Impact Analysis of Ergonomic Bicycle Helmet Made from Polymeric

Foam Composite Strengthened by Coconut Fiber

Mahadi

1

, A. Syahrul

1

and

K. Tugiman

1

1

Department of Mechanical Engineering, Faculty of Engineering, Universitas

Sumatera Utara Padang Bulan Medan 20155 Indonesia

Keywords: Bicycle, Helmet, Impact, Coconut Fiber.

Abstract: This research contains report result manufacture and impacts analysis of bicycle helmet made from polymeric

foam composite materials strengthened by coconut fiber. The ergonomic helmets are protective head gears

wear by bicycle riders for protection against injury in case of the accident. Helmet standards require helmets

to be tested with a simple drop test onto an anvil.The geometric helmet structure consists of shell and liner,

both layers have sandwich structure. The shell uses matrix unsaturated Polyester BQTN-157EX material,

chopped strand mat 300 glass fiber reinforce and methyl ethyl ketone peroxide (MEKPO) catalyst with the

weight composition of 100gr, 15gr, and 5gr. The liner uses matrix unsaturated Polyester BQTN-157 EX

material, coconut fiber reinforces , Polyurethane blowing agent, and MEKPO catalyst with the composition

of 33% wt (181,5gr), 10% wt (55gr), 52% wt (285 gr) and 5% wt (27.5 gr). Layers of the helmet made by

using hand lay-up method and gravity casting method. Mechanical properties of polymeric foam were the

tensile strength (ơ

t

) 0,09MPa, compressive strength (ơ

c

) 0.51 MPa, flexure strength (ơ

b

) 0,52MPa, elasticity

modulus (E) 2,76MPa, density (ρ) 140 (kg/m

3

). Sample model helmet is the most ergonomic with the

thickness 10 mm and the amount of air channel 5. Free fall impact test was done in 9 samples with the

thickness of 10 mm with the height of 1.5 m. The result of the impact test was maximum impact force (Fi)

381,13N, maximum Impact Stress (ơi) 5,71 MPa and maximum Impact Energy absorption (Ei) 493,41Joule.

1 INTRODUCTION

The appliance of laminated composites is improve in

all sorts of engineering applications especially in

bicycle sport. Function of helmets are protective head

by bicycle riders for protection against injury in case

of the accident (Peter A.Cripton 2014). Ergonomics

is the study of the interaction between humans and

system elements with the goal of increasing

efficiency and compatibility. Through an

understanding of the human form, muscle systems

and human limitations, ergonomic principles can be

applied to products used in business and personal

settings. Ergonomic products are any goods designed

to increase ease of use and reduce injuries.

The application of conservation of energy to a

falling object allows us to predict its impact velocity

and kinetic energy, but we cannot predict its impact

force without knowing how far it travels after impact.

The dynamic energy in a moving object can be

expressed as follows:

Potential Energy, PE = mgh

(2)

Kinetic Energy, KE = mv

2

(3)

The impact velocity, (4)

2 MATERIAL PROPERTIES

The material used is Polymer Unsaturated Polyester

BQTN-157 EX as the matrix, Coconut fiber as

reinforces and polyurethane as Blowing Agent (BA).

Unsaturated polyester resins are the condensation

products of unsaturated acids or anhydrides and diols

with/without diacids. The unsaturation present in this

type of polyesters provides a site for subsequent

cross-linking (Reinhold 1956). The properties of

matrix was Modulus Young (E) 2 s/d 4,5 GPa,

Density (ρ) 1,2 s/d 1,5 mg.mm

3

and Tensile Strength

(σ

T

) 90MPa.

ghv 2

Mahadi, ., Syahrul, A. and Tugiman, K.

Impact Analysis of Ergonomic Bicycle Helmet Made from Polymeric Foam Composite Strengthened by Coconut Fiber.

DOI: 10.5220/0010082802630266

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

263-266

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

263

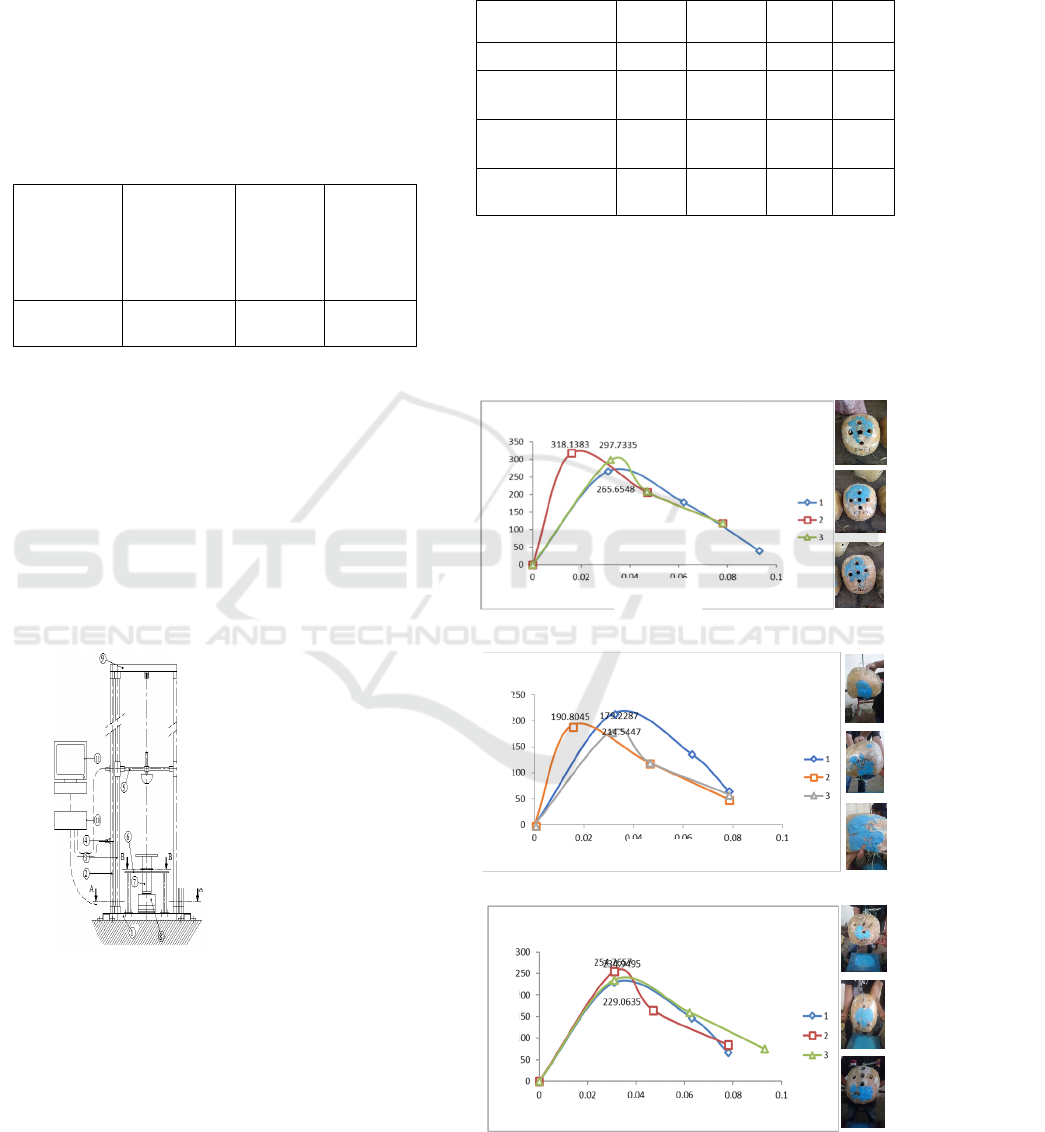

Ket:

1. Framebase

2. Barrier

3. Pipe launcher

4. Height sensor

5. TestrigArm

6. Supporttable

7. Anvilsupport

8. Loadcell

9. Upper

10. Power DAQ

11. Com

p

ute

r

The research material is unsaturated polyester

BQTN-157 EX resin as the matrix, oil palm empty

fruit bunch fiber as reinforcement, polyurethane as

blowing agent and MEKPO as catalyst. Polymeric

foam helmet material is made using composition of

fiber 10% wt (55gr), unsaturated polyester 157

BQTN-EX 33% wt (181,5gr), polyurethane blowing

agent 52% wt (285 gr) and catalys methyl ethyl

ketone peroxide (MEKPO) 5% wt (27.5 gr).

Table 1: Material helmet mechanical properties

Tensile

Strength

(σ

t

) (MPa)

Compress

Strength

(σ

c

) (MPa)

Flexure

Strength

(σ

b

) (MPa)

Modulus

of

Elasticity

(E)

(MPa)

0,09 0,51 0,52 2,76

3 IMPACT TEST

The suitable utilization of protective helmets can

minimalize the danger of interminable harm. A free-

fall drop test construction as in Figure 1 was

employed to drop sample helmets onto a flat anvil

steel base which replicates a road surface. The drop

height based of the helmet was 1.5 to 2 m, which

coincides with the standard of Consumer Product

Safety Commission (CPSC) drop height.

Figure 1: Free fall drop test impact

The three institutions most frequently used helmet

testing standards are EN1078, CPSC, ASTM F1447

and Snell B-95. Table 2 demonstrates the correlations

among each standard for helmet strength. The

application of conservation of energy to a falling

object allows us to predict its impact velocity and

kinetic energy but cannot predict its impact force

without knowing how far it travels after impact.

Table 2: Helmet Test Criteria (CPSC 1998)

CPSC ASTM

F1447

Snell

B-95

EN

1078

Flat anvil (m) 2.0 2.0 2.2 1.5

Hemispherical

anvil (m)

1.2 1.2 1.5 N/A

Head form

weight (kg)

5 5 5 4

Failure

threshold (g)

300 300 300 250

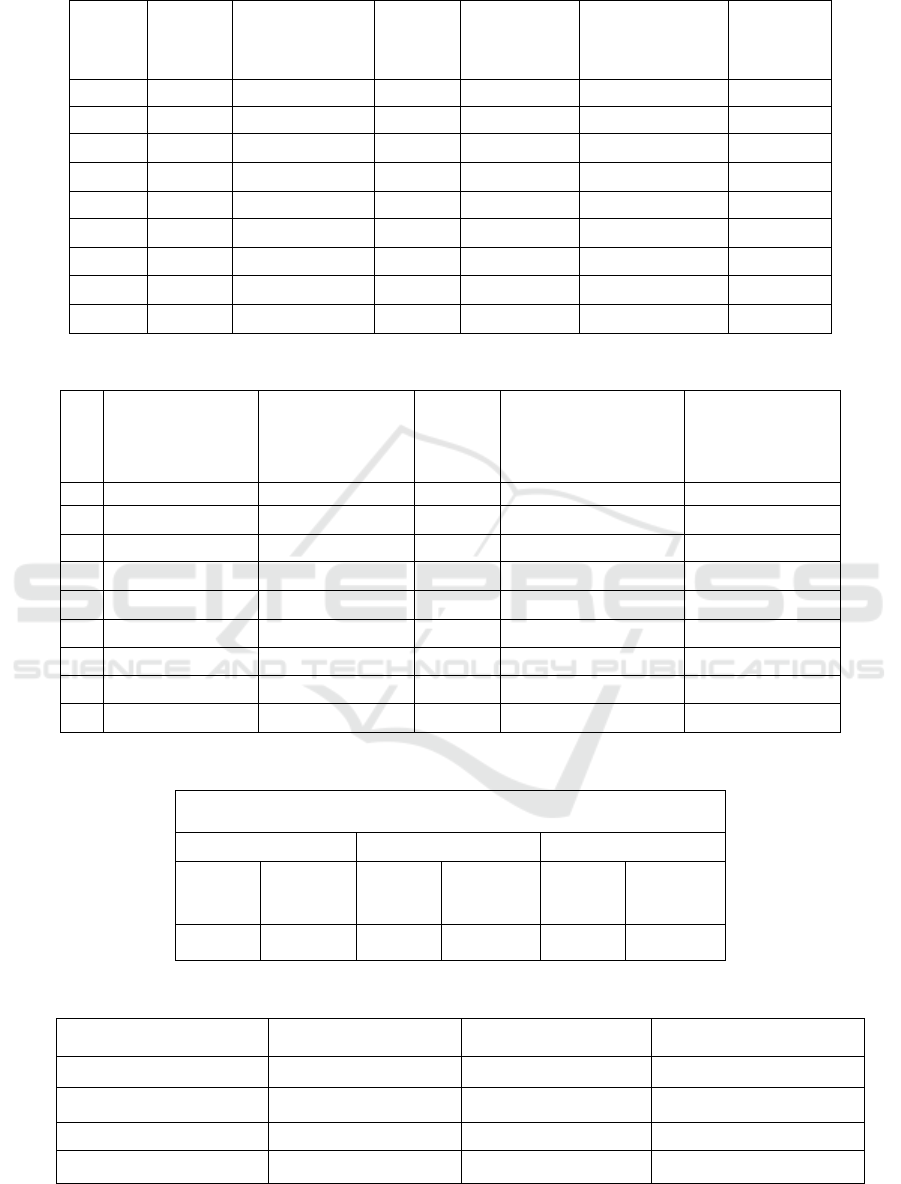

4 RESULTS

The results of impact test on nine helmets thick 10

mm and drop height on flat anvil 1.5m and impact

area 119 mm

2

is shown in Figure 2 up to 4.

Figure 2: F vs. t Top

Figure 3: F vs. t Side

Figure 4: F vs. t Front

F

o

r

ce

vs

Tim

e

Force

(

N

)

Tim

e

(s)

Time

(

s

)

Force

(

N

)

Force vsTime

Time (s)

Force vsTime

(

s

)

Force

(

N

)

Time (s)

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

264

Table 3: Result of Helmet Impact Test

Helm Impact

Point

Mass

(Helm+Rig)

(kg)

Impact

Force

(F

i

)(N)

Impact Time

(T

i

)(det)

Impact Stress

(σ

i

)

(MPa)

Condition

1 Top 5,38

265,65 0,03 3,98

Fracture

2 Top 5,32

381,13 0,02 5,71

Fracture

3 Top 5,35

297,73 0,03 4,46

Fracture

4 Front

5,37 229,06 0,03 3,43

Fracture

5 Front

5,36 254,76 0,03 3,82

Fracture

6 Front

5,38 234,94 0,03 3,52

Fracture

7 Side

5,35 179,23 0,03 2,68

Fracture

8 Side

5,34 190,80 0,03 2,86

Fracture

9 Side

5,37 214,54 0,02 3,21

Fracture

Table 4: Impact Energy Absorption

Helmet

Weight

Helmet + Test Rig

(kg)

Theoretical

Impact Energy

Et = m.g.h

(Joule)

Impact

Force

(F

i

)(N)

Experimental Impact

energy

Ee =F

i

.h (Joule)

Impact Energy

Absorption

E

i

=Ee-Et (Joule)

1 5,38 79,16

265,65

398,47 319,31

2 5,32 78,28

381,13

571,69 493,41

3 5,35 78,72

297,73

446,60 367,88

4 5,37 79,02 220,92 331,38 252,36

5 5,36 78,87 185,61 278,40 199,53

6 5,38 79,16 106,04 159,06 79,90

7 5,35 78,72 159,12 238,68 159,96

8 5,34 78,57 167,85 251,77 173,20

9 5,37 79,01 260,48 390,72 311,71

Tabel 5: Force (F) and Impact Energy (Ei)

Average

Force (F) and Impact Energy (E

i

)

Top Front Side

Force

(N)

Impact

Energy

(

J

)

Force

(N)

Impact

Energy (J)

Force

(N)

Impact

Energy

(

J

)

314,83 393,53 170,85 177,26 195,81 214,95

Tabel 6: Result of free fall drop impact test

Parameter

Helmet Commercial CPSC

Impact Force (F

i

) (max) 381,13 N 441,84 N

-

Impact Energy (E

i

) (max) 493,41Joule 555,64 Joule 110 Joule

Impact stress (σ

i

) (max) 5,71 MPa 3,78 MPa

-

Mass (m) 357,7 g 300 g

300

Impact Analysis of Ergonomic Bicycle Helmet Made from Polymeric Foam Composite Strengthened by Coconut Fiber

265

5 CONCLUSIONS

Base on data of research can be concluded as the

impact energy of the helmet is greater than the

standard and technique of making helmet is shell

layer with hand lay up method, liner with cast method

and the both layers are sandwich structured. The shell

helmet uses matrix unsaturated Polyester BQTN-

157EX material, chopped strand mat 300 glass fiber

reinforced, and Methyl Ethyl Ketone Peroxide

(MEKPO) catalyst. The liner composition is matrix

unsaturated Polyester BQTN-157 EX material 33%

wt (181,5gr) , coconut fiber reinforces 10% wt (55gr),

Polyurethane blowing agent 52% wt (285 gr), and

catalyst MEKPO 5%wt (27.5 gr). The results of the

free fall impact test shows that there are different

parameters of the helmet with a sample, commercial

and CPSC standard.

ACKNOWLEDGEMENT

This research was supported by Universitas Sumatera

Utara

REFERENCES

Consumer Product Safety Commission (CPSC) 1998

16 CFR Part 1203. Federal Register. Rules and

Regulations 63.46

Karthigadevi Elangovan, Sohithanjan Gopisetty,

Lokchandu Kummara 2018, Impact Scrutiny of a

Glass Fibre Reinforced Polyester-Foam

Sandwich Bike Helmet Using Fem, Journal of

Chemical and Pharmaceutical Sciences,

Department of Mechanical Engineering, Saveetha

School of Engineering, Chennai, Tamil Nadu,

ISSN: 0974-2115.

N.J.Mills and A.Gilchrist 2007, Oblique impact

testing of bicycle helmets, Metallurgy and

Materials, University of Birmingham, B15

2T,UK.

M.N. Abdullah, M.K.H. Muda, F. Mustapha, M.S.

Yaakob 2016, Oblique Impact Analysis of

Helmets Made From Kenaf (Hibiscus

Cannabinus) and Flax (Linum Usitatissimum)

Natural Fiber, Journal of Movement, Health &

Exercise, 57-67.

Reinhold 1956, Polyesters and Their Applications,

Bjorksten Research Laboratories, New York;

Asiminei, A. G., Van der Perre, G., Verpoest, I., &

Goffin, J 2009. A transient finite element study

reveals the importance of the bicycle helmet

material properties on head protection during an

impact. Proceedings of the International Research

Council on Biomechanics of Injury (IRCOBI)

conference. New York, UK: 357-360.

Peter A.Cripton, Daniel M.Dressler 2014., Bicycle

helmets are highly effective at preventing head

injury during head impact, Accident Analysis &

Prevention, Elsevier Vol.70, pp 1-7.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

266