Analysis Line Balancing at Moslem Clothing Producer

Case Study: X Convection

Mokh. Adib Sultan, Chairul Furqon and Winda L. Putri

Faculty of Economic and Business Education, Universitas Pendidikan Indonesia, Bandung, Indonesia

{adiebsultan, c_furqon}@upi.edu, windalies@gmail.com

Keywords: Line Balancing, Work station, Productivity, Idle Time, Balance Delay.

Abstract: X Convection is a moslem clothing producer which the production process determined by orders. X

Convection has to increase the output of the production to follow market demand. On the other side, the

convection has limited capacity to supply it. The problem arises due to the imbalance of line production in

the Convection. The aims of line balancing implementation are to understand the current line production, to

understand the advantage of line balancing towards the current line production, and to understand the optimal

labours as to reach target production. Based on the matters, the use of line balancing method is to measure

standard time and arrange flow of production process on each line. The heuristic method is used in this study,

namely Large Candidate Rules, Region Approach, and Ranked Positional Weight. Based on heuristic method,

the highest line efficiency is 65.03% and balance delay 34,97% with the use of Large Candidate Rules (LCR)

approach. The results indicate that

1)

The most optimum of line balancing method is LCR which turns out the

alteration in the number of work stations from 5 to 4 work stations and

2)

the change of labour allocation.

1 INTRODUCTION

X Convection is a private company located in

Cigadung, Bandung. Muslim clothing are produced

by X convection, including dress and koko.

Production system is conducted by orders or known

as made by order. In a month, X convection is able to

produce over 600 pieces which are done by five

workers. To produce one piece of dress, it takes about

two hours through several stages of the production

process for marking, cutting, machine hemming,

sewing, ironing, mounting accessories/pairing of

studs, controling quality (qc), steaming and packing.

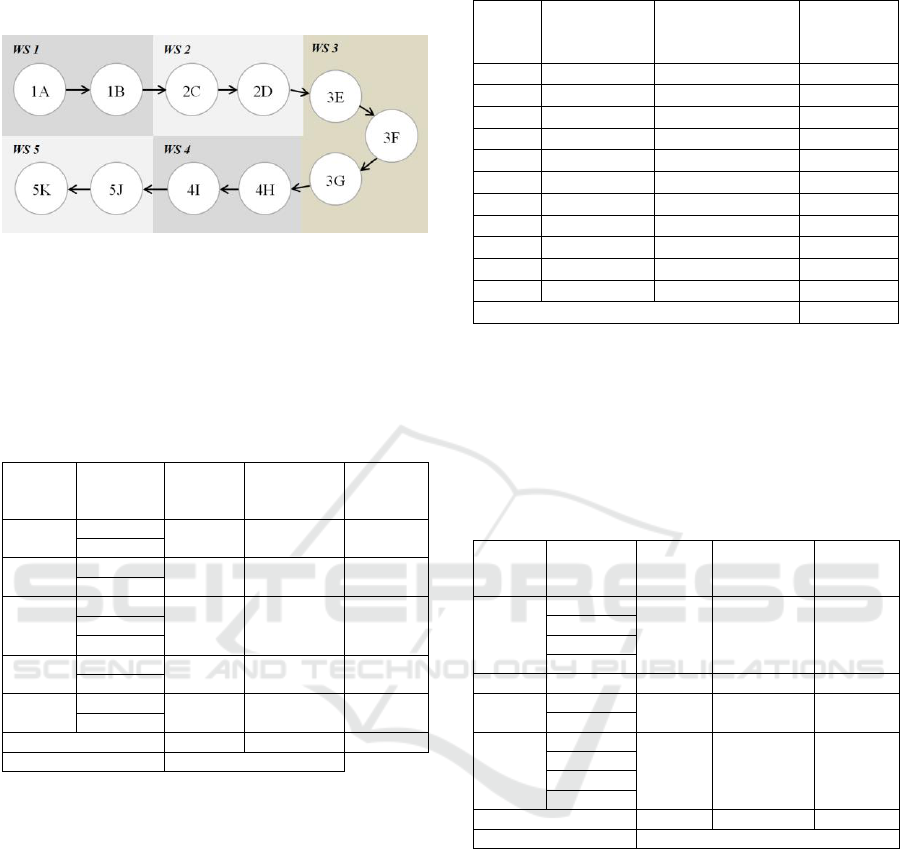

In the process, the production process are divided

into five work stations, which are work station 1 for

marking and cutting, work station 2 for machine

hemming 1 and sewing 1, work station 3 for ironing,

sewing 2, and machine hemming 2, work stations 4

for pairing of studs and qc, and work station 5 for

steaming and packing.

In practice, any organization or certain business

are faced particular problems or obstacles. Similarly,

experienced by X convection. The main problem in

this convection is not achieving the production

targets. It is influenced by many things.

Prior to the study, the researchers are conducted a

pre-study and discovered the phenomenon that

indicated the problem of line balancing in X

convection, namely the existing of idle time, the

hoarding of the product on several work stations

(bottleneck), and the waiting time caused by the

product retained on previous work station (starfing).

These things are the factors which cause the X

convection could achieve companies’ target

production.

Based on that phenomenon, it is necessary to plan

a strategy to produce a decision to achieve efficiency

of production processes. One of them is the decision

regarding the layout. To produce an effective layout,

line balancing analysis can be used as analysis

method. There are several approaches in line

balancing, such as heuristic methods (Kholil and

Mulya, 2014).

The problems experienced by X convection can

be solved by using the method of line balancing,

heuristic approach. With the application of line

balancing is done, it is expected Convection X can

streamline production lines and increase production

output.

Pursuant to the problems that occurred in

Convection X, the purpose of this study is to

optimalize production process by using line balancing

analysis method.

478

Sultan, M., Furqon, C. and Putri, W.

Analysis Line Balancing at Moslem Clothing Producer - Case Study: X Convection.

In Proceedings of the 1st International Conference on Islamic Economics, Business, and Philanthropy (ICIEBP 2017) - Transforming Islamic Economy and Societies, pages 478-483

ISBN: 978-989-758-315-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 LITERATURE REVIEW

Line balancing is a method for balancing tasks in each

work stations to minimize the number of work

stations and the number of idle time.

There are several terms to calculate line balancing

as follows (Kholil and Mulya, 2014).

Presedence Diagram

Presedence diagram is a graphical

representation of the sequence of work

operations and the dependency on other work

operations.

Assemble Product

Assemble product is the product that passes

through the work station.

Work Element

Work element / work operation / task / is part of

the whole assembly process that is undertaken

Operating Time (Ti) and Time Standard (Wb)

Operating time is the time standard for

completing an operation which is including and

considering adjustment and allowance factors.

In this research, both factors are not included in

the calculation, so the time standard (Wb) is

equal to the normal time (Ws).

Station Time (SI)

Station time is the amount of time of work

elements or tasks completed at the same

work station. Wti<Ws

Average time of work station (

)

(

) =

Work Station (K)

Work station is a place on the assembly line

where the assembly process is performed. After

determining the cycle time then the number of

efficient work stations can be determined by

dividing the total amount of the work time of

each element with cycle time as follows.

K min =

Cycle Time (CT)

Cycle time is the maximum time allowed to

complete every task on each work station.

To calculate line production performance, there

are some parameters or indicators that can be

used to measure performance of assembly line

(Elsayed and Boucher, 1994; in Azwir and

Pratomo, 2017).

Line Efficiency (LE)

LE =

(1)

Balance Delay (BD)

BD =

(2)

Smoothness Index (SI)

SI =

(3)

Idle Time

Idle Time = (K)(Ws) -

(4)

In line balancing, there are three basic methods

commonly used in line balancing analysis, such as

mathematical method, probability method, and

heuristic method (Kholil dan Mulya, 2014). In this

study, heuristic method is used to analyze production

process without special tools are needed for

calculating. This methods are consist of Large

Candidate Rules (LCR), Region Approach (RA), and

Ranked Positional Weight (RPW) (Saiful and

Rahman, 2014).

3 RESEARCH METHOD

This study is included as descriptive analysis used

line balacing analysis. The target population of this

study is line production activity for ‘A’ dress model

and the number of sampling as many as 1 batch

production.

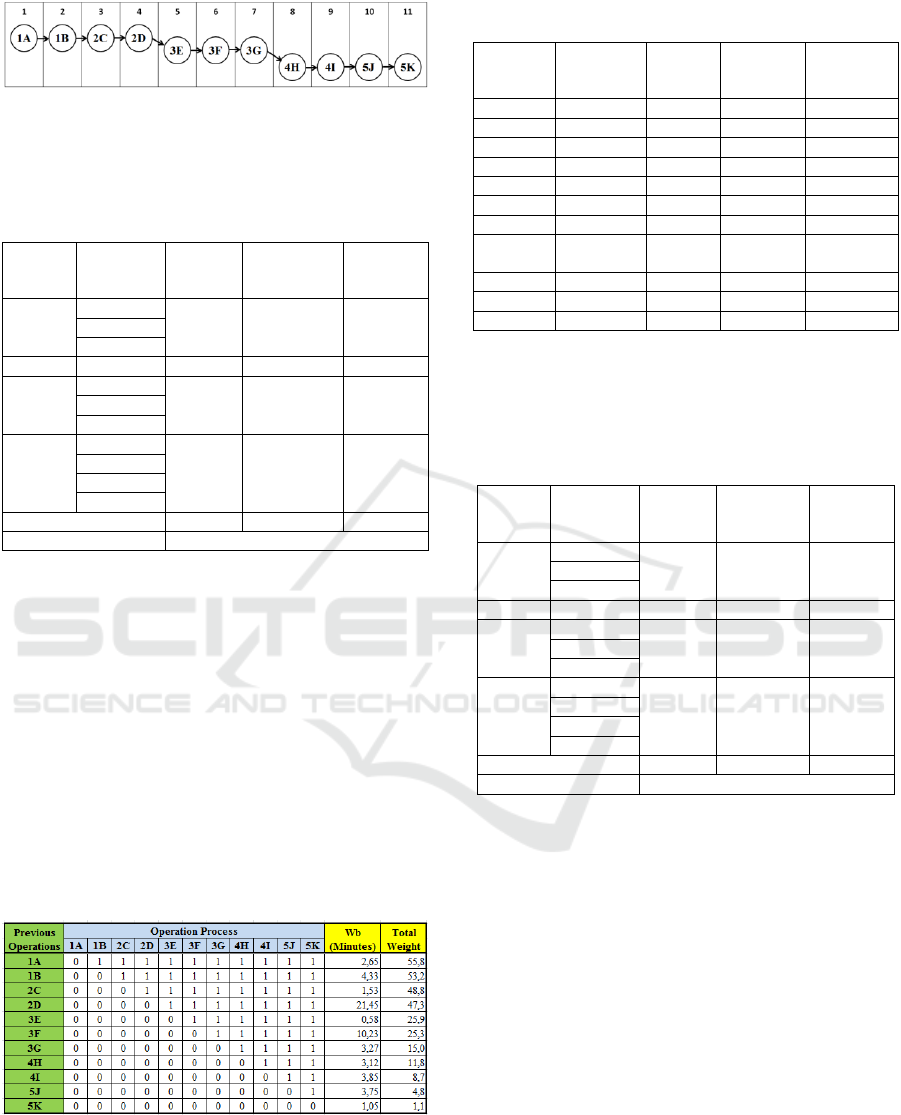

The research stages can be illustrated in the

research methodology as in Figure 1 in Appendix.

4 RESULTS AND DISCUSSION

Based on observations, there are several conditions

found, such as number of cycle, production line

process, and the number of efficiency. In Table 1, It

shows that to produce one dress, it takes around 55,8

minutes which known as one cycle.

Table 1: Calculation of time standard.

Work

Stations

Number of

Work

Element

Work Element

Time

Standard

(Minutes)

1

1A

Marking

2,65

1B

Cutting

4,33

2

2C

Obras 1

1,53

2D

Sewing 1

21,45

3

3E

Ironing

0,58

3F

Sewing 2

10,23

3G

Obras 2

3,27

4

4H

Pairing of

studs

3,12

4I

QC

3,85

5

5J

Steaming

3,75

5K

Packing

1,05

Total

55,8

Analysis Line Balancing at Moslem Clothing Producer - Case Study: X Convection

479

The calculation of Table 1 can be described in

presedence diagram as seen on Figure 2.

Figure 2: Current presedence diagram.

From the table and presedence diagram, the

current work stations performance can be calculated

by parameters of line balancing, such as idle time,

efficiency, balance delay, and smoothness index.

Table 2 shows perfomance of current work stations.

Table 2: Current work stasions.

Work

Stations

Number

of Work

Element

Idle

Time

Efficiency

Balance

Delay

1

1A

347,35

32,52%

67,48%

1B

2

2C

-36,67

107,12%

-7,12%

2D

3

3E

176,83

65,65%

34,35%

3F

3G

4

4H

347,55

32,48%

67,52%

4I

5

5J

399,68

22,36%

77,64%

5K

Total

1234,75

52,03%

47,97%

Smoothness Index

658,64

As seen on Table 2, it is obtained that the number

of idle time is equal to 1234,75 minutes, line

efficiency 52,03%, balance delay 47,97%, and the

smoothness index 658,64.

To reach the best performance can be done by

calculation of work station proposal based on line

balancing method of heuristic approach, which large

candidate rules, region approach, and ranked

positional weight.

First, Large Candidat Rules Approach (LCR) is

calculated by time element (te) whether the number

of sequence of processing time as seen in Tabel 3.

Table 3: The sequence of work element based on Te.

No.

Number of

Work

Element

Work Element

Time

Standard

(Minutes)

1

2D

Sewing 1

21,45

2

3F

Sewing 2

10,23

3

1B

Cutting

4,33

4

3H

QC

3,85

5

5J

Steaming

3,75

6

3G

Obras 2

3,27

7

4I

Pairing of studs

3,12

8

1A

Marking

2,65

9

1C

Obras 1

1,53

10

5K

Packing

1,05

11

3E

Ironing

0,58

Total

55,8

The sequence of the tabel above is an ideal task

by LCR appoach, yet it cannot be applied to

production line because there are some unflexible

tasks which cannot be changed easily. So that, the

sequence of work operations can be seen on Table 4.

Table 4: Proposed work station based on large candidat

rules approach.

Work

Stations

Number

of Work

Element

Idle

Time

Efficiency

Balance

Delay

1

1A

296,70

42,36%

57,64%

1B

2C

3E

2

2D

0

100%

0%

3

3F

190,82

62,93%

37,07%

3G

4

4I

232,46

54,84%

45,16%

4H

5J

5K

Total

719,98

65,03%

34,97%

Smoothness Index

422,47

In Table 4, the result shows that WS 2 is the most

efficient work station because it did not have idle time

and balance delay. By using LCR, total number of

idle time, balance delay, and smoothness index will

be decreased while line efficiency will be increased.

It indicates that to get this line balancing, work

element 2C should be moved from WS 2 to WS 1 and

3E from WS 3 to WS 1, so the efficiency could be

achieved.

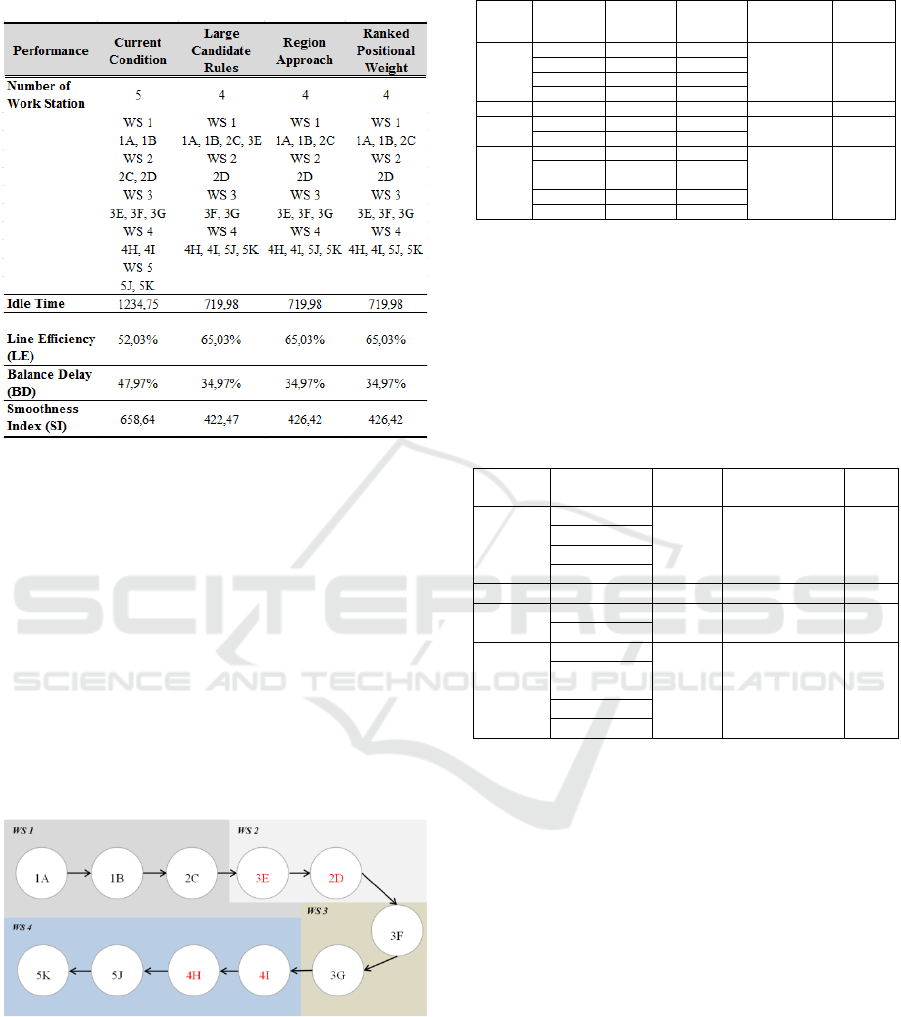

Then, the second method in line balancing is

Region Approach (RA) which the calculation count

by dividing work networking region from left to right

based on work position in presedence diagram.

ICIEBP 2017 - 1st International Conference on Islamic Economics, Business and Philanthropy

480

Figure 3 : Dividing work networking region.

After obtaining a sequence of work operations

based on the division of the region, then the proposed

work station can be calculated as Table 5.

Table 5: Proposed work station based on region approach.

Work

Stations

Number

of Work

Element

Idle

Time

Efficiency

Balance

Delay

1

1A

310,68

39,65%

60,35%

1B

2C

2

2D

0

100%

0%

3

3E

176,83

65,65%

34,35%

3F

3G

4

4H

232,46

54,84%

45,16%

4I

5J

5K

Total

719,98

65,03%

34,97%

Smoothness Index

426,42

The result from using RA method shows that WS

2 is the most efficient work station because of idle

time and balance delay did not occur. By applying

RA, total number of idle time, balance delay, and

smoothness index will be decreased while line

efficiency will be increased.

Some changes need to be applied to get this

efficiency which are moving out work element 2C

from WS2 to WS1, and merging WS 5 to WS4.

As for the last, the third approach is Ranked

Positional Weight (RPW) method which generated

the calculation of positional weight of work element.

The following matrix of positional weight from each

work element can be seen in Figure 4.

Figure 4 : Matrix of positional weight of work element.

Based on the calculation of positional weight of

work element on the Figure 4, it is obtained that the

sequence of work element can be seen as Tabel 6.

Table 6: The sequence of work element based on positional

weight.

Number

of Work

Element

Work

Element

Weight

Time

Standard

(Minutes)

Previous

Work

Element

1A

Marking

56

2,65

0

1B

Cutting

53

4,33

1

2C

Obras 1

49

1,53

2

2D

Sewing 1

47

21,45

3

3E

Ironing

26

0,58

4

3F

Sewing 2

25

10,23

5

3G

Obras 2

15

3,27

6

4H

Pairing of

studs

12

3,12

7

4I

QC

9

3,85

8

5J

Steaming

5

3,75

9

5K

Packing

1

1,05

10

As seen on Table 6, line balancing performance

by RPW method can be calculated as follows (Table

7).

Table 7: Proposed work station based on ranked positional

weight approach.

Work

Stations

Number

of Work

Element

Idle

Time

Efficiency

Balance

Delay

1

1A

310,68

39,65%

60,35%

1B

2C

2

2D

0

100%

0%

3

3E

176,83

65,65%

34,35%

3F

3G

4

4H

232,46

54,84%

45,16%

4I

5J

5K

Total

719,98

65,03%

34,97%

Smoothness Index

426,42

In Table 7, by using RPW method, It is shows that

WS 2 is the most efficient work station because it did

not have idle time and balance delay. By

implementing RPW, total number of idle time,

balance delay, and smoothness index will be

decreased while line efficiency will be increased.

The position of work element in work station by

RPW approach as same as by RA which are moving

out work element 2C from WS2 to WS1, and merging

WS 5 to WS4.

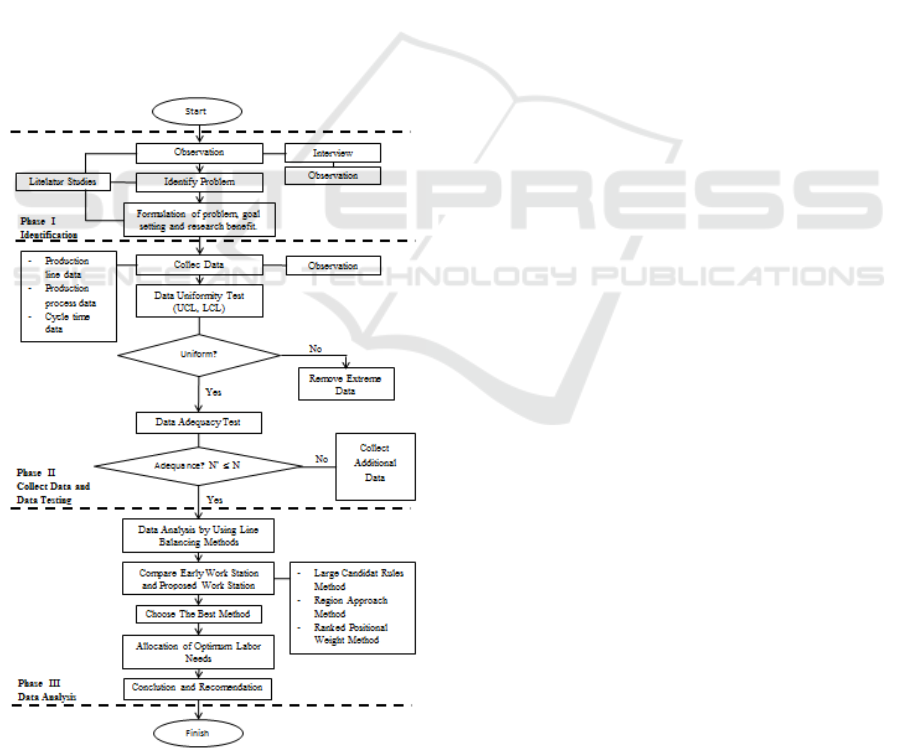

After calculating performance of line balancing

by using Large Candidate Rules, Region Approach,

and Ranked Positional Weight, it shows that every

approaches has different results from the current work

station. These result can be compared as seen on

Table 8.

Analysis Line Balancing at Moslem Clothing Producer - Case Study: X Convection

481

Table 8: Comparation of current work station and proposed

work station by heuristic methods.

In table 8, it shows that large candidate rules

generated the best performance among others. It has

the smallest number of smoothness index which is the

number of SI has decreased up to 236,17 point while

RA and RPW only decreased up to 232,22 point.

On the other side, all these heuristic methods have

the same number of idle time, line efficiency, and

balance delay. By looking the current condition of

work station, the number of idle time has decreased

up to 514,77 minutes and also balance delay that has

decreased up to 13% whereas the number of line

effiency has increased up to 13%.

Therefore, the design of work station by LCR

approach is choosen as recomendation work station

as follows in the presedence diagram below.

Figure 5 : Presedence diagram of recomendation work

station.

After obtaining the best design of work station,

then calculating for allocation of labor as follows

(Table 9).

Table 9: Calculation of labor’s allocation.

Work

Station

s

Work

Element

Unit/

Month/

Labor

Demand

per

Month

Quantity of

Cumulative

Labor Needs

Roun-

ding Up

1

Marking

3968,50

600

0,52

1

Cutting

2425,02

600

Obras 1

6872,73

600

Ironing 1

18021,45

600

2

Sewing 1

489,54

600

1,23

2

3

Sewing 2

1026,76

600

0,77

1

Obras 2

3209,51

600

4

Qc

2727,27

600

0,67

1

Pairing of

studs

3365,38

600

Steaming

2800,00

600

Packing

10046,52

600

In Table 9, it is seen that company should have 5

persons to fill the work stations, which are distributed

in work station 1 as many as 1 person, work station

2 as many as 2 person, work station 3 as many as 1

person, and work station 4 as many as 1 person. This

allocation is the ideal number of labor. So, in Table

10, it can be seen recomendation allocation of labor

to achieve an effiency production line.

Table 10: Recomendation allocation of labor.

Work

Station

Work

Element

Current

Labor

Recomendation

Labor

Info.

1

Marking

1

1

-

Cutting

Obras 1

Ironing 1

2

Sewing 1

1

2

-1

3

Sewing 2

1

1

-

Obras 2

4

Qc

2

1

+1

Pairing of

studs

Steam

Packing

Table 10 shows that work station 2 was lack of

labor while work station 4 was excesse of labor, so it

is necessary to change the allocation of labor, namely

the transfer of labor positions from work station 4 into

work station 2 as many as 1 person.

5 CONCLUSIONS

Based on the analysis of the discussion in the previous

part, there are several conclusions. First, the current

production line is not effective, so the company has

to do some changes. The results show that company

should reduce the number of work station from 5 to

4. Second, the calculation based on the time standard

and the number of requests in every month, company

need to make changes of the structure of labor as

many as one person, from work station 4 to work

station 2. By applying several changes, the company

ICIEBP 2017 - 1st International Conference on Islamic Economics, Business and Philanthropy

482

may increase the number of production as well as

reach the target production.

REFERENCES

Azwir, H. H., Pratomo, H. W. 2017. Implementasi Line

Balancing untuk Peningkatan Efisiensi di Lini Welding

Studi Kasus: PT X. Jurnal Rekayasa Sistem Industri,

6(1), ISSN 2339-1499.

Kholil, M., Rudini Mulya. 2014. Implementasi Line

Balancing Proses Produksi Refrigerator Unit Factory

NRF-2 Menggunakan Metode Heuristik di PT LG

Electronic Indonesia. Jurnal Ilmiah PASTI Teknik

Industri UNB.

Saiful, Mulyadi, Rahman, T. M. 2014. Penyeimbangan

Lintasan Produksi dengan Metode Heuristik (Studi

Kasus PT XYZ Makassar). Jurnal Teknik Industri,

15(2), 183-190.

APPENDIX

Figure 1: Research methodology.

Analysis Line Balancing at Moslem Clothing Producer - Case Study: X Convection

483