Analysis of the Influence of the Use of Palm Oil Fuel Ash (POFA) and

Lime against Unconfined Compressive Strength Value on Clay

Ika Puji Hastuty

1

, Roesyanto

1

and Rudian Syah Nst

1

1

Departement of Civil Engineering, Universitas Sumatera Utara, Jl. Dr. Mansur Kampus USU, Medan, Indonesia

Keywords: Unconfined Compressive Strength, Clay, Palm Oil Fuel Ash.

Abstract: Unconfined Compression Test is one of the parameters needed to determine the shear strength of the soil.

Unconfined Compressive Test in the laboratory is performed on original and remoulded soil samples. Soil is

one of the materials used in the construction. However, not all soils can be used as construction materials.

Therefore, it is necessary to improve the properties of the clay soil that meet the technical requirements and

parameters. One of the efforts made is by soil stabilization method. This study will discuss the stabilization

of clay soil with the addition of lime and Palm Oil Fuel Ash (POFA) as stabilizer material which is expected

to improve the physical and mechanical properties which will be observed with Unconfined Compression

Test (UCT) to obtain a clay soil that meets the technical requirements of use on construction field. The

mixture combinations which will be used in this research are 2%-12% of POFA, 4% and 6% of lime. From

the test of index properties for the original soil has 34.43% of water content; 2.65 of specific weight;

47.33% of liquid limit; and 29.88% of plastic index, this soil is included in the group of CL (clay – low) and

this soil could be classified as type of soil A7-6. The CBR value for unsoaked original soil is 6.29%.

Meanwhile the optimum CBR value for all mixture variations of unsoaked soil is obtained in the mixture of

4% lime and 12% POFA which is equal to 9.48% and the optimum unconfined compressive strength also

obtained from the same mixture which is equal to 3,908 kg/cm

2

.

1 INTRODUCTION

The soil consists of three components, they are

water, air, and solid materials. Air is considered to

have no technical effect, meanwhile water

significantly affects the engineering properties of

soil. The cavity between the grains can be partially

or completely filled by water or air. When the cavity

is completely filled with water, the soil will become

partially saturated. Water content is expressed in

percent, where the transition from solid to semi-solid

state is defined as the shrinkage limit. The water

content in which the transition from a semi-solid

state to a plastic state occurs is called the plastic

limit, and from the plastic state to the liquid state is

called the liquid limit. These limits are also known

as Atterberg limits.

Clay has some distinctive characteristics, which

are, in a dry condition it will be hard, in a wet

condition it will be plastic and cohesive, clay also

expands and shrinks rapidly so that it will get a great

volume change and it happens because of the

influence of water. The shear strength of the soil will

be decreased if the structure of the soil is disturbed.

The volume of soil which has a lot of clays will

change if the water content changes. The level of

expanding generally depends on several factors, they

are the type and amount of minerals present in the

soil, water content, soil structure, salt concentration

in pore water, cementation and the presence of

organic materials.

Due to the unstable clay properties, stabilization

is required in order to increase the soil bearing

capacity. Stabilization can be done with mixing the

soil with another materials like cement, lime stone

and others to increase engineering properties. The

soil stabilization process involves mixing the soil

with other soils to obtain the desired gradation, or

mixing the soil with the manufactured materials so

that the engineering properties will be better. Lime

can be used as stabilizer with condition that the

plasticity index of the soil has to less than or equal to

10%. The purposes of this research are to modify the

soil properties, to improve the wet soil in order to

make it can be used, to decrease the plasticity so that

the materials will get more stable, and to increase

Hastuty, I., Roesyanto, . and Nst, R.

Analysis of the Influence of the Use of Palm Oil Fuel Ash (POFA) and Lime against Unconfined Compressive Strength Value on Clay.

DOI: 10.5220/0010072101630167

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

163-167

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

163

the bearing capacity of clay. The palm oil industry

produces solid waste such as fibers, shells and empty

bunches. Palm bunches contain lime (CaO) and

silica that has the potential to be used as stabilizers.

The previous research (2017) on the stabilization

using lime obtained a result that lime mixture with a

mixture of 10% lime gave an optimum CBR value of

8.75%. Farras Nazwa (2017) conducted a study on

the stabilization using cement, lime and gypsum

with Unconfined Compression Test (UCT) and

obtained a result that lime mixture with a mixture of

10% lime gave a maximum compressive strength

(q

u

) of 3.307 gr/cm

2

.

2 METHOD

In this research, the materials that we used are clay,

lime, and POFA. Soil samples used in this study

were taken from PTPN II, Patumbak, Deli Serdang,

North Sumatra. The lime which is used is dry lime

bought from the store. Then the lime was filtered

using a sieve no. 200. The POFA used in this study

was taken from PT. London Sumatera, Tanjung

Morawa, North Sumatera.

2.1 Experimental Apparatus

The equipments used in this research are the tools

for Water Content Test, Specific Gravity Test,

Atterberg Limit Test, Compression Test, Unconfined

Compression Test, and other tools in Soil Mechanics

Laboratory, Faculty of Engineering, Universitas

Sumatera Utara

2.2 Manufacture of Specimens

The sample was divided into two parts: the original

soil sample without lime and the POFA and samples

with the mixture of lime and POFA, as for the

percentage mixture of POFA are 2%, 3%, 4%, 5%,

6%, 7%, 8% , 9%, 10%, 11%, 12% and for lime are

4% and 6%, with curing time for 7 days.

2.3 Sample Testing

Tests for the original soil include: Water Content

Test, Specific Gravity Test, Atterberg Limits Test,

Sieve Analysis Test, Compaction Test, Unconfined

Compression Test

The tests for soils that have been mixed with

POFA and lime include: Atterberg Limits Test,

Compaction Test, Unconfined Compression Test.

2.4 Data Analysis

Analyzing the data is done after the whole sample

has been tested and analyzed. Test results can be

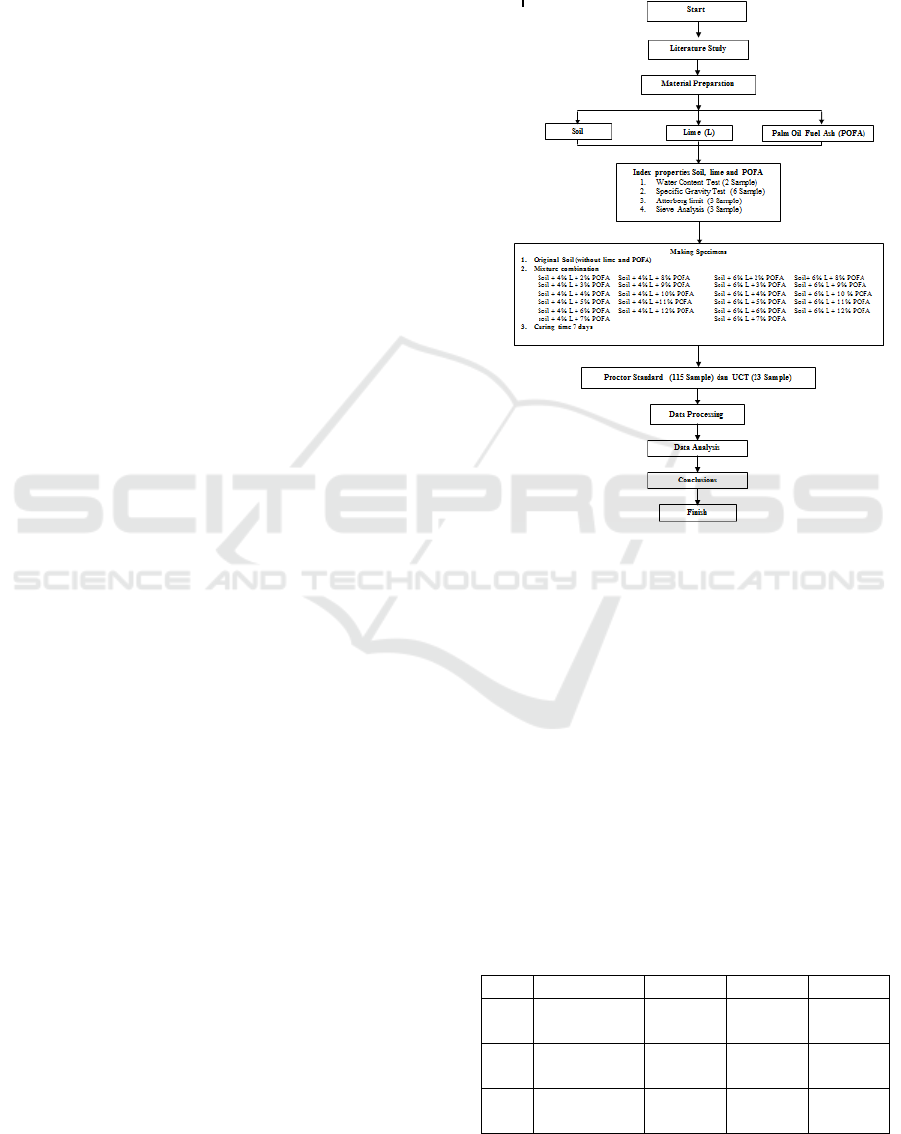

graphs and tables. The flowchart is show in Figure 1.

Figure 1: Research Flow Chart

3 RESULT AND DISCUSSIONS

The results will be discussed in three subsections,

they are physical properties, soil mechanics with

stabilizer, and engineering properties (Proctor

Standard and of Unconfined Compression Test).

3.1 Physical Properties of Soil

The results of testing the physical properties of soil

can be seen in Table 1 below.

Table 1: Result of Physical Properties

No. Data Soil POFA Lime

1

Water

Content

34.43 % - -

2

Specific

Gravity

2. 6537 2.5744 2.59

3

Liquid

Limit

47.33 %

Non -

plastic

Non -

plastic

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

164

4

Plastic

Limit

17.45 %

Non -

plastic

Non -

plastic

5

Plasticity

Index

29.88 %

Non -

plastic

Non -

plastic

6

Sieve

Analysis

51.38 % 75.91% 30.05%

From the data above obtained that the percentage

of soil passed the sieve no.200 is 51.38% with liquid

limit 47.33% and index plasticity 29.88%. Based on

the AASHTO soil classification, for the percentage

of passing the sieve no. 200 minimum 36%, has a

liquid limit of at least 41% and a plasticity index

value of at least 11% then the soil samples can be

classified in soil type A-7-6. Based on soil

classification according to USCS, which obtained

liquid limit value of 47.33% with plasticity index

value of 29.88%, soil samples are included in Clay

Low.

Table 2: Chemical Composition of POFA and Lime.

N

o

.

Chemical

Compounds

POFA

(%)

Lime

(%)

1 Silica (S

i

O

2

) 67.4 3.03%

2

Calcium oxide

(CaO)

1.542 51.8%

3

Magnesium

oxide (MgO)

3.024 0.81%

4

Iron(III) oxide

(Fe

2

O

3

)

0.001 0.4%

5

Aluminium

oxide (Al

2

O

3

)

10.999 1.53%

3.2 Soil Mechanic with Stabilizer

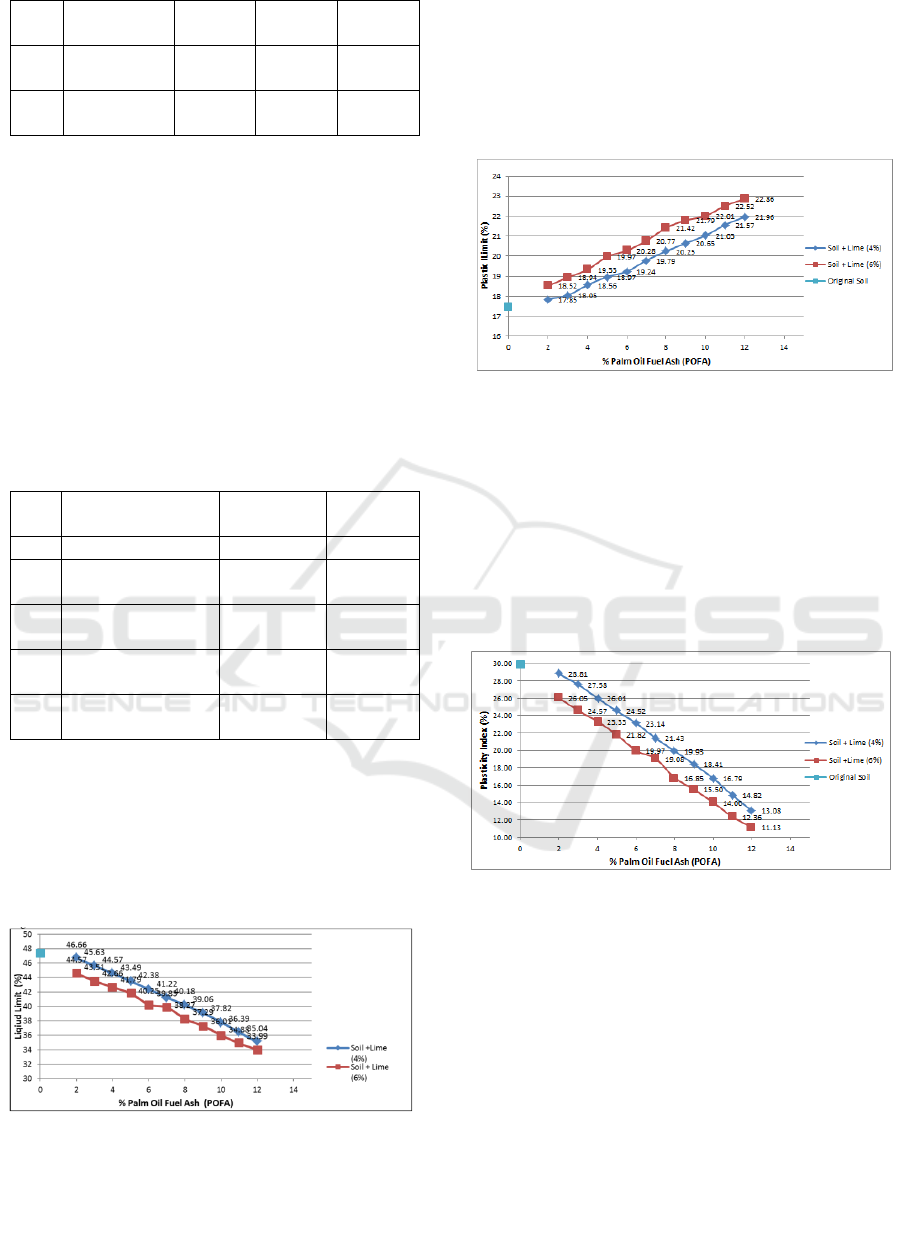

Atterberg Limit test results for the original soil and

soil stabilizer are shown in Figure2, Figure 3, and

Figure 4.

Figure 2: Graph of liquid limit with percentage variations

of POFA.

The results show that the liquid limit of the

original soil is equal to 47.33% and the lowest liquid

limit value obtained from the addition of 6% lime +

12% POFA with 7 days of curing time is equal to

33.99%. It can be seen that the liquid limit has

decreased due to the addition of lime and POFA.

The greater the percentage of the addition of POFA

and lime, the smaller the liquid limit.

Figure 3: Graph of plastic limit with percentage variations

of POFA.

Figure 3 shows an increase in the plastic limit

value due to the addition of lime and POFA. The

plastic limit is 17.45% to soil and continues to

increase until the highest plastic limit value in the

6% Lime + 12% POFA of 22.86%. The greater the

percentage of the addition of POFA and lime, the

higher the plastic limit.

Figure 4: Graph of plasticity index with percentage

variations of POFA.

Figure 4 describes decrease in the plasticity

index value due to the addition of lime and POFA.

Swelling on the soil can be reduced if the plasticity

index value is low. The addition of POFA can

increase the attachment of soil particles so that the

granules formed are more stable and harder. If the

POFA and limestone are used together, the silica

contained in the POFA can cover the soil pores and

the soil will be more resistant to water, resulting in a

decrease in the plastic properties of the soil [1]. The

decrease in plasticity index is relatively large,

namely from 28.88% to 11.13% in the variation of

Analysis of the Influence of the Use of Palm Oil Fuel Ash (POFA) and Lime against Unconfined Compressive Strength Value on Clay

165

6% limestone + 12% POFA mixture in curing time 7

days.

3.3 Unconfined Compression Test

(UCT)

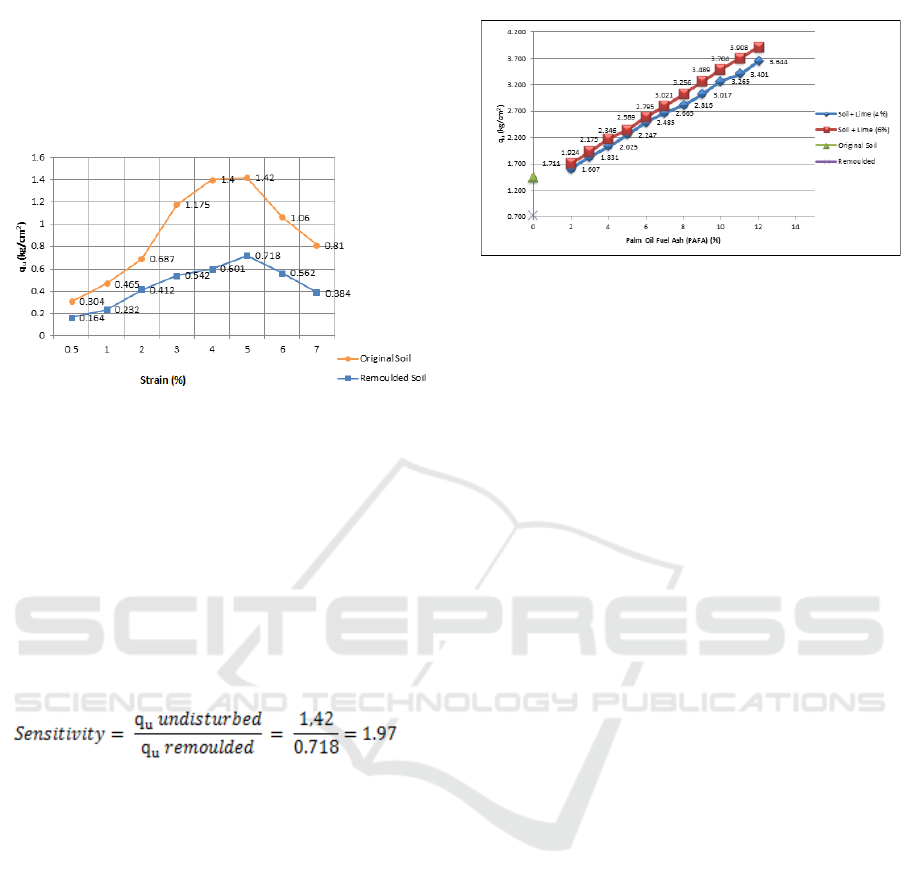

Figure 5: Graph of Relation of Soil Compressive Strength

(q

u

) and Strain on Original and Remoulded Soil

Figure 5 tells the compressive strength value for the

original soil of 1.42 kg / cm² and for remoulded soil

0.718 kg / cm². The decrease will occur if the

maximum compressive strength value has been

reached. The decline occurred due to damage to the

structure of the soil received on remoulded soil. Soil

damage due to reduced soil strength is called

sensitivity.

(1)

The soil sample used in this study has a

sensitivity ratio of 1.97. So, it is classified into low

sensitivity soil. That is, the structural damage

experienced by the soil does not have a big effect on

the change of compressive strength or the shear

strength of the soil. Clay with low sensitivity do not

lose much of their structural strength after they have

been disrupted in their original order or after

remoulded. The higher the sensitivity value of the

soil, the larger the change to the parameters of its

strength when it receives a disturbance.

Figure 6 below that the strength of original soil

(q

u

) is 1.42 kg/cm

2

. Then, the unconfined

compressive strength keeps increasing along with

the addition of lime and POFA. The maximum

unconfined compressive strength is obtained from

the addition of 6% lime + 12% POFA that is equal to

3.908 kg/cm

2

.

Figure 6: Graph between Unconfined Compression

Strenght (qu) with mixed variation of Lime and POFA

addition

Thus, the more the addition of lime and POFA

will result in greater compressive Strength of soil.

This is because the percentage of addition of lime

and POFA in this study is still classified in the

addition of an effective stabilizer.

4 CONCLUSIONS

1. The optimums CBR obtained on the

addition of 4% Lime + 12% POFA and 6%

Lime + 12% POFA which are 8.98% and

9.48%.

2. The maximum compressive strength are

obtained on the addition of 4% Lime + 12%

POFA and 6% Lime + 12% POFA with

compressive strength which are equal to

3.644 kg/cm

2

and 3.908 kg/cm².

3. Along with the addition of stabilizer

materials with different percentages, there

is a decrease in the value of PI on the soil

which means the soil becomes more stable.

4. Increasing the value of the maximum dry

weight (γd

max

) causes a decrease in the

optimum water content (w

opt

).

5. CBR values obtained with the addition of

stabilizers in the form of lime and POFA

increase as the amount of mixture of the

stabilizer material increases.

6. The unconfined compressive strength (q

u

)

and Cu obtained from the unconfined

compression test are increasing as the

amount of mixture of the stabilizer material

increases.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

166

ACKNOWLEDGEMENTS

The authors gratefully acknowledge that the present

research is supported by Laboratory of Soil

Mechanics, Department of Civil Engineering

Universitas Sumatera Utara.

REFERENCES

Bowles, J.E., 1989, Sifat-Sifat Fisis dan Geoteknik Tanah

(Mekanika Tanah), Jakarta: Erlangga.

Hardiyatmo, H C 2010 Mekanika Tanah 1 (Yogyakarta:

Gadjah Mada University Press)

Ronny Hutahuruk, 2016 Stabilisasi Tanah lempung

dengan menggunakan abu Vulkanik di tinjau dari

Nilai Unconfined Compression Test (UCT) (Medan:

Program Studi Teknik Sipil Universitas Sumatera

Utara.

Refi, Ahmad, dkk. 2015. Pengaruh Variasi Abu Sawit

Terhadap Kembang Susut Tanah Lempung. Padang:

Insitut Teknologi Padang.

Warsiti. 2009. Meningkatkan CBR dan Memperkecil

Swelling Tanah Sub Grade Dengan Metode

Stabilisasi Tanah dan kapur. Semarang: Politeknik

Negeri Semarang.

Ika Puji Hastuty, Roesyanto, and Jeriko A 2017 Study of

the Effectiveness of the Use of Cement and Bottom Ash

Towards The Stability of Clay in Term of UCT Value

Science Direct Procedia Engineering 171, 484 – 491.

Analysis of the Influence of the Use of Palm Oil Fuel Ash (POFA) and Lime against Unconfined Compressive Strength Value on Clay

167