Development of Graphene Oxide and TiO

2

Heterojunctions for

Hybrid Solar Cells

P. Custódio, P. A. Ribeiro, M. Raposo and S. Sério

CEFITEC, Departamento de Física, Faculdade de Ciências e Tecnologia da Universidade Nova de Lisboa,

2829-516 Caparica, Portugal

Keywords: Hybrid Solar Cells, Layer by Layer Films, Graphene Oxide, Pei, TiO

2

.

Abstract: This work reports the development of hybrid devices composed of organic and inorganic thin films,

deposited on fluorine doped tin oxide coated glass substrates (FTO). The organic layers, graphene oxide

(GO) and poly (ethylenimine) (PEI) were deposited by the layer by layer technique (LbL), through the

aerosol spray variant. The inorganic layer, titanium dioxide (TiO

2

), was deposited by sputtering and the

aluminium electrode by thermal evaporation. To characterize these devices was used UV-Visible

spectrophotometry to observe the films growth and optical microscopy to analyze the surface morphology.

Finally, the electrical measurements were performed by measuring the I-V characteristic curves. The final

device (FTO/PEI/GO/ TiO

2

/Al)

20

showed a significant change in the behaviour when interacting with light.

1 INTRODUCTION

The industrial revolution has marked the beginning

of a new technological stage, which was characteri-

zed by the use of fossil fuels and minerals as the

main source of energy.

Since then, several studies have shown the

harmful impact of these forms of energy production

have on planet Earth, causing depletion of the ozone

layer and increasing of global warming. Currently,

about 80% of CO

2

emissions come from the energy

sector, thus demonstrating the need to develop new

approaches of generating energy in a sustainable and

clean way. Therefore, it is important and urgent the

development of devices capable of generating

energy without the need of use fossil fuels, such as

solar cells, biomass, wind turbines, among others.

However, this type of technology has two inherent

limitations, the price of the materials used and their

efficiency, leading to the prevalence of fossil fuels.

Nevertheless, great progress has been made in

these technological areas, making its use more

feasible, being presently around 8% of the energy

generated in the United States coming from

renewable sources (Serrano 2009).

This growing demand for alternative methods for

energy production has led to the development of

new architectures as well as research of new

materials in order to increase the efficiency of these

devices. One of the materials that has attracted

significantly the researchers' attention is graphene

and its derivatives (graphene oxide (GO) and

reduced graphene oxide (rGO)). These materials

have been extensively studied due to their electrical,

mechanical, optical and thermodynamic properties

and are presently used in several applications such

as: solar cells, solar fuels, lithium ion batteries,

supercapacitors, among others.

In the particular case of solar cells, these

compounds have been used as transparent and non-

transparent electrodes, in photoactive layers and in

electron transport layers and gaps (Yin 2014).

Based on the technological progress made in this

area during the last decades solar cells with hybrid

heterostructures have emerged in order to overcome

some disadvantages of organic solar cells such as

low optical absorption and degradation of the

compounds used (Roland 2015 and Wright 2012).

In this context, with this work it is aimed to find

solutions to capture solar energy, based on the

knowledge acquired in the last two decades under

organic conductive polymers, photoluminescent and

photochromic (Ferreira 2013, Ferreira 2007 and

Ferreira 2007) and also on semiconductors oxides

films, in particular titanium dioxide, TiO

2

(Sério

2011 and Sério 2011).

Custøsdio P., Ribeiro P., Raposo M. and SÃl’rio S.

Development of Graphene Oxide and TiO2 Heterojunctions for Hybrid Solar Cells.

DOI: 10.5220/0006324103860390

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 EXPERIMENTAL DETAILS

The layer-by-layer films were prepared from

aqueous solutions of poly(ethyleneimine) (PEI)

(Mw) 750 000 g/mol) and graphene oxide (GO) 2

mg/mL, dispersion in H

2

O, with concentrations of

3×10

-3

M

and 10

-2

M, respectively, using the LbL

technique, implemented through aerosol spray

variant, instead of adsorption from bulk solution.

The chemicals were obtained from Aldrich and the

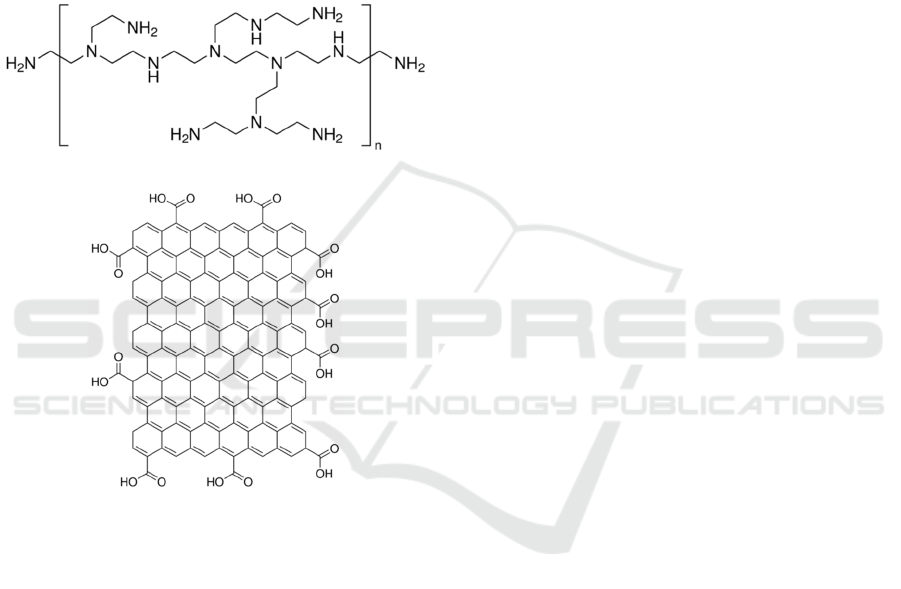

corresponding molecular structures are depicted in

Figure 1.

(a)

(b)

Figure 1: (a) poly(ethyleneimine) (PEI) (b) graphene oxide

(GO).

The ultrapure water with a resistivity of 18 MΩ

cm was supplied by a Millipore system (Milli-Q,

Millipore GmbH). Accordingly, both cationic and

anionic solutions, as well as washing ultra-pure

water, were placed in aerosol spray dispensers and

were ordered with the following sequence: cationic

solution, ultra-pure water, anionic solution and ultra-

pure water. The films were sprayed onto Fluorine-

doped tin oxide (FTO) coated glass substrates

(TEC15, 12-14 Ω/). The solid supports were

placed at a distance of 6 cm from the spray dispenser

and the solutions were alternately sprayed following

the order aforementioned. Each dispenser was

pressed twice to guarantee a satisfactory amount of

ejected solution towards the supports. After the

adsorption of the cationic layer solution, the

substrate becomes positively charged. It is then

washed with water to remove the amount of cationic

molecules solution that wasn’t satisfactorily

adsorbed on the substrate. Then the same procedure

was used for the anionic layer, washed again with

water and finally dried with nitrogen flow. After this

sequence, the first bilayer film was formed and, the

steps abovementioned were repeated until obtain the

desired number of bilayers. The lag time between

each solution spraying was of 10 s and all the films

were produced with 20 bilayers: (PEI/GO)

20

.

After, the inorganic layer (TiO

2

) was deposited

by DC-magnetron sputtering. The sputtering was

carried out at room temperature (RT) using a

titanium disc (99.99% purity, GoodFellow) with

64.5 mm of diameter and 4 mm of thickness as

sputtering target. A turbomolecular pump was used

to achieve a base pressure of 10

-4

-10

-5

Pa (before

introducing the sputtering and reactive gases).

Before the deposition, a movable shutter was

interposed between the target and the substrates, and

the target was pre-sputtered in Ar atmosphere for 5

min to clean the target surface. The deposition of

TiO

2

was carried out in 100% O

2

atmosphere

(99.999% purity) at constant total gas pressure of 1.2

Pa, a sputtering power of 500 W during 10 min. The

target-to-substrate distance was kept constant at 100

mm. No external substrate heating was used during

the depositions. The substrate temperature was

measured by a thermocouple passing through a small

hole in a copper piece, which was placed in contact

with the substrate. During the deposition process the

sample temperature increased up to 60 °C due to the

plasma particle‘s bombardment of the substrate.

Finally, to obtain the desired solar cell device (FTO /

PEI / GO / TiO

2

/ Al), an aluminium (Advent

Research Materials, 99.5%) electrode was deposited

by thermal evaporation, in a vacuum chamber at a

pressure between 10

-6

and 10

-5

mbar, over an area of

approximately 0.95 cm

2

. The films were

characterized by optical microscopy using a Nikon

Eclipse LV100.

The UV-vis spectroscopy for the films was

carried out with a Shimadzu UV b - 2101PC

UV/VIS spectrophotometer at room temperature

within the wavelength range 200-900 nm. The

electric measurements (I-V characteristic curve) of

the final device were carried out using a

programmable DC power supply model Rigol

DP811A in absence of light, at ambient light and

with light from a 250 watts halogen lamp positioned

at a distance of 40 cm from the device. All the I-V

measurements were performed by changing the

voltage between 0V and ~1.5 V, with an increment

of 50 mV at room temperature, which was

guaranteed by a vent placed in the measurement

system.

3 RESULTS AND DISCUSSION

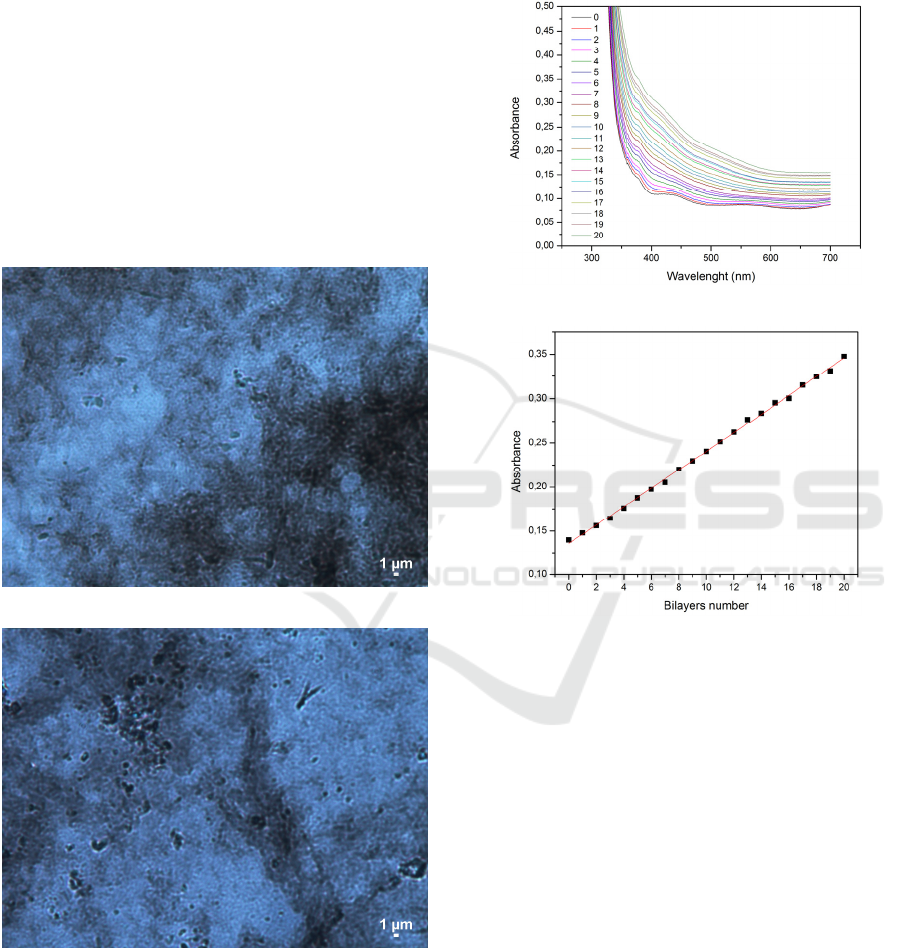

In figure 2 are depicted some representative images

obtained by optical microscopy for the PEI/GO LBL

films with 20 bilayers without and with TiO

2

film. In

general it can be observed that the films are

homogeneous in both situations, although can be

detected some aggregates (with and without TiO

2

).

This homogeneity remains even for bigger

magnifications.

(a)

(b)

Figure 2: Optical microscopic images for (a) (PEI/GO)

20

without TiO

2

(b) (PEI/GO)

20

with TiO

2

.

In figure 3 a) and b) is shown the ultraviolet-

visible absorbance spectra of different number of

bilayers of PEI/GO LBL films and the absorbance

intensity at 380 nm as a function of the number of

bilayers, N, respectively. It can be observed that the

absorbance at maximum increases with the number

of bilayers indicating a linear film growth (see figure

3b).

(a)

(b)

Figure 3: (a) Absorbance spectra of PEI/GO LBL films as

a function of the number of bilayers, N. (b) Absorbance

intensity at 380 nm as a function of the number of

bilayers, N.

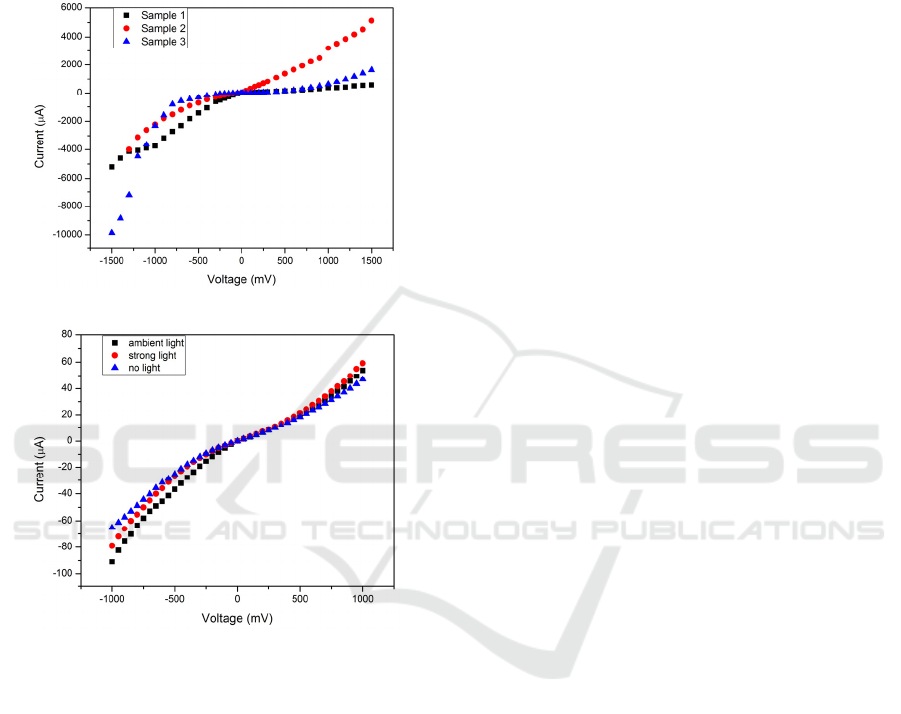

Figure 4 shows the I-V curves for three devices with

the structure (FTO/PEI/GO/TiO

2

/Al)

20

after

production and without interaction with radiation.

Although, it is expected that the LBL films have the

same thickness, the presence of aggregates as

revealed by optical microscopy may have led to

regions with different thicknesses. Considering this

possible difference in the thickness of the deposited

films, this fact can lead to a short circuit and

therefore explaining the erratic behavior of the I-V

curves observed in Figure 4 a). However, with a

another similar device produced using the same

conditions, I-V curves were obtained for different

experimental conditions (without light, strong light,

ambient light), which are depicted in Figure 4 b).

The analysis of the figure shows an increase of the

current for positive voltages when the device is

exposed to the light in comparison to the other

experimental conditions. The same behavior is

verified for negative voltages, however when the

device interacts with ambient light there is an

increase in current in the circuit, indicating an

increase of the charge carriers.

(a)

(b)

Figure 4: Electrical characterization for three devices with

the architecture (FTO/PEI/GO/TiO

2

/Al)

20

a) without the

interaction with light b) ambient light, strong light and in

absence of light.

Presently, more studies are in progress in order

to avoid the short circuit of the devices, increasing

the number of the bilayers.

4 CONCLUSIONS

In this work we report the development of hybrid

solar cells with the configuration

(FTO/PEI/GO/TiO

2

/Al)

20

. The organic layers, PEI

and GO, were deposited by layer-by-layer technique

through the aerosol spray variant and it was revealed

by optical microscopy that the deposited LBL films

are homogeneous, although are detected some

aggregates.

Considering the I-V characteristic curves for

several devices developed with this architecture, it is

observed a change of the behavior for the different

experimental conditions, increasing the conduction

in the following order: absence of light, ambient

light and strong light, for positive voltages.

However, for negative voltages the devices exhibit

increased conduction when exposed to ambient light,

indicating an increase in charge carriers. It was

further observed that some devices with this

architecture, the I-V curves performed without the

interaction with radiation presented an erratic

behavior, possibly due to differences in the thickness

of the films leading to the short circuit of the

devices. Moreover, this study also evidences that the

inorganic layer prevents the degradation of the

organic layers when exposed to the atmospheric

conditions.

Therefore, this work allows to conclude that this

device not only reacts to light but also that the

combination of materials and techniques used for its

manufacture are appropriate.

ACKNOWLEDGEMENTS

The authors acknowledge the financial support from

FEDER, through Programa Operacional Factores de

Competitividade − COMPETE and Fundação para a

Ciência e a Tecnologia − FCT, for the project

UID/FIS/00068/2013.

REFERENCES

Ferreira, Q., Gomes, P. J., Ribeiro, P. A., Jones, N. C.,

Hoffmann, S. V., Mason, N. J., Oliveira Jr., O. N.,

Raposo, M.,. 2013. Determination of Degree of

Ionization of Poly(allylamine hydrochloride) (PAH)

and Poly[1-[4- (3-carboxy-4 hydroxyphenylazo)

benzene sulfonamido]- 1,2-ethanediyl, sodium salt]

(PAZO) in Layer-by-Layer Films using Vacuum

Photoabsorption Spectroscopy. Langmuir, 29 (1),

448–455.

Ferreira, Q., Gomes, P. J., Raposo, M., Giacometti, J. A,

Oliveira Jr., O. N., Ribeiro, P. A., 2007. Influence of

Ionic Interactions on the Photoinduced Birefringence

of Poly[1- [4-(3-Carboxy-4 Hydroxyphenylazo)

Benzene Sulfonamido]-1,2-Ethanediyl, Sodium Salt]

Films. J. Nanosci. Nanotechnol. 7, 2659–2666.

Ferreira, Q., Gomes, P.J., Maneira, M. J. P., Ribeiro, P. A.,

Raposo, M.. 2007. Mechanisms of Adsorption of an

Azo- polyelectrolyte onto Layer-by-Layer Films.

Sensors and Actuators B: Chemical, 126, 311-317.

Roland, S. et al., 2015. Hybrid Organic / Inorganic Thin-

Film Multijunction Solar Cells Exceeding 11 % Power

Conversion Efficiency. Advanced Materials. 27, 1262–

1267.

Sério, S., MeloJorge, M.E., Maneira, M.J.P., Nunes,Y.

2011. Influence of O

2

Partial Pressure on the Growth

of Nanostructured Anatase Phase TiO

2

Thin Films

Prepared by DC Reactive Magnetron Sputtering.

Mater. Chem. Phys., 126, 73−81.

Sério, S., Melo Jorge, M. E., Coutinho, M. L., Hoffmann,

S.V., Limão-Vieira, P., Nunes, Y., 2011.

Spectroscopic Studies of Anatase TiO

2

Thin Films

Prepared by DC Reactive Magnetron Sputtering.

Chem. Phys. Lett., 508, 71−75.

Serrano, E., Rus, G. & García-Martínez, J., 2009.

Nanotechnology for sustainable energy. Renew.

Sustain. Energy Rev. 13, 2373–2384.

Yin, Z. et al. 2014. Graphene-Based materials for solar

cell applications. Adv. Energy Mater. 4, 1–19.

Wright, M. & Uddin, A. 2012. Solar Energy Materials &

Solar Cells Organic — inorganic hybrid solar cells : A

comparative review. Solar Energy Materials and Solar

Cells, 107, 87–111.