The Comparison of Compressive Strength of Normal Concrete with

Artificial Lightweight Aggregate Concrete

Andi Yusra, Inseun Yuri Salena and Heri Safrizal

Civil Engineering Department, Teuku Umar University, Alue Peunyareng, Meulaboh, Indonesia

Keywords: Artificial Lightweight Agregate (ALWA) Concrete, Clay Soil, Normal Concrete.

Abstract: This study was conducted to investigate the effect of using Artificial Lightweight aggregates (ALWA) from

clay soil as partial substitution for coarse aggregates in normal concrete by determine the mass of concrete

and its effect on the compressive strength. The proportion of ALWA in design mix was 0%, 10%, 20%, and

30% with w/c ratio 0.3 and 25 Mpa in concrete strength. The method used was ACI with cylinder sample at

test age 28 and 56 days. The weight of ALWA concrete was 12.97 kg and 13.05 kg (0%), 12.07 kg and 12.12

kg (10%), 11.45kg and 11.58kg (20%) and 10.95 kg and 11.17 kg (30%). The test result in 0 % ALWA

concrete was 25.67 MPa and 25.95 MPa, 23.40 MPa and 23.87 MPa (10%), 18.02 MPa and 18.49 MPa (20%)

and 15.29 MPa and 15.85 MPa (30%). The results indicated that the higher the percentage in ALWA, the less

the weight of concrete. Variation in ALWA percentages affected the compressive strength, but in concrete

ages, it did not have effect. However, the strength of the concrete may decrease, but still can be used as a

structural concrete with a lighter weight.

1 INTRODUCTION

Aceh Province is one of the areas that have a high

level of earthquake intensity. The magnitude of the

intensity of the earthquake caused many casualties

and destroyed many residentsial building. Generally,

construction planning and implementation in

residential buildings, educational institutions,

commercial, industrial and other public facilities are

dominated by concrete structures that use aggregate

materials as one of the main components.

These Aggregates make the mass of concrete

increased and heavier. Another way to get lighter

concrete is to replace some of the coarse aggregates

with lightweight aggregates using alternative

materials that are easily found in the environment.

The lightweight aggregates can reduce the unit weight

of concrete, but has compressive strength that is

almost the same as normal concrete.

One way to get lighter concrete is to replace some

of the coarse aggregates on the concrete. This coarse

aggregate will be partially substituted with artificial

Lightweight aggregates (ALWA) made from clay

soils. The number of small industries engaged in the

manufacture of bricks in Aceh Barat, especially

Meulaboh has a type of clay soil that can be utilized

as a material of lightweight aggregates.

This coarse aggregate of ALWA is made from

clay soil by adding rice husk ash in it. The addition of

rice husk ash is to increase the strength because the

silica content in it is high. The use of rice husk ash is

to reduce the rice husk waste that accumulates at the

location of rice mill. Also rice husk ash and clay soil

easily found in the surrounding Regency of West

Aceh.

2 MATERIAL AND METHODS

2.1 Preparation of Samples

Production of ALWA is completed in brick factory in

Gampong Ujong Patihah, Nagan Raya District.

Concrete work started from examination of aggregate

physical properties, making of specimens, curing and

testing of specimens were conducted at the Public

Works Laboratory of West Aceh.

The material used to produce artificial lightweight

aggregate (ALWA) is Portland cement, clay soil, rice

husk ash, fine aggregate (sand) and water. Then, as

comparison, normal concrete was made at 25 MPa

concrete strength with Portland cement material, fine

aggregate (sand), coarse aggregate (gravel) and

water. Portland cement type I used as ingredients in

Yusra, A., Salena, I. and Safrizal, H.

The Comparison of Compressive Strength of Normal Concrete with Artificial Lightweight Aggregate Concrete.

DOI: 10.5220/0010037300290034

In Proceedings of the 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and Technology (ICEST 2018), pages 29-34

ISBN: 978-989-758-496-1

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

29

producing concrete. There is no Laboratory

examination for cement because it meets Indonesian

National Standard (SNI) l5-20490-1994. The

examination is only done visually against the torn bag

and there are no hard clumps on the cement.

Examination of coarse aggregates (gravel) and

fine aggregates (sand) as concrete-forming materials

is necessary to obtain good material quality

(anonymous 1982). This examination is performed on

aggregate properties that include specific gravity,

absorption, bulk density, sieve analysis, and fineness

modulus. Then continue with ALWA aggregate

production process which is done in brick making

factory in gampong Ujong Patihah of Nagan Raya

Regency.

The water used in the mixture of concrete and its

curing comes from clean water obtained from the

West Aceh Public Works Laboratory. The water in

this laboratory meets the standard of clean water

suitable for concrete mix.

2.2 Stage of Works

2.2.1 Process and Producing Artificial

Lightweight Aggregates (ALWA)

According to SNI 03-2461-2002, Artificial

Lightweight Aggregates (ALWA) made by heating

materials, such as furnace slag, smelting iron

diatomaceous clay, fly ash, ground flakes, slate and

clay. One of the artificial light aggregates is made of

sedimenter clay that through burning process with

temperature between 500-1250

0

C and can be used for

lightweight structural concrete with specific gravity

with ranges from 1400-2000 kg / m

3

.

The clay should fulfill the requirements such as,

containing alumina silicates and dissociated

substances which may produce gases above its

melting temperature. Because the weight is very light

then the concrete produced will be lighter than normal

concrete. Aggregates gradation requirements for

lightweight concrete using ALWA following ASTM

C330-89 standard (Standard Specification Aggregate

for Structural Concrete) can be seen in table 1 below:

Table 1: Gradation of ALWA ASTM C330-89

The basic ingredients of lightweight aggregate

ALWA are clay soils. Clay used as aggregate is first

destroyed and mixed with rice husk ash about 15%

from the weight of clay soils. Then clay formed in to

granular shape with grain size +16 mm and burned

with temperature between 500-1250

0

C. After

burning for several hours, then the ALWA aggregate

is cooled at room temperature. The aggregate ALWA

then soaked in to the water for 24 hours, in order for

the aggregate to be in saturated surface dry condition.

After soaking, ALWA aggregate is ready to be used

as light aggregate in concrete.

Figure 2: Artificial Lightweight Aggregates (ALWA)

2.2.2 Testing of Physical Properties of

Aggregates

Aggregates used in concrete mixtures can be either

natural aggregates or artificial aggregates. Sand and

gravel are natural while artificial aggregates are

derived from processed products first such as the

result of blast furnace slag, fraction tile, concrete

waste, fly ash, clay soil and so on. Examination of

aggregate physical properties includes examination:

Specific gravity

Absorbtion

Bulk Density

Sieve analysis

2.2.3 Mixture Proportions

Mix design of normal concrete and artificial

aggregate concrete (ALWA) planned using American

Concrete Institute method (ACI 2I1.1-91) with

concrete strength of 25 MPa. The Planning is based

on the method of weight comparison between

concrete material component.

2.2.4 Concrete Mixture Work

Normal concrete work begins with mixing of

concrete-forming materials (sand, gravel, cement and

water). Then the material is placed into concrete

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

30

mixer. Slump test measurement for fresh concrete is

carried out. The mix was then placed into the mold

for 24 hours.

In lightweight artificial aggregate concrete

substitution (ALWA) processes, materials such as

sand, gravel, aggregate ALWA and cement are mixed

first according to their own percentages. Then the

material is placed into concrete mixer and water

added. Slump test measurement for fresh concrete is

carried out. The mix was then placed into the mold

for 24 hours.

After 24 hours, the concrete were taken out from

every mold and then they were submerged in the

water tank in the Laboratory of Public Works of West

Aceh. Testing of compressive strength is carriet out

after the concrete reaches the age of 28 and 56 days.

Concrete is loaded vertically or parallel to the

cylinder slowly until the test object is destroyed. The

total number of test specimens is 24 cylindrical pieces

(Ø15 cm, T = 30 cm) with various percentage of

aggregate, shown in table 2.

Table 2: The number of concrete specimen

0% 10% 20% 30%

28 Days 3333 12

56 Days 3333 12

6666 24

Age of

Compressive

Strength Test

Percentage of ALWA

Total of

Specimen

0%

1

28Da ys 3 3

56Da ys 3 3

66

Ageof

Compressive

StrengthTest

Perce

n

3 RESULTS AND DISCUSSION

3.1 Results

This section presents the results analysis from the

examination of aggregate physical properties, the

design of the proportion of concrete mixtures and the

test results of compressive strength. The description

of the results of the analysis is presented in the form

of tables and graphs, in order to be easy to understand.

3.1.1 Physical Properties of Aggregates

The results of examination of aggregate physical

properties indicate that the aggregate used qualifies as

concrete forming material.

Bulk Density

The result of theaverage of bulk density calculated for

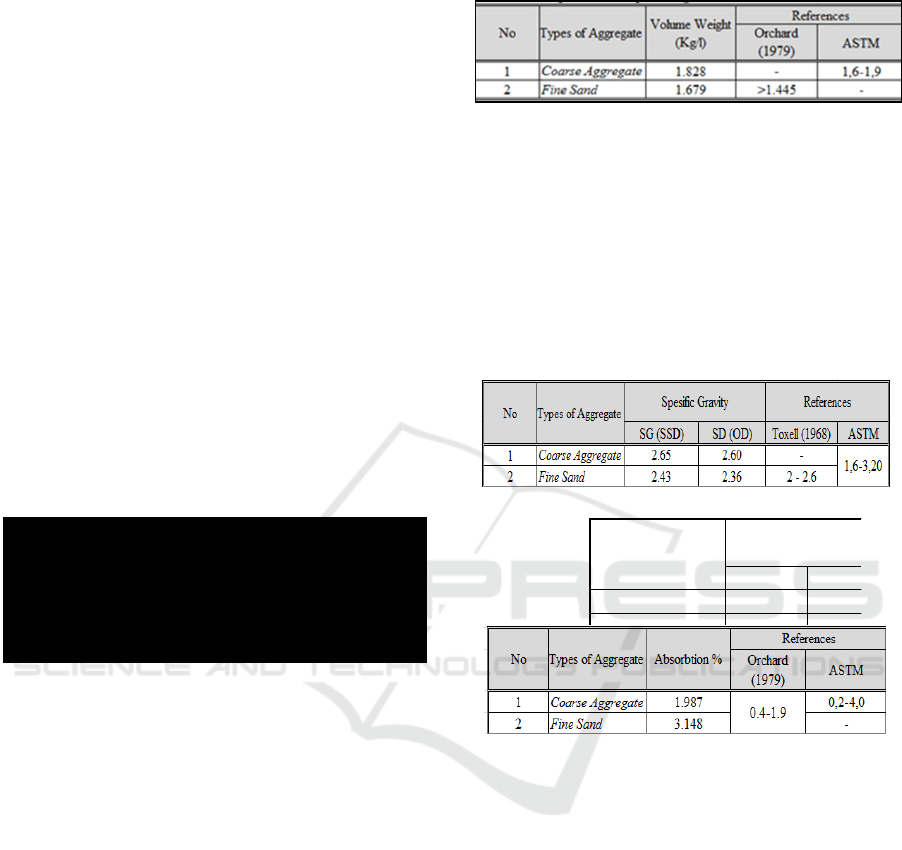

each type of aggregate is shown in Table 3.

Table 3:

Bulk

Density of Aggregates

The fine aggregate used in this study can be used

as a concrete-forming material with a volume weight

of 1.679 kg / L. As suggested by Orchard (1979), he

thinks that the weight of a good aggregate volume is

greater than 1,445 Kg / L. Based on ASTM the weight

of the aggregate aggregate volume also meets the

specification of 1,828 kg / L, ranging from 1.6-1.9 kg

/ L.

Specific gravity and absorption

Table 4: Specific Gravity

The results of the calculation of specific gravity

and absorption obtained for each type of aggregate

are presented in the following tables 4 and 5.

Table 5: Absorption

From table 4 it can be seen that the specific gravity

of the Saturated Surface Dry aggregates (SSD) used

comply with the requirements indicated by ASTM, ie

for gravel 2.65 kg / L and 2.60 kg / L dry aggregate

weight (OD), for the specific gravity of the Saturated

Surface Dry aggregates (SSD saturated sand

aggregate (SSD) is 2.43 kg / L and 2.36 kg / L dry

sand aggregate (OD). this aggregate has also met the

requirements specified by Troxell (1968) ranging

from 2.0 kg / L -2.6 kg / L and ASTM 1.6 kg / L -3.20

kg / L.

Furthermore, in table 5 it can be seen that the

coarse aggregate absorption value obtained is 1.987.

Absorption of coarse aggregate is still in accordance

with absorbency value determined by ASTM that is

0,2-4,0. While for fine aggregate absorption is 3,148.

Fine aggregate absorption did not match Orchard's

determined 0.4% -1.9% and ASTM 0.2% -2.0%.

The Comparison of Compressive Strength of Normal Concrete with Artificial Lightweight Aggregate Concrete

31

Gradation of Aggregates

Table 6: Fineness Modulus (FM)

3.1.2 Casting of Concrete Specimens

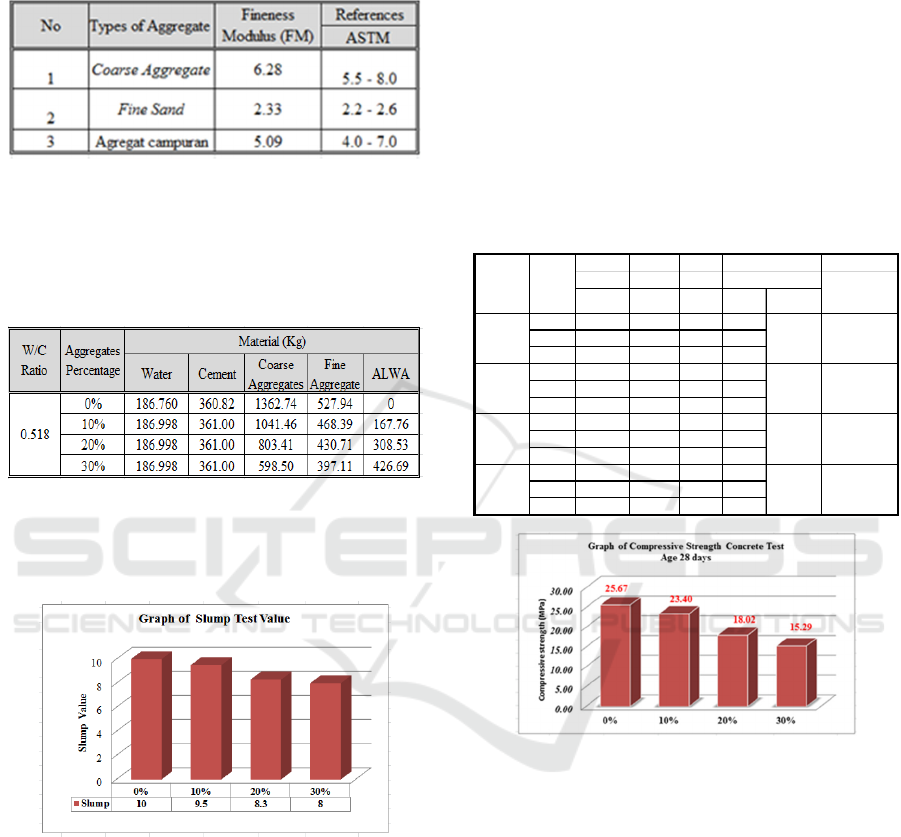

The following table shows the proportion of mixture

for 1 m3 of concrete.

Table 7: Mix Proportions

3.1.3 Slump Test

Data obtained from the execution of slump values on

each foundry are showed in Figure 3.

Figure 3: Graph of Slump Test

From the slump test graph above, shows that the

slump form will be different according to the

aggregate percentage of ALWA. Slump results in 0%

percentage is 10 cm, 10% percentage is 9.5 cm, 20%

percentage is 8.3 cm, and the percentage of 30% is 8

cm. This shows that the higher percentage of ALWA

aggregates used, the concrete water absorption will

increased.

3.1.4 Compressive Strength Test Result

Testing of concrete compressive strength is

completed when the test object is 28 days and 56

days. Prior to the test, the object is removed first from

the tank, then stood until the specimen is on the

surface dry state, weighing the specimens after that.

Tests of concrete compressive strength of 28

days

The results of concrete compressive strength test at

age 28 days are showed in table 7 and figure 4 below:

Table 7: Mix Proportions

Volume of Weight of Load Classification

Cylinders Concrete (P)

(cm3) (kg/m3) (KN) f'c

f'c

(average)

BU.1 0.0053 2384.26 450 25.48

BU.2 0.0053 2493.66 460 26.04

BU.3 0.0053 2461.60 450 25.48

BU.A.1 0.0053 2341.82 410 23.21

BU.A.2 0.0053 2263.54 415 23.50

BU.A.3 0.0053 2225.81 415 23.50

BU.B.1 0.0053 2148.47 315 17.83

BU.B.2 0.0053 2169.22 320 18.12

BU.B.3 0.0053 2159.79 320 18.12

BU.C.1 0.0053 2056.05 280 15.85

BU.C.2 0.0053 2046.61 250 14.15

BU.C.3 0.0053 2091.89 280 15.85

0%

10%

20%

30%

Compressiv e

Strength (MPa)

Percentage

of

ALWA

N

umber

0f

Sp e c im e n

SNI

03-6468-2000

25.67

23.40

18.02

15.29

Structura l

Concrete

Structura l

Concrete

Structura l

Concrete

NonStructural

Concrete

Figure 4: Graph of Compressive Strength Concrete Test

Age 28 Days

From Table 7 and Figure 4, showed the

compressive strength of concrete reduced when the

proportion of aggregates ALWA increased. However,

the weight of the concrete will be lighter in proportion

to the increasing of aggregate ALWA. On specimens

with 0% percent aggregate ALWA has an average

compressive strength of 25.67 MPa and weight of

12.97 kg. While on the specimen with the percentage

of 30% aggregate ALWA has an average compressive

strength of 15.29 MPa and weight 10.95 kg.

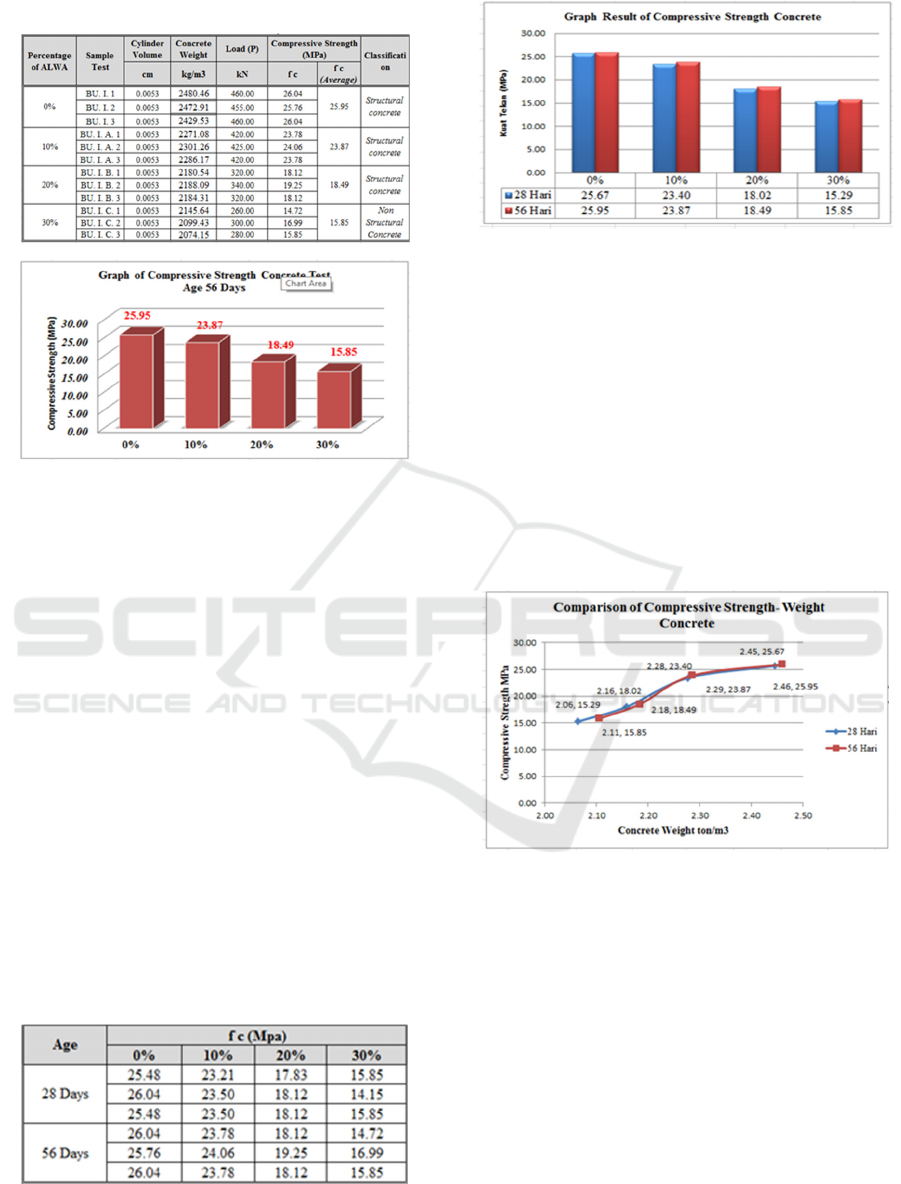

Compressive strength concrete of 56 days

The concrete compressive strength test results at age

56 days are showed in table 8 and the figure 5 below:

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

32

Table 8: Compressive strength test age 56 days.

Figure 5: Graph of Compressive Strength Concrete Test

Age 56 Days

Based on Table 8 and Figure 5, showed the

decreases of concrete compressive strength due to the

higher proportion of aggregates ALWA. The weight

of the concrete will be lighter based on proportion

increases of aggregate ALWA. On specimens with

0% percent aggregate ALWA has an average

compressive strength of 25.95 MPa and average

weight of 13.05 kg. While on the specimen with the

percentage of 30% aggregate ALWA has average

compressive strength of 15.85 MPa and average

weight of 11.17 kg.

3.1.5 Comparison Results of Concrete

Compressive Strength

The comparison results of compressive strength of

concrete at age 28 days and 56 days are showed in

table 9 and figure 6 below.

Table 9: Comparison of compressive strength of 28 and 56

days old concrete

Figure 6: Graph of Compressive Strength Concrete Days

and 56 days

From the table and figure shows the compressive

strength of concrete has increased. However, the

increasing in strength is not too large, because the

concrete has reached the compressive strength of the

plan at the age of 28 days.

3.1.6 Relation of Volume Weight with

Compressive Strength of Concrete

The weight of the concrete volume has a great effect

on the compressive strength of the concrete, this can

be seen in graph 7 below:

Figure 7: Graph of average compressive strength of

concrete aged 28 and 56 Days

Based on Figure 7, weight of the concrete was

2.45 ton/m3 at 28 days and compressive strength of

25,67 Mpa. Concrete weight at age 56 days was 2,46

ton/m3 have compressive strength of 25,95 MPa.

Then on concrete weighing 2.06 ton / m3 at age 28

day have compressive strength 15,29 MPa, and

weight of concrete at age 56 day with weight 2,11

ton/m3 have compressive strength 15,85 MPa. In

other words, normal concrete with a large volume

weight has a large compressive strength, while the

lighter concrete, its compressive strength smaller than

normal concrete.

The Comparison of Compressive Strength of Normal Concrete with Artificial Lightweight Aggregate Concrete

33

3.2 Discussion

The results of the aggregate inspection conducted at

the West Aceh Public Works Laboratory indicates

that the aggregate used has fulfilled the requirements

as concrete-forming materials based on ASTM C33,

Troxell (1968) and Orchard (1979). Instead of the

absorption of fine aggregate does not meet the criteria

implied by Orchard (1979) which ranges from 0.4-

1.9. The result of slump test at 0% percentage was 10

cm, 10% percentage was 9.5 cm, percentage 20% was

8,3 cm, and percentage 30% equal to 8 cm. The slump

test results showed decreases in slump value. In other

words, the higher the percentage of ALWA

aggregates used the higher the water absorption of

concrete. The concrete produced in this study

indicates that the concrete is below the normal

concrete limit, but not including the lightweight

concrete specification. Because based on SNI-03-

2847-2002 lightweight concrete has a unit weight of

not more than 1900 kg / m3. Based on SNI 03-6468-

2000 concrete with 10% aggregate substitution

ALWA at 28 and 56 days can be used for structural

purposes, since the compressive strength is in the

range of 21-40 MPa. Meanwhile, according to

Tjokrodimuljo (1996) aggregate substitution ALWA

20% - 30% can still be used for structural purposes,

because according to the strength of medium quality

concrete press for the use of the structure that is 15-

40 MPa.

4 CONCLUSION

From the results of research and data processing that

has been carried out, concrete with artificial

lightweight aggregate substitution gives the effect of

lightness to the concrete itself. It can be seen on

aggregate ALWA usage of 10%, 20% and 30%

weight average of test specimens continues to

decrease. The use of 10% at age 28 and 56 days,

aggregate ALWA resulted in the compressive

strength of concrete close to the compressive strength

of the plan was 23,40 MPa and 23,87 MPa, with

average weight 12,07 kg and 12,12 kg. The aggregate

usage of ALWA 30% at age 28 and 56 days of

compressive strength of concrete average 15,29 MPa

and 15,85 MPa with average weight 10.95 kg and

11,17 kg, but still can be used as structural concrete.

Preparation of artificial lightweight aggregate

concrete has economic value, because concrete-

making materials are obtained easily. However, in the

aggregate stages ALWA has several obstacles, due to

the equipment used and the process itself is still

simple.

REFERENCES

ASTM C.33-02 (2002) Standard Spesification for Concrete

Agregates, Annual Books of ASTM C.33 – 02a, USA.

ASTM C330-89 (2002), Standard Specification Agregate

for Structural Concrete, Annual Books, USA.

Mulyono, (2004, 2005) Teknologi Beton, Andi, Yogyakarta

SNI 03-246l-2002, Spesifikasi Agregat Ringan Untuk

Beton Ringan Struktural, Badan Standarisasi Nasional.

SNI -03-2847-2002, Persyaratan Beton Struktural Untuk

Bangunan Gedung (Beta Version), Badan Standarisasi

Nasional

Tjokrodimuljo, K, (l996, 2004, 2007) Teknologi Beton,

Nafiri. Yogyakarta

Troxell, R.E., et.al, (1968), Composition And Properties Of

Concrete, Mac Graw Hill Book Company, London.

ICEST 2018 - 3rd International Conference of Computer, Environment, Agriculture, Social Science, Health Science, Engineering and

Technology

34