Design of Hydrogen Fuel Supply Chain Distribution Network from

the Potency of Palm Oil Empty Bunches

Rahmi M. Sari

1

, Indah Rizkya

1

, Taufiq Bin Nur

2

, Wandika A. Syahputra

1

and Reggy Nouvan

1

1

Industrial Engineering Department, Faculty of Engineering, Universitas Sumatera Utara, Medan, Indonesia

2

Mechanical Engineering Department, Faculty of Engineering, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Hydrogen Fuel

Abstract: In Indonesia, the production of biomass is wasted because it is considered as “waste” that has no use anymore

such as bagasse, rice grain skin, corn cob, and oil palm waste. Oil palm empty bunches have C and H chemical

bonds, where most of the materials with chains C and H store heat energy so that hydrogen can be obtained

as fuel. Process to convert a biomass into hydrogen is by gasification and pyrolysis. The purpose in this

research is to design the distribution network from the potential oil palm empty bunches. The hydrogen

produced is only 0.469% of the available potential and is similar to the existing of the used empty bunches

potential. Selection of factory location is based on 4 criteria. From the criteria, obtained LabuhanBatu District

as the best regencies in North Sumatra. Potential plantations can supply as much as 6,390,423,000 kg with

the ability of oil palm factory distribution of 1,469,797,290 kg.

1 INTRODUCTION

As the depletion of fossil fuel and natural gas reserves

make the world look for replacement energy.

Biomass is an alternative fuel source that is still

abundant and has not been fully utilized(Mirela,

2018)

Exploration for renewable alternative energy

sources for the long term will takes an

environmentally friendly source of energy, one of

which is hydrogen. In the long term, especially in

Indonesia, the production of hydrogen through coal

gasification and through biomass gasification will

provide economic benefits. Consider the potential of

biomass in Indonesia today and in the future,

hydrogen production will have a positive effect on the

national economy.

Globally the need for hydrogen as an alternative

energy has been increasing in recent years hydrogen

as one of the hydrocarbon fuels that has the advantage

of being eco-friendly and having great energy

efficiency especially if used on vehicle fuel (Michael,

2018)

Biomass that has the potential to be processed is

empty bunch palm oil. Oil palm empty bunches have

considerable potential to be utilized. However, empty

bunch utilized as organic fertilizer presently. The

remaining empty bunches will make problem for the

place and its disposal transport resulting in additional

production costs for the processor (Chen, etc,

2018)(Yanan, etc, 2018)

Hydrogen in the industry is generally produced

using the Steam Methane Reforming (SMR) method

from natural gas resulting from pyrolysis and

gasification methods(Josua, etc, 2018)(Melaina and

Penev, 2013). Steam Methane Reforming is more

efficient with low cost through pyrolysis and

gasification process (Delgado, etc, 2018)

Supply chain management is now important for oil

palm companies and other companies as the

competition grows and the position of palm oil and

mill suppliers and millers as partners. The process of

fulfilling the customer needs in the supply chain is a

value-adding chain that not only stops at one

company but includes all the companies that are

members of the supply chain (Muhammad, 2012).

Pyrolysis is decomposed with the aid of heat in the

absence of oxygen or with a limited amount of

oxygen. Usually there are three products in the

process of pyrolysis such as charcoal, gas, and liquid.

Pyrolysis process is influenced by several factors

such as time, temperature, particle number, particle

size, particle weight (Ramadhan, etc, 2018)(Ali,

2018).

Strategic business location can maximize the

business profit. Location is where to serve consumers,

defined as a place to introduce goods. Thus the

232

Sari, R., Rizkya, I., Nur, T., Syahputra, W. and Nouvan, R.

Design of Hydrogen Fuel Supply Chain Distribution Network from the Potency of Palm Oil Empty Bunches.

DOI: 10.5220/0010078802320236

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

232-236

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

definition of a location is a place to run an activity

that serves consumers, production activities, storage

activities, or to control the activities of the company

as a whole part of the company. The main factors in

choosing the location are (1) Availability of Raw

Materials, (2) The location of the intended market, (3)

Availability of energy source, water, and

communication facilities, (4) Availability of

manpower and (5) Availability of transportation

(Sunil, etc, 2013).

Supply chain is a network of companies that work

together to produce and deliver a product into the end

users. These companies usually include suppliers,

producers, distributors, stores or retailers, as well as

support agencies such as logistics services agencies.

(Dawei, 2011). According to the definition, several

number of key characteristics that used to portrait a

supply chain. First, supply chain needs participation

of more than one company. Second, the participating

companies within a supply chain should be in

difference business ownership, therefore there is a

legal independence in between. Third, those

companies are inter-related on the common

commitment to add value of material flow that run

through the supply chain. The material flow, to every

company, transformed inputs and goes out as outputs

with value added. (Directorate general of the farm,

2017)

2 METHODOLOGY

Research object is hydrogen fuel that produced from

palm oil empty bunch with pyrolysis method. The

data gathered from the result of empty bunch,

plantation location and factory locations in Sumatera

Utara. This data then processed to gain the

information of distribution network palm oil empty

bunch.

First step is to figure out the needs of raw material

by define the capacity per day based on the steam

methane reformer machine. Second step is to define

the needs of raw material needed based on the

percentage of hydrogen by gas and the percentage of

gas from empty bunch from the result of pyrolysis

process and also percentage data from empty bunch

and fresh fruit bunch. In this step, also resulting the

hydrogen potential that can be get from empty bunch

in Sumatera Utara.

Next, designing the distribution network is done by

defining the location of hydrogen plant in Sumatera

Utara with qualitative method. The assessment based

on raw material supply and added material, utility,

transportation and surroundings. The result is the best

location to build the hydrogen plant.

The last step is figuring the distribution network

after resulting the ideal plat location and factory data

in Sumatera Utara. The result is shown by the

distribution figure from farm to hydrogen plant.

3 RESULT AND DISCUSSION

3.1 Production Capacity

The determination of production capacity is based on

rated power capacity (MW) using Steam Methane

Reformer. The results of a study by the National

Renewable Energy Laboratory for the production of

hydrogen using pyrolysis and Steam Methane

Reformer methods obtained a production capacity of

1,000 kg / day (Joshua Eichman, etc.2016).

3.2 Raw Materials Needs

The needs of raw material calculated by the following

steps :

1. Hydrogen Calculation Result

Based on the calculation, Percentage of empty

bunch turns in to gas is 52.02%. Then the

percentage of hydrogen in gas is 8.69%.

2. Potential of Hydrogen Produced in North

Sumatera

The processing of fresh fruit bunches (FFB) will

produce 23% palm empty fruit bunches, 6.5%

shell waste, 4% wet decanter, 13% fiber and liquid

waste as much as 50%.

The following is the calculation of the amount of

hydrogen produced in North Sumatra.[14]

a. The number of FFB produced in 2015 is

6,390,423,000 kg.

b. The percentage of oil palm empty fruit

bunches from fresh fruit bunches is 23% so

that there are empty bunch of 1,469,797,290

kg.

c. The percentage of oil palm empty bunches into

gas as much as 52.02% to obtain gas of

764,588,550 kg by pyrolysis method.

d. The percentage of hydrogen in the gas as much

as 4.52% to obtain hydrogen of 690.265.368

kg per year.

2. Needs of Empty Bunch per hour CalculationThe

hourly empty bunch requirement is calculated

using the hydrogen percentage in empty bunch

The results can be seen in Table 1.

Design of Hydrogen Fuel Supply Chain Distribution Network from the Potency of Palm Oil Empty Bunches

233

Table 1: The Needs of Palm Oil Empty Bunch

Percentage

(%)

Weight (Kg) Type Weight (Kg) Type

Percentage Hydrogen in

Gas

4,52 22,123.89 Gas 1,000 Hydrogen

Percentage Gas in Empty

Bunch

52,02 42,529.58 Empty Bunch 22,123.89 Gas

PercentageEmpty Bunch

from Fresh Fruit Bunch

23 184,911.24

Fresh Fruit

Bunch

42,529.58

Empty

Bunch

Table 1. shows that the need of empty bunch fruit

to gain 1000 kg hydrogen per day is 42,529.58 kg.

3.3 Plant Site Selection

The ideal plant site selection is the location that will

provide the minimum total cost of production and

transportation and maximum profit for the company.

The selected regions are districts located in the

province of North Sumatra. In the selection process

of several alternative locations will be used

qualitative methods to determine the alternative

locations should be selected.

Then the determination of the weight of the criteria

that affect the selection of factory location. Giving

weight of each factor or criteria identified based on

degree of importance. The highest market share is

Labuhan Regency with 37.09% market share

followed by Asahan District with 13.13% market

share and Langkat Regency with market share of

12.05% as location 1, location 2 and location 3 (Data

center and farmig information system, 2016).

Table 2: Weight and Value Matrices from Each Location Factor and Alternative

Criteria Weight

Alternatives

Alternative 1 Alternative 2 Alternative 3

Easy supply of raw materials and auxiliary

materials

35%

9 7 7

Utility 30%

8 9 7

Easy Transportation 20%

8 8 8

Environmental and social circumstances

15%

8 8 8

The value get from research considerations based

on the actual conditions in which location. Then get

the values of each alternative location that can be seen

in Table 3.

Table 3: Assessment of Location Alternatives

Criteria

Alternative

Alternative 1 Alternative 2 Alternative 3

Easy supply of raw materials and auxiliary materials

3.15 2.45 2.45

Utility

2.8 3.15 2.45

Easy Transportation 2.8 2.8 2.8

Environmental and social circumstances 2.8 2.8 2.8

Total

11.55 11.2 10.5

From the results of the calculation above, then the

selection of alternative locations that are considered

good alternative location that has the greatest value of

z / total. Thus location 1 has the largest total value of

11.55, so the best location according to this analysis

is alternative 1.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

234

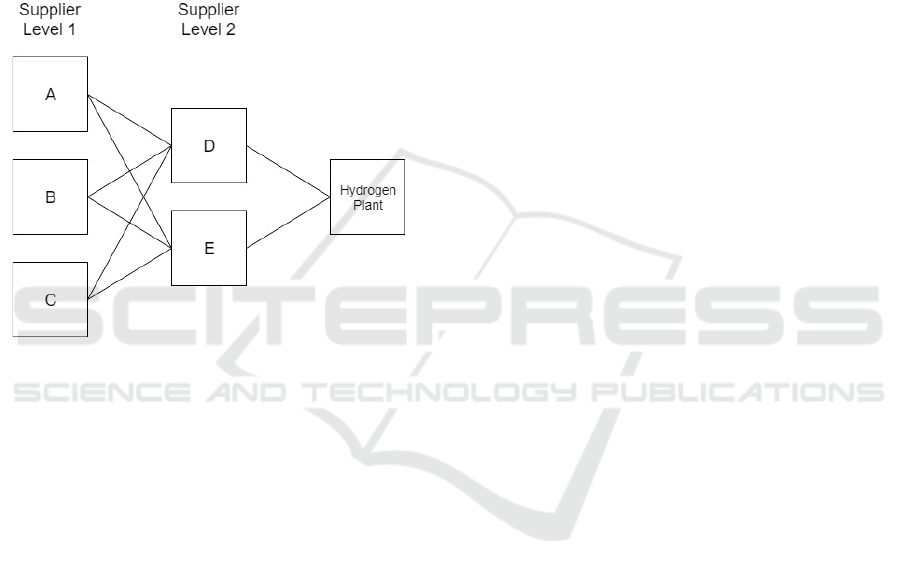

3.4 Distribution Network

Supply chain problem can be done by using a facility

location capacity approach. The development of

supply chain networks is carried out at three levels of

supply chain distribution (suppliers, distribution

centers, and consumers) in consider of multi-period,

multi-product issues, and adding inventory issues to

anticipate uncertainty in supply. Hydrogen fuel

supply chain distribution network can be seen in

figure 1.

Figure 1. Hydrogen Fuel Supply Chain Distribution

Network

The supply chain is divided into three groups: (1)

Suppliers level 1, that is oil palm plantations that

produce FFB for processing in Palm Oil Mill, (2)

Suppliers level 2, which is leaving empty bunch to

become the raw material for the process of making

hydrogen fuel, and the last destinationwhich is

Hydrogen Plant that produces hydrogen fuel.

4 CONCLUSION

Sumatera Utara has a great potential of empty bunch

for making a hydrogen fuel. To make it come true, it

needed a distribution network start from fresh fruit

bunch from farm until hydrogen fuel from factory.

Supply chain consist of three part such as supplier

level 1, supplier level 2, and hydrogen plant as

consumer. Supplier level 1 is farm that send a fresh

fruit bunch to supplier level 2. Supplier level 2 is a

palm oil factory that sent palm oil empty bunch to

hydrogen plant. The calculation shows that the palm

oil farm in Sumatera Utara can supply empty bunch

as the production capacity that makes this supply

chain can be applied.

ACKNOWLEDGMENTS

This work has been fully supported by TALENTA

Research Program (Universitas Sumatera Utara), No:

2590/UN5.1.R/PPM/2018, March 16th, 2018

REFERENCES

Muresan, Mirela.”Techno-economical Assessment of Coal

and Biomass Gasification-based Hydrogen Production

Supply Chain System,” accessed from

https://doi.org/10.1016/j.cherd. 2013.02.018 on 03 Juli

2018 at 1.45 PM

http://ebtke.esdm.go.id/post/2014/10/20/693/fuel.cell.ener

gi.masa.depan

Matzen, Michael,”Technoeconomics and Sustainability of

Renewable Methanol and Ammonia Productions Using

Wind Power-based Hydrogen,” accessed from

http://dx.doi.org/ 10.4172/2090-4568.1000128 on 03

July 2018 at 1.45 PM

Lin-Jin, Chen, dkk,” Economic Assessment of Biomass

Gasification and Pyrolysis: A review,” accessed from

https://doi.org/10.1080/15567249.2017.1358309 on 01

Juni 2018 at 08.00 PM

Zhang, Yanan, dkk.“Integrated Supply Chain Design for

Commodity Chemicals Production Via Woody

Biomass Fast Pyrolysis and Upgrading” accessed from

https://doi.org/10.1016/ j.biortech.2014.01.049 on 01

Juni 2018 at 08.00 PM

Eichman, Josua, dkk.2016.Economic Assessment of

Hydrogen Technologies Perticipacating in California

Electricity Markets accessed from

https://www.nrel.gov/docs/fy16osti/65856.pdf on 01

Juni 2018 at 08.00 PM

Melaina, M dan Penev, M.2013. Hydrogen Station Cost

Estimates. accessed from

https://www.nrel.gov/docs/fy13osti/56412.pdf on 01

Juni 2018 at 08.00 PM

González-Delgado, Angle Dario and Peralta,

Yeimmy,”Techno-economic Sensitivity of Bio-

Hydrogen Production From Empty Palm Fuit Bunches

Under Colombian Conditions” accessed from

http://www.aidic.it/cet/16/52/187.pdf on 01 Juni 2018

at 08.00 PM

Jahirul, Muhammad. 2012. Biofuels Production through

Biomass PyrolysisA Technological Review.

Queensland University of Technology,Brisbane,

Queensland 4000. Australia

Ramadhan, dkk. “Pengolahan Sampah Plastik Menjadi

Minyak Menggunakan Proses Pirolisis”. diakses dari

http://eprints.upnjatim.ac.id/4247/1/(6)Jurnal_Munawa

Design of Hydrogen Fuel Supply Chain Distribution Network from the Potency of Palm Oil Empty Bunches

235

r.pdf on 03 Juli 2018 at 2.03 PM

Fathoni, Ali. “Analisa Faktor-Faktor yang

Memperangaruhi Pemilihan Lokasi Terhadap Tingkat

Penjualan Usaha Jasa Mikro di Kabupaten Lamongan”

accessed from on 02 Juni 2018 at 08.00 PM

Chopra, Sunil, dkk. Supply Chain Management. Strategy,

Planning, and Operation. Fifth Edition. England:

Penerbit Pearson. 2013.

Lu, Dawei. Fundamentals of Supply Chain Management.

London: Ventus Publishing. 2011.

Direktorat Jendaral Perkebunan.2017.Statistik Perkebunan

Indonesia 2015-2017 Kelapa Sawit

Pusat Data dan Sistem Informasi Pertanian Sekretariat

Jendral-Kementrian Pertanian.2016. Outlook Kelapa

Sawit Komoditas Pertanian Subsektor Perkebunan

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

236