Lean Manufacturing Concept: Minimizing Non-value Added

Activities in Wood Manufacturing Process

Ukurta Tarigan.

1

, Aulia Ishak

1

, Vincent Sukirman

1

, and Uni Pratama P. Tarigan

1

1

Faculty of Engineering, Industrial Engineering Department, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Lean Manufacturing, Value Stream Mapping, 5W and 1H, Non-Value Added.

Abstract: PT. XYZ is a wood processing manufacturing company that produces household appliances. From the results

of monitoring to the company, it is seen that in the production process there is still a lot of waiting activities

and transport activities (non-value added activity) which leads to waste of processing time and resulting in

the longer lead time production process. Based on the problems, the lean manufacturing approach is used to

reduce non-value added activities. Through this method its analyze value-added activities and non-value

added activities with Value Stream Mapping tool then to reduce non-value added activities used 5W and 1H

principles. The study aims to eliminate non-value added activities through simplification of production

processes in order to reduce production time. After doing this research, obtained the improvement of

manufacturing lead time from the initial of 21471,76 seconds to 16352,76 seconds. Improvement by Lean

Manufacturing method also caused Process Cycle Efficiency to increase by 22 % and to increase the average

production per day by 42 units.

1 INTRODUCTION

PT. XYZ is engaged in processing wood into

furniture of household appliances such as chairs,

tables, cabinets, clothes hangers, wagons, shelves,

and others. This company uses raw material in the

form of wood brick from the wood of hull bought

from other company.

From the results of monitoring to the company, it

can be seen that in the production process there are

still many waiting activities and transportation

activities which is the non-value added activity that

leads to waste of processing time and longer lead time

production process. Therefore, it is applied to

improve production process with a lean

manufacturing approach to reduce the non-value

added activities.

The lean principle is an ongoing effort to

eliminate waste and increase the value added of the

product (Gaspersz, 2007). The lean process is

characterized by flow and prediction that overall

reduces uncertainty and confusion in manufacturing

plants (Liker, 2006). The concept of lean

manufacturing was developed to maximize the source

of utilization through minimizing disposal, then

formulated in response to a fluctuating and

competitive business environment (Sundar, 2014).

Lean Manufacturing is a philosophy that maximizes

efficiency, reduces costs, improves product quality,

and also sees the importance of how people work in

factories (Ali, 2015). Waste or waste is any human

activity that uses resources but does not create added

value (Haghani, 2015). Production at each process

must be triggered by a request from the process that

follows it (Das, 2014). Production Process of wood

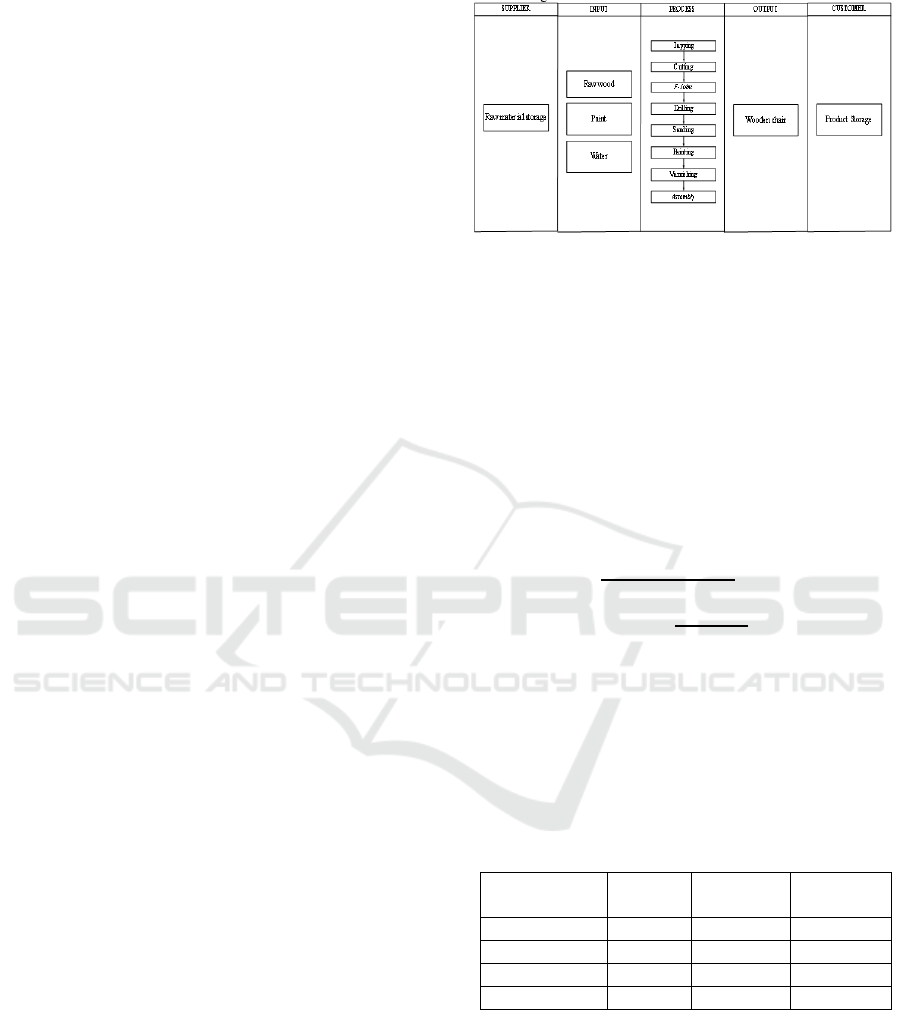

processing at PT. XYZ can be seen in Figure 1.

T-1

S-1

O-1

Taken from raw

material storage

Brought to the

tapping station using

forklift

Tapping raw m aterial

T-2

Brought to the cutting

station using forklift

O-2 Cut into 40 cm in size O-3

Cut into 60 c m i n

siz e

T-3

Taken to drilling

sta tion

O-4

Drilled on parts that

will be assemblied

T-7

Brought to the

refinement station

using forklift

O-8

Conducting s anding

activity

T-8

Taken to painting

sta tio n

O-9

Pa i n te d wi t h bas ic

colour

T-9

Taken to va rnish

sta tio n

O-10

Var nishi ng

T-10

Taken to drying

sta tion

Dryi ng

T-4

Taken into f-joint

sta tion

O-5

Conducting sti cking

activity t o form a

seating wit h (40x40)

cm in si ze

I-2

Dryi ng

I-1

D-1

Stacking t apping

results

T-6

Taken to drilling

sta tio n

O-7

Drilled on pa rts that

wil l b e a sse mb lie d

D-2

Stacking dril ling

result

T-5

Taken int o dri ling

sta tio n

O-6

Drilled on pa rts that

wil l b e a sse mb lie d

D-4 Stacking all parts

O-11

Assembly the chair

parts

T-11

Taken to pa cking

sta tion

T-12

Taken to product

stor age

S-2

Keep in product

stor age

5"

700"

5" 5"

60"

15"

60"

60"

D-3

Stacking sanding

results

1200"

300"

3600"

600"

600"

600"

600"

2000"

3600"

Figure 1: Wood Processing Process Chart

208

Tarigan, U., Ishak, A., Sukirman, V. and Tarigan, U.

Lean Manufacturing Concept: Minimizing Non-value Added Activities in Wood Manufacturing Process.

DOI: 10.5220/0010076602080212

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

208-212

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 RESEARCH METHOD

The research begins with the review and data

collection at PT. XYZ. Data collected from company

documents are the production volume, and

description of the production process using direct

observation and interviews directly in the field

The data processing steps in this research are as

follows :

a. Current state map

1) Constructing the value stream manager

2) SIPOC Diagram (Supplier-Input-Process-

Output-Customer)

3) Calculation of Standard Time

4) Waste Identification using Process Activity

Mapping

5) Map Creation for Each Process Category

Throughout the Value Stream

6) Forming the Overall Factory Flow Chart

7) Calculating Process Cycle Efficiency

b. Analyzing Current State Map

1) Waste Analyzing using 5W and 1H Method

c. Improvement using Lean Manufacturing

1) Proposed Process activity mapping

2) Constructing future state map

3 RESULT AND DISCUSSION

3.1 Constructing Current State Map

The paper Current state map is a description of the

production process that takes place within the

company covering material flow and information

flow. The steps of forming the current state map are

as follows

3.1.1 Deciding Value Stream Manager

In this research, the selected value stream manager is

the production manager

3.1.2 SIPOC Diagram (Supplier-Input-

Process-Output-Customer)

SIPOC Diagram (Supplier-Input-Process-Output-

Customer) of the wood processing production process

can be seen in Figure 2.

Figure 2: SIPOC Diagram of the Wooden Chair Production

3.1.3 Calculation of Standard Time and

Normal Time

The example of standard time and normal time

calculation for WC 1 is as follow (Sulataksana, 2005).

Normal Time =

𝐶𝑦𝑐𝑙𝑒 𝐶𝑦𝑐𝑙𝑒 𝑡𝑖𝑚𝑒 𝑥 𝑟𝑎𝑡𝑖𝑛𝑔 𝑓𝑎𝑐𝑡𝑜𝑟 (1)

= 705 x 1.04 = 733.2 sec

Standard Time =

Normal Time x

100 %

100% - Allowance %

(2)

= 733.2 x

100 %

100 % - 17%

= 883.37 sec

3.1.4 Deciding Value Stream Manager

Through process activity mapping of wooden chair

making above obtained the number of operation

process, transportation, inspection, storage and delay

along with its time can be seen in Table 1. (Vanany,

2005)

Table 1: Process Added Mapping

Symbol Amount

Time

(sec)

Percentage

(%)

Operation 11 5340 29.84

Transportation 12 6260 34.97

Inspection 2 1200 6.70

Delay 4 5100 28.49

3.1.5 Map Creation for Each Process

Category throughout the Value Stream

Mapmaking for each process category along the value

stream uses the standard time data for each process

plus other data such as processing time, and the

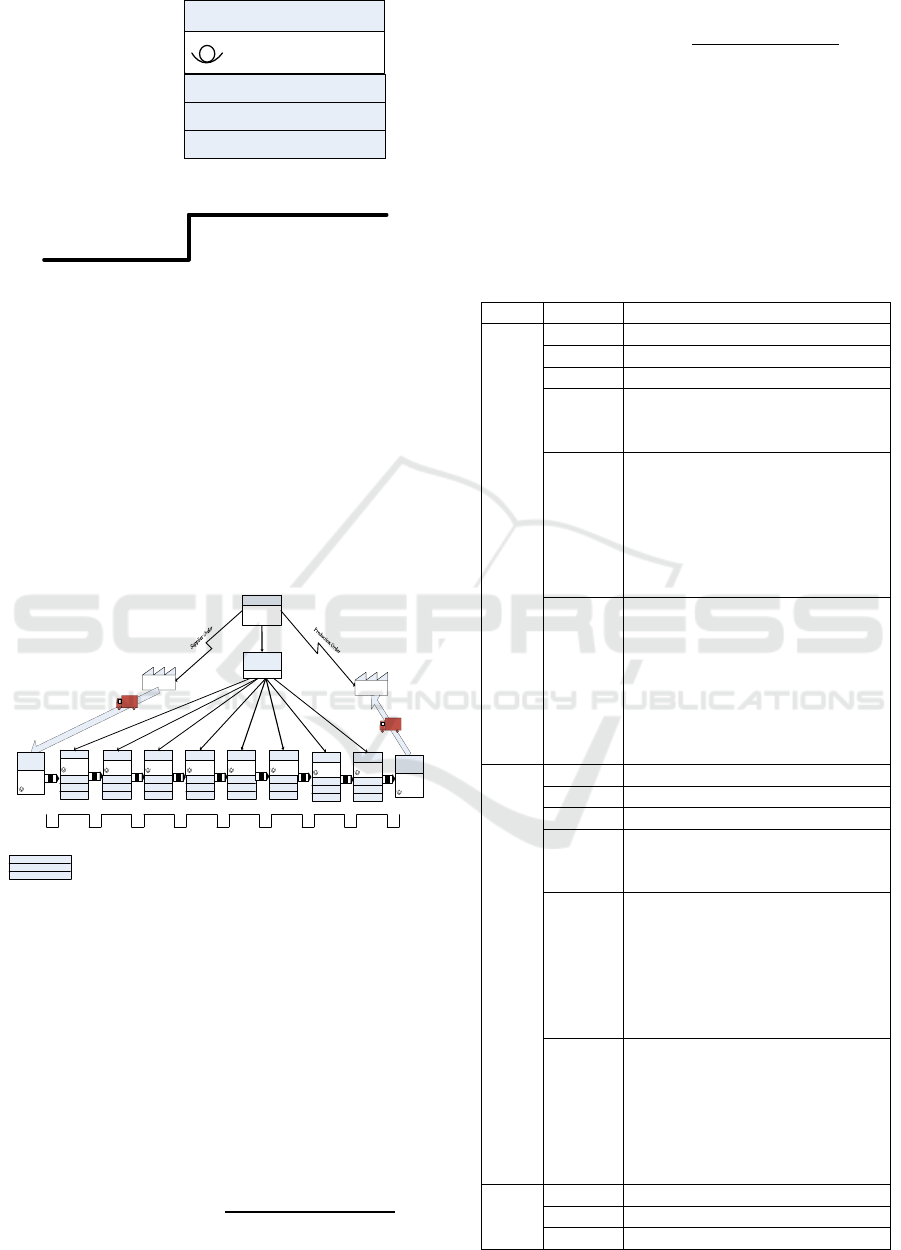

number of operators. a preliminary process category

map for the preparation of wooden chair production

as shown in Figure 3 (George, 2005)

Lean Manufacturing Concept: Minimizing Non-value Added Activities in Wood Manufacturing Process

209

883,37

Tapping

Op : 4

C/T : 883,37

1 shift = 8 hours

Figure 3: Map of Tapping Category

3.1.6 Forming the Overall Factory Flow

Chart

Each process along the value stream is combined with

material flow and information flow so that it becomes

a single flow in the factory. After all, information is

obtained, thus the current state map can be formed by

placing all material and information flows into the

folder.(Vanany, 2005). Current state map of wooden

chair products can be seen in Figure 4.

F-jointCutting Sanding

Op : 3

C/T : 2490,7

1 shift

Supplier

Customer

Operasional Manager

Head of Production

Department

Lead Time Manufacturing

: 21471,76

Value Added Time : 15171,76

Non Value Added Time

: 6300

Product

storage

Raw material

storage

Op : 4

C/T : 2359,52

1 shift

Op : 2

C/T : 767 ,86

1 shift

Op : 4

C/T : 346,07

1 shift

Op : 4

C/T : 882,3 7

1 shift

Tappi ng

Drilling

Painting

Assembly

Op : 8

C/T : 4 653, 18

1 shift

Op : 4

C/T : 8 261, 9

1 shift

Op : 2

C/T : 1691, 16

1 shift

Varnishing

182,37 346,07

700

767,86 1159,52 1290,7

1200 1200 600

1091,16 5661,9

2600

4653,18

Figure 3: Current State Map of Wooden Chair Product

3.1.7 Calculating Process Cycle Efficiency

The calculation of manufacturing lead time is done to

determine the condition of the original factory.

Calculation of Process Cycle Efficiency which

consists of manufacturing lead time calculation,

process cycle efficiency. The manufacturing lead

time is 21471.76 seconds. The calculation of process

cycle efficiency is as follows

Process Cycle Efficiency

(3)

= 15171.76 / 21471.76 = 0.7066 ≈ 70.66 %

Average Finishing Time

(4)

= 55200/312 = 176.92 ≈ 177 unit/day

3.1.8 Improving Activities using Lean

Manufacturing

The activities included as non-value added activity

and can be improved will be analyzed using the 5W

and 1H method which can be seen in Table 2.

Table 1: Activities Analyzing using 5W and 1H Method

Num. Analyze Information

1

What Stacking Results of the Tape

Who O

p

erato

r

Where Work center I

When

This activity is done before the

result of the tape are brought to the

cuttin

g

section

Why

This delay activity is considered

ineffective because it takes a long

time, this activity occurs because

the operator stacking the tapping

results first before being

transported due to the distance

b

etween the two remote stations

How

Activity can be minimized by

closer the tuning station and the

cutting station where the

operational manager gives

direction to the operator so that

the result of the tape can be

directly brought to the cutting

machine

2

What Stacking Drilling Results

Who Operato

r

Where Work center IV

When

This activity is done before the

drilling results are brought to the

refinement section

Why

This delay activity is considered

ineffective because it takes a long

time, this activity occurs because

the operator stacking the drilling

results first before being

transported due to the distance

b

etween the two remote stations

How

Activity can be minimized by

closer the drilling station and the

refinement station where the

operational manager gives

direction to the operator so that

the drilling results can be directly

b

rought to the refinement station

3

What Stackin

g

Refinement Results

Who O

p

erato

r

Where Work center V

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

210

When

This activity is done before the

refinement results is brought to

the painting section

Why

This delay activity is considered

ineffective because it takes a long

time, this activity occurs because

the operator stacking the

refinement results first before

being transported due to the

distance between the two remote

stations

How

Activity can be minimized by

closer the refinement station and

painting station where the

operational manager gives

direction to the operator so that

the refinement results can be

directly brought to the painting

station

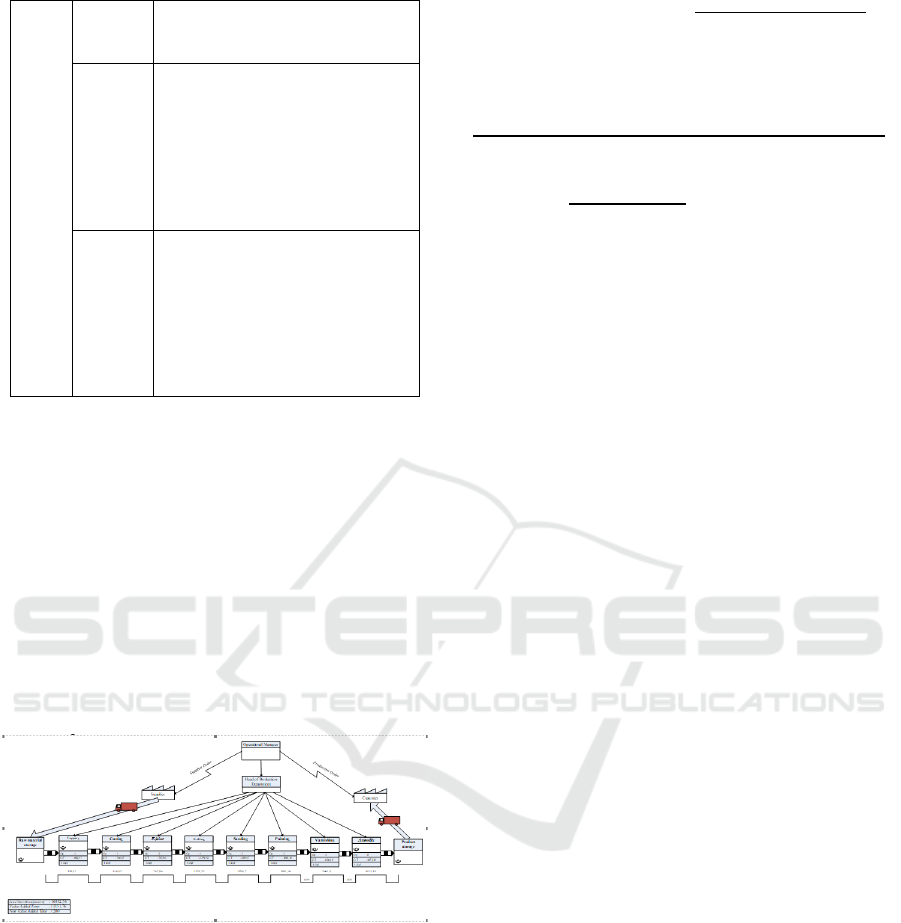

3.1.9 Future State Map Depiction

Future State Map based on the results of proposed

improvements that have been made previously.

Changes in time included are changes in time that can

be observed or estimated from the current conditions,

while for the reduced time that can be obtained such

as a reduction of transport time and wood buildup due

to the reduction of activities that can cause waste at

the time of production. Future State Map can be seen

in Figure 5 below

Figure 5: Proposed Future State Map

3.1.10 Calculating Improved Process Cycle

Efficiency

The calculation of manufacturing lead time is done to

determine the condition of the original factory.

Calculation of Process Cycle Efficiency which

consists of manufacturing lead time calculation,

process cycle efficiency. The proposed

manufacturing lead time is 16352,76 seconds. The

calculation of process cycle efficiency is as follows

Process Cycle Efficiency

= 15151.76 / 16352.76 = 0.9266 ≈ 92.66 %

Efficiency increased = 92.66 % - 70.66 % = 22 %

Production Improvement =

Actual Manufacturing Lead Time - Proposed Manufacturing Lead Time

Actual Manufacturing Lead Time

(5)

=

21471.76 - 16352.76

21471.76

= 0.2384 x 177 = 42 units

4 CONCLUSIONS

Based on the analysis result using Lean

Manufacturing approach, the delay or non-value

added the activity that occurs during the production

process of wood making affects the productivity of

the company. This can be seen where after the

improvement with lean manufacturing approach there

is a change in manufacturing lead time which initially

equal to 21471.76 seconds become 16352.76 seconds.

Improvements to the Lean Manufacturing method

with improved results for Process Cycle Efficiency

increased by 22 % and for an average daily

production increase of 42 units to 219 units per day.

REFERENCES

Gaspersz, V, 2007. "Lean Six Sigma for Manufacturing and

Service Industry, PT. Gramedia Pustaka Utama,

Jakarta.

Liker, Jefrey K., 2006, The Toyota Way, Erlangga:

Indonesia.

Sundar, R., Balaji, A., & Kumar, R. S. 2014. A Review on

Lean Manufacturing Implementation Techniques.

Procedia Engineering 97, 1875-1885

Ali, Syed N. 2015. Productivity Improvement of a

Manufacturing Facility Using Systematic Layout

Planning

Haghani. 2015. A Genetic Algorithm For solving A Multi-

Floor Layout Design Model Of A Cellular

Manufacturing System With Alternative Process

routings And Flexible Configuration, Springer.

Das, B., Venkatadri, U., & Pandey, P. ((2014)). Applying

Lean Manufacturing System to Improving Productivity

of Coil Manufacturing. Int J Adv Manuf Tech, 307-323.

Wijayanto, Bagas, dkk. 2015. “Rancangan Proses Produksi

Untuk Mengurangi Pemborosan Dengan Penggunaan

Konsep Lean Manufacturing Di PT. Mizan Grafika

Sarana”. Bandung :Institut Teknologi Nasional

(ITENAS)

Sutalaksana, Iftikar, dkk. 2005. Teknik Perancangan Sistem

Kerja. Bandung: ITB.

Lean Manufacturing Concept: Minimizing Non-value Added Activities in Wood Manufacturing Process

211

Vanany, Iwan. 2005. “Aplikasi Pemetaan Aliran Nilai Di

Industri Kemasan Semen”. Surabaya :Institut

Teknologi Sepuluh Nopember (ITS).

George L, Michael. 2005. Value Stream Management for

the Lean Office : Eight Steps for Planning, Mapping,

Sustaining Lean Improvements in Administrative

Areas. Productivity Press.

Rother M, and Shook J. 2003. Learning to See, Value

Stream Mapping to Create Value and Eliminate Muda.

USA: The Lean Enterprise Institute, Inc.

Soenaryo, Hadi, dkk. 2015. Usulan Meminimasi Waste

Pada Proses Produksi Dengan Konsep Lean

Manufacturing Di CV.X. Bandung : Institut Teknologi

Nasional (Itenas)

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

212