Effect of Isolation Methods on Physicochemical Properties of

Purple-fleshed Sweet Potato Starch

Elisa Julianti

1,2

, Herla Rusmarilin

1

, Ridwansyah

1,2

and Era Yusraini

1,2

1

Department of Food Science and Technology, Faculty of Agriculture, Universitas Sumatera Utara,

Jalan prof. A.Sofyan No. 3 Medan, Indonesia

2

Centre for Tuber and Root Crops Study Faculty of Agriculture, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Purple-fleshed Sweet Potato, Starch, Isolation Methods

Abstract: Pretreatment methods in starch manufacturing will influence starch properties. In the present study the

purple-fleshed sweet-potato (PFSP) starch was produced with different isolation agents: distilled water,

sodium metabisulfite, and citric acid, and their effect on yield and physicochemical properties of starch was

evaluated. Isolation of PFSP starch by sodium metabisulfite yielded the greatest recovery of starch

(12.12%). Isolation methods significantly affected the fat, total starch, amylose, amylopectin and crude

fiber content of PFSP starch. The isolation methods gave no significant effect on the color (lightness) and

whiteness of PFSP starch. The starch content of PFSP starches from distilled water, sodium metabisulfite

and citric acid isolation were 58.49; 50.20; and 62.93% respectively, while amylose content and whiteness

of PFSP starch varied from 20.69 – 28.34% and 64.09 – 66.93 respectively.

1 INTRODUCTION

Sweet potato (Ipomoea batatas L. Lam) is one of

tuber crops that has been grown in many areas in

Indonesia including in North Sumatera, since it has a

high adaptability to a wide variety of climatic

conditions. It does not require a lot of input and has

a shorter harvest period than other crops (Horton,

1989). It also has high starch content with low in

glycemic index {ILSI, 2008) and high fiber content

(Zhang, 2009). The common locally varities of

sweet potato in North Sumatera are purple-skin

white-fleshed, yellow-skin purple-fleshed, yellow-

skin yellow fleshed, yellow skin-orange fleshed, and

purple-skin purple fleshed (Hutasoit, 2018). Purple-

fleshed sweet potato (PFSP) had a high antocyanin

content, and therefore it showed stronger antioxidant

activity than other vegetable crops (Van Hall, 2000).

The most utilization of sweet potatoes in

Indonesia are consumed fresh such as boiled, fried

or processed into variety of snacks and cake. In the

other hand, sweet potato tubers have high post-

harvest losses, and these can be minimized if the

tubers can be converted into non- perishable forms

by drying or extracting the starch. The utilization of

sweet potato starch was determined by its

physicochemical and functional characteristics,

where they depend on the processing technologies

such as isolation methods of starch. The use of

enzyme or chemical agents such as sodium

metabisulfite, sodium hydroxide or citric acid) will

help to inactivate the indigenous enzyme (e.g.

polyphenol oxidase), so they can maintain the

quality of sweet potato starch (Jangchud, 2003). This

study was aimed to study the physicochemical

properties of starch that was isolated by different

isolation agents namely water, sodium metabisulfite

and citric acid.

2 MATERIAL AND METHODS

PFSP tubers were obtained from farmers in Phak

Phak Barat North Sumatera Province – Indonesia.

Tubers were washed and cleaned to remove the soil

and dirt by using tap water.

2.1 Isolation of PFSP Starch

Isolation of PFSP starch was done according to

(Tharise, 2014) with modification in isolation agent

of starch. This study uses the different isolation

Julianti, E., Rusmarilin, H., Ridwansyah, . and Yusraini, E.

Effect of Isolation Methods on Physicochemical Properties of Purple-fleshed Sweet Potato Starch.

DOI: 10.5220/0010079900370041

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

37-41

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

37

agents namely water, sodium metabisulfite, and

citric acid. The cleaned tubers were peeled

manually with stainless steel kitchen knife, shredded

by a grating machine, diluted 1 : 3 w/v with different

agents of starch isolation i.e. distillation water, 0,2%

sodium metabisulfite, and 0,2% citric acid, and then

filtered by using filter cloth. The filtrate was allowed

to settle for 12 hours at room temperature (27-30

o

C). The supernatant was poured while the starch

was collected and resuspended in water for 3 hours

and kept at room temperature for 3 hours to settle.

This process was repeated three times until the white

starch sediment was obtained. The collected starch

was dried in a convection oven at 50

o

C for 12 hours,

cooled to room temperature. Dry matter content of

the resulting starch for each treatment was calculated

to obtain the starch yield, and then finely ground,

sieve through a 80 mesh sieve, packed and sealed in

polyethylene plastic bags for further analyzed.

2.2 Determinonati Physicochemical

Properties of PFSP Starch Samples

Determination of starch yield (SY) was done by

using the following formula :

Extracted starch

SY (%) = --------------------------------------- x 100 (1)

Total amount of raw PFSP tubers

The starch color was determined by using a

Minolta Chromameter CR-400 type and the Hunter

color values (L*,a *, b*) were obtained. The

whiteness of starches were calculated as described

by Thao and Noomhorn (2011) by using following

formula :

Whiteness = 100 – [(100-L

2

) + a

2

+ b

2

]

1/2

The chemical properties of PFSP starches

including moisturem protein (N x 6,25), crude fat,

ash, and crude fiber were determined by using

AOAC methods (AOAC, 1995). The determination

of starch content was done by acid hydrolyzing the

PFSP starch samples with 25% HCl for a period 2.5

hours in water bath at 100

o

C. The quantification was

performed using 3.5 dinitrosalicylic acid (DNS)

spectrophotometric methods at 490 nm, using

glucose as standard (Dubois, 1956). Amylose

content (%) was determined by using IRRI method

(IRRI, 1996). Amylopectin was calculated by

difference method as follows :

Amylopectin (%) = (100 - Amylose)

2.3 Analysis of Data

A completely randomized design and analysis of

variance were employed to study the effect of

isolation agents on the physicochemcial properties

of PFSP starch. Least significant different (LSD)

tests at 95% confidence level (p<0.05)was used to

determine the differences between the ranges of

physicochemcial properties of PFSP starch.

3 RESULTS AND DISCUSSIONS

3.1 Starch Yield and Physical

Properties

The isolation methods gave no significant effect on

starch yields, lightness and whiteness of PFSP starch

as shown in Table 1. The highest starch yield was

obtained by sodium metabisulfite isolation

(12.12%). The starch yiels obtained in this study

was similar to the study of (Soison, 2015) and

reporting the starch yield of 6-13% from four

varieties of sweet potato. But this result differ from

previous studies (Babu and Parimalavalli, 2014),

showing that starch isolation by using distillation

water produced higher starch yields than sodium

metabisulfite.

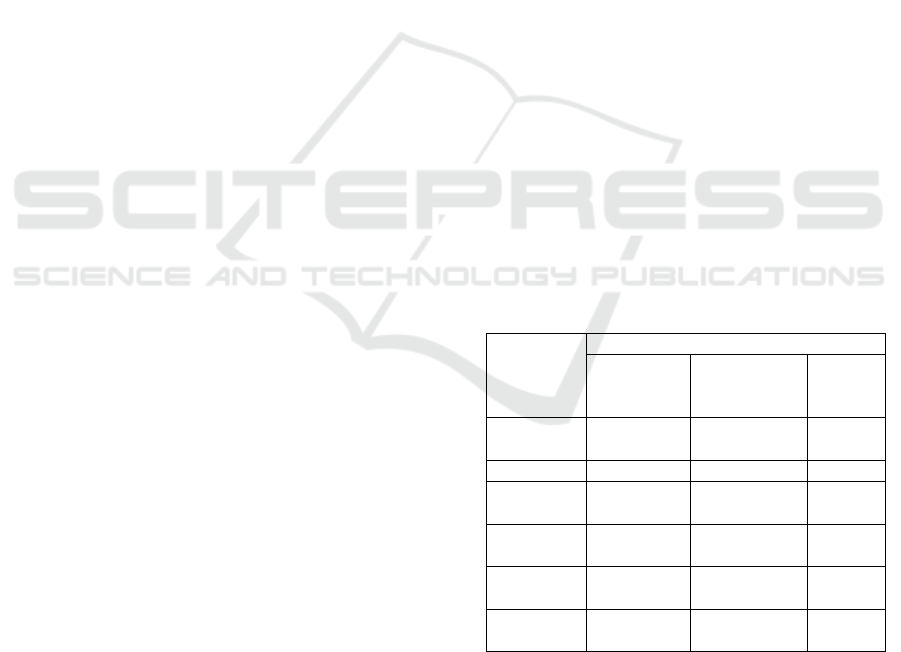

Table 1: The effect of isolation agents on starch yield,

lightness and whiteness of PFSP starch.

Parameter

s

a),b)

Isolation Agents of Starch

Distillation

Water

Sodium

Metabisulfit

e

Citric

Acid

Starch

yield (%)

11.53

±0.44

12.12

±1.18

10.38

±0.96

Colo

r

L* 64.33

±2.80

65.60

±3.31

67.43

±1.19

a* -1.17

±0.45

b

0.70

±0.36

a

-1.53

±0.46

b

b* 3.70

±1.84

3.33

±1.05

5.50

±0.36

Whiteness 64.09

±2.96

65.42

±3.35

66.93

±1.24

a)

Value reported as the mean ± Std. Dev. of three

replications

b)

Means followed by same letter superscripts within a row

are not significantly different (p<0.05)

Color was the most important characteristics for

determining the successful starch applications in

food products. The starch color was determined by

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

38

polyphenolic compounds and anthocyanin content of

PFSP starch (Glavez and Resureccion, 1993). There

was no significant difference observed for PFSP

starch color isolated by difference methods in terms

of lightness (L*), yellowness (b*) and whiteness but

there was slight difference in greenness (a*).

However PFSP starch which isolated by citric acid

found to be more lightness and whiteness followed

by sodium metabisulfite and distillation water. The

lightness and whiteness of PFSP starch observed in

this research were lower than those obtained by

Thao and Noomhorm (2011) and Babu and

Parimalavalli (2014). In their studies they found that

the lightness and whiteness of sweet potato starch

were ranged from 90.27-93.66. The lower of the

lightness and whiteness of PFSP starch obtained in

this research were due to anthocyanin pigment is

carried over the starch product during the starch

isolation (Glavez and Resureccion, 1993).

3.2 The Chemical Composition of

PFSP Starch

Table 2 showed that there was a significant

difference (p<0.05) in the moisture, crude fat,

starch, amylose, amylopectin and crude fiber content

of PFSP starch, but there is no significant difference

(p>0.05) in the protein and ash content among the

samples. Moisture content of PFSP starch ranged

from 8.52-14.86% similar to the results of Babu and

Parimalavalli (2014), and it was within the range of

recommended moisture content of commercial

starch i.e. 10-10% (Soni, 1993). Starch isolation by

using citric acid produced PFSP starch with the

lowest moisture content. However, basically the

starch moisture content depends mainly by the

drying methods and time, and also by the

surrounding humidity (Lawal, 2004).

The fat content was found to be 0,68% in sodium

metabisulfite isolation, 0,62% in citric acid isolation

and 0,50% in distillation water isolation, and these

values were similar with Thao and Noomhorm

(2011) studies i.e. 0.06-0.07%. The fat content in

PFSP starch that isolated by sodium metabisulfite

and citric acid were higher than distillated water

isolation. Ash content of PFSP starch ranged from

0.26 – 0.36, and the same result was found by (Babu

and Parimalavalli 2014) and (Abegunde, 2012). The

variation in the values of ash and fat content could

be attributed to extraction method and degree of

homogenization for isolation of starch (Kale, 2017).

Table 2 shows that the protein content of PFSP

starch ranged from 0.14-0.17%. The protein and fat

content of PFSP starch were lower than PFSP flours

that had 1.9-2.6% protein and 0.4-0.7% fat

(Jangchud, 2003). The high content of protein, lipid

and ash indicated the low purity of starch (Thao and

Noomhorm, 2011).

Table 2: Effect of isolation agents on chemical

composition of PFSP starch

Parameters

a),b)

Isolation A

g

ents of Starch

Distillatio

n Wate

r

Sodium

Metabisulfite

Citric

Aci

d

Moisture (%) 14.86

±3.83

a

16.93 ±0.82

a

8.52

±0.46

b

Crude fat (%) 0.50

±0.05

b

0.68 ±0.03

a

0.62

±0.04

a

Ash (%) 0.26

±0.01

0.28 ±0.04 0.36

±0.11

Protein (%) 0.17

±0.03

0.14 ±0.08 0.16

±0.04

Starch (%) 58.49

±1.84

a

50.20 ±2.80

b

62.93

±0.70

a

Amylose (%) 37.79

±0.94

a

30.87 ±2.72

b

34.59

±0.62

ab

Amylopectin

(%)

20.70

±2.98

b

20.85 ±1.17

b

28.34

±1.07

a

Crude Fiber

(

%

)

0.25

±0.11

b

0.56 ±0.16

b

2.59

±1.15

a

a)

Value reported as the mean ± Std. Dev. of three

replications

b)

Means followed by same letter superscripts within a row

are not significantly different (p<0.05)

The isolated PFSP starch had the lower starch

content (50.20-62.93%) than those in previous

studies i.e. 97-99% (Soison, 2015) and 92-96%

(Abegunde, 2013). The differences of starch content

may be due to a difference in variety and extraction

methods. PFSP starch isolated by citric acid

significantly had the higher purity of starch followed

by distillation water isolation and sodium

metabisulfite isolation had the lowest purity (Table

2).

Amylose content ranged from 30.87-37.79%,

while amylopection content ranged from 20.70-

28.34%. Isolation of PFSP starch by using

distillation water produced the high amylose content

of starch followed by citric acid isolation, and the

highest amylopectin content was found in citric acid

isolation. Various studies showed that the amylose

content of sweet potato starches varied greatly with

range of 8.5 to 38% (Abegunde, 2013; Collado.,

1999; Tian, 1991;Takeda, 1987). The difference in

amylose content of the PFSP starches will affect the

physicochemical properties of starches and

technological quality of starch-based foods (Ngoc,

2017). Amylose content in starch influences the

pasting properties and strength of starch gel, because

Effect of Isolation Methods on Physicochemical Properties of Purple-fleshed Sweet Potato Starch

39

of rapid retrogradation. The association and

interaction to lipids and amylopectin in forming

helical complex gave the strong structure of gel. The

high content of amylose in starches were desired for

manufacture of starch noodles (Tan, 2009; Jane,

1999).

Crude fiber content of PFSP starch from citric

acid isolation significantly was higher than those in

distillation water and sodium metabisulfite isolation.

The crude fiber content of PFSP starch ranged from

0.25-2.59%. Sweet potato was a significant source

of dietary fibre (Collins and Walter, 1982) and

therefore it plays a role in reducing the ocurence of

certain diseases such as diabetes, coronary heart

disease, colon cancer and various digestive disorders

(Augustin, 1978).

4 CONCLUSIONS

The physicochemical properties of PFSP starch

isolated from different kind of isolation agent

(distillation water, sodium metabisulfite, and citric

acid) were evaluation in this study. The result

showed that, each isolation method had its own

physicochemical characteristics, which affect the

end-use quality of starch based foods. The sodium

metabisulfite isolation produced the highest yield of

starch with higher lightness and whiteness of PFSP

starch color, but it had a lowest starch and amylose

content. While starch isolation by using citric acid

isolation produced the lowest yield of starch but had

the highest starch content. The isolation PFSP starch

by using distillation water produced the starch with

the lowest lightness and whiteness of color, but it

had the highest amylose content. It may be

concluded that purple fleshed sweet potato starch

can be applied for the development of food products.

ACKNOWLEDGEMENTS

We wish to thank to Directorate General of Research

Strengthening and Development, Ministry of

Research, Technology and Higher Education

Republic of Indonesia for funding this research

through “Penelitian Strategis Nasional 2018”

project.

REFERENCES

Abegunde, O.K., Mu, T., Arogundade, L.A., Deng, F., and

Chen, J. 2012. Physicochemical characterization of

starches from some Nigerian and Chinese roots and

tubers. African Journal of Food Science 6 317-329

Abegunde, O.K., Mu, T.H., Chen, J.W., and Deng, F.M.

2013 Physico-chemical characterization of sweet

potato starches popularly used in Chinese starch

industry. Food Hydrocolloids 33169-177

AOAC, 1995. Official Methods of Analysis of The

Association of Official Analytical Chemists

Washington.

Augustin, J., Johnson, G.K., Teitzel, C., True, R.H.,

Hogan, J.M., and Deutsch, R.M. 1978. Changes in

nutrient composition of potatoes during home

preparation. American Potato Journal 55 653-662

Babu, A.S. and Parimalavalli, R. 2014 Effect of starch

isolation method on properties of sweet potato starch.

The Annals of the University Dunarea de Jos of Galati

Fascicle VI – Food Technology 38 (1) 48-63

Collado, L.S., Mabesa, R.C., and Corke, H. 1999 Genetic

variation in the physical of sweet potato starch.

Journal of Agricultural and Food Chemistry 47 4195-

4201.

Collins, W.W. and Walter, W.M. 1982 Potential for

increasing nutritional value of sweet potatoes. In: R.L.

Villareal and T.D. Griggs, Sweet Potato. Tainan Int.

Symp., Taiwan, 355-363.

Dubois, M., Giles, K.A., Hamilton, J.K., Rebers, P.A., and

Smith, F. 1956 Colorimetric method for determination

of sugars and related substances. Analytical Chemistry

28 350-356

Glavez, F.C.F. and Resureccion, A.V.A. 1993 The effects

of decortications and method of extraction on the

physical and chemical properties of starch from mung

bean (Vignaradiate L. Wilcze). Journal of Food

Process Preservation 17 93-107

Horton, D., Prain, G., and Fregory, P. 1989 High-level

investment return for global sweet potato research and

development CIP Cir 17 1-11

Hutasoit, M.S., Julianti, E., and Lubiz, Z. 2018 Effect of

pretreatment on purple-fleshed sweet potato flour for

cake making. IOP Conference Series: Earth and

Environmental Science122 012086

http://iopscience.iop.org/article/10.1088/1755-

1315/122/1/012086. doi :10.1088/1755-

1315/122/1/012086

International Life Science Institute (ILSI). 2008

Nutritionally improved sweet potato. In: Assessment

of foods and feeds. Comprehensive Review in Food

Science and Food Safety 7 81-91

IRRI. 1996 Standard Evaluation System For Rice. INGER

Genetic Resources Center, International Rice Research

Institute, Manila, Philippine

Jane, J., Chen, Y.Y., Lee, L.F., McPherson, A.E., Wong,

K.S., Radosavljevic, M. and Kasemsuwan, T. 1999

Effects of amylopectin branch chain length and

amylose content on the gelatinization and pasting

properties of starch. Cereal Chemistry 76 629- 637.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

40

Jangchud, K., Phimolsiripol, Y., and Haruthaithanasan, V.

2003 Physicochemical Properties of Sweet Potato

Flour and Starch as Affected by Blanching and

Processing Starch/Stärke 55 258–264

Kale, R.V., Shere, D.M., Sontakke, M.D., and Gadhe, K.S.

2017 Effect of isolation methods on physicochemical

and functional properties of sweet potato (Ipomoea

batatasL.) starch. Journal of Pharmacognosy and

Phytochemistry 6(4) 223-227

Lawal, O.S. 2004 Composition, physicochemical

properties and retrogradation characteristics of native,

oxidized, acetylated and acid thinned new cocoyam

(Xanthosoma sagittifolium) starch. Food Chemistry 87

205-218.

Ngoc, L.B.B., Trung, P.T.B., Hoa, P.N., and Hung, P.V.

2017 Physicochemical properties and resistant starch

contents of sweet potato starches from different

varieties grown in Vietnam. International Journal of

Food Science and Nutrition 2 (1) 53-57

Soison, B., Jangchud, K., Jangchud, A., Harnsilawat, T.,

and Piyachomkwan, K. 2015 Characterization of

starch in relation to flesh colors of sweet potato

varieties. International Food Research Journal 22 (6)

2303-2308

Soni, P.L., Sharma, H., Dun, D., and Gharia, M.M. 1993.

Physicochemical properties of Quercus

leucotrichophora (Oak) starch. Starch/Starke 45 127-

130

Takeda, Y., Hizukuri, S., Takeda, C., and Suzuki, A. 1987

Structure of branched molecules of amylose of

various origins and molar fractions of branched and

unbranched molecules. Carbohydrate Research

165:139- 145.

Tan, H.Z., Li, Z.G., and Tan, B. 2009 Starch noodles:

History, classification, materials, processing, structure,

nutrition, quality evaluating and improving. Food

Research International 42 551-576.

Thao, H.M. and Noomhorm, A. 2011 Physiochemical

Properties of Sweet Potato and Mung Bean Starch and

Their Blends for Noodle Production. Journal of Food

Processing & Technology 2(1) 2-9

Tharise, N., Julianti, E., and Nurminah, M. 2014

Evaluation of physico-chemical and functional

properties of composite flour from cassava, rice,

potato, soybean and xanthan gum as alternative of

wheat flour. International Food Research Journal

21(4): 1641-1649

Tian, S.J., Rickard, J.E., and Blanshard, J.M.V. 1991

Physicochemical properties of sweet potato starch.

Journal of The Science of Food and Agriculture

57:459-491.

Van Hall, M. 2000 Quality of sweet potato flour during

processing and storage J Food Reviews Int 16 1-37

Zhang, Z.E., Fan, S.H., Zheng, Y.L., Lu, J., Wu, D.M.,

Shan, Q.,, and Hu, B. 2009 Purple sweet potato color

attenuates oxidative stress and inflammantory

response induced by D-galactose in mouse liver. Food

and Chemical Toxicology 47 (2) 496-501

Effect of Isolation Methods on Physicochemical Properties of Purple-fleshed Sweet Potato Starch

41