Supercapacitors Serving as Power Supply in Tiny Sport Sensors

Field Testing Through Heart Rate Monitoring in Endurance Trail Runs

Hans Weghorn

BW Cooperative State University, Kronenstrasse 53A, 70174 Stuttgart, Germany

Keywords: Body Sensor, Heart Rate Monitor, Endurance Training, ANT+, Bluetooth LE.

Abstract: In professional and in non-elite sport activities, people today are using various electronic monitoring tools

quite commonly. Sportspersons often are embedded into a personal body sensor network, which traces

different parameters of their physiological activity. Especially heart rate sensors are used broadly, but often

all kinds of meters, e.g., for counting foot steps and pedal turning, are also utilized in parallel. As technical

construction, it has commonly established that these sensor devices are autonomously operated as very tiny

computer systems from built-in lithium battery cells. Replacing such sensor batteries from time to time is

expensive, the mechanical handling of this process is not very easy due to the small sensor housings, and it

has to be reminded that use of throwaway batteries represents a waste of resources. In this work, an

alternative power supply for sports sensors is investigated, which bases on the use of so-called

supercapacitors. Construction concepts, advantages of the approach related to handling and manufacturing,

and the possible application ranges are thoroughly discussed, while the study is complemented with

practical experiments from endurance running sports.

1 INTRODUCTION

Improving health by controlled physical activities

plays an important role in our modern and aging

societies. Performing personal sports on regular and

moderate base from early living days represents a

valuable key for preserving an extended period with

fewer health problems already at middle age

(Oguma and Shinoda-Tagawa, 2004) up to higher

ages (Jefferis et al, 2014). Both categories of

physiological activities are today usually monitored

with the help of electronic devices and tools for

achieving optimal response (Arts and Kuipers,

1994). The simplest variants of such monitoring

units are pedometers or smartphones with

corresponding software tools (Tudor-Locke and

Basset, 2004).

A higher or more professional elaboration level

is achieved, when sports computers with built-in or

RF-linked sensors are employed (Malkinson, 2009).

One of the most well-known samples of this multi-

device monitoring are chest straps with an

autonomous sensor module for detecting heart beats

from skin surface electrodes and producing

continuously measures of the heart rate (HR), which

are sent to other control units for display, evaluation

and recording. Fig. 1 shows three different HR

devices, two of them communicate through the so-

called Bluetooth LE standard (Bluetooth SIG, 2017),

while the third unit (device S) broadcasts its

measures through ANT+ radio (Dynastream Innov.

Inc., 2011). The latter can be received by many

sports computer systems and by some smartphones

with special RF electronics, while Bluetooth LE is

readable by most modern smartphones. It has been

reported earlier (Weghorn, 2015) that the electrical

power consumption of the ANT+ system is lower

compared to the Bluetooth LE solution.

Similar sensors exist for different other

physiological measures, which are likely to be

observed and traced during sports and health

exercises. For instance, tread rate in foot stepping,

wheel and pedal turning rate in cycling and other

information may be of relevance and interest in such

applications. Accordingly, many sensor types are

available on the market and a training person can be

embedded into an extended wireless body network,

which consists of one central control unit and

several autonomous sensor elements.

Since such sensors are constructed as tiny

wireless computer modules, they do require also an

electrical power supply. For this, commercial

Weghorn H.

Supercapacitors Serving as Power Supply in Tiny Sport Sensors - Field Testing Through Heart Rate Monitoring in Endurance Trail Runs.

DOI: 10.5220/0006515100560065

In Proceedings of the 5th International Congress on Sport Sciences Research and Technology Support (icSPORTS 2017), pages 56-65

ISBN: 978-989-758-269-1

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

devices use lithium battery cells (B in Fig. 1), which

have to be replaced and disposed as hazardous

waste, when they are emptied. This manual

exchange is not very easy, because the mechanical

parts are tiny and some systems need considerable

force and torque for opening and closing the battery

mould covers. Fig. 1 shows above each sensor its

back case part for the battery cell; for sensor S very

small screws have to be handled, which is already

inconvenient and complicate for younger people and

may render impossible for older people or health

patients with reduced sensitivity. Another negative

aspect of inconvenience is, that these batteries are

rather expensive.

Figure 1: In here at bottom left, three different heart rate

sensors are visible from backside. Above each sensor, its

cover for the supply battery is shown, the middle one has

to be fixed with four tiny screws. On bottom right, rear

and top view of supercapacitors samples are sown, which

are possibly feasible for replacing the lithium sensor

batteries.

In the tiny sensor devices rechargeable batteries

like in wristbands are not in use, because such a

technology would increase size and price of the

systems. Furthermore, wrong maintenance like deep

discharge for a longer while damages accumulators

and make the entire unit worthless, because the

accumulator usually cannot be exchanged.

Coin-type accumulators are available in the same

housing like the batteries, but with ten times lower

capacity, what means the manual exchange for

recharging would be required even ten times more

often. Derived from commerce of simple time

watches, development has concentrated therefore on

reducing power consumption of the sensor devices.

The energy load of a single-use battery cells allows a

continuous operation of the sensors for few days, but

in real practical use cases this long operational time

is not really required for physical exercises. In

medical investigation, in health and sports

monitoring, workouts and exercises quite typically

last in the order of one hour (USD Labor, 2009).

Using switching capacitors as power cell

theoretically provides much better convenience for

electronics design than batteries, but this was not

possible since the electro-chemical capacitors with

sufficient energy storage amount haven't been

available for long time. Around two decades ago, so-

called supercapacitors, which are also named

ultracapacitors, could be developed on base of

upcoming nanotechnology (Conway, 1999) and

since then, capacitor parts caught up to the desirable

high storage of one Farad and more. Today after

many years of further evolvement, supercapacitor

(SC) application is well-known in sports, e.g., as

power supply for boosting temporarily Formula 1

race cars as term of an ultra high power and extreme

current cell (Lu, 2013).

Another recent application field for SCs is the

replacement of backup batteries for configuration

memory on computer boards (SC samples are C

x

and

C

y

in Fig. 1). This scenario is very similar to what is

required for operating sport sensors, since they need

also a high capacity value, which is sustaining very

long time a rather small electrical current. Out of the

four fundamental SC types, this variant represents a

prospective candidate for replacing the throw-away

lithium battery cell in autonomous sports sensors

with a self-sustaining electronic part.

Inspired from this existing knowledge and the

new technologies, the work here discusses first the

general properties of modern supercapacitors with

respect to the targeted application frame in sports

sensing; next the substitution idea particularly is

used for the most common sensor of HR detection in

endurance training for a real-world evaluation of the

approach. Following this, the derived findings and

possible concepts for further applications and

improvements are critically reflected in their

relevant details.

2 PROPERTIES OF FEASIBLE

SUPERCAPACITORS

From practical experience through a longer period of

on-going investigation about handheld sports tools

and sensors, it had been estimated as initial working

base, that a SC part in the order of one Farad should

provide sufficient energy for at least one or even few

hours of sport sensor operation. This estimate bases

on the practical experience, that a 230 mAh lithium

battery can be used approximately one week full

week (Weghorn, 2015). The error bar of this

assumption is rather high, because controversially

the advertisements and promotion material for the

sensors and their technologies promise much longer

operational times. Due to the small voltages and the

very small supply current it is not possible to

measure the sensor energy consumption directly

with high precision, especially not during longer

physical workouts. Therefore, an indirect

methodology was applied in the further investigation

for the determination of a sufficient power supply

capacity.

2.1 Initial Parts Selection and

Laboratory Setup

At first, two different supercapacitor types had been

selected from a quality manufacturer for passive

electronic parts, which are matching the targeted use

of low voltage combined with low current. Other

important criteria were also, that these parts are

available from stock and that the size of the parts is

comparable to the size of lithium battery cells. Part

C

x

is specified as SC with 5.5 Volts maximum and a

capacity of 1.5 F, while C

y

- despite it has got a

bigger housing - comes with the same voltage rating

and 1.0 F. For the evaluation of statistical variation

in specified ratings and parameters, sample sets were

purchased from professional suppliers for electronic

parts. The data sheets specify for the storage

capacity possible differences from -20% up to

+80%, but this wide range is expected to emerge

reduced, since the body sensors are used in a much

narrower temperature band than allowed in the total

specification ratings.

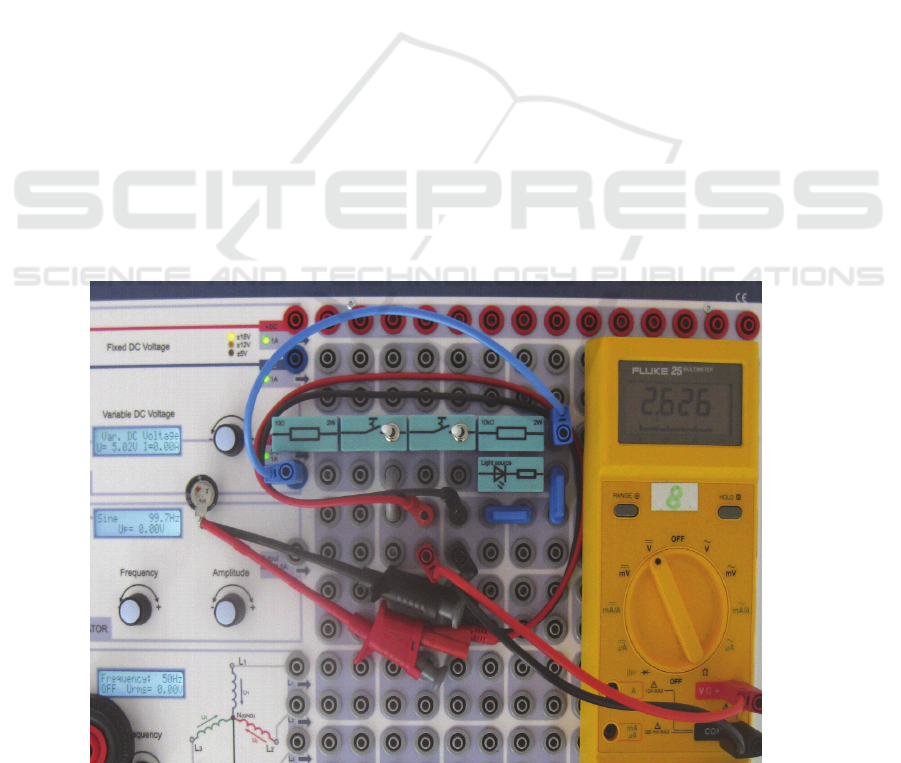

Fig. 2 shows the laboratory board setup for

conducting the basic experiments. The circuit allows

to charge the SC probe through a protection shunt at

a defined voltage and to discharge it through a

defined load. The load in the test circuit was

dimensioned, so that the discharge from 5V down to

3V takes in the order of one hour, since this should

be similar like to the minimal estimated working

time of a health or sports sensor. This test circuit

maps to the following replacement construction for

the battery cell: a linear voltage regulator

downscales the SC voltage band to the valid sensor

supply voltage, which lies between 2.7V and 3.3V as

yielded by lithium battery cells during their life

span.

2.2 Determining SC Storage Capacity

For each of the two different SC parts C

x

and C

y

five

samples were tested with the laboratory setup in a

charge/discharge cycle. In this first experimental run

the variation in capacity should compared be under

conditions similar to the use inside a sport sensor.

Table 1 shows the corresponding results, and it

indicates that the experienced variation of the

capacity between different part samples is much

lower than specified in the data sheets.

Figure 2: Laboratory board for charging and discharging the supercapacitor probe. A digital voltmeter measures

precisely the probe output.

Although the discharging is non-linear according

to the fundamental rules, this can not explain high

difference between the discharging slope within the

defined voltage steps completely. The reason more

is, that supercapacitors behave in some aspects

considerably different to electrolytic capacitors,

since they do stand only low switching frequencies

and their internal resistance increases with charging

load. As observed in the experiments, it is not

sufficient to connect SC for a short while to the

desired charging voltage, following the definition of

how to measure SC capacity, it would even more be

required to keep the target charging voltage up for

half an hour. Since this is not realistic for the

intended application frame here, charging was

terminated after an acceptable time for a sports user.

The consequence is, that the discharge rate is over-

proportional high in the first phase as seen in the

middle row in Table 1, because the SCs were not

charged completely.

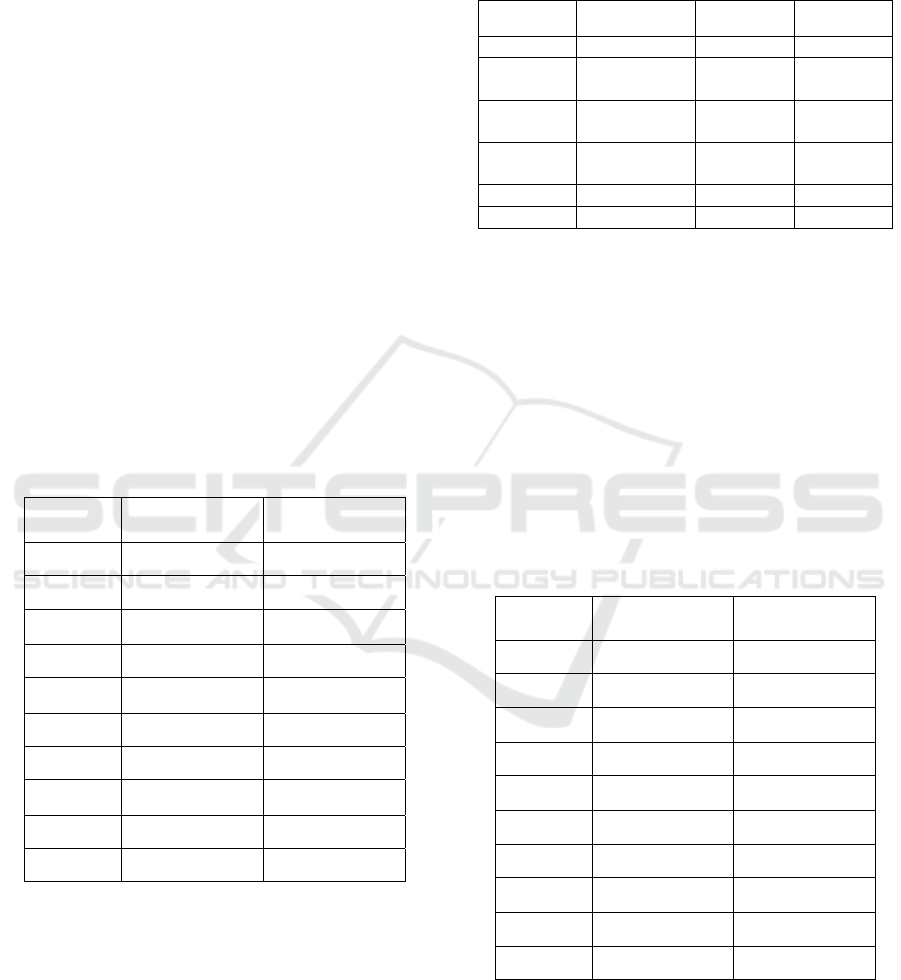

Table 1: Discharging time results for the ten SC samples:

each probe was charged up to 5.00V, then this load

voltage was sustained for a further minute, after which the

discharging was initiated. From there, the time delay was

measured in seconds for a voltage drop of each probe

down to 4.00V and then further down to 3.00V.

SC probe

t for

5.00V 4.00V

t for

4.00V 3.00V

x

C

1

534s 1155s

x

C

2

555s 1164s

x

C

3

490s 1117s

x

C

4

491s 1123s

x

C

5

478s 1105s

y

A

C

456s 880s

y

B

C

422s 854s

y

C

C

457s 865s

y

D

C

422s 876s

y

E

C

394s 856s

Next, two reference measurements of the

absolute capacity had been performed for SC type

C

x

and C

y

. For obtaining precise values, the SC

probes were charged in the beginning to a higher

voltage for an increased waiting time.

Following this, the slope of the discharge curve

was measured at a lower voltage frame, i.e. after the

over-proportionally fast discharge phase. In addition,

a plain resistive load was used. Table 2 shows all

experimental parameters and the deduced results.

The determined reference capacities are much lower

than the specified values from the data sheets.

Table 2: Experiment of determining the absolute capacity

value for reference.

item/event mode

x

C

3

y

C

C

V

SC

(t

0

=0) defined&set 5.00V 5.00V

R

L

= 10k

selected

measured

resistance R

L

9.93kΩ 9.93kΩ

@V

SC

(t

1

)

= 4.50V

measured

time t

1

05:16:05 08:44:22

@V

SC

(t

2

)

= 4.00V

measured

time t

2

05:35:40 09:01:08

t

2

- t

1

calculated 1175s 1006s

C calculated 1.00 Farad 0.86 Farad

From these reference values in Table 2, the

mutual measures in Table 1 can be calibrated as

difference from the nominal capacity, which would

be C

x

= 1.5 F and C

y

= 1.0 F, like this is stated in

their data sheets. Table 3 lists the derived results for

the measured capacities, which arise systematically

too low. The difference appears considerably smaller

for C

y

, for which most measures are even within

data sheet specification. Interestingly, the housing of

C

y

is bigger than the one of C

x

while the latter

claims having 50% higher capacity.

Table 3: Calibrated capacitor values in reference to the

nominal data sheet values for the upper and for the lower

discharge voltage frame.

SC probe

deviation

5.00V 4.00V

deviation

4.00V 3.00V

x

C

1

-27% -31%

x

C

2

-24% -31%

x

C

3

-33% -33%

x

C

4

-33% -33%

x

C

5

-35% -34%

y

A

C

-14% -13%

y

B

C

-21% -15%

y

C

C

-14% -14%

y

D

C

-21% -13%

y

E

C

-26% -15%

2.3 Self-discharge Behaviour

According to the concept, that the SC should supply

a health sensor for the very next use period in a

physical workout, which lasts typically around one

hour, the sensor would have to be charged each time

before this use. The question arises, how convenient

this can be handled; one relevant factor for

answering this is, how much delay is allowed

directly after SC charging before using the sensor.

When sensors are inactive, they consume only

reduced energy; storage cells in general - regardless

which technology - suffer from own self-discharge.

Both effects have to be regarded to optimize the

entire use cycle starting with any kind of

preparation.

Therefore, the self-discharging effect also was

measured for the SC samples. In the corresponding

experimental series, C

y

was excluded, because its

size slightly too big, so that it wouldn't directly fit

into the sensor without major rework of the housing.

From this stage of the fundamental investigation

should evolve specifically to the final application,

therefore the capacitor samples were charged for an

extended time to the start voltage of 3.3V, which is

what a fresh lithium battery cell would feed to the

sensor. Table 4 lists the discharging measures in

time; the digital voltmeter was connected always

only for a short time when collecting the sample

points, so any discharging distortion by the voltage

measurement itself was avoided.

Table 4: Measuring voltage drops invoked solely by self-

discharge of the SCs.

x

C

1

x

C

2

x

C

3

x

C

4

x

C

5

@ t

0

=0 3.30V 3.30V 3.30V 3.30V 3.30V

t

0

+ 1h 3.14V 3.26V 3.30V 3.21V 3.19V

t

0

+ 12h 2.87V 3.16V 3.26V 3.01V 2.93V

t

0

+ 1d 2.79V 3.11V 3,.23V 2.94V 2.84V

t

0

+ 1.5d 2.74V 3.07V 3.20V 2.90V 2.78V

Concerning self-discharge, the variation between

different SC samples appears high. Another snapshot

is seen in Fig. 2, which shows the voltage of C

1

three

days after starting the experiment in Table 4. From

the other results it can be derived, that it is advisable

to early use the sensor after charging, if a SC is used

as power supply cell, since the nominal supply

working range for sensors ends at 2.7 Volts.

2.4 Interpretation of Results and

Derived Selection Strategy for SC

Components

For intermediately summarizing at this point the

general results on supercapacitors, it can be stated,

that the measured variation in capacity appears much

lower than specified in the data sheets. On the other

hand, self-discharge rate varies extremely between

individual samples. Some parts have got almost no

self-discharge effect, while others discharge

themselves within one day down so far, that they can

not be used as sensor supply after this time.

This leads to the recommendation, that a user has

to charge the sensor supply capacitor directly before

the workout. The specified capacitor values from the

data sheets are far above than what can be achieved

in practical use. This certainly is rooted in the

defined measurement methods for the ratings, e.g.

charging a capacitor for 30 minutes may be useful

for achieving highest capacity counts in

advertisement sheets, but it is totally unrealistic in

practical application.

Hence, parts selection should compensate this by

choosing intentional too high values; from the

experiments here, 50% oversize seem a method of

feasible dimensioning. Certainly, quality control in

sensor mass production will be specially required for

their power cell, if supercapacitors parts are used.

3 PRACTICAL USE OF A SC

POWER CELL IN HR SENSORS

In the next phase of this investigation, the practical

application in terms of replacing the lithium battery

of a heart rate sensor by a supercapacitor was

prepared. Based on the findings, which were

collected so far, the following was decided: at first,

an ANT+ HR sensor was selected for the rework,

because of its low power consumption (unit S in Fig.

1) in comparison to other units; secondly, since SC

part model C

x

is only barely bigger than the lithium

battery (B in Fig. 1), it was chosen for the concrete

re-work for limiting the required mechanical

adoption in the sensor housing. This was performed

in two stages, first without and then including an

additional voltage regulation electronics.

3.1 Direct Supply Connection for First

Proof of Concept

During the analysis of the battery mould in the

sensor cover it turned out, that the selected SC could

directly replace the lithium cell battery with few

modifications in the sensor housing and at the

soldering lugs of the SC (Fig. 4a). Therefore, the

sensor was connected directly as supply to the

electrical sensor supply inputs in the fist practical

use tests. The consequence is that the exploitable

voltage range of the SC had to be limited to a frame

between 3.3 Volts down to 2.7 Volts. One further

discharge test with these new limits showed that

type C

x

can provide more than 60 minutes sufficient

supply voltage at the expected discharge current of

the used HR sensor. In the following work, several

use tests have been performed in this simplified way

and the implementation of the regulator circuitry in

the test sensor was postponed to a later experimental

phase.

The SC part sample of type C

x

with the smallest

self-discharge rate was selected, so that the power

consumption of the sensor in sleep mode could also

be determined and qualified accurately. In a first

laboratory experiment, the SC was charged to the

maximum allowed input supply voltage with the

board in Figure 2. Then it was installed inside the

closed cover of the HR sensor. With a proprietary

smartphone App and a sports watch in parallel the

operation of the sensor was observed, while it was

worn for the next hour by an experimenter. During

this phase, only lab working activities, but no strain

sport actions, were performed, Table 5 list in its first

row the measuring results for this cycle.

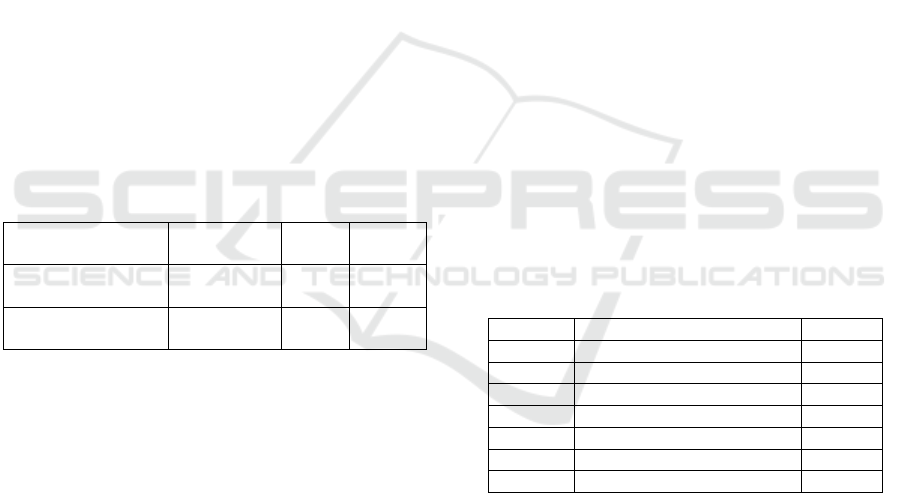

Table 5: First documented test runs of the HR sensor

supplied from the SC cell: the columns show the voltage

just before installing the SC in the sensor and the voltage

immediately after removing the SC.

use mode

overall time

frame

just

before

directly

after

normal work, no

physical strain

09:08-10:17 3.29V 2.99V

slow jogging on

natural trail

10:38-11:43 3.31V 3.03V

The measured voltage drop of 0.3 Volts in the

first practical use of more than an hour suggested

that the SC-supplied sensor is directly feasible for a

first field test. For this, an endurance training was

performed in terms of a controlled slow jogging for

one hour at a constant speed of 6.5 mph (lower row

in Tab. 5). In this experiment, the HR sensor was

connected to a wearable sports computer, from

which the recorded running data can be transferred

to software running on a personal computer, in order

to display the results in bigger screen collections and

plotting graphs.

The whole system worked during the exercise

without problems and in a way as known from the

normal HR sensor use. In this run, there was some

additional preparation time for dressing and moving

between laboratory space and the running path

outside the building. Again this experiment showed

that the simplest concept easily supplies the HR

sensor for one full hour while consuming only half

of the available capacity. In other words, the ANT+

HR sensor can be operated in this configuration for

at least two hours plus several minutes for setup and

preparation times.

According to these first positive results, a longer

sensor test with a complete use cycle was prepared.

Since one of the two chest strap connectors on the

sensor housing (unit S in Fig. 1) is directly

connected to Ground level on the sensor board, only

one other electrical access point to the positive pole

of the SC was required. This was established by

drilling a hole into the back cover case above the

battery mould. After this, the SC could be firmly

enclosed into the sensor housing, since charging and

voltage measurement was now available through

access from outside. Few undocumented

experiments with slight overcharging, observation

and validation of the SC-supplied HR sensor had

been conducted in the following working phase.

After all, participating a public street run over

half-marathon distance was prepared in terms of

complete and quite regular handling cycle by a

sports person using and wearing the modified sensor

unit. The running event took place in 50 mi distance

from the laboratory environment, therefore typical

activities like traveling to the event place, registering

for the run and changing clothes was part of this

extended field experiment. Table 6 protocols the

relevant steps in this experiment.

Table 6: Protocol for the stages in attending a street

running competition with the SC-supplied HR sensor.

time mode/action measure

09:15am charging for 1 min 3.40V

09:30am test after settling time 3.37V

11:30am quiescent discharge test 3.35V

11:40am activation + walk to start

12:01am race start

01:42pm cross finishing line

01:50pm entering sensor sleep mode 2.27V

Unfortunately, correct HR recording failed

already 10 minutes after the run was started. After

leaving the race place and when the sensor entered

sleep mode, an unexpected deep discharge of the SC

had to be detected. In the following phase of the

investigation, it was found that humidity collected

inside the sensor caused the partial failed of the half-

marathon experiment. Several additional field tests

on nature trails and inspections of the sensor

unveiled, that the sealing of the sensor casing has to

be improved in the further work. Despite this

unexpected problem, the entire phase of the event

participation, which started with sensor charging,

then continued with preparation of the event

attendance and running the first mile, has shown,

that the SC capacity can supply a complete handling

cycle when attending such a sports event of two

hours duration. The SC discharge, which was

contributed by the HR sensor in sleep mode, is

found being negligible, hence no particular

expedition with the sensor in sleep mode is required,

even when conducting a two-hour workout with this

very simple power cell concept.

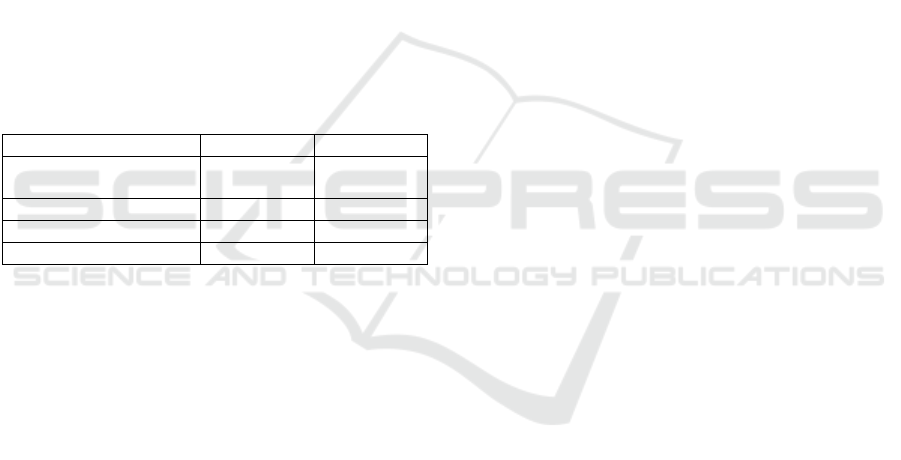

3.2 Regulated SC Power Supply and

Extended Field Test

For the final working stage in this context, a SC was

implemented firmly together with a linear voltage

regulator circuit (Fig. 4b) into the battery mould of

the HR sensor's back case (Fig. 4a). Charging and

measurement access was enabled through a

connection wire, which was fixed on the front of the

cover case as this side is not touching the skin. The

housing was closed mechanically and the system

was made watertight properly with electronic tape.

After the first test runs, it turned out that as well the

plus contact on the front side had to be electrically

insulated, because this contact point also started to

distort HR measurements as soon as the touching

clothes of the experimenter became moist from

sweat. Accordingly, the charge access pin was

modified further, so that it can be contacted by a test

prod, but it is protected against unintended electrical

contact of other items like wet shirts. As regulator

IC a type was selected, which has got low voltage

drop and ultra low power dissipation. Despite this

and according to its specification, the voltage

regulator increased the self-discharge rate of the

power supply, while it expanded the usable voltage

span of the SC from 2.8 Volts up to theoretically 5.5

Volts. Under the assumption, that in practice a wired

USB cable charger provides 5 Volts only, this value

was applied as upper charging voltage limit in all

further tests.

The following experiments (Tab. 7) yielded, that

the discharge rate of the regulated power cell is

again approximately 0.3Volts/hour for the SC with

one Farad true capacity. The self-discharge rate of

the expanded supply system with regulator IC was

observed being increased by approximately 1/3. For

the final test shown in Fig. 3, a natural trail run was

decided, which should cover half-marathon distance

and should last two hours. During this workout, the

decaying capacitor voltage was measured with

equipment, which was carried in a rucksack. For

practicability of the voltage measurements during

the test trail, the run-walk-run method was applied,

which is proposed and advertised by a runners

coach, who is successfully active since many

decades in this sports field (Galloway, 2017).

Figure 3: A half-marathon was covered by the run-walk-run method as reflected in the middle function plot, which

displays the moving pace in units of minutes per mile. The lower curve shows the SC voltage, which was measured in the

one minute walking breaks. This plot starts 15 minutes before the run with one minute charging at 5 Volts. The uppe

r

functional graph shows the HR curve, which suffers from distortion peaks induced by the voltage measurements.

In this mode, the moving speed alternates

between quicker running for one mile and relaxation

phases for one minute at walking speed, which

causes dynamics in the corresponding HR trace. In

the strain pauses, the voltage measurements were

performed. Since the Ground contact of the sensor is

also used as skin electrode for HR detection, the

connection of the digital voltmeter disturbed the

very sensitive HR monitoring. This is reflected as

spurious distortion peaks in the HR curve in Fig. 3.

The preparation of the trail run started 1/4 hour

earlier with charging the SC for a minute with 5

Volts. Immediate measurements after the charging

showed, that the SC can not sustain the end voltage,

which refers to the fundamental property of

supercapacitors that their internal resistance is

increasing with accumulated charge. This implies

that a connection of the loading voltage for just one

minute is not sufficient for injecting the full

electrical load. Nevertheless, also the partial load is

already sufficient for longer workouts as seen here.

Table 7: Tests of the HR sensor supplied from the SCC

with voltage regulation.

use mode lab work trail run

charging method

@3.4V for

one minute

@5.0V for

one minute

active time frame 04:43-05:43 10:38-11:43

voltage at use start 3.29V 4.39V

voltage after use 2.95V 4.01V

Together with this final trail running experiment,

the findings about the new power supply can be

summarized as follows: 1) The usable voltage range,

which can be practically harvested from the SC

supply, is reduced, especially under the assumption

of USB cable charging for a limited time; 2) the

sensor should be used early after charging; 3) a one

minute charge load for a one Farad SC is capable of

operating an ANT+ HR sensor for reliably more

than six hours. Overall, the construction renders

feasible for typical workouts in sports and health

exercises, since these use to last around one hour as

discussed above.

3.3 Further Aspects on Design

Convenience

The selected capacitors have got a slightly bigger

size and a higher weight than a lithium battery cell,

while their price is similar or even lower. All these

differences are not high, but still consequence

modifications of the sensor housing. If the complete

SC voltage band is exploited and the sensor

operation time is specified to the typical value of one

hour plus - reasonably - 200% extra reserve, a

smaller and cheaper SC can be used, especially in

ANT+ devices. This means, that the sensors could

be constructed more slim and lightweight, which

would provide a further handling benefit.

4 DISCUSSION OF RESULTS

AND COMPLEMENTING

CONCEPTS

The experimental results and the proof-of-concept in

several field tests have shown here that the lithium

battery cell in sports and health sensors can be

replaced by an appropriately selected supercapacitor.

Already with a very simplified, direct connection of

the one Farad SC power cell an operational time of

more than two hours can be achieved for the most

typical unit of a heart rate sensor. When adding a

voltage regulator in the supply path (Fig. 4b), the

usable voltage range can be increased from (3.3-

2.7)Volts to (5.0-2.8)Volts, which stands for a factor

of approximately 3.5 and by that an operational time

with one single charge of at least seven hours. This

certainly will be enough for most personal

applications, only in extreme cases like attending an

Ironman Triathlon this supply capacity wouldn't be

sufficient.

It has to be noted that this efficiency applies in

such extend to ANT+ sensors, the more universal

systems with Bluetooth low Energy would reach -

due to their higher power consumption - only in the

order of 2.5 hours total operational time, which is

also sufficient for 80% of non-elite sports people

(USD Labor, 2009). The electrical power

consumption of other sensors are very similar to the

HR units, because most energy is required for their

RF transmissions. The voltage regulation has to be

performed in the experiments here with an additional

semiconductor circuit, because the sensor unit

represents a black box with non-transparent

internals, which cannot be modified.

For a final product on the market, the sensor

manufacturers can simply integrate the expanded

regulation into the device without additional effort in

electronics, since stabilization of supply voltage has

to be implemented anyway always. When using

instead of linear regulation so-called voltage pumps,

the supply band could be expanded towards much

lower SC output voltages, which would then

factorize the working time by another value of

approximately 1.5. Hence, with this improved

supply electronics, also BT sensors can reach a very

reliable operational duration.

Using a supercapacitor as power cell of a sensor

provides a series of advantages for construction and

manufacturing, for usability and for environment.

The SC would be implemented firmly inside the

sensor housing, therefore no mechanisms are

required for manual exchange by the user.

Considering, e.g., sensor S in Fig. 1, six mechanical

parts could be omitted in the design, which are in

detail the four screws, the backside cover and a

sealing ring. Furthermore, the sensor housing case

could be simplified. This all saves development

costs and even in fabrication by multiplication with

a high count of produced units, the costs for raw

material, production processing stages and

production cycle time.

Figure 4: Collection of devices for discussion of charging

concepts: a) backside mould of the open case of sensor S,

and the installation of the SC plus required electronics b)

voltage regulator IC installed left hand; c) commercial

solution of contacting device for charging; d) pedal and

wheel turning sensors as samples without regular contacts

but battery mould.

The price of the lithium battery cell, which is

usually contained in newly sold sensor packages, is

even higher than the one for a SC. Either the selling

price of the sensor could be reduced, which would

represent a customer benefit, or the earnings

statement for the vendor could be slightly improved.

The cumbersome handling of changing batteries like

discussed before could be avoided completely,

which represents evidently an important benefit for

the customer. Using a self-sustaining power cell is

obviously more environment-friendly than any type

of throw-away batteries, especially those wasting

rare earth metals. Capacitors provide advantages

even more compared to accumulators, because the

number of charge/discharge-cycles is almost

unlimited, and the capacitor cannot be destroyed by

deep discharge. This all preserves a much longer use

of SC-supplied sensors than when using

theoretically micro accumulators, and therefore

again an improvement of environment-friendliness.

One other important aspect hasn't been covered

in the discussion up to here: The question how the

SC can be charged prior to sensor operation appears

also relevant for the degree of handling convenience.

For HR sensors, which are equipped with electrodes

for their sensor inputs anyway (Fig. 4a), the

charging could be performed by a DC cable

connection through these connectors as well. For

other types (Fig. 4d), which do not have any

electrical connectors to outside, any kind of plug

adapter would be required, but for this technical

solutions are known and widely in use like, e.g., for

charging sports watches (Fig. 4c). For such cases,

some additional technical effort would be incurred.

Use of a charging cable would map perfectly to USB

connectors, which are known worldwide as universal

system for charging small units and which is

partially even enforced by laws. A more modern

solution would be inductively charging through an

RF field; this would require additional components

in the electronic circuitry of the sensor, but may

keep the mechanical design of the its housing

simple.

Contact-less charging represents a comfortable

method, if the charge loading is limited to a

reasonable time span, but even more modern would

be a complete self-supply of electrical sensor energy

as discussed for medical applications (Bachmann et

al., 2012). Sourcing heat dissipation from the human

body for generating the required electricity (Thielen

et al, 2017) would be another prospective concept, in

sports activities similar ideas would be possible with

tapping mechanical acceleration forces.

It shall be remarked at this concluding point, that

the study here is aiming just for achieving

fundamental findings and for demonstrating the

applicability of a relatively new components

technology in electronics to a new field of use. The

development of certified and professional sensor

products is deferred to companies, who want to

implement such ideas into new product generations

feasible for mass production and long-term use in

health and sports sensing.

5 CONCLUSIONS

As it has been demonstrated and validated in the

experiments here, supercapacitors sustain enough

electrical power for operating wireless body sensors

for a reasonable duration in sports workouts.

Therefore, super capacitors can replace the

commonly used lithium battery cell in terms of a

much more environment-friendly part for typical use

cases. In addition, mechanical sensor construction

can be simplified, since no exchange of the power

cell has to be regarded any more, and all

cumbersome manual user handling of this can be

completely avoided. Hence, the supercapacitor

solution arises more comfortable and cheaper than

using lithium batteries.

Physical workouts are limited for most people to

a duration around one hour; during this time frame

the one Farad SC easily delivers enough energy for

operating sensors with ANT+ or Bluetooth LE, even

if only a limited supply voltage range like the one of

lithium batteries is exploited. Depending on the

effort, which is invested in the power regulation

electronics, an expanded voltage band can be

harvested from the SC and the operational time can

be factorized considerably, which means that, e.g.,

an ANT+ HR sensor can be used up to half a day

without recharge.

SCs can be reloaded in practice for an unlimited

number of repetitions, and they cannot be destroyed

by deep discharge; hence, SCs provide also clear

advantages over the possible, alternative use of

micro accumulators. Since feasible SCs have got

similar size and weight like the lithium battery cells,

there remains no deterioration or restriction during

their use as sensor energy supply.

Preparation of the sensor use, on the other hand,

represents indeed an aspect of handling convenience,

which has not been covered intensely in this study so

far. Therefore, the concept work of this investigation

will be continued by developing and testing

improved discharge and recharge mechanisms like

contact-less methods and voltage-pumping. The

resulting increased duration for the sensor supply

will be validated with further practical experiments,

especially also for Bluetooth sensors with higher

power dissipation, because Bluetooth reaches almost

all modern smartphone devices and this may inspire

more people for performing also healthy sports

activities.

Up to here, this investigation has shown clearly

the potential, that supercapacitors can be used as

more comfortable, more cost-efficient and more

environment-friendly power supply than the

established solution of using throwaway lithium

cells in sport sensors.

REFERENCES

Arts, F. J., Kuipers H., 1994. The relation between power

output, oxygen uptake and heart rate in male athletes.

Int. J. of Sports Medicine, Vol. 15, No. 5, pp228-231.

Bachmann C., et al., 2012. Low-Power Wireless Sensor

Nodes for Ubiquitous Long-Term Biomedical Signal

Monitoring. IEEE Communications Magacine, vol.

50(1), pp 20-27.

Bluetooth SIG,

https://developer.bluetooth.org/DevelopmentResource

s/Pages/White-Papers.aspx, last access: April 2017.

Conway, B.E., 1999. Electrochemical Supercapacitors,

Scientific Fundamentals and Technological

Applications. Springer Science+Business Media, New

York, USA.

Dynastream Innovations Inc., 2011. ANT message

protocol and usage. http://thisisant.com, Rev. 4.5

(2011).

Galloway, J., Run Walk Run: It began in 1974.

http://www.jeffgalloway.com/training/run-walk/, last

access: July 2017.

Jefferis, B.J. et al, 2014. Protective Effect of Time Spent

Walking on Risk of Stroke in Older Men. Stroke, vol.

45, pp 194-199.

Lu, M., 2013. Supercapacitors: Materials, Systems and

Applications. John Wiley and Sons Inc., New Jersey,

USA.

Malkinson T., 2009. Current and emerging technologies in

endurance athletic training and race monitoring. In

TIC-STH 2009, Science and Technology for Humanity.

IEEE, Toronto, Canada, pp. 581-586.

Oguma, Y., Shinoda-Tagawa, T., 2004. Physical activity

decreases cardiovascular disease risk in women.

American Journal of Preventive Medicine, vol. 26(5),

pp 407-418.

Thielen, M., et al., 2017. Human Body Heat for Powering

Wearable Devices: From Thermal Energy to

Application. Energy Conversion and Management,

vol. 131, pp 44-54.

Tudor-Locke, C., Basset D.R., 2004. How many steps/day

are enough? Preliminary pedometer indices for public

health. Sports Med., vol. 34(1), pp 1-8.

Weghorn, H., 2015. Usability and Engineering Aspects of

Competing RF Technologies for Communication with

Commercial Sports Sensors in Ubiquitous

Applications - Experimental Comparison of Power

Consumption and Use Cases for ANT+ and Bluetooth

Low Energy Sensor Devices. In icSPORTS 2015, 3rd

International Congress on Sports Science and

Technology Support, SCITEPRESS, pp 263-270.

USD Labor, 2009. Sports and Exercise. Spotlight on

Statistics, May 2009, https://www.bls.gov/spotlight/

2008/sports/, last access: June 2017.