Prospect of Establishing a Micro Industry of Ginger Coffee

Production

Fithria Novianti, Febtri Wijayanti, Carolina Carolina, Mirwan A Karim, and Arie Sudaryanto

Center for Appropriate Technology Development - Indonesian Institute of Sciences

Keywords: Sumba Barat Daya, Sustainabilty, Ginger Coffee Microenterprise.

Abstract: Low value add gained by farmers of Sumba Barat Daya (Southwest fo Sumba) as they sell coffee as beans

rather than processed product. We conducted a research to explore opportunity to develop microenterprise

based on ready to consume processed coffee production. A case study was implemented through direct

observation to activities of a micro industry producing ginger coffee in Wewewa Tengah SubDistrict of Sumba

Barat Daya District of East Nusa Tenggara Province. In-depth interview was used for data collection in order

to gain quantitative depiction of the business. The data was inserted in financial calculation to find out business

feasibility. Financial analysis reveals a positive Net Present Value of IDR109,696,529 and Internal Rate of

Return of 5.76% assuming that the interest rate of Credit for Bussines (KUR) ia 9,0%. It also shows 3.05

Probability Index which indicate the prospect of developing the business sustainable in micro scale providing

that 1) they acquire continuous assistance of technology as well as business management 2) the business is

managed based on socio-business system accommodating sosio-economic condition of the locals 3) the

business is managed as a community owned cooperative in which fair share system is applied. To conclude,

this could be a feasible business system to achieve prosperity for rural.

1 INTRODUCTION

Coffee is one of plantation main commodities in

Indonesia. There are several cultivated common kinds

of coffee, such as arabica coffee, robusta coffee,

liberica coffee and so on. There are also various kinds

of Indonesian coffee famous internationally and

become source of pride in Indonesian archipelago,

namely, Luwak coffee, Jawa coffee, Toraja coffee,

Sumatera coffee, Kintamani coffee, Lanang coffee,

Wamena coffee, Gayo coffee, Jember coffee, etc.

(Neilson.J, 2013)

According to Coffee Commodity Tree Crop

Estate Statistics of Indonesia (2014), the coffee plants

are mostly spread in Sumatera, Java, Nusa Tenggara

and Bali, and Sulawesi. Indonesian coffee production

in 2015 increased approximately 739,005 tons per

year from the total plantation area of 1,254,382 Ha.

The production, mainly derived from public

plantation sector was by 706,770 tons (95.64%), and

the rest was derived from Indonesia state plantation

by 14,690 tons (1.99%) and private plantation by

17,545 tons (2.3%). Robusta coffee is the most kind

planted with quantity production 559,058 tons

(75.65%) then Arabica coffee of which the

production was 179,947 tons (24.35%).

In Sumba Barat Daya District in 2013, it was

produced 3,521 tons or 23,06% of Nusa Tenggara

Timur total production. This product was obtained

from 10,197 Ha area of planting (Tree Crop Estate

Statistics of Indonesia, 2014). Coffee is a potential

plantation commodity that becomes the source of the

livelihood of most people in Sumba Barat Daya.

Although, the coffee plantation dominates the public

plantation in some areas, particularly in Wewewa

Tengah, in contrary, the society income from this

plantation is low. It is because of the low added value

that can be obtained as a result of the low skills in

processing coffee commodities. Whereas, the

increase of value added in coffee commodity can

contribute to regional economic development through

the establishment of coffee processing business unit

which does not only produce dry coffee beans, but

also in the form of processed products (dried green

coffee beans, coffee powder) which has added value

(Haryati, 2008).

The coffee processing into worth-selling coffee

powder is a relatively new idea for Sumba Barat

Daya. Most of the total coffee production is traded in

the form of coffee beans so that the added value

obtained by farmers is very limited. In other words,

234

Novianti, F., Wijayanti, F., Carolina, C., Karim, M. and Sudaryanto, A.

Prospect of Establishing a Micro Industry of Ginger Coffee Production.

In Proceedings of the 2nd International Conference on Economic Education and Entrepreneurship (ICEEE 2017), pages 234-239

ISBN: 978-989-758-308-7

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

there is an opportunity to increase the added value

through the introduction of appropriate technology,

especially in coffee processing. There are two

business units that recently begins to process dried

green coffee beans into coffee powder. This case take

the only one legally registered business unit in Sumba

Barat Daya.

As a start-up business unit in coffee processing,

several constraints and weakness are found in this

coffee processing related to limited fund, human

resources, and not intensified marketing (promotion)

and limited supporting production tools (Supriatna

and Aminah, 2014). Actually, this business has the

potential to be developed due to its variations in

accordance with local tastes (ginger coffee), and the

business competition is low and there is government

support such as training, exhibition and capital

assistance.

According to the explanations above, the author

conducts this research to analyze the business of

small-scale ginger coffee processing in Wewewa

Tengah of Sumba Barat Daya. It aims to recognize the

opportunity of the added value gain for those who

process the coffee and sell it in the local market.

Using the financial feasibility analysis on this ginger

coffee production, it is expected to provide input for

the people coffee business in order to become a

sustainable micro business activities.

2 METHODS

2.1 Research Place and Time

This research was conducted in the business unit of

ginger coffee processing in Omba Rade Village,

Wewewa Tengah, Sumba Barat Daya District, Nusa

Tenggara Timur. The research period was September

until December 2015.

2.2 Research Method

This research used a case study method. By using this

method, it is expected to learn the complex

phenomena in the limited opportunity to organize the

activity observed (Baxter and Jack, 2008). To obtain

the accurate data, we conducted direct observation

towards processing of coffee beans into ginger coffee

powder in the business unit of coffee production so,

therefore, it was collected information about

equipment investment capital, working capital,

production cost, variable cost, fixed cost, labor cost

and other data related to this study. An in-depth

interview was used as data and information collecting

technique to obtain quantitative description for the

financial analysis. The descriptive analysis was used

to depict phenomena found in organization process of

business unit as the subject of this research.

2.3 Data Processing Method

According to Chauhan. (2014), to explore financial

feasibility in agro-industry business, financial

analysis method can be applied. Therefore, the data

were processed in the form of tabulation to apply R/C

Ratio analysis, Net Present Value (NPV), Internal

Rate of Return (IRR), Profitability Index, and

Payback Period. The total cost of production (Total

Cost = TC) is calculated through variable cost

indicator (Variable Cost = VC) and Fixed Cost (FC)

as follows:

(1)

Calculation of R/C Ratio (Revenue Cost Ratio) is

business efficiency that is comparison size between

Revenue (R) and Total Cost (TC). By R/C value, it

can be known whether a business is a profitable or

not. The business will be appointed as a profitable

business if the value of R/C > 1.

(2)

An analysis of NPV (Net Present Value) is

applied to see how high the investment value by

considering the value of currency. NPV is a criterion

of business feasibility that can be defined as a recent

net−the result of the difference between Benefit (B)

and Cost (C). A business is feasible to run if the value

of NPV is > 0.

(3)

Bt = Gross Benefit in year –t

n = Economic age

Ct = Gross cost in year –t

i = Interest rate

IRR (Internal Rate of Return) is used to know how

high the fund of a planned business which allow the

business to cover back the capital and interest issued.

The business is feasible to run if the value of IRR is

> applicable interest rate. Generally, the formula of

IRR:

(4)

i1 = discount factor that still contributes NPV

to be positive

Prospect of Establishing a Micro Industry of Ginger Coffee Production

235

I2 = the lowest discount fator that contributes

NPV to be negative

NPV1 = Positive Net Present Value

NPV2 = Negative Net Present Value

Profitability Index (PI) is a comparison of the

present value of future cash inflows to the value of the

proposed investment. Through Profitability Index, it

can be calculated the amount of value created per unit

of invested investments. An investment is feasible to

run if the value of PI is > 1. In general, the

Profitability formula is:

(5)

Payback Index (PI) is used to estimate the

duration of a business investment refund. Payback

Period is the minimum time to return the initial

investment in the form of cash flow based on total

receipts minus all costs.

(6)

The processing of coffee bean into coffee powder

is conducted by limited technology support. The

specific tools, such as drying rack, tray, pan, stoves,

crockery, coffee grinder, and tilting sealer have

become the main capital of this business. Other tools

are needed such as outer skin peeler machine, peeler

machine through rent tool system in coffee harvest

season.

3 RESULTS AND DISCUSSION

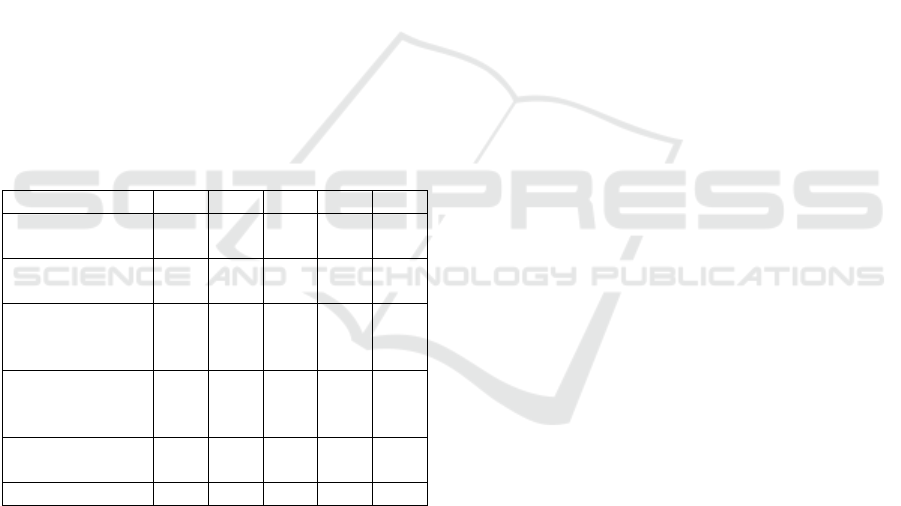

The costs included into investment cost in the unit of

ginger coffee processing are cost capital for 5 years

consisting of fixed cost and variable cost. Investment

costs consist of machine and tools purchasing cost

with the total amount of IDR. 4,500,000 is used

during the investment period with the details shown

in table 1. The purchase of this machine and

equipment is only once at the beginning of investment

for subsequent replacement of equipment according

to tool age with depreciation value by IDR. 88,194.

Table 1: Equipment Investment on Ginger Coffee Processing Unit

No.

Tools

Qty (unit)

Total Price (IDR)

Tool age

(month)

Depreciation (IDR)

1

Drying rack

2

400,000

36

11,111

2

Tray

20

400,000

24

16,667

3

Pan

2

300,000

60

5,000

4

Stove

3

450,000

60

7,500

5

Coffee Grinder

1

2,100,000

60

35,000

6

Tilting sealer

1

250,000

24

10,417

7

Crockery

1

150,000

60

2,500

Total

4,050,000

88,194

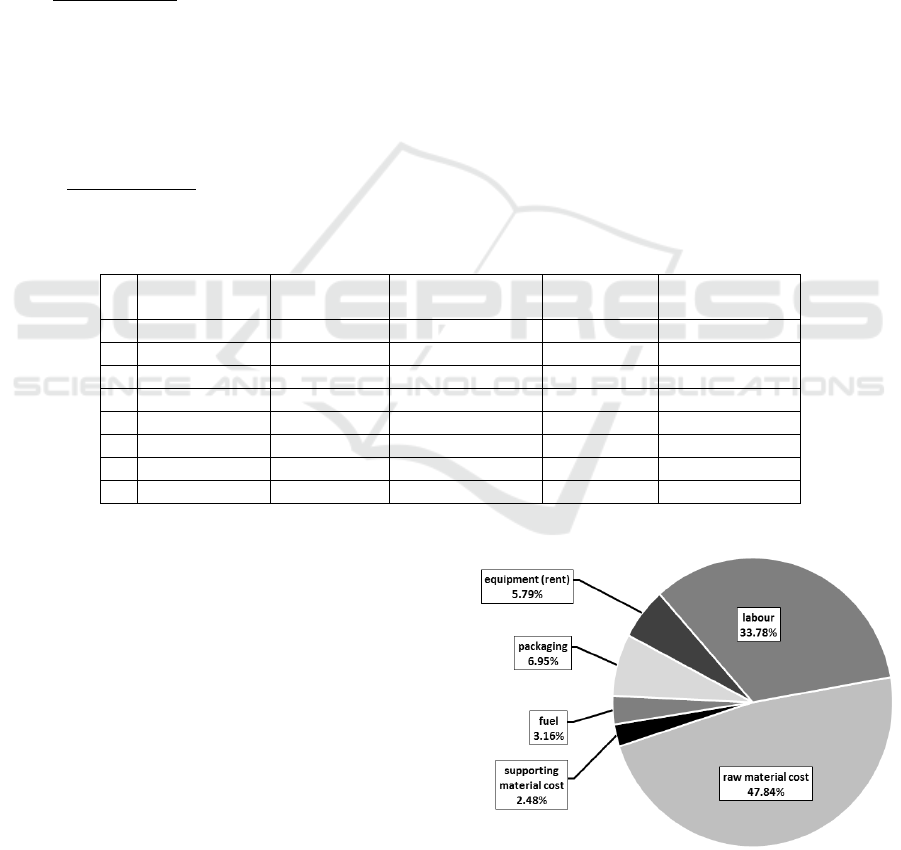

The variable cost is the cost incurred by the

business unit in each production process cost that

includes the cost of purchasing raw materials of

coffee and non-coffee, fuel costs, packaging costs,

equipment rental costs, and labor costs (daily) with

the proportion of expenditures (See Figure 1).

Variable costs (VC) spent by this coffee processing

business unit worth IDR 10,522,195/month. Fixed

costs (FC) include equipment depreciation cost,

transportation and communications costs, promotion

and administration costs, and general costs

(electricity, water and sanitation) of IDR

398,194/month. Therefore, the total production cost

(TC) required by this business unit is IDR 10,910,389

each month.

Figure 1. Variable Cost Proportion in the Process of Ginger

Coffee Processing

ICEEE 2017 - 2nd International Conference on Economic Education and Entrepreneurship

236

To know the feasibility of an agroindustry

business, it can be seen from the aspect of financial

feasibility which includes the determination of R/C

Ratio, Net Present Value (NPV), Profitability Index

(PI), Internal Return Rate (IRR), and Payback Period

(PBP).

The frequency of the production process

performed by the coffee processing business unit in

the first year ranges around 6 times a month, each

processing produces 15 kg of coffee beans and 3 kg

of local ginger becomes 17.5 kg of ginger coffee

powder. Ginger coffee powder is sold in 2 types of

packaging namely, pure ginger coffee with the

contents of 50 grams and 100 grams as the main

product, and a 20 grams of ginger coffee as a

promotional product.

In this calculation, it is used the increase of ginger

coffee production assumption and due to the limited

ability of the business unit in terms of technology

procurement and business management. The business

is assumed to increase its production slowly by

increasing the production time to 8 times a month in

the 2nd year and 10 times a month in the 3rd year and

beyond.

Table 2: Cash Flow in Ginger Coffee Production Process

Every Month (IDR)

Unit Description

Year 1

Year 2

Year 3

Year 4

Year 5

Ginger Coffee

Production (kg/month)

84

140

166

169

175

Total Production Cost

(IDR1000/month)

6,183

10,073

11,922

12,101

12,477

Sales of Packaging

Ginger Coffee 50 gr

(IDR1000/month)

7,059

11,704

13,899

14,142

14,630

Sales of Packaging

Ginger Coffee 100gr

(IDR1000/month)

1,604

2,660

3,159

3,214

3,325

Total Sale

(IDR1000/month)

8,663

14,364

17,057

17,356

17,955

R/C Ratio

1.40

1.43

1.43

1.43

1.44

Based on the calculation results, it is obtained that

R/C Ratio is more than one, so the business is

considered profitable. The ginger coffee sales

increase every month (See Table 2). Although the

production of ginger coffee is increasing every year

but R/C Ratio tends to be stagnant, which ranges from

1.40 to 1.44 (See Table 2).

The NPV value is used to see whether a business

is feasible or not. The positive NPV value indicates

that the effort is feasible to implement, whereas if the

NPV is negative then it means the business is not

feasible to implement. From the calculation results, it

is obtained the value of NPV ginger coffee production

with a positive value, amounted to IDR 134,173,933

in the period of business for five years which means

that the business is feasible to do.

The value of Profitability Index (PI) is more than

one, indicating that the business is feasible to run.

Based on the calculation with initial capital worth

IDR 36.000.000, ginger coffee business has a value

of PI= 3.73, so, the business is considered feasible to

run. This means that in 5 years this business has a cash

flow of 3.73 times of the value of initial investments.

The IRR value is used to see whether or not a

business is worth developing. If the IRR value is

higher than the prevailing interest rate then the

business is feasible to develop. In this business

calculation this bussines use Credit for Bussiness

(KUR) with 9.0% annual, where the ginger coffee

processing business is a micro business that needs

support from the government. From the calculation

results, it is obtained IRR value of ginger coffee

business worth 6.66%. The IRR value which is only

slightly larger than the interest rate indicates that the

business is feasible to develop but has a slight profit.

Oppong, et al. (2014) study recommend re-

introduction of soft loans for small and medium

business by the government and financial institutions

as a solution to develop micro-business

entrepreneurship (Zabaznova, 2014).

A business is considered feasible if Payback

Period value is smaller or equal than the age of

business investment. From the calculation results, it

is obtained Payback Period for 19 months with the

assumption of borrowing funds for 3 years for

business age for 5 years, therefore, ginger coffee

processing business can be considered feasible to do.

Based on the results of financial analysis, ginger

coffee production increases every year from the sales

value of IDR 8,663,287/month in the first year,

increasing to IDR 17,955,000/month in the fifth year.

However, this business has R/C Ratio that tend to be

stagnant, which ranges from 1.40 to 1.44. Several

possible causes are (1) production of ginger coffee

using simple technology; and (2) a traditionally sales

pattern, where the ginger powder coffee market is

limited to the Waikabubak market (8 km far from the

production house), and one outlet in the district town.

According to the research results of Radam, et al.

(2008), in order to sustain operations and growth of

SMEs, efforts should be taken to assist SMEs to

develop their managerial and technical skills

especially in creating innovations and generating

economic value from knowledge. Existing training

and outreach programs should aim at enhancing

entrepreneurial skills and capabilities in the area of

business planning, marketing and financial

management among the owners/managers. Although

market expansion could be a solution to stangnant

business performance, being a micro small

enterprises the effort cannot be performed easily. It

Prospect of Establishing a Micro Industry of Ginger Coffee Production

237

should always start with skill development and

capability to adopt market access (Githaiga et al.

2016).

From the positive NPV value, which has the

amount of IDR 134,173,933 with initial investment of

IDR 36.000.000 it is obtained the value of

Profitability Index of 3,73. Both points show that the

business is feasible and can be developed, but the

value of IRR coffee processing business is likely to

be low, at 6.66% and only slightly higher than the

interest rate with Payback Period for 19 months.

Therefore, the profit earned by this business is quite

low. Therefore, in the coffee processing business in

Sumba Barat Daya, it is necessary to intervene local

government to protect the coffee processing business

through any program such as Credit for Bussiness

(KUR) program or other similar program that gives

low interest to business actor, technical assistance for

SMEs, and help the SMEs to market penetration.

General challenge faced by micro-small enterprise is

their slow growth, and idea of inducing venture

capital to boost the growth as found in a study to

creative SMEs in Makasar (Heslina, 2016) could be

accommodated. It is recommended that SMEs

operators should be educated on how to plan,

organize, direct and control their businesses (Oppong,

et al.2014).

As the results of in-depth interview to business

owner, it is obtained that the business nature of this

coffee processing business unit is more directed to the

creation of employment for the community around

the production house. While the product is sold at a

price that does not give burden buyer who is a

community with low purchasing power. Based on the

proportion of variable costs in the process of ginger

coffee production, it can be seen that the highest cost

is the cost of purchasing raw material coffee (47.84%)

and labor costs (33.78%). This indicates that the

ginger coffee processing business is trying to provide

the greatest benefit for local economic development.

According to the research results of Atmaja, et al.

(2015), coffee farmers can increase their income,

apart from the coffee harvest, through increasing the

added value of coffee by processing coffee powder.

Powder coffee processing business can be improved

by promotional efforts and expansion of marketing

area.

If the coffee processing business uses the

cooperative system, the profits collected can be

directed to improve the welfare of its members

through the fair annual benefits (SHU) and the

establishment of new business units that can expand

employment. Based on this, the role of the

government is very significant in developing and

expanding of public-based coffee processing business

where this business can expand employment need and

provide benefits for the community of cultivators and

coffee processors in Sumba Barat Daya. Oppong, et

al. (2014) study recommend that government should

re-introduce the small business credit scheme so that

beneficiaries can use them to run the micro, small and

medium enterprises.

4 CONCLUSIONS

The coffee business unit may become a sustainable

micro-enterprise activity if (1) a consistent mentoring

is performed both for the technology and

management sides of the business; (2) the business is

a social business that concerns the low purchasing

power of local society and it does not harm the

business itself; (3) the business is conducted in groups

through cooperatives where the remaining results can

be used to improve the welfare of the community

members.

The results of this research can be used as a source

of information to build community empowerment

roadmap through coffee processing business with

specific character in Sumba Barat Daya.

ACKNOWLEDGEMENTS

The author thanks the Center for Appropriate

Technology Development of LIPI (Indonesian Scince

Agency) in Sumba Barat Daya, as well as to the

Regional Government of Sumba Barat Daya that has

provided support so that this activity can be

implemented. Special thanks are given to Hari

Siswoyo, Dominggus Bula, Elizabeth Malo, Merry,

and Johanis Pageru who have helped us in reading the

socio-economic potentials of coffee producers in

Sumba Barat Daya.

REFERENCES

Atmaja, I.P.E.P., Tamba, I.M., Kardi, C., 2015,

Peningkatan Pendapatan Petani Kopi Arabika Peserta

Unit Pengolahan Hasil (UPH) (Kasus di Desa Belok

Sidan Kecamatan Petang Kabupaten Badung), Jurnal

Agrimeta, No. 10, Vol. 5, Page 32-42.

Baxter, P. dan Jack, S., 2008, Qualitative Case Study

Methodology: Study Design and Implementation for

Novice Researchers, The Qualitative Report Journal,

No. 4, Vol. 13, Page 544-559.

Chauhan. S K, 2014, Fundamentals of Farm Business

Management Including Project Development Appraisal

& Monitoring, Department of Agricultural Economics,

Extension Education & Rural Sociology College of

Agriculture, India

ICEEE 2017 - 2nd International Conference on Economic Education and Entrepreneurship

238

Directorate General of Estate Crops, 2014, Tree Crop

Estate Statistics of Indonesia 2013-2015: Coffee,

Jakarta

Neilson.J, 2013, The Value Chain for Indonesian Coffee in

a Green Economy, Buletin Ristri 4 (3): 183-198

Githaiga, R.W., Namusonge G.S., Kihoro, J.M., 2016,

Marketing Strategies Adoption and Competitiveness of

Micro and Small Enterprises in Food Processing Sub-

Sector: An Empirical Review. Journal of Humanities

and Social Science, Volume 21, Issue 2, Ver. I Page 18-

22.

Haryati, N., 2008, Kontribusi Komoditas Kopi Terhadap

Perekonomian Wilayah Kabupaten Jember, Jurnal

Sosial Ekonomi Pertanian, No. 1, Vol. 2, Page 56-69.

Heslina, 2016, Factors Affecting the Business Performance

of the Micro, Small and Medium Enterprises in

Creative Economic Sector in Makassar, Indonesia,

Scientific Research Journal (SCIRJ), Volume IV, Issue

I, Page 41-49.

Oppong, M., Owiredu, A., Churchill, R.Q., 2014. Micro

and Small Scale Enterprises Development in Ghana.

European Journal of Accounting Auditing and Finance

Research, Vol.2, No.6, pp. 84-97.

Radam, A., Abu, M.L., Abdullah, A.M., 2008, Technical

Efficiency of Small and Medium Enterprise in

Malaysia: A Stochastic Frontier Production Model,

International Journal of Economics and

Management 2(2): 395-408

Supriatna, S. dan Aminah, M., 2014, Analisis Strategi

Pengembangan Usaha Kopi Luwak (Studi Kasus

UMKM Careuh Coffee Rancabali-Ciwidey, Bandung),

Jurnal Manajemen dan Organisasi, No. 3, Vol. V, Page

227-244.

Zabaznova.T.A, Karpushova.S.E, Patsyuk.E.V,

Surkova.O.A and Khmeleva.G.A, 2014, Mechanism of

Rural Entrepreneurship Development on the Base of

Micro-business, Asian Social Science; Vol. 10, No. 23;

2014

Prospect of Establishing a Micro Industry of Ginger Coffee Production

239