Optimization for Sustainable Manufacturing

Application of Optimization Techniques to Foster Resource Efficiency

Enrico Ferrera

1

, Riccardo Tisseur

1

, Emanuel Lorenço

2

, E. J. Silva

3

, Antonio J. Baptista

2

,

Gonçalo Cardeal

3

and Paulo Peças

4

1

Istituto Superiore Mario Boella, Via Pier Carlo Boggio 61, Turin, Italy

2

Instituto de Ciência e Inovação em Engenharia Mecânica e Engenharia Industrial,

Rua Dr. Roberto Frias, Campus da FEUP, 400 4200-465, Porto, Portugal

3

Instituto de Soldadura e Qualidade, Avenida do Professor Doutor Cavaco Silva 33, Oeiras, Portugal

4

Instituto Superior Técnico, Universidade de Lisboa, Avenida Rovisco Pais, 1, 1049-001, Lisboa, Portugal

Keywords: Optimisation, Metaheuristics, Resource Efficiency, Sustainability, Industry 4.0.

Abstract: Resource efficiency assessment methods, along with eco-efficiency assessment methods are needed for

various industrial sectors to support sustainable development, decision-making and evaluate efficiency

performance. The combination of eco-efficiency with efficiency assessment allows to identify major

inefficiencies and provides means to foster sustainability, through the efficient and effective material and

energy use. Despite the available information for decision making, this proves to be a difficult task in the

manufacturing industry, therefore, there is a real need to develop and use optimization techniques to enhance

resource efficiency. In this context, and due to the lack of simple and integrated tools to assess and optimize

resource efficiency, crossing the different environmental and economic aspects, arises the need to develop

optimisations models, enabling support and optimize sustainable decision making process and identification

of potential improvements. The optimisation method should provide robust knowledge to support decision-

making, allow comparability of the results and consider a cost-saving approach to help set priorities.

Moreover, the optimisation techniques should centre the process through design/configuration of the

production system, without considering time, in order not to limit the physical agents.

1 INTRODUCTION

Sustainability assessment has become a rapidly

developing topic with a growing number of concepts

and tools being developed during the last decades.

This has been particularly relevant for manufacturing

industries, main consumers of natural resources

(Garetti, 2012). Despite the fact that the concept of

sustainability might be understood intuitively, yet to

evaluate the sustainability of production systems is a

complex task and not intuitive, which led industries

to deviate from these kind of issues. Therefore, an

accurate management of sustainability issues is

proven to be essential to achieve continuous

improvement, and became a fundamental principle

for successful organisations.

Common decision support tools provide the

ability to access the immediate state of the process

and some add the capability of simulating different

configurations. The concept of sustainable

manufacturing comprehends a significant number of

objectives. The most quoted definition is given by the

U.S. Department of Commerce: sustainable

manufacturing is “the creation of manufactured

products that use processes that minimize negative

environmental impacts, conserve energy and natural

resources, are safe for employees, communities, and

consumers and are economically sound” (U.S

Department, 2014).

Thus, maximizing resources and energy

efficiency, reducing environmental and social

impacts and promoting the use of renewable

technologies are all key objectives included in the

concept of sustainable manufacturing (Kersten,

1999). While evaluating these parameters might

appear simple, using them for decision making can be

more difficult, as these objectives must meet

requirements regarding the impacts on employee,

community and especially on the economic aspects

(Kulatunga, 2015). Combining this set of conditions

424

Ferrera, E., Tisseur, R., Lorenço, E., Silva, E., Baptista, A., Cardeal, G. and Peças, P.

Optimization for Sustainable Manufacturing - Application of Optimization Techniques to Foster Resource Efficiency.

DOI: 10.5220/0006374604240430

In Proceedings of the 2nd International Conference on Internet of Things, Big Data and Security (IoTBDS 2017), pages 424-430

ISBN: 978-989-758-245-5

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

lead to complex problems. Sustainable decision

support tools and frameworks simplify the

assessment by using a single value to identify the

immediate state of the process and by using carefully

chosen indicators to simplify and compare the

information.

Simulation tools go a step further and add the

possibility to foresee the outcome of possible

improvements in the process. However, the

quantification of those changes can be a difficult

process. Thanks to the indicator based system used in

decision support tools there is a common comparison

element between the immediate assessment and the

simulated scenario. According to (Sproedt 2015), the

major shortcomings regarding the simulation for the

environmental assessment of production systems are

the following:

Product specific allocation of resources is rarely

provided

Materials and direct emissions not considered

No seamless integration of Life Cycle

Assessment (LCA) evaluation

Focus either on environmental or cost evaluation

High efforts for data acquisition and modelling

required

Lack of methodical guidance for application

Level of detail not sufficiently scalable

Yet, advances towards industry 4.0 and total

control of manufacturing systems, will lead to a

significant increase of available information. Industry

4.0 leverages on the concept of Internet-of-Things

(IoT), which incorporates machine learning and big

data technology, exploiting the sensor data, machine-

to-machine (M2M) communication and automation

technologies that have existed in industrial settings

for years. Smart systems are better than humans in

capturing and communicating data. This data can

enable companies to detect inefficiencies and

problems earlier, saving time and money and

optimizing business intelligence efforts. This would

be overwhelming without proper tools to assist the

treatment of that data. Decision support tools and

frameworks assist in simplifying the problem

identification process and the comparison of different

alternatives.

1.1 Objectives

The goal of this paper is to present an approach to

improve the overall sustainability of manufacturing

through the simulation and optimisation of resource

efficiency and eco-efficiency performance.

The eco-efficiency assessment through simulation

is a support to better understand the influence of any

process parameter on the production system

performance. This can be done by the solver, which

introduces changes regarding the process parameters

quantitative amount, and assessing the influence of

these changes on the production system efficiency

and/or eco-efficiency performance. As a

consequence, participants are able to identify and

select process parameters that should be targeted for

the identification of improvement actions. Moreover,

the solver will support the identification of the

optimal scenario.

2 BACKGROUND

2.1 Efficiency Framework

The proposed Efficiency Framework, developed

under the H2020 SPIRE Project MAESTRI, consists

in the integration of two methodologies, namely eco-

efficiency and efficiency assessment methods and

Information and Communication Technology (ICT)

tools. The eco-efficiency method is oriented for the

evaluation and assessment of eco-efficiency

performance, while the lean based efficiency method,

is to assess overall efficiency performance.

The eco-efficiency approach, here considered,

aims to promote continuous improvement and a more

efficient use of resources and energy, by providing a

set of indicators easy to understand/analyse. The goal

is to assess eco-efficiency performance in order to

support decision making and enable the maximization

of product/processes value creation while minimizing

environmental burdens. Therefore, the use of the eco-

efficiency approach, which base concept is to

measure the environmental and economic aspects of

activities as sustainability aspects that evidence, for

instance, more value from lower inputs of material

and energy (Baptista 2016). The common expression

for eco-efficiency is the ratio between value and

environmental influence (see equation 1).

Eco-Efficiency=

Production or Service Value

Environmental Influence

(1)

The resource efficiency assessment methodology,

takes into account the base design elements from the

Value Stream Mapping. Namely, by considering the

value streams, in order to identify and quantify, at

each stage of the process system, the "value added"

(VA) and "non-value added" (NVA) actions, i.e. all

types of waste and inefficiencies along the production

system (Lourenço 2013). Therefore, the basic

principle relates to Lean Principles via clear

definition between value and waste (in the Lean

Optimization for Sustainable Manufacturing - Application of Optimization Techniques to Foster Resource Efficiency

425

Principles context). The goal is to assess the overall

performance, by taking into account the efficiency of

each process parameter/variable (e.g. time, energy,

water, raw material) associated to one or more

processing units. Consequently, the approach will

provide an efficiency analysis (see equation 2), which

supports the decision making process and helps

prioritize the implementation of improvement actions

by identifying inefficiencies in a very direct manner.

Efficiency=

ValueaddedVA

ValueaddedVANon‐valueaddedNVA

(2)

The outline of the Efficiency Framework, consists

in the integration of eco-efficiency and efficiency

methods through the mutual exchange of information,

which corresponds to the central objective of the

Efficiency Framework. Such integration strategy

enables to obtain, besides the efficiency and eco-

efficiency stand-alone, results to support decisions

and new integrated results, namely the Total

Efficiency Index (TEI) - obtained by combining

normalized eco-efficiency results with efficiency

results.

Regarding TEI, this index is calculated for each

processing unit of the production system under

analysis. In quantitative terms, the TEI is obtained by

multiplying the normalized eco-efficiency and the

efficiency assessment results. The logic behind this

index is to combine two fundamental efficiency

aspects, namely eco-efficiency, which considers the

ecology and economy aspects, and resource and

operational efficiency, which considers the NVA and

VA activities aligned with the Lean Principles from

Multi-layer Stream Mapping (MSM). Consequently,

TEI main outcome relates with providing the ability

of evaluating if eco-efficiency performance variation

is due to higher or lower environmental influence, or

due to higher or lower economic value.

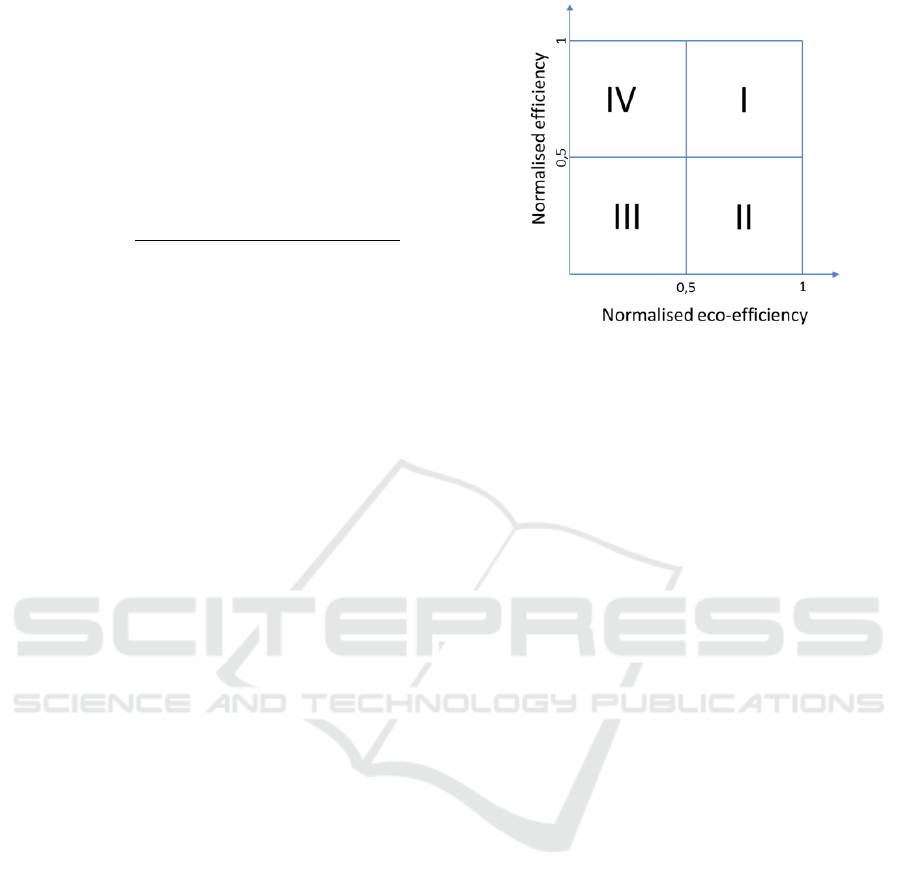

In practice, this results from the distribution

variance of TEI results that occur on two major axes:

the efficiency and eco-efficiency. This distribution is

presented in a graphical way in Figure 1. The main

characteristics and insights related to the TEI results

distribution is:

Quadrant I - High efficiency and eco-

efficiency performance.

Quadrant II - Low efficiency and High

eco-efficiency performance.

Quadrant III - Low efficiency and eco-

efficiency performance.

Quadrant IV - High efficiency and low

eco-efficiency performance.

Figure 1: Theoretical distribution of TEI values.

2.2 Optimisation Problem

Problem arising in the industrial decision making

process are a trade-off of conflicting objectives, e.g.

identify which technology or processes sequence

provides highest eco-efficiency and efficiency ratios,

or identify the resource efficiency, environmental

influence and costs of, for instance, different

materials in order to identify the one that enables

higher TEI. This kind of problem is commonly named

Multi-objective Optimization Problem (MOP) and

are mathematically represented by

min

̅

(3)

where ̅ is the array of process variable that influence

the decision and

̅

represents the set of

objective function taken into account.

MOP problem does not have a single solution but

provide a set of solutions, named Pareto front, where

different set of ̅ have the same

. Therefore, is not

possible to have a global optimum but only near

optimum solution are possible.

One way of representing

̅

is the weighted

sum approach that is a linear relation of the single

objective functions as follows:

̅

̅

(4)

where

̅

is the i-th objective function and

is the weight associated to

. The single

objective function is a relation between the process

variable/parameters that can be controlled by the user

and one of the objective. This relation can be of

different form:

Analytic - a mathematical representation of

is available or can be retrieve through

regression models.

IoTBDS 2017 - 2nd International Conference on Internet of Things, Big Data and Security

426

Black box - the system is too complex to be

analytically modelled so the a

.is

established through the use of trained

machine learning algorithm.

Many problem arising in this context are

NonPolynomial-hard, meaning that they cannot be

solved optimally in polynomial time. To solve large

instances of this kind of problem the use of heuristic

algorithm can provide approximate optimal solutions.

They use some kind of knowledge in order to provide

problem specific rules to explore the solution space,

e.g. k-exchange neighbourhoods local search

algorithm (Lin, 1973) (Helsgaun, 2000). A derived

form of heuristic algorithm are the metaheuristic ones

where a general applicable algorithm concept is used

to define a heuristic method, e.g. Simulated

Annealing (Kirkpatrick, 1984), Genetic Algorithm

(Deb, 2002), Tabu Search, Particle Swarm (Shi,

2001) and Ant Colony (Dorigo, 2004).

Ant Colony Optimization (ACO) is a family of

algorithm inspired by ants’ behaviour and their way

of communication when searching from food which

allows them to find the shortest way between the

colony and the food source.

Genetic Algorithm (GA) are inspired by the

natural evolution process of a population. Each

individual correspond to a point in the solution space

and undergo to an evolution process. Individuals that

have better results produce more offspring than others

and genes from good individuals contribute to the

generation of improved solution. Random mutation in

the evolution process allow the algorithm to explore

the solution space.

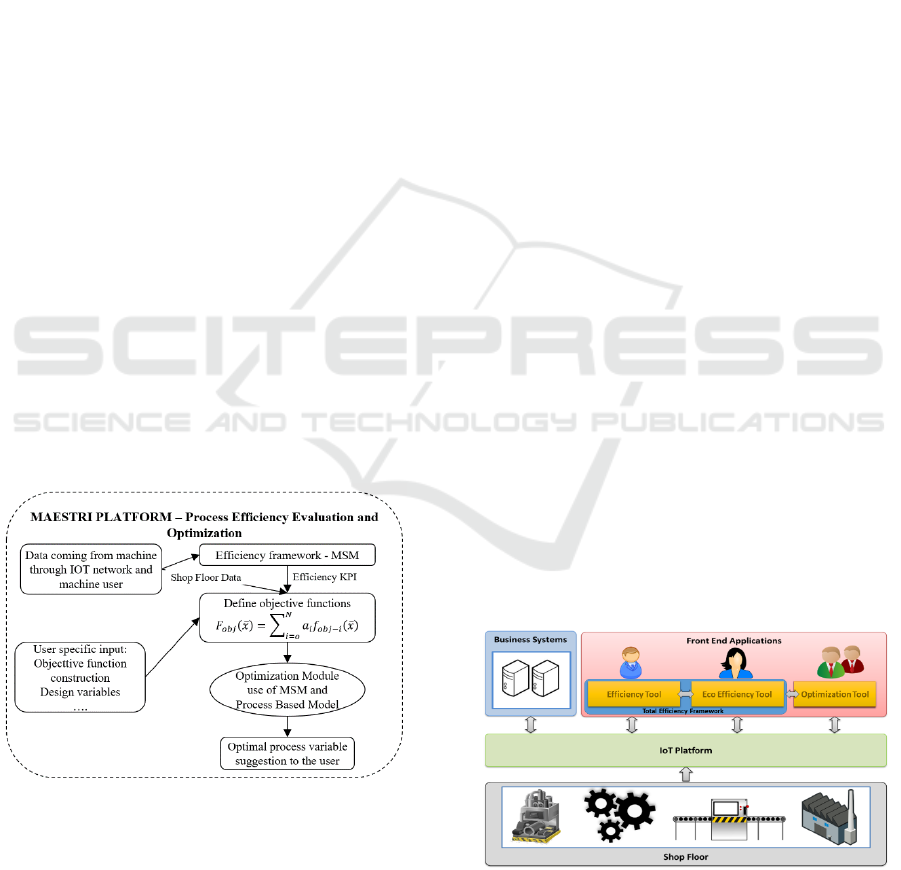

Figure 2: Optimization Module Architecture.

2.3 Use Case Example

The reference example used in the project to develop

the efficiency framework and optimization module

concept is the injection moulding. This production

process is characterized by a variety of materials,

shape and sizes that can be used by the same machine

to produce from simple to complex products.

The use case example will consider the following

variables:

Cycle time measurement,

Energy consumption per cycle,

Material consumption per cycle,

Parts produced per cycle,

Number of Not-OK (NOK) parts per cycle.

The use case example considers that company

established goals to continuously increase

sustainability and resource efficiency. In order to

assess efficiency and eco-efficiency performance

based on energy consumption, material consumption

and other key variables, like cycle-time. The use case

considers that all necessary data on resources and

materials costs, energy costs, as well as other cost

factors related to process operation (machine

operating costs, labour costs, parts selling price, etc.)

can be retrieved via the IoT Platform, to enable

calculation of eco-efficiency related Key

Performance Indicators (KPIs).

The goal here is to better understand and optimise

the interdependencies between process stages, both

from technical and economic perspectives. For this

reason, it is necessary to optimize energy and material

consumption, in a manner that does not affect process

productivity by creating problems on the other

upstream and downstream process stages.

3 PROPOSED SOLUTION

Figure 2 shows the proposed methodology that will

be implemented in the MAESTRI platform to support

the decision making process in order to optimize the

environmental impact and the overall efficiency.

Figure 3 shows the MAESTRI platform architecture.

Figure 3: MAESTRI platform architecture.

The central element is an IoT platform, which

facilitates the data transfer from machines, systems,

Optimization for Sustainable Manufacturing - Application of Optimization Techniques to Foster Resource Efficiency

427

and sensors at shop floor to end user software tools

and applications at the industrial sites. Data coming

from the IoT Platform and eco-efficiency KPI are

used by the platform user to design specific objective

function. The IoT Platform provides interoperable

interconnection of appliances, devices, terminals,

subsystems, and services. The platform has been

designed according to the service-oriented

architecture (SoA) approach where services are

provided to the other components by loosely-coupled

application components.

Each of the functional submodules of the

architecture is explained in the following. The Shop

Floor will usually be the place where the major part

of the relevant data is being produced, e.g. material

consumption in injection moulding machine. Device

Connectors (DC) provide the means for devices to

communicate with the rest of the framework

regardless of the communication protocol it uses.

DCs need to be developed specifically for each new

device or protocol. Business Systems are the second

type of data source. Enterprise Resource Planning

(ERP) and Manufacturing Execution System (MES)

systems can be connected to the IoT Platform in order

to complement the data from shop floor. Frontend

Applications represent all the end user software tools

and services, which are the main data consumers from

the point of view of the IoT Platform. These include

mainly tools for eco-efficiency and process

efficiency, which allow the overall assessment

providing relevant KPIs. The optimization tool then

finds the optimal solution, based on defined objective

function and process based model, see section 3.1,

with the result of optimizing the KPIs.

3.1 Modelling of the Process

The process modelling allows the optimization

algorithms to iterate the influence of the design

variables in the response function. Most of those

relationships representing the influence of those

variables are linear or can be simplified as linear (e.g.

production rate vs. material consumption, parts per

cycle vs cycle time per part, etc.). Nevertheless, the

complexity increases when several linear correlations

influencing the same process performance output are

analysed simultaneously. One powerful approach is

recommended to deal with this complexity – the

process-based models (PBM) (Peças, 2013). The

PBM comprises mathematical relations that bridge

the design choices and the resources inventory from

where the costs, environmental impact and value are

calculated. PBM is composed by a process model and

by an operations model. In the process model the

relation between process variables and performance

output are established and programmed. In the

operations model the production context is defined,

like number/type of machines, production time,

operators use rate, etc. The PBM outputs are, in

general, the time required to produce the parts, the

material, energy and consumables consumed, as well

as the number of tools, number of machine and other

resources required (if applicable).

The aim of the intended analysis to be performed

influences the PBM design (its extension in number

of variables and outputs). Therefore, the eco-

efficiency KPIs aimed to be accessed (optimized)

should be defined in this phase. There are some

almost obvious KPIs like the ratio between the

product added-value and total environmental impact,

parts produced and energy consumed or tool/system

duration (in shots or parts produced during its life

cycle) and its life cycle environmental influence

(LCA results). For each specific analysis particular

KPIs should be defined and the PBM must be

designed to allow the output of time and resources

consumed figures required for the KPIs calculations.

Aiming to optimize a set of KPIs at the same time is

not a simple task, since for the same process variables

variation each KPI will vary in a distinct way, so

metaheuristics methods abilities allow the

identification of the most proper variable setting that

maximizes performance.

3.2 Optimization Module

The process based model approach defined in the

previous section can describe a relation between the

input process variable ̅ and the resulting process

behaviour. With this and the tools implemented in the

efficiency framework we can extract the TEI and

other KPI that measure the ECO-efficiency of the

process.

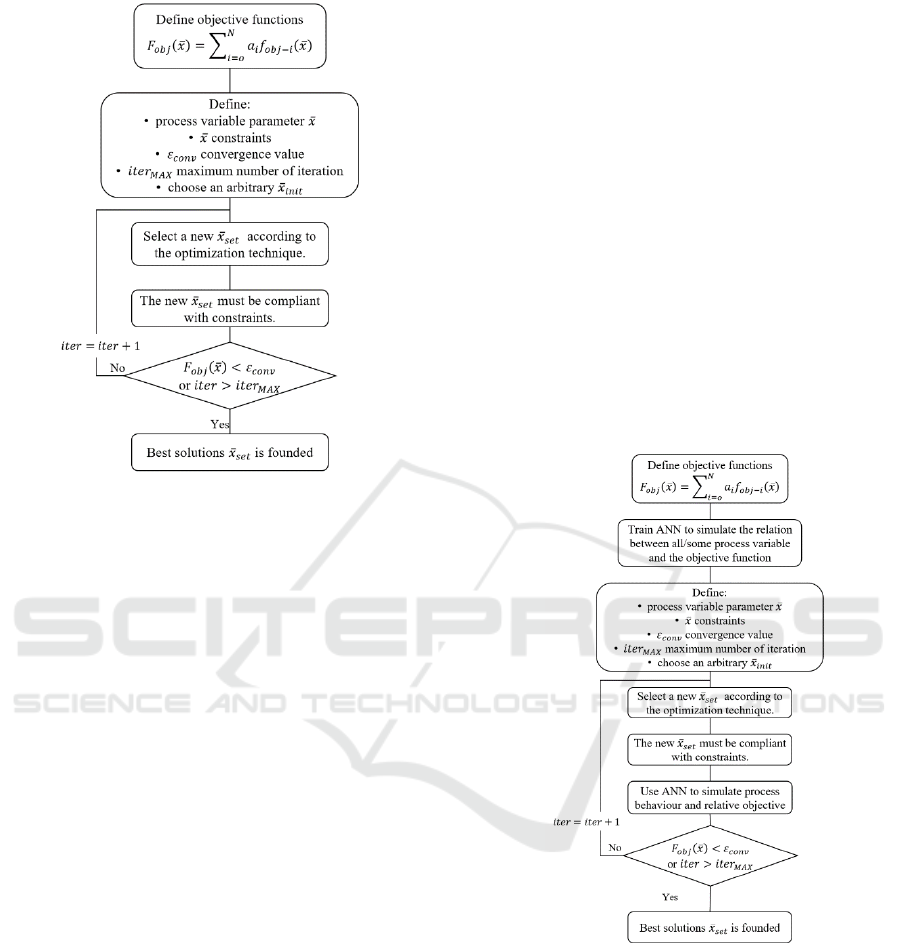

Figure 4 represents the optimization approach

applied to the efficiency framework concepts. After

the definition of the objective function composition

that can be personalized following the specific project

under study the optimization algorithm defines a new

set of possible solution following its own

characteristic strategy. The new set of solutions is

evaluated through

̅

and if the value is minor

than a user defined value the solution is accepted

otherwise a new iteration of the optimization

algorithm is run to find a new set of solutions. If the

number of iteration is higher than a predefined

maximum number defined by the user, the best

solutions founded until that iteration are given to the

user.

IoTBDS 2017 - 2nd International Conference on Internet of Things, Big Data and Security

428

Figure 4: Optimization algorithm application schema.

In industrial process the number of parameters to

be controlled can be very high so the selected

optimization algorithm must be able to deal with a lot

of input and to find the best solution of multiple

objectives. In this application context metaheuristic

algorithm, see section 2.2, are widely use (Satadru,

2015). The major drawback of metaheuristic

algorithm is the fine tuning of the algorithm

parameters to the specific problem but specific

algorithm can be used to partially overcome this issue

(Eiben, 2011).

The combination of different techniques, like

Artificial Neural Network (ANN) and GA (Shen,

2007), is named Hybrid approach and can give good

results especially in presence of non-linear

relationship between the process parameter and the

objective function.

Figure 5 shows the hybrid approach using ANN

to simulate the process behaviour. The ANN must be

trained during an initial phase and can be used in the

iteration process to simulate the process. ANN can

also be trained through simulation, that are time

consuming, and continuously trained during the

iterations, see (Shen, 2007). An example of

application is the relation between the energy

consumption and the process design variable. The

black box approach through the use of ANN suite this

kind of application due to the non-linear nature and

difficulties in the evaluation with standard

approaches.

3.3 Decision Support Capabilities

The connection of a highly integrated framework for

both eco-efficiency and operations efficiency

assessment, the MAESTRI Efficiency Framework,

with a suitable optimization module and algorithms

opens new vast opportunities towards providing

solutions to complex problems in sustainability

domain namely in industrial companies. Indeed, the

capabilities of such rich methods and associated tools

as the Efficiency Framework, besides their potential

to individual analysis “what if improved scenarios

creation” or even online monitoring, can become of

more impact in the improvement strategies and

deployment with the support of the adequate

optimization technics. Providing only a selection of

best available solutions the MAESTRI platform will

help the user in the results selection and avoid wrong

choices.

Figure 5: Optimization approach using ANN hybrid

technique.

4 CONCLUSIONS

This work presents a first preposition towards an

effective connection between a high level

sustainability oriented tool, the Efficiency

Framework, with the potential usefulness and

industrial impact of a suitable optimization scheme.

These connected tools will allow deeper analysis

Optimization for Sustainable Manufacturing - Application of Optimization Techniques to Foster Resource Efficiency

429

towards the optimization of resource efficiency,

crossing the different environmental and economic

aspects, enabling support and optimize sustainable

decision making process and identification and

quantification of potential improvements in the

industrial processes. For that result, the optimisation

methods should provide robust knowledge to support

decision-making, allow comparability of the results

and consider a cost-saving approach to help set

priorities. Moreover, the optimisation techniques

should centre the process through

design/configuration of the production system,

without considering time, in order not to limit the

physical agents. The optimization task is enabled and

facilitated leveraging a SOA IoT platform which

provides services for efficiency and eco-efficiency

assessment other than optimization.

ACKNOWLEDGEMENTS

This work was supported by the European Union’s

Horizon 2020 research and innovation program

through the MAESTRI project (grant n° 680570).

REFERENCES

Garetti, M. and Taisch, M. 2012. Sustainable

manufacturing: trends and research challenges.

Production Planning & Control 23.2-3: 83-104.

U.S. Department of Commerce 2014. “How does

Commerce define Sustainable Manufacturing?”

International Trade Administration.

Kersten, G. E.; Mikolajuk, Z., and Yeh, A. G. 1999,

“Decision Support Systems for Sustainable

Development” Kluwer Academic Publishers. ISBN: 0-

88936-906-2.

Kulatungaa, A.K., Karunatilakeb N., Weerasinghea N.,

Ihalawattaa R. K., 2015. Sustainable Manufacturing

based Decision Support model for Product Design and

Development Process, Procedia CIRP - The 12th CIRP

Conference on Sustainable Manufacturing, Volume 26,

Pages 87 – 92.

Sproedt, A., Plehn, J., Schönsleben, P., & Herrmann, C.

2015. A simulation-based decision support for eco-

efficiency improvements in production systems.

Journal of Cleaner Production, 105, 389-405.

A.J. Baptista, E.J. Lourenço, J.P. Pereira, F. Cunha, E.J.

Silva, P. Peças. 2016. ecoPROSYS: An Eco-Efficiency

Framework Applied to a Medium Density Fiberboard

Finishing Line, Procedia CIRP, Volume 48, Pages 170-

175, ISSN 2212-8271.

Lourenço, E. J., Baptista, A. J., Pereira, J. P., Dias-Ferreira,

C. 2013. Multi-Layer Stream Mapping as a Combined

Approach for Industrial Processes Eco-Efficiency

Assessment. In: Re-engineering Manufacturing for

Sustainability: 427-433.

Lin, Shen, and Brian W. Kernighan. 1973. An effective

heuristic algorithm for the traveling-salesman problem.

Operations research 21.2: 498-516.

Helsgaun, Keld. 2000. An effective implementation of the

Lin–Kernighan traveling salesman heuristic. European

Journal of Operational Research, 126.1: 106-130.

Kirkpatrick, Scott. 1984. Optimization by simulated

annealing: Quantitative studies. Journal of statistical

physics 34.5-6: 975-986.

Deb, Kalyanmoy, et al., 2002. A fast and elitist multi-

objective genetic algorithm: NSGA-II. IEEE

transactions on evolutionary computation 6.2: 182-197.

Shi, Yuhui. 2001. Particle swarm optimization:

developments, applications and resources."

evolutionary computation. Proceedings of the 2001

Congress on. Vol. 1. IEEE.

M. Dorigo and T. Stuzle, 2004. Ant Colony Optimization,

A Bradford Book.

P. Peças, I. Ribeiro, A. Silva, E. Henriques. 2013.

Comprehensive approach for informed life cycle-based

materials selection, Mater. Des. 43 220–232.

K. Satadru, and Dilip Datta. 2015. Process parameter

optimization of plastic injection moulding: a review.

International Journal of Plastics Technology 19.1: 1-

18.

Shen, Changyu, Lixia Wang, and Qian Li. 2007.

Optimization of injection moulding process parameters

using combination of artificial neural network and

genetic algorithm method. Journal of Materials

Processing Technology 183.2: 412-418.

Eiben, Agoston E., and Selmar K. Smit. 2011. Parameter

tuning for configuring and analysing evolutionary

algorithms." Swarm and Evolutionary Computation

1.1: 19-31.

Zhao, Jian, et al. 2015. Multi-objective optimization design

of injection moulding process parameters based on the

improved efficient global optimization algorithm and

non-dominated sorting-based genetic algorithm. The

International Journal of Advanced Manufacturing

Technology 78.9-12: 1813-1826.

IoTBDS 2017 - 2nd International Conference on Internet of Things, Big Data and Security

430