Comparison of Silica and Zeolite as Fillers on Unsaturated Polyester

Resin (UPR) Composites: The Effect on Tensile Properties

H. Nasution

1

, H. Harahap

1

, S. Pandia

1

and F. Wijaya

1

1

Department of Chemical Engineering, Faculty of Engineering, University of Sumatera Utara, Padang Bulan, Medan

20155, Indonesia

Keywords: Unsaturated polyester resin (UPR), Silica, Zeolite, Tensile strength, Matrix-filler interface.

Abstract: The effect of unsaturated polyester resin (UPR) composite filled with silica or zeolite on the tensile properties

were investigated. The composites were prepared by hand-lay up process with the variations of filler content

viz. 0, 10, 20, 30, and 40% by weight. The properties and characterization were carried out using tensile

properties and scanning electron microscopy. The results showed in the lower content of filler the tensile

properties of composite filled with zeolite were higher than filled with silica. The presence of pores and

tunnels in zeolite structure have increased the addition of the matrix-filler interface. The results were also

confirmed by image on morphology of the materials by scanning electron microscopy.

1 INTRODUCTION

Unsaturated polyester resin (UPR) is the most widely

used thermoset material because it has low shrinkage

properties, low viscosity, low cost, can be molded at

room temperature, and good weather resistance

(Prasad, Rao and Nagasrinivasulu, 2009; Deepa et al.,

2011; Waigonkar et al., 2011; Ray and Rout, 2005).

However, UPR tends to have relatively brittle

properties with low impact strength due to the

relatively high molecular weight. Specifically, one

way to increase the strength of the material is by

adding the dispersed phase in the matrix, so that when

the crack starts between the dispersed phase (filler), it

will be elongated, not spread, and muffled which

cause increased fracture toughness (Jesson and Watts,

2012).

The filler used in the composite matrix can be

organic or inorganic. Several studies on UPR

composites using organic fillers have been widely

reported (Gao et al, 2011; Du et al., 2010; Adenkunle

et al., 2011; Khalil, Bhat and Sartika, 2010).

Consideration of the use of organic fillers in UPR,

among others, is because of the easily attainable

organic filler and also the good biodegradation

ability. However, in terms of mechanical properties,

especially tensile strength, impact and also resistance

to heat and water absorption, organic filler still gives

less satisfactory effect. Therefore, the selection of

inorganic materials such as silica and zeolite is

feasible to be considered as fillers in UPR matrix.

Silica is a polymerization compound of silicic

acid, composed of a tetrahedral SiO

4

chain with a

general formula SiO

2

. Silica as a compound found in

nature has crystal structure. Silica has large surface

area and pore volume, hence it has the ability to

absorb various substances. In the usage, silica can

increase the mechanical strength of composites,

because silica has the ability to absorb water and as a

hardener. On the other hand, zeolite is porous

hydrated alumina silicate crystals mineral having a

three-dimensional skeletal structure formed of

tetrahedral [SiO

4

]

4

and [AlO

4

]

5

which form a network

of tunnel and cavities or pores (Pecover, 1987). By

the presence of the pores/cavities/tunnel structure, the

wetting of fillers by the matrix is better and will result

in more perfect interface interaction. The composite

produced will not need any additives such as

compatibilizer or coupling agent. The advantage of

using zeolite as a filler in the preparation of composite

material is that the matrix will be absorbed by zeolite

through surface absorption process and trapped in the

tunnel of zeolite structure, based on this absorption

mechanism it is expected that the matrix can be bound

in zeolite so that there is a good interaction between

matrix and filler. From the above-stated, the research

on the study of the addition of silica powder and

zeolite in the preparation of UPR based composites

Nasution, H., Harahap, H., Pandia, S. and Wijaya, F.

Comparison of Silica and Zeolite as Fillers on Unsaturated Polyester Resin (UPR) Composites: The Effect on Tensile Properties.

DOI: 10.5220/0010077902270231

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

227-231

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

227

on the mechanical properties and thermal of

composite materials is feasible for study.

2 METHODS

2.1 Materials

Materials unsaturated polyester resin (UPR) as

matrix, silica and zeolite as fillers and methyl ethyl

ketone peroxide (MEKP) as catalyst/hardener were

supplied by chemical store and used as received.

2.2 Preparation of Composite

Materials

Composites preparation were done using hand layup

method, in which unsaturated polyester resin (UPR)

was mixed with silica respectively with filler

variations: 0, 10, 20, 30, and 40% of composite total

weight. The mixtures were also added with methyl

ethyl ketone peroxide (MEKP) catalyst of 1.5% by

weight of the matrix weight and molded in the mold

according to the predefined test. Similar preparations

were also done for the UPR composite filled with

zeolite.

2.3 Tensile Properties

Tensile test was performed refers to the standard

ASTM D 638 Type IV using an instrument of Instron

machine AI700. The results of tensile test were

obtained in the form tensile strength and elongation at

break.

2.3.1 Tensile Strength

Tensile strength is a measure of maximum load that a

composite material can withstand without fraction.

Tensile strength is measured in force per unit of cross-

sectional area.

2.3.2 Elongation at Break

Elongation at break is the ratio between increased

length and initial length after breakage of the tested

composite.

It measures how much bending and

shaping a material can withstand without breaking.

2.4 Morphological Analysis

Scanning electron microscopy (SEM) analysis were

performed to observe the morphological changes that

occur in the unsaturated polyester resin (UPR), UPR

filled silica composite as well as UPR filled zeolite

composite. SEM analysis were done using SEM EVO

MA 10 ZEISS.

3 RESULT AND DISCUSSION

3.1 The Effect of the Filler

Composition on the Tensile

Strength of the Unsaturated

Polyester Composite Filled with

Silica and Zeolite

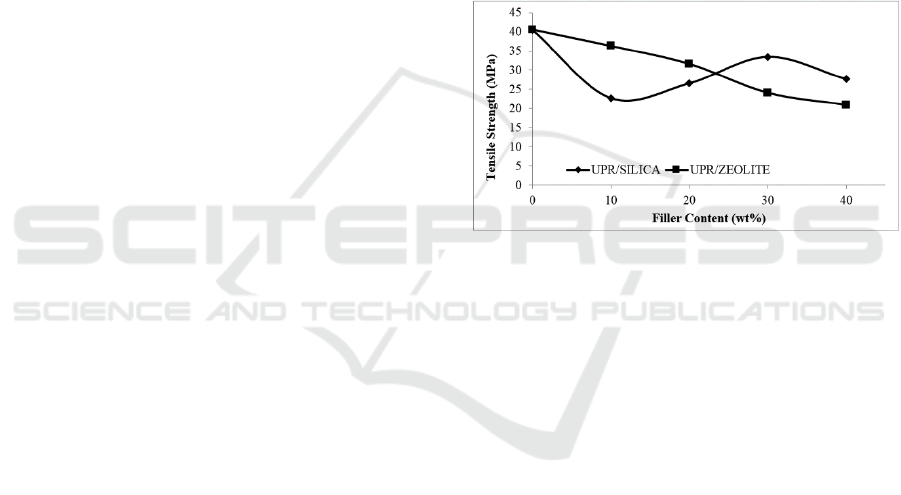

Figure 1 below shows the effect of filler content on

tensile strength of unsaturated polyester resin (UPR)

composite filled with silica as well as zeolite.

Figure 1: The effect of filler content on tensile strength of

unsaturated polyester filled with silica and zeolite

composite.

From the figure above it can be observed that in the

addition of silica filler as much as 10%, the composite

tensile strength decreased from 40.5 MPa to 22.7

MPa. The presence of silica as filler in a polyester

matrix has created a new phase. This leads to

increased matrix and filler interface tension. The

small composition of silica has not dispersed evenly

in the polyester matrix, and thus, its presence actually

makes the composite become weak. However this

changed in the addition of silica by 20% (26.6 MPa)

and continued with 30% (33.4 MPa), where the

tensile strength of composite materials was increased.

In the addition of 20% followed with 30% silica, the

polyester will be absorbed by the silica through

surface absorption process. Silica has a large surface

area and pore volume that has the ability to absorb the

matrix. Based on this absorption mechanism, the

matrix trapped in the pores of silica could be bound

so that there is a good interaction between the matrix

and the filler. However, the addition of 40% silica

again reduced the tensile strength of composite

materials to 27.6 MPa. This is due to the presence of

a relatively large amount of fillers, so that not all

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

228

fillers could be moistened by the matrix perfectly and

also the agglomeration potential of the filler.

For zeolite filler, a continuously declining trend of

tensile strength in composite materials was observed,

where the addition of 10% - 40% of fillers has

decreased the tensile strength properties from 36.3

MPa - 20.9 MPa. This shows that incorporating

zeolite filler to polyester matrix has not been able to

increase composite tensile strength. The presence of

zeolite fillers having a hollow and tunnel-like

structure is likely to have caused a large number of

interface phases that weaken the interaction between

matrix and filler. This weak interaction caused high

interface tension of matrix and filler as well as

weakening the attachment between the two phases.

However, in addition to the 10% and 20% fillers,

the tensile strength value exhibited by the zeolite-

filled polyester composite was better than the silica

filled. This indicates that the presence of a relatively

small amount of zeolite filler was more effective than

the silica filler. The presence of pores and tunnels

within the zeolite filler structure in optimum amount

(10-20%) gave a better effect on the tensile properties

of the composite material than the pore structure in

the silica filler.

3.2 The Effect of Filler Composition on

Elongation at Break of the

Unsaturated Polyester Resin

Composite (UPR) Filled with Silica

and Zeolite

Figure 2 below shows the effect of the filler content

on the elongation at break of unsaturated polyester

composite filled with silica as well as zeolite.

Figure 2: The effect of filler content on elongation at break

of unsaturated polyester composite filled with silica and

zeolite.

The figure above shows that both the silica and zeolite

filler have lower the elongation at break of the

composite material. The decrease occurs for each

addition of the filler composition ranging from 10%

to 40%. This shows that the presence of such fillers

has lowered the elasticity of the polyester matrix. In

this case, the interaction between the polyester matrix

with the silica and zeolite fillers has resulted in a more

limited movement of the polymer chain causing the

elongation at break in the resulting composite to

decrease. Furthermore, from the figure can also be

observed that the composite materials filled with

zeolite were more elastic than those containing silica

filler for the addition of 10-20% filler. In this case, the

tunnel and pores present in the silica structure and

absorbing the matrix can still maintain the elasticity

of the composite material.

3.3 The Morphological Characteristics

of Unsaturated Polyesters Resin

(UPR) and UPR Composites Filled

with Silica and UPR Composites

Filled with Zeolite

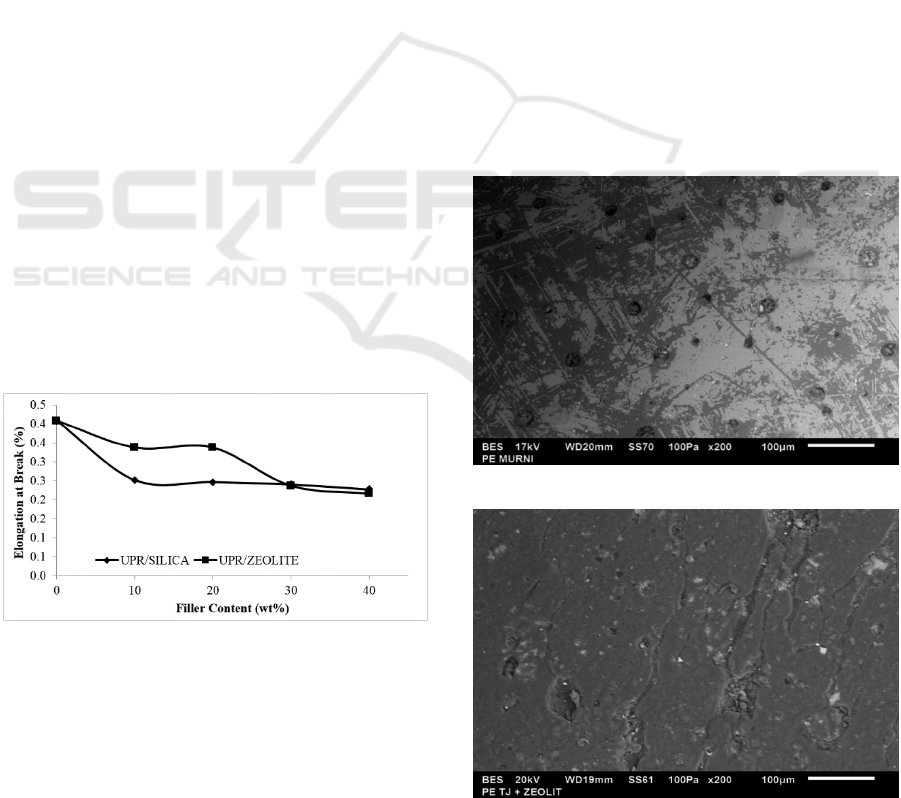

The images of surface morphology of unsaturated

polyesters resin (UPR) and UPR composites filled

with silica as well as UPR composite filled with

zeolite can be seen in Figure 3 below.

(a)

(b)

Comparison of Silica and Zeolite as Fillers on Unsaturated Polyester Resin (UPR) Composites: The Effect on Tensile Properties

229

(c)

Figure 3: Characteristics of surface morphology (a)

unsaturated polyester resin (UPR); (b) UPR filled with

silica; (c) UPR filled with zeolite.

The figure above shows the surface morphology of

unsaturated polyester resin (UPR), UPR composite

filled with silica as well as filled with zeolite. In the

figure of UPR (Fig. 3a) the surface image appeared to

have rigid structure, some empty fractions (voids),

and brittle. Whereas for the morphology of UPR

composite filled with silica (Fig. 3b) indicated that the

matrix has been absorbed into the silica filler.

However, in some regions it was observed that the

fillers were localized, marked with uneven clumps.

Compared with the morphological characteristics of

the UPR (Fig. 3a), it can be observed that the presence

of the silica filler in the unsaturated polyester matrix

(Fig 3b) has increased the matrix-filler interface

tension. This causes the lower composite tensile

strength than that of a UPR. Meanwhile, for the

zeolite-filled composite (Fig. 3c) it appeared that an

UPR matrix has also been absorbed into the zeolite

filler. However, when compared to the silica-filled

composite (Fig 3b), this composite showed a slightly

different morphology. The surface was observed to

contain tunnels that came from the filler structure, and

dispersion of the filler were observed to be more

uniform. This showed that the porous and tunnel form

zeolite filler structure was more compatible in the

matrix absorption, so that the surface tension between

the matrix-filler could be reduced. Thus the tensile

strength results also showed that for relatively small

compositions, zeolite was more suitable to be used as

filler in unsaturated polyester composite.

4 CONCLUSION

Unsaturated polyester resin (UPR) composite filled

with silica as well as zeolite still showed a lower

tensile strength value compared to polyester material.

Meanwhile, the most optimum silica filler

composition was 30% by weight, while for the zeolite

filler was 10% by weight. In lower composition, the

ability of zeolite as filler was better than silica. In this

case, this showed that the porous zeolite structure and

the tunnel form were more compatible in the matrix

absorption, so that the surface tension between the

matrix-filler can be reduced.

ACKNOWLEDGEMENT

The authors gratefully acknowledge that the present

research is supported by Directorate of Research and

Community Service Director General Strengthening

Research and Development Ministry of Research and

Technology and The Higher Education Republic of

Indonesia on year of grant 2018.

REFERENCES

Prasad A. V. N., Rao K. M. and Nagasrinivasulu G., 2009.

Mechanical properties of banana empty fruit bunch

fibre reinforced polyester composites. Indian Journal of

Fibre & Textile Research 34 pp 162-167.

Deepa B., Pothan L. A., Mavelil-Sam R. and Thomas S.,

2011. Structure, properties and recyclability of natural

fibre reinforced polymer composites. Recent

Developments in Polymer Recycling pp 101-120.

Waigaonkar S., Babu B. J. C., and Rajput A., 2011. Curing

studies of unsaturated polyester resin in FRP products.

Indian Journal of Engineering & Material Sciences 18

pp 31-39.

Ray D., Rout J., 2005. Thermoset biocomposites natural

fibers, biopolymers, and biocomposites, CRC Press.

United States of America.

Jesson D. A. and Watts J. F., 2012. Matrix composites:

effect on mechanical properties and methods for

identification. Polym. Rev 52 pp 321–354.

Gao Z., Ma D., Lv X., and Wang Q., 2011. Formation and

evaluation of kraft fibre-reinforced unsaturated

polyester (UPE) composites. BioResources 6 pp 5167-

5179.

Du Y., Zhang J., Yu J., Lacy T. E. Jr., Xue Y., Toghiani

H., Horstemeyer M. F., and Pittman C. U. Jr., 2010.

Kenaf bast fiber bundle-reinforced unsaturated

polyester composites. IV: Effects of fiber loadings and

aspect ratios on composite tensile properties. Forest

Prod.J 60 pp 582-591.

Adekunle K., Cho S. W., Patzelt C., Blomfeldt T., and

Skrifvars M., 2011. Impact and flexural properties of

flax fabrics and lyocell fiber-reinforced bio based

thermoset. Journal of Reinforced Plastics &

Composites 30 pp 685- 697.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

230

Khalil H. P. S., Bhat I. B., and Sartika M. Y., 2010.

Degradation, mechano-physical, and morphological

properties of empty fruit bunch reinforced polyester

composites. BioResources 4 pp 2278-2296.

Surya E., Michael, Halimatuddahliana, and Maulida, 2014.

Impact and thermal properties of unsaturated polyester

(UPR) composites filled with empty fruit bunch palm

oil (EFBPO) and cellulose. Advanced Materials

Research 896 pp 310-313.

Pecover, S. R., 1987. A review of the formation and geology

natural zeolites, natural zeolites. New South Wales:

Geological Survey Report GS 145 Department of

Mineral Resources Sydney pp 11-24.

Comparison of Silica and Zeolite as Fillers on Unsaturated Polyester Resin (UPR) Composites: The Effect on Tensile Properties

231