Global Energy Management for Propulsion, Thermal Management

System of a Series-parallel Hybrid Electric Vehicle

Xiaoxia Sun, Chunming Shao, Guozhu Wang, Rongpeng Li, Danhua Niu and Jun Shi

China North Vehicle Research Institute, Beijing, China

Keywords: Global Energy Management, Dynamic Heat Characteristics, Adaptive Controllable Thermal Management,

Coupled Modelling.

Abstract: Energy management in vehicles is a key issue, especially in the case of hybrid electric vehicle. In this paper,

a global energy management for propulsion, thermal management system of a series-parallel hybrid electric

vehicle is studied. An adaptive controllable thermal management system with two different control

strategies suitable for series-parallel hybrid electric vehicle is presented. According to the vehicle structure

and schematic, a multi-disciplined coupled model of a series-parallel hybrid electric vehicle combined with

propulsion system model and thermal management system model is proposed. The coupled model is

explored with the hybrid modelling method which combines experiment modelling and theory modelling.

Then the vehicle driving cycle simulations under different cooling control strategies are conducted. Results

show that the coupled simulation model can be used to study the energy delivery, distribution and dynamic

heat characteristics of propulsion system efficiently. Compared to the traditional on-off cooling control

strategy, the power consumption of thermal management system using rule-based cooling control strategy

can be decreased by 31.7%.

1 INTRODUCTION

Nowadays, concerns about air pollution and future

of energy issues are dramatically increased. In the

short term full electric vehicles are prepared to be a

substitute to the traditional internal combustion

vehicles because of the technology challenges of

energy storage system. At present, the hybrid

electric vehicle (HEV) is the viable alternative to

conventional vehicle. Series-parallel hybrid electric

vehicle (SPHEV) is a complex type of HEV, which

combines the series and parallel structure with a

planetary power split device. With advanced control

strategy it can not only take advantage of both series

and parallel HEV but also avoid their disadvantages

(C. C. Chan, 2002).

With the potential for achieving higher fuel

economy, PSHEV has been seen as one of the

hybrid powertrain architecture to improve fuel

economy when their power-management algorithms

are properly designed. Most of the attention has been

given to designing energy management control

systems in PSHEVs which is responsible to achieve

better vehicle fuel efficiency (C. L. Xiang, 2017).

Aside of propulsion, thermal management

occupies a significant part of the total energy

consumption of the hybrid electric vehicle. Recently,

there are a series of research on the thermal

management and power distribution of HEV which

is presented in depth. Among these, there are some

researches considering the effect of thermal

management based on different system structures (S.

Park, 2008,2010) and different control strategies (F.

J. Espadafor, 2015) on whole energy management of

series hybrid electric vehicle. The existing energy

management strategies of SPHEVs just focus on the

improvement of fuel efficiency based on hot engine

characteristics neglecting the effect of thermal

management system such as temperature on the

propulsion system components performance and the

vehicle power demand.

In this paper, an adaptive controllable thermal

management system suitable for SPHEV is

presented. According to the vehicle structure and

schematic, a mechanical-electrical-thermal coupled

model of a SPHEV combined with propulsion

system model and thermal management system

332

Sun, X., Shao, C., Wang, G., Li, R., Niu, D. and Shi, J.

Global Energy Management for Propulsion, Thermal Management System of A Series-parallel Hybrid Electric Vehicle .

DOI: 10.5220/0006370403320338

In Proceedings of the 3rd International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2017), pages 332-338

ISBN: 978-989-758-242-4

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

model is proposed to study the global energy

management of the whole vehicle.

2 SCHEMATIC OF SERIES-

PARALLEL HYBRID

ELECTRIC VEHICLE

2.1 Schematic of Propulsion System

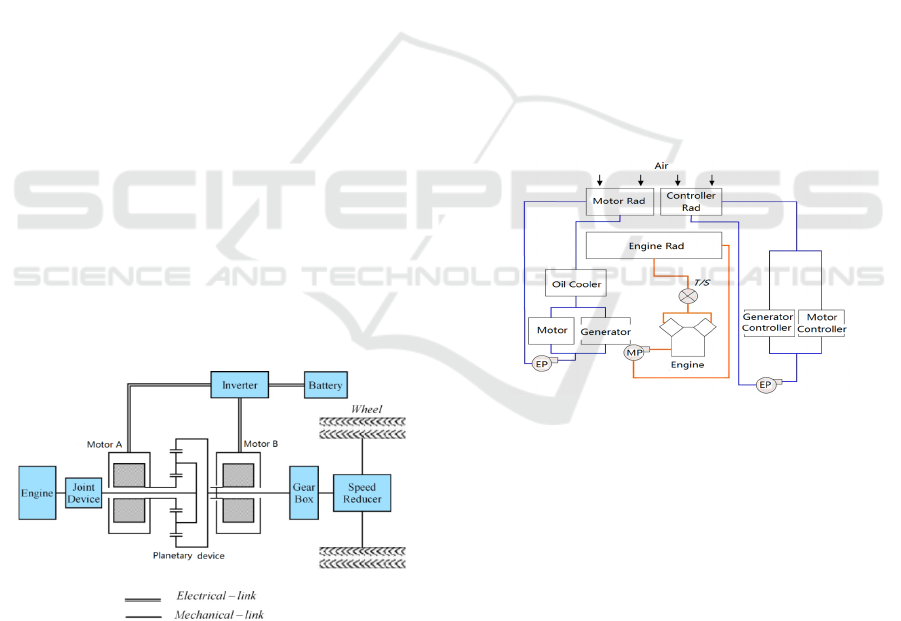

Compared to the others HEV propulsion system, the

SPHEV is characterized by multi-range

electromechanical transmission belongs to the power

split hybrid propulsion system. The schematic of the

SPHEV propulsion system is illustrated in Figure 1.

Except for internal combustion engine, there are

also two motors in the hybrid propulsion system.

These main components are connected by the

planetary device. The internal combustion engine is

jointed to the planet carrier of the planetary device.

The motor A is jointed to the sun gear of the

planetary device. The motor B is jointed to the ring

of the planetary device which is paralleled with the

vehicle output shaft. Considering to the vehicle

driving conditions, both the motor A and the motor

B can not only operate as a generator but also work

as a driving motor. In SPHEV, the engine speed is

adjusted by the motor A when it works as a

generator according to the work conditions. The

power generated by the engine is split by the

planetary power coupling device and then formed

into different power flow under different driving

condition.

Figure 1: Schematic of series-parallel hybrid electric

vehicle propulsion system with planetary device.

2.2 Schematic of Thermal Management

System

An adaptive controllable thermal management

system suitable for SPHEV is proposed which is

shown in Figure 2. It is fully designed on the

consideration of the global energy management

which not only consider the temperature effect on

the propulsion system components but also take into

account the effect of thermal management power

consuming on the whole vehicle power demand.

There are three water circulation loops in the

thermal management system. One is high

temperature water circulation loop which is used to

cool the internal combustion engine. The other two

are low temperature water circulation loops which

are used to cool the electric motors and their

controllers separately. The oil cooler is arranged in

the motor low temperature water circulation loop

because of transmission oi temperature requirement.

Three radiators are integrated into one radiator

module. In the air loop, an air stream is inducted

through a grille from the top of vehicle which is

powered by two electric fans. Then it passes in turn

through two low temperature water radiator which is

installed in parallel and one high temperature water

radiator which is installed with the low temperature

radiators in series. Finally, the air stream washes

over the powertrain set in the power compartment

and be exhausted by the fans through another grille.

Figure 2: Schematic of series-parallel hybrid electric

vehicle thermal management system (Rad: Radiator, EP:

Electric Pump, MP: Mechanical Pump, T/S: Thermostat).

3 MULTI-DISCIPLINED

COUPLED SIMULATION

MODELLING

A mechanical-electrical-thermal coupled model is

established by multi-disciplinary hybrid modelling

method which can decompose the whole system into

several relatively independent subsystems. The large

coupling problem can be decomposed into small and

easy handling sub-problems. The complex mutual

coupled Modelling can be converted into a number

of independent subsystem modelling.

Global Energy Management for Propulsion, Thermal Management System of A Series-parallel Hybrid Electric Vehicle

333

3.1 Propulsion System Modelling

This part introduces the models of the components

in the vehicle propulsion system. The hybrid

modelling method which combines experiment

modelling with theory modelling is adopted.

3.1.1 Internal Combustion Engine

Due to the significant nonlinearity of the engine, the

real engine model is quite complicated. In this paper,

the experimental data are used to obtain the engine

performance maps, including the engine's external

characteristic map and the engine fuel consumption

characteristics map. Then an engine torque output

module is used to acquire the engine output torque

from a look-up table by the engine throttle signal

and the current speed. The engine fuel consumption

is calculated by the current engine speed, torque and

engine fuel consumption rate.

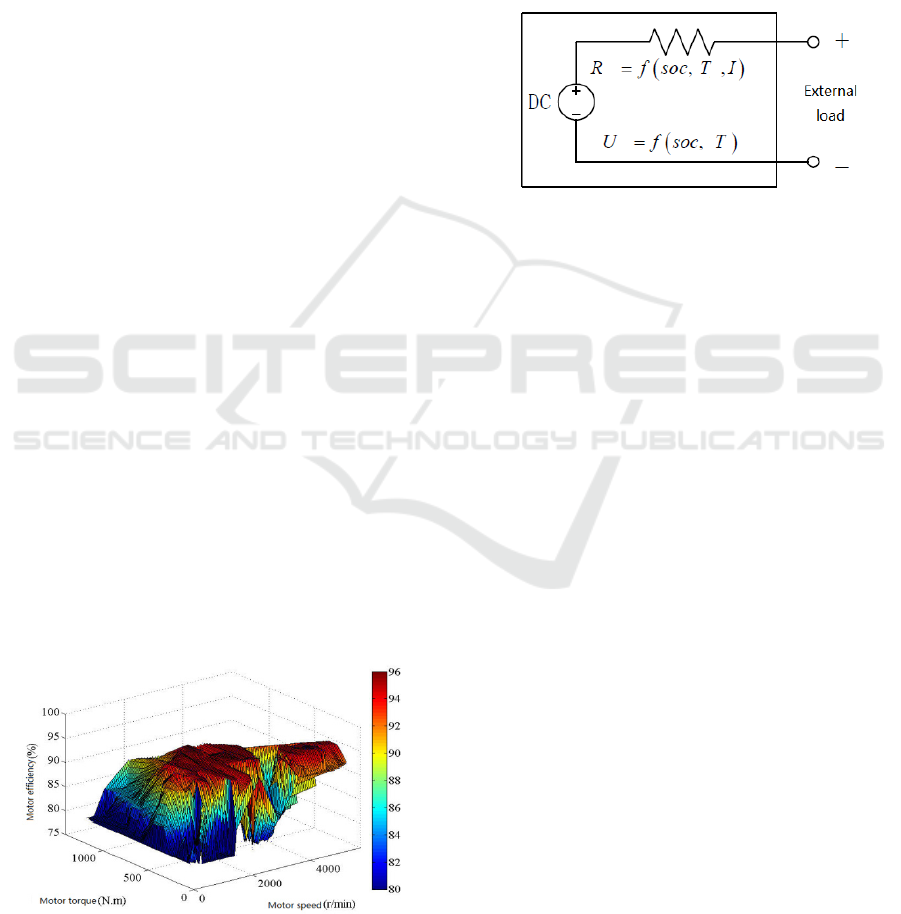

3.1.2 Motor and Controller System

The experimental modelling method is also used in

motors and controllers modelling process, which

emphasizes on the input and output characteristics.

The characteristic maps of the motors are obtained

by the motor bench test. The motor model mainly

includes a torque calculation module and a current

calculation module. Firstly, the motor receives the

target torque command. Then the torque calculation

module determines the maximum drive torque in

electric operating condition or the maximum braking

torque in braking condition which can be used as a

constraint of the motor output torque. Motor current

calculation module is used to calculate the driving

power or the generating power by the motor current

output speed, torque and motor efficiency factor

acquired from the motor efficiency curve shown in

Figure 3.

Figure 3: Motor efficiency curve.

3.1.3 Energy Storage System

In the SPHEV, the energy storage system is lithium

battery pack. In this paper, the model of the battery

pack is modelled by the internal resistance model.

The battery pack is modelled as a controllable

voltage source and a variable resistor. The

equivalent circuit diagram is shown in Figure 4. The

battery model outputs the state of charge (SOC) of

the battery pack and provides an electrical interface

to the generator and the motor.

Figure 4: Battery internal resistor model. (R: Battery

internal resistor, U: Voltage, soc: state of charge, T:

Temperature, I: Current ).

3.2 Thermal Management System

Modelling

In order to guarantee working performance and

reliability of the propulsion system components, an

adaptive controllable thermal management system

has been used for the propulsion system heat

dissipation. On the other side, the thermal

management system requires electrical energy to

fulfil its duty. Therefore the power consumption of

the thermal management system drive components

such as electric fan and electric pump need to be

considered in the total power demand.

The battery has the integrated cooling system in

the battery pack which is not the research focus in

this paper. So this part can be neglect in the thermal

management system.

3.2.1 Heat Sink Component

Heat sink components are heat exchangers that reject

heat to the ambient air. The calculation applies the

following formula (Z. P. Yao, 2001).

)(

'''

aapaaa

ttcm

(1)

a

is the quantity of heat removed of air side,

a

m

is the air mass flow,

pa

c

is the specific heat capacity of

the air,

'

a

t

is the inlet temperature of air,

''

a

t

is the

outlet temperature of air.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

334

)(

"'

wwpwww

ttcm

(2)

w

is the quantity of heat removed of water side,

w

m is the mass flow rate of water,

wp

c

is the specific

heat capacity of water,

'

w

t

is the inlet temperature of

water,

''

w

t

is the outlet temperature of water.

''''

''

''''''

ln

wa

wa

wawa

m

ms

tt

tt

tttt

t

tKA

(3)

s

is the quantity of heat removed of radiator,

K

is the heat transfer coefficient of the radiator,

A

is the heat transfer area,

m

t

is the difference in

temperature between the fluid entering the heat

exchanger.

e

aa

d

L

u

fP

2

2

(4)

P

is the air flow pressure drop,

f

is the air

flow resistance coefficient,

a

is the air density,

a

u

is the air velocity, L is the length of flow pipe,

e

d is

the equivalent diameter.

g

u

d

l

h

c

f

2

Re

316.0

2

25.0

(5)

f

h

is the coolant pressure loss of the straight

pipe,

Re

is the Renault number,

l

is the length of

the coolant flow pipe,

d is the inside diameter of

the pipe,

c

u is the coolant velocity,

g

is the

acceleration of gravity.

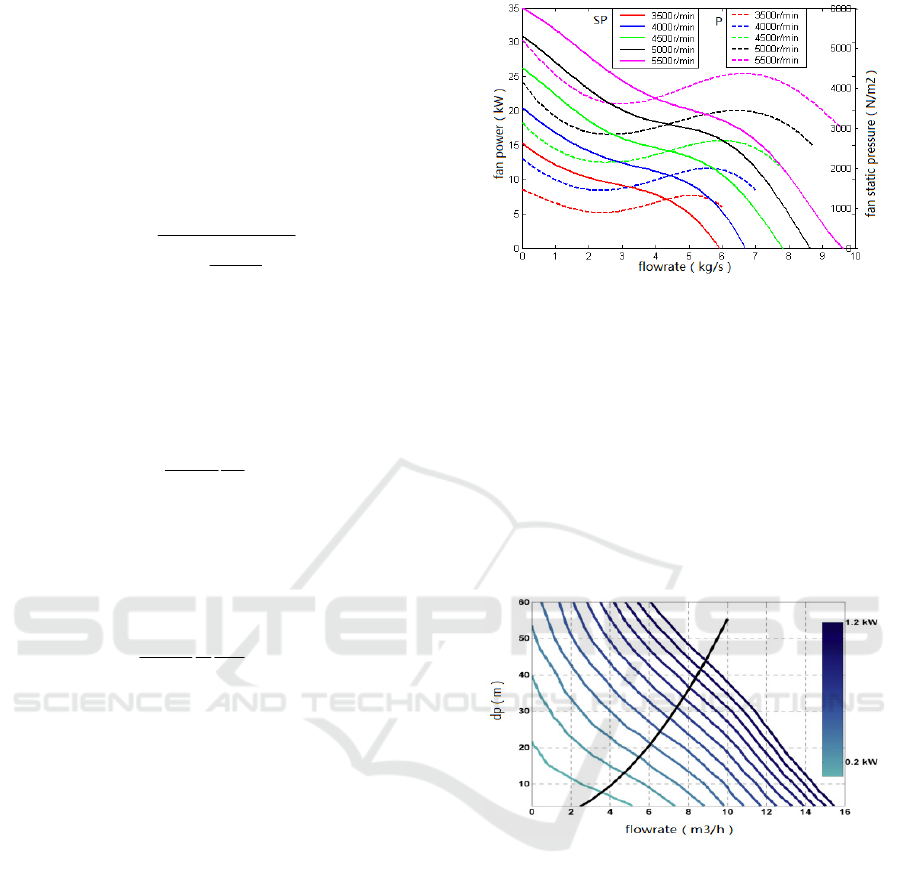

3.2.2 Electric Fan

The heat dissipation of the internal combustion

engine and electrical components is delivered by

water and through radiators where it is transferred to

air by electric fans. Two electrical fans have been

arranged in parallel according to the structure of the

thermal management system. The specific

performance curve of the electric fan is described in

Figure 5.

Figure 5: Electric fan performance curve. (SP: static

pressure, P: power).

3.2.3 Coolant Pump

There are totally three pumps in the thermal

management system. Two electric water pumps are

used in the circulation of the motor cooling circuit

and controller cooling circuit. One mechanic water

pump which is propelled by engine directly is used

in the engine cooling circuit. The specific

performance curve of the electric pump is described

in Figure 6(Francisco, 2015).

Figure 6: Electric pump performance curve.

4 GLOBAL ENERGY

MANAGEMENT STRATEGY

FOR SPHEV

The power distribution flexibility of SPHEV brings

a more complex energy management problem. The

energy management strategy of HEV can be divided

into two categories, namely rule-based and

optimization-based. Although on some particular

occasions driving cycle can be known, it is usually

unavailable in some off-road conditions which

causes rule-based strategies be the most useful. In

Global Energy Management for Propulsion, Thermal Management System of A Series-parallel Hybrid Electric Vehicle

335

this paper a rule-based energy management strategy

has been chosen for the SPHEV.

According to the driving condition, the SPHEV

can explore a variety of working modes. Vehicle

stop mode includes vehicle stopping and stopping &

charging conditions. The latter one is a special case

of the vehicle stopping mode. Electric driving mode

is applied in the low speed and small load condition.

Engine single driving mode is applied in the

situation that vehicle required torque is in the engine

high efficiency load areas. Hybrid driving mode is

applied to full load acceleration or climbing

conditions. Braking mode includes electrical braking

and mechanical braking is applied in brake

condition.

For different working modes, the energy

management adopts the control strategy based on the

power distribution rules. First, the total demand

power of the vehicle including the vehicle driving

power and auxiliary power is distributed between the

engine and the battery, and then the engine power is

distributed between the motor A and the mechanical

power. On the premise that battery SOC is

maintained at optimal working range, engine works

in the optimal efficiency range by the adjustment of

the battery. Motor A is used to adjust the engine

speed into the optimal speed range in order to realize

the best fuel consumption.

Under this situation, the speeds of fans and

pumps are controlled by the thermal management

system which is also considered in the global energy

management system. There are two thermal

management control strategies are applied in this

paper. One is traditional on-off control strategy. The

other one is rule-based control strategy which is

realized by the rule-based map determined by the

different vehicle working modes. Compared to the

traditional on-off control, this rule-based cooling

control strategy is more elaborate. The specific

control target temperatures of propulsion

components can be seen in Table 1.

Table 1: The control target temperatures of propulsion

components.

Propulsion component

Control target outlet water

temperature(K)

Engine 376

Generator 358

Motor 358

Generator controller 338

Motor controller 338

5 RESULTS AND DISCUSSIONS

A series of simulations under UDDS driving cycle

using different cooling control strategies are

conducted. The international general urban road

driving cycle UDDS is shown in Figure 7. In the

UDDS driving cycle, the maximum velocity is 91.2

km/h. In the simulation, the initial SOC of the

battery is set to 0.8. The vehicle needs to start, stop,

accelerate and brake frequently throughout this

driving cycle. The total demanding power of

SPHEV is shown in Figure 8. The demanding power

is distributed between the engine power and the

battery power. The engine power over the whole

driving cycle can be seen in Figure 9. The histories

of battery SOC and power over the driving cycle can

be seen in Figure 10. During the driving cycle, the

SOC of the battery always declines. In light of

recycling energy of the electrical brake, the SOC

changing curve goes up and down accordingly

which is related to the charge-and-recharge process.

Figure 11 shows the engine and electric components

temperature histories over the driving cycle under

rule-based cooling control strategy. Figure 12 shows

the vehicle thermal management system power

consumption over the driving cycle under different

cooling control strategies.

The simulation results show that the adaptive

controllable thermal management system with rule-

based control strategy proposed in this research is

suitable for the SPHEV, which can satisfy the heat

dissipation requirements of the propulsion

components under different driving conditions.

Under this circumstance, the propulsion components

can work effectively in a better temperature range.

On the other side, the power consumption of the

vehicle thermal management system can be reduced

significantly by using the rule-based control strategy.

Compared to the traditional on-off control strategy,

the power consumption of the thermal management

system using rule-based control strategy can be

decreased by 31.7%.

Figure 7: UDDS driving cycle.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

336

Figure 8: vehicle total demanding power under UDDS

driving cycle.

Figure 9: Engine Power under UDDS driving cycle.

Figure 10: Battery state of charge and power under UDDS

driving cycle.

(a) Engine

(b) Motor

(c) Generator

(d) Motor controller

(e) Generator controller

Figure 11: Temperature histories of engine and electric

components.

Figure 12: Power consumption of thermal management

system under different control strategies. (TMS: thermal

management system).

6 CONCLUSIONS

The mechanical-electrical-thermal coupled model

established in this paper is very efficient in the

power delivery, distribution and dynamic heat

response research of SPHEV. With the multi-

disciplined coupled model, a global energy

management can be realized. The propulsion

components heat characteristic and thermal

management system power consumption can be

synthetically considered. With suitable cooling

control strategy, it can not only enhance the

propulsion performance, but also reduce the system

power consumption.

ACKNOWLEDGEMENTS

Fanatical and technical supports from the Chinese

Scholarship fund and China North Vehicle Research

Institute are gratefully acknowledged.

Global Energy Management for Propulsion, Thermal Management System of A Series-parallel Hybrid Electric Vehicle

337

REFERENCES

C. C. Chan, 2002. The state of the art of electric and

hybrid vehicle, in Proceedings of IEEE, Vol. 90, No. 2,

pp. 247-275.

C. L. Xiang, F. Ding, W. D. Wang and W. He, 2017.

Energy management of a dual-mode power-split

hybrid electric vehicle based on velocity prediction

and nonlinear model predictive control, Appl Energy,

189: 640-653.

S. J. Park and D. Jung, 2008. Numerical Modeling and

Simulation of the Vehicle Cooling System for a Heavy

Duty Series Hybrid Electric Vehicle, SAE Paper No.

2008-01-2421.

S. J. Park and D. Jung, 2010. Design of Vehicle Cooling

System Architecture for a Heavy Duty Series-Hybrid

Electric Vehicle Using Numerical System Simulations,

Journal of Engineering for Gas Turbines and Power,

Vol. 132, 2010, pp. 092802-092802-11.

F. J. Espadafor, D. P. Guerrero, E. C. Trujillo, M. T.

Garcia and J. Wideberg, 2015. Fully optimizied energy

management for propulsion, thermal cooling and

auxiliaries of a series hybrid electric vehicle, Appl.

Thermal Engineering 91 (2015) 694-705.

Z. P. Yao and X. G.Wang, 2001. Heat transfer in vehicle

cooling, Beijing: Beijing Institute of Technology

Press, 2001, pp.129-147.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

338