic component consisting of a D-

Fructose unit monomer connected by a β-(2→1)

bond and has a D-Glucose terminal group connected

to an α-(1→2) bond. The arrangement of fructose

monomers makes inulin cannot be hydrolyzed in the

digestive system. However, inulin can be fermented

by microbiota in the digestive tract in the colon by

Bifidobacterium and Lactobacillus (Li et al., 2015).

The results of inulin fermentation in the digestive

system are short-chain fatty acids that can be used

by cells to stimulate the growth of intestinal mucosal

cells and become the main source of cell energy

(Pompei et al., 2008). In addition, the results of

inulin fermentation have immunomodulatory effects

and increase the mineral absorption (Dominguez et

al., 2014; Panchev et al., 2011). The food industry

has been using inulin in various applications in

various products today.

This sparked a great deal of research and

publication about the production of inulin from

different types of plants (Roberfroid, 2005). Inulin

has been commercially produced from chicory root

(Chicorium intybus) and Jerusalem artichoke tubers

(Helianthus tuberosus) in some western countries

such as America, England and some European

countries.

According to the research that has investigated

by Winarti et al. (2011) and also Zubaidah and

Akhadiana (2013) reported that one of the major

sources of inulin in Indonesia can be found in plants

such as gembili (Dioscorea esculenta) tuber. Winarti

et al. (2011) reported that the content of inulin in

fresh gembili was 14.77% (db). While Ciptaningrum

(2015) reported that the inulin extraction method of

gembili chip with water addition ratio resulted in a

yield of 36.40% (db) with an inulin content of

21.64%.

According to previous study, gembili has the

potential to serve as a raw material on inulin

extraction. However, gembili has a relatively long

Hilman, A., Har mayani, E. and Cahyanto, M.

Inulin Extraction and Characterisation of Fresh and Chip Gembili (Dioscorea esculenta) Extract by Ultrasound-assisted Extraction.

DOI: 10.5220/0010084000470053

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

47-53

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

47

harvest time of about seven to nine months. In

addition, the gembili that is kept in fresh condition

only has a relatively short shelf-life of about 10 to

14 days in room temperature (Kasno, Saleh and

Ginting, 2006). These problems can be solved by

giving preliminary treatment at fresh gembili

processed into the chip. Only a few studies have

studied the extraction of inulin from the materials of

the chip, among others, from the Jerusalem artichoke

chip (Saengthongpinit, 2005; Bekers et al., 2008)

and Cichorium intybus L dried (Park, de Oliveira,

Brod, 2006). Current research has studied the

extraction of inulin from raw materials in the form

of gembili chip (Ciptaningrum, 2015).

Arumdinari (2015) reported that the inulin

extraction method performed was the development

of the method Gupta, Kaur and Kaur (2003) which

used the principle of extraction by heating in boiling

water (90

o

C) for 20 min, filtrate freezing process for

24 h, inulin precipitation with ethanol 20% and

drying used by cabinet drying in overnight at 50

o

C.

The study obtained in inulin yield of 43.39% (db)

and inulin content of 28.89%.

Therefore, research is needed to improve the

inulin yield of the gembili on an industrial scale. The

ultrasound-assisted extraction is used as a new

method capable of extracting inulin from various

plant tissues. The aim of this study was to determine

the effect of ultrasound-assisted extraction on the

stage of inulin extraction to the yield and the

characteristics of fresh and chip gembili extract.

2

MATERIALS AND METHOD

The research was conducted in two stages: 1) inulin

extraction from fresh and chip gembili by

ultrasound-assisted extraction and compared by non-

ultrasound extraction and 2) characterization of

physical and chemical properties.

2.1

Materials

The research material was harvested from fresh

gembili tubers obtained from Watubonang Village,

Tawangsari District, Sukoharjo Regency, Central

Java Province. Gembili chip was a fresh gembili that

has been sliced thin chip-shaped and dried at 50

o

C in

cabinet drying for 12 hours. Another materials used

are inulin (C6H10O5)n standard produced by Sigma

Aldrich and fructooligosaccharides for inulin purity

analysis using HPLC (High Liquid Performance

Chromatography).

2.2

Instruments

The research instruments used were waterbath

shaker, HPLC Shimadzu, chromameter CR-400

(Konica Minolta), viscosity Brookfield LVDV-II+P,

column ion-exclusion Aminex HPX-87H 150X7.8

mm ID (BioRad, Watford, Herts), freeze drying,

centrifuge, sonicator bath.

2.3

Statistical Analysis

The research method was conducted by Complete

Randomize Experimental Design. The treatment

factor was the type of material consist of 1) fresh

gembili with non-ultrasound extraction (G1) and by

ultrasound-assisted extraction (G2); 2) chip gembili

with non-ultrasound extraction (G3) and by

ultrasound-assisted extraction (G4). Each treatment

was repeated 3 times to minimize experimental

error. The analysis was performed by analysis of

variance (ANOVA) and followed by Duncan's test

with a significance level of 5%. Statistical data is

calculated by SPSS 17.0 software.

2.4

Inulin Extraction

Inulin extraction from fresh and chips gembili in this

study used the method by Arumdinari (2015) with

modification. Fresh gembili cleaned, peeled and

mixed in 800 ml of hot water (80

o

C). Gembili

crushed with blender for 3 min to get the puree. The

puree was extracted used ultrasound-assisted in a

sonicator bath for 5 min. As a comparison, the other

puree was extracted used the treatment non-

ultrasound extraction. Both of the puree were

extracted used hot water extraction on waterbath

shaker at 80

o

C for 60 min at 80 rpm. The hot puree

was filtered with four layers of cotton to get the

filtrate. The filtrate was added to 1000 ml of hot

water (80

o

C) and reheated by the same method. In

the third stage of heating, the filtrate was added 500

ml of ethanol 96% and reheated on a waterbath

shaker at 80°C for 60 min at 80 rpm. The filtrate was

then frozen at -20°C for 24 h. The frozen filtrate was

thawed for 12 h and centrifuged at 1500 rpm for 15

min to obtain the natan. The supernatant section is

separated from natan as it contains the impurities

component. White natan is taken and washed with

ethanol 20% and centrifuged again (Kaur and Gupta,

2015). Furthermore, natan was washed by used

aquades as a neutralizer. Natan was dried in freeze

drying at -87

o

C for 48 h. (The same experiment was

also done for the material of gembili chip).

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

48

2.5

Calculation of the Yield

The yield is the ratio between the weight of the dried

gembili extract (a) and the weight of the gembili

material (b). The yield can be used to determine the

depreciation or addition of weight after processing.

2.6

Analysis of Moisture Content

The sample of 1-2 g was inserted into an aluminum

foil plate that has been dried in an oven at 105°C. It

was known to be constant to weight (a). The sample

dried at 105°C for 3-5 h and cooled in a desiccator,

then weighed. Heated again in the oven for 30 min,

chilled and weighed. This treatment was repeated

until it reaches a constant (b).

𝑎𝑏

𝑎

100%

(1)

2.7

Analysis of Inulin Content (Li et al.,

2015)

Inulin content can be calculated by differences

between the difference in total sugar content used by

phenol-sulfuric acid and inulin as standard (Dubois

et al., 1956) with reducing sugar content used by the

method of 3,5-dinitrosalicylic acid (DNS) and D-

fructose as standard (Miller, 1959).

2.8

Analysis of Solubility (Jiang et al.,

2013)

Solubility assay was performed by heating 50 ml

inulin solution 1% w/v (S). The solution put into the

water at 25°C, 60°C and 90°C and stirred for 15 min.

The solubility time was calculated used the

stopwatch until all dissolves. The solution filtered by

a filter paper that has been known the weight (K1).

The solution left in the filter paper dried at 105°C for

3 h and weighed (K2).

𝑆𝑇𝑆𝑆

𝐾2𝐾1

𝑆𝑇𝑆𝑆

100%

(2)

2.9

Analysis of Viscosity

Prepared fresh and chip of gembili extract solution

of 10% with aquades and heated while stirring to a

temperature at 100°C. The viscosity was measured

used by Brookfield LVDV-II+P viscosimeter.

Spindles were used adjusted to the viscosity of

solution. The analysis began with temperatures of

90°C, 80°C, 70°C, 60°C, 50°C, 40°C and 30°C. The

results were compared with inulin standard solution.

2.10

Analysis of White Degree (Takeuchi

and Nagashima, 2011)

Coordinate of L* a* b* is measured by chromameter

CR-400 (Konica Minolta) with visual angle 20. The

color parameters were expressed as follows:

brightness (L*), redness (a*) and yellowish (b*).

The lowest value of L* was 0 which indicate by

blackness and the highest was 100 indicate by white.

a* negative value indicate by green and positive

showed by red. While the negative b* value showed

by blue and positive colors indicate by yellow.

100

100𝐿

𝑎

𝑏

(3)

2.11

Analysis of Inulin Purity

(Retnaningtyas, 2012)

The inulin purity test was measured used by HPLC

with Aminex Ion-Exclusion HPX-87C (250mm x

4mm) column, 410 model water refractive detector

and LCHE Waters model M-45 pump. Aquades

water were used as a mobile phase with a speed of

0.5 ml/min, injection volume 20 μl. The column

temperature was set at 60°C and detector at 40°C.

The inulin standard was used by inulin (C6H10O5)n

obtained from Sigma Aldrich.

2.12

Measurement of pH

The pH measurement was performed by dissolving

the sample with a concentration of 10% (w/v). The

pH measurement analysis aims to determine the

condition of substrate acidity in the dissolved

sample. The pH Measurement was made in

triplicate. The pH measurement was performed used

by pH-meters.

3

RESULTS AND DISCUSSION

3.1

Yield

The average yield of fresh and chip gembili extract

by ultrasound-assisted extraction were 32.47% and

30.78% respectively. The ultrasound-assisted

extraction was not different significantly on the yield

of fresh and chip gembili extract. However, the yield

of fresh and chip gembili extract obtained increased

Inulin Extraction and Characterisation of Fresh and Chip Gembili (Dioscorea esculenta) Extract by Ultrasound-assisted Extraction

49

through the extraction process used by ultrasound-

assisted extraction (Table 1). Lingyun et al. (2007)

reported that the efficiency of inulin extraction will

increase efficiency by ultrasound-assisted extraction.

ultrasound extraction with the cleaning bath is non-

destructive to the sample which will eliminate the

possible contamination and loss of the extract.

Moreover, the cleaning bath is usually much quieter

than the probe horn during the operation. Therefore,

an ultrasonic cleaning bath might be more

convenient and efficient for the inulin extraction.

Table 1: Yield, inulin content, solubility at 25

o

C, inulin

purity and degree of white from fresh and chip of gembili

extract by non-ultrasound and ultrasound-assisted

extraction.

Characteristic of

physico-chemistry

Fresh gembili extract

non-

ultrasoun

d

ultrasound

Yield (%)

26.91 ± 5.56

ab

32.47 ±

0.61

b

Inulin content (%) 6.35 ± 0.13

a

0.00 ± 0.08

c

Solubility 25

o

C (%) 11.26 ± 0.03

a

11.48 ±

0.09

a

White degree 92.37 ± 0.32

a

2.44 ± 0.30

a

Inulin purity (mg/kg) 56.55 ± 19.80 61.57 ± 0.56

Characteristic of

physico-chemistry

Chip gembili extract

non-

ultrasoun

d

ultrasound

Yield (%)

25.23 ± 1.18

a

30.78

±4.21

ab

Inulin content (%) 7.67 ± 0.14

b

1.13 ± 0.18

d

Solubility 25

o

C (%) 12.41 ± 0.02

b

12.75 ±

0.32

b

White degree 92.18 ± 0.49

a

2.69 ± 0.20

a

Inulin purity (mg/kg) 96.70 ± 5.70

119.22

±0.74

Description: different superscripts on the same line

showed significant differences (p <0.05)

3.2

Moisture Content

The moisture content of fresh and chip gembili

extract by ultrasound-assisted estraction were

11.48% and 11.28% respectively. Winarti et al.

(2011) reported that inulin extracted from fresh

gembili tubers dried by cabinet drying method with

temperature at 60

o

C had a moisture content of up to

13.5%. While Franck (2007) reported that the

percentage of inulin standard from chicory had dry

material of 95%, which means that inulin standard

from chicory only had moisture content of 5%.

Inulin moisture content of information should be

known to limit the amount of water in the material

that will affect the resistance to damage caused by

microorganisms.

3.3

Inulin Content

Fresh and chip gembili extract by ultrasound-

assisted extraction have inulin levels of 10.00% and

21.13% respectively. Ciptaningrum (2015) reported

that the inulin content of gembili chip ranged

between 21.13% to 21.64%. The ultrasound-assisted

extraction has provided an increase in inulin content

of fresh and chip gembili extract (Table 1).

Ultrasound-assisted extraction released of inulin

compounds within the plant cell vacuoles and

diffuses out of the cell with kinetic waves derived

from the resulting vibration (Vinatoru, 2001).

Analysis of inulin content by the spectrophotometric

method still reads all the sugars present in the

material. Thus the readable inulin content may be a

component other than inulin, such as starch, soluble

fiber and other carbohydrates. Therefore, it is

necessary to continue a more accurate analysis of

inulin levels by using methods other than

spectrophotometry, such as HPLC.

3.4

Solubility

The quality of inulin can be measured by the level of

solubility in water. This parameter is one of the

physical properties possessed by inulin. Fresh and

chip gembili extract by ultrasound-assisted

extraction have a solubility at 25

o

C by 11.48% and

12.75% respectively. Franck (2007) reported that the

rate of inulin solubility at 25°C was 12% (w/v).

However, the solubility of inulin will increase as the

temperature increases as well. The statistical results

show that there is increased solubility of the gembili

extract between the fresh and chip, where the

solubility of the chip gembili extract is higher than

that of fresh gembili extract. Lee and Cheng (2006)

reported that drying techniques using hot

temperatures can lead to smaller particle sizes that

exhibit better redispersing properties.

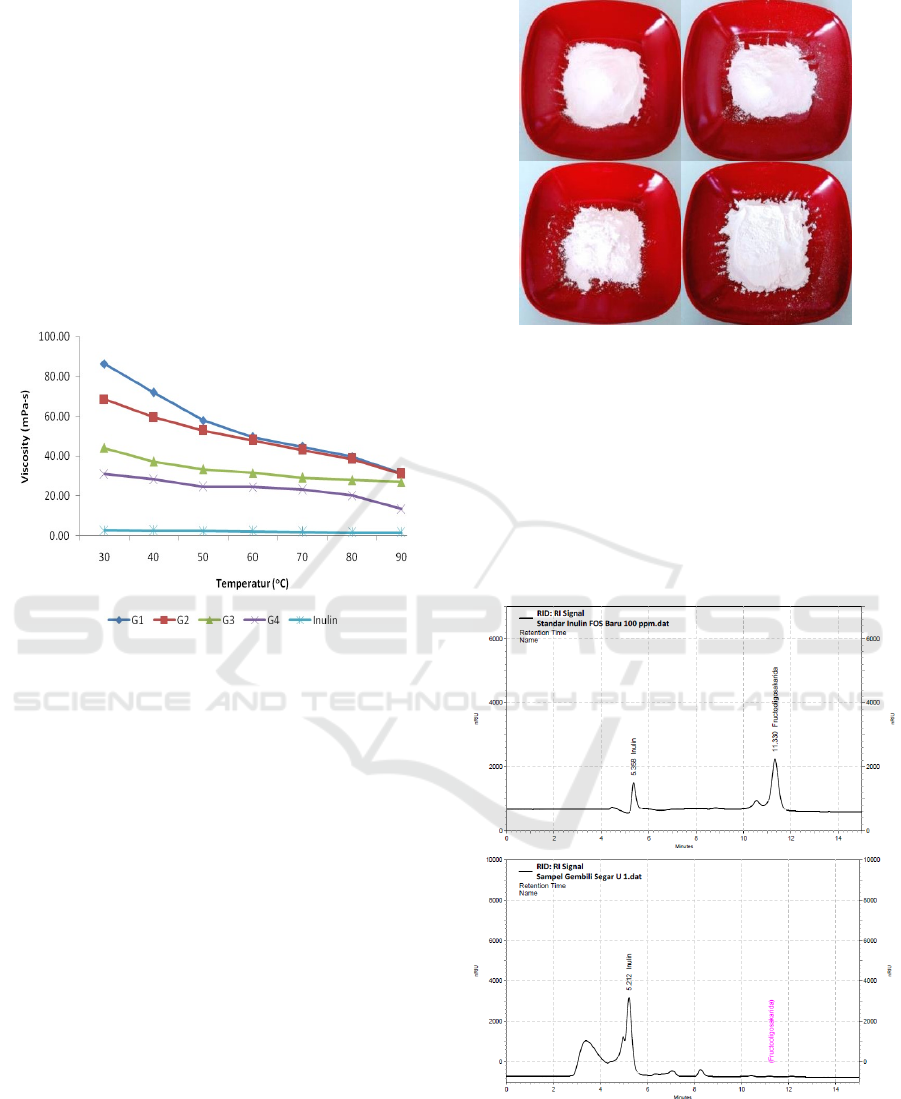

3.5

Viscosity

The viscosity is measured at a concentration of 10%

(w/v) and starts at 90°C until the temperature drops

at 30°C. The viscosity of fresh and chip gembili

extract by ultrasound-assisted extraction can be seen

in Figure 1. The results showed that the higher

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

50

temperature so the viscosity value will become

smaller. The temperature factor becomes the

determinant of the small value of the inulin viscosity

as the distance between the molecules further and

the frictional force decreases. Wada et al. (2005)

reported that the viscosity value may increase due to

the increase in molecular weight and temperature

drop. Bouchard, Hofland and Witkamp (2007)

reported that the value of inulin viscosity at 37°C

with a 10% concentration of 1.12 mpa-s. The low

level of inulin viscosity is a characteristic of

standard inulin physical properties commonly used

in food products (Franck, 2007).

Figure 1: The viscosity of gembili extract from fresh

gembili by non-ultrasound (G1) and ultrasound

(G2), chip gembili by non-ultrasound (G3) and

ultrasound (G4), and inulin

.

3.6

White Degree

Fresh and chip gembili extract by ultrasound-

assisted extraction have a white degree of 92.44 and

92.69 respectively. The results showed that the

ultrasound-assisted extraction did not affect a white

degree of fresh and chip gembili extract. The

gembili extract can be seen in Figure 2. Color is one

of the standard physical properties of inulin. Visual

appearance is a determinant of inulin quality. Franck

(2007) reported that the appearance of chicory and

arthicoke colors is white. However, the white degree

obtained was better than previous studies using

cabinet drying with a white degree of 81.39

(Ciptaningrum, 2015).

Figure 2: Gembili extract from fresh gembili by non-

ultrasound (a) and ultrasound (b), chip gembili by non-

ultrasound (c) and ultrasound (d).

3.7

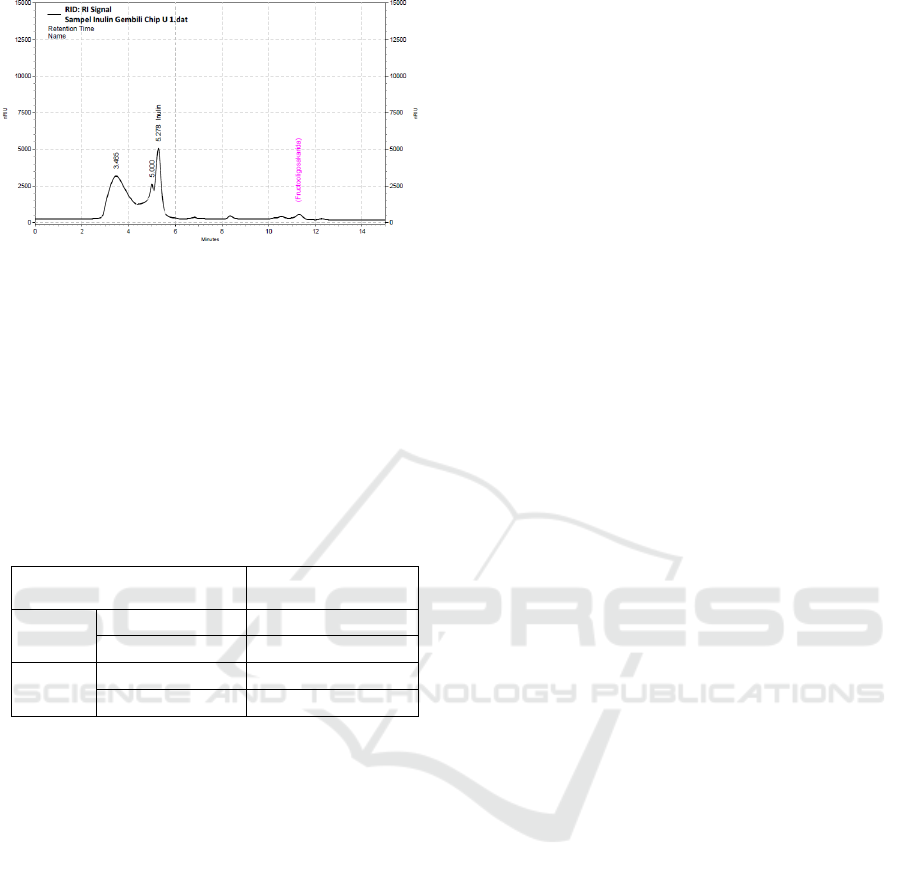

Inulin Purity

Figure 3. point (a) showed that there were two main

peaks used as peaks of inulin and FOS standard with

a retention time of 5.3 and 11.3 min respectively.

Figure 3. points of (b) and (c) were the result of

chromatograms of gembili extract that have the same

retention times as inulin and FOS standard.

(b)

(a)

(a) (b)

(c) (d)

Inulin Extraction and Characterisation of Fresh and Chip Gembili (Dioscorea esculenta) Extract by Ultrasound-assisted Extraction

51

Figure 3: Chromatograms of inulin and FOS standard (a),

fresh gembili extract by ultrasound (b) and chip gembili

extract by ultrasound (c).

However, since the concentrations of FOS

standard still exist that have not been detected in

some chromatograms then the data is not shown.

The inulin purity is calculated by the multiplication

of concentration obtained by the diluting factor of

the gembili extract and divided by the initial weight

of the gembili extract. The inulin purity from

gembili extract is presented in Table 2.

Table 2: Inulin purity of gembili extract

Gembili extract

u

lin purity (mg/kg)

Fresh

Non-ultrasound

56.55 ± 19.80

Ultrasound

61.57 ± 0.56

Chip

Non-ultrasound

96.70 ± 5.70

Ultrasound

119.22 ± 0.74

Data as mean values ± standard deviation (n = 2)

Table 2. showed that there is an increase in inulin

purity of fresh and chip gembili extract by

ultrasound-assisted extraction. Fresh and chip

gembili extract by ultrasound-assisted extraction

have an inulin purity of 61.57 mg/kg and 119.22

mg/kg respectively. Zubaidah and Akhadiana (2013)

reported that inulin concentration in the fresh

gembili extract of 67.66 mg/kg.

This suggests that ultrasound-assisted extraction

of inulin extraction from fresh and chip gembili can

improve inulin purity. Lingyun et al. (2007) reported

that extraction by ultrasound-assisted extraction

effective can cause disruption of plant cell walls to

break and release compounds extracted from within

the cell wall.

3.8

pH

The pH parameter becomes important because inulin

is an additive in various food products to increase

functional value. So the base-acid information from

gembili extract can be used as a basic knowledge in

its use in various food products. The average pH

value of gembili extract from fresh gembili non-

ultrasound, fresh gembili ultrasound, chip gembili

non-ultrasound, chip gembili ultrasound extract were

6,55. The pH value of 6.55 is still within the normal

pH range. Franck (2007) reported that the standard

inulin pH range of 10% (w/v) concentration was 5-7.

So this can make the gembili extract as fortification

or food additives into food products.

4

CONCLUSIONS

The inulin extraction of fresh and chip gembili by

ultrasound-assisted extraction was not different

significantly to the yield (30.78%-32.47%); degree

of white (92.18-93.69); pH (6.55) and solubility at

25

o

C (11.26%-12.75%), 60

o

C (22.50%-25.97%),

90

o

C (36.34%-37.71%) compared by non-ultrasound

extraction. Gembili extract from fresh and chip

gembili by ultrasound-assisted extraction have inulin

content was about 10.00%-21.13%; inulin purity

was about 61.57-119,22 mg/kg; and the viscosity

becomes smaller as the temperature increases. It

could be concluded that inulin can be extracted from

fresh and chip gembili. Study of inulin extraction

from fresh and chip gembili by ultrasound-assisted

extraction needed to be developed by adding a

longer time variation in the future.

ACKNOWLEDGEMENTS

This work was financially supported by funded and

part of Prof. Dr. Ir. Eni Harmayani, MSc research

with the theme of Development of Functional Food

from Local Tuber.

REFERENCES

Arumdinari, R. (2015). Karakterisasi dan evaluasi sifat

prebiotik inulin hasil ekstraksi dari tepung gembili.

MSc. Universitas Gadjah Mada.

Bekers, M., Grube, M., Upite, D., Kaminska, E.,

Danilevich, A., Viesturs, U. (2008). Inulin syrup from

dried Jerusalem artichoke. Proceedings of the Latvia

University of Agriculture, 21(315), pp. 116-121.

Bouchard, A., Hofland, G. W., Witkamp, G. J. (2007).

Properties of sugar, polyol, and polysaccharide

water−ethanol solutions. Journal of Chemical &

Engineering Data, 52, pp. 1838–1842.

(c)

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

52

Ciptaningrum, A. B. (2015). Ekstraksi inulin dari chip

umbi gembili (Dioscorea esculenta) dengan variasi

rasio chip dan air serta evaluasi potensinya sebagai

prebiotik. MSc. Universitas Gadjah Mada.

Dominguez, A. L., Rodrigues, L. R., Lima, N. M.,

Teixeira, J. A. (2014). An overview of the recent

developments on fructooligosaccharide production and

applications. Food Bioprocess Technology, 7, pp. 324–

337.

Dubois, M., Gilles, K. A., Hamilton, J. K., Rebers, P. A.,

Smith, F. (1956). Colorimetric method for

determination of sugar and related substances.

Analytical Chemistry, 28, pp. 350–356.

Franck, A. (2007). Technological functionality of inulin

and oligofructose. British Journal of Nutrition, 87, pp.

S287–S291.

Gupta, A. K., Kaur, N., Kaur, N. (2003). Preparation of

inulin from chicory roots. Journal of Sciencetific &

Industrial Research, 62, pp. 916 - 920.

Jiang, Q., Gao, W., Shi, Y., Li, X., W., Haiyang, H., Luqi,

Xiao, P. (2013). Physicochemical properties and in

vitro digestion of starches from different Dioscorea

plants. Food Hydrocolloids, 23, pp. 432-439.

Kasno, A., Saleh, N., Ginting, E. (2006). Pengembangan

pangan berbasis kacang-kacangan dan umbi-umbian

guna pemantapan ketahanan pangan nasional. Buletin

Palawija, (12), pp. 43-51.

Kaur, N., Gupta, K. (2002). Applications of inulin and

oligofructose in health and nutrition. Journal of

Biosciences, 27(7), pp. 703–714.

Lee, J., Cheng, Y. (2006). Critical freezing rate in freeze

drying nanocrystal dispersions. Journal of Controlled

Release, 111, pp. 185–192.

Li, W., Zhang, J., Yu, C., Li, Q., Dong, F., Wang, G., Gu,

G., Guo, Z. (2015). Extraction, degree of

polymerization determination and prebiotic effect

evaluation of inulin from Jerusalem artichoke.

Carbohydrate Polymers, 121, pp. 315–319.

Lingyun, W., Jianhua, W., Xiaodong, Z., Da, T., Yalin, Y.,

Chenggang, C., Tianhua, F., Fan, Z. (2007). Studies on

the extracting technical conditions of inulin from

Jerusalem artichoke tubers. Journal of Food

Engineering, 79, pp. 1087–1093.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent

for determination of reducing sugar. Analytical

Chemistry, 31, pp. 420–428.

Panchev, I., Delchev, N., Kovacheva, D., Slavov, A.

(2011). Physicochemical characteristics of inulins

obtained from Jerusalem artichoke (Helianthus

tuberosus L.). European Food Research and

Technology, 233, pp. 889–896.

Park, K. J., de Oliveira, R. A., Brod, F. P. R. (2006).

Drying operational parameters influence on chicory

roots drying and inulin extraction. Institution of

Chemical Engineering, 85, pp. 184-192.

Pompei, A., Cordisco, L., Raimondi, S., Amaretti, A.,

Pagnoni, U. M. (2008).

in vitro comparation of the

prebiotic effect of two inulin type fructans. Aerobe,

14(5), pp. 280-286.

Retnaningtyas, Y. (2012). Determination of inulin from

multivitamin syrup product by high performance

liquid chromatography with RI detector. Indonesia

Journal of Chemical, 12(2), pp. 201 – 205.

Roberfroid, M. B. (2005). Inulin-Type Fructans:

Functional Food Ingridients. Boca Raton: CRC Press.

Saengthongpinit, W. (2005). Influence of harvest time and

storage temperature on characteristics of inulin from

jerusalem artichoke and physicochemical properties of

inulin-starch mixed gel. PhD. Kasetsart University.

Takeuchi, J., Nagashima, T. (2011). Preparation of dried

chips from Jerusalem artichoke (Helianthus tuberosus)

tubers and analysis of their functional properties. Food

Chemistry, 126, pp. 922 – 926.

Vinatoru, M. (2001). An overview of the ultrasonically

assisted extraction of bioactive principles from herbs.

Ultrasonics Sonochemistry, 8, pp. 303– 313.

Wada, T., Sugatani, J., Terada, E., Ohguchi, M., Miwa, M.

(2005). Physicochemical characterization and

biological effects of inulin enzymatically synthesized

from sucrose. Journal of Agricultural and Food

Chemistry, 53, pp. 1246–1253.

Winarti, S., Harmayani, E., Nurismanto, R. (2011).

Extraction of inulin from various yam tubers

(Dioscorea, spp.). In: The 12

th

ASEAN Food

Conference. Bangkok: BITEC.

Zubaidah, E., Akhadiana, W. (2013). Comparative study

of inulin extracts from Dahlia, Yam, and Gembili

tubers as prebiotic. Food and Nutrition Sciences, 4,

pp. 8-12.

Inulin Extraction and Characterisation of Fresh and Chip Gembili (Dioscorea esculenta) Extract by Ultrasound-assisted Extraction

53