A Taxonomy and Systematic Approach for Automotive System

Architectures

From Functional Chains to Functional Networks

Johannes Bach, Stefan Otten and Eric Sax

FZI Research Center for Information Technology, Haid-und-Neu-Str. 10-14, 76131 Karlsruhe, Germany

Keywords:

Systems Engineering, System Architecture, Advanced Driving Assistance Systems, Automated Driving.

Abstract:

Technological advances enable realization of increasingly complex customer features in the automotive sector.

Traffic jam pilot or predictive energy management depict examples of recently introduced features that span

across different conventional vehicle domains. The increased interconnectivity and functional complexity im-

pose new requirements on the automotive systems engineering practice. The resulting challenge is to develop

integrated approaches that combine the established procedures with innovative techniques. To address this

challenge, we present a comprehensive taxonomy for existing automotive features. Based on this characteri-

zation, established industrial and new research approaches for logical system architectures are consolidated.

We introduce levels of hierarchy in the logical system architecture to facilitate systems engineering of inno-

vative functions and highly distributed features. The systematic approach provides a novel rationale for the

evolution from functional chains to functional networks in the automotive industry.

1 INTRODUCTION

Within the last decade a multitude of Advanced

Driver Assistant Systems (ADAS), such as Adap-

tive Cruise Control (ACC) and Lane Keeping Assist

(LKA) were introduced into the automotive market.

These features leading the way, automated driving be-

comes a reality (Becker et al., 2014). The new featu-

res are enabled by the steadily advancing technologi-

cal progress, which provides high-performance com-

puting in automotive environments. The new features

raise the functional complexity regarding utilized al-

gorithms, distribution of functions and the amount of

processed information, which has a considerable im-

pact on Electrics/Electronics (E/E) system architec-

tures. Current development methods and approached

are not sufficient to cope with the new complexity.

Several roles, teams and organizations participate

in the development of an automotive system. Scatte-

ring over different development locations leads to col-

laborative development (Weber and Weisbrod, 2002).

The development in automotive vehicles is histori-

cally structured into different domains (Reinhardt and

Kucera, 2013), such as powertrain, safety and chassis.

This modularization evolved from the product per-

spective and lead to corresponding organization struc-

tures to facilitate product engineering (Weber, 2009).

The domains originate from mechanical engineering

and were expanded with electrical and information

processing aspects. Within the different domains,

several approaches for development processes, met-

hods and tools are established and integrated into the

overall product development process. These methods

serve different needs and foci of the engineers, which

differ from domain to domain. As upcoming custo-

mer features lead to fuzzy system borders, the diffe-

rent domains’ development is moving closer together

(Haas and Langjahr, 2016). The integration and colla-

boration of domains is necessary without abandoning

methodological flexibility and individuality.

For Original Equipment Manufacturer (OEM),

well-established and long-existing systems such as

Electronic Stability Control (ESC) are iteratively op-

timized achieving a high-level of maturity. Supplier

structures and adjacent business units, such as pur-

chase or after sales, are shaped to the originated

needs. As new highly-integrated features partly col-

lude with the existing systems, the question of how to

use legacy systems during development poses a chal-

lenge. To foster the reuse of specific functionalities

of the established systems is a key issue for efficient

development.

Novel research and development approaches for

systems engineering focus on automated driving

90

Bach, J., Otten, S. and Sax, E.

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks.

DOI: 10.5220/0006307600900101

In Proceedings of the 3rd International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2017), pages 90-101

ISBN: 978-989-758-242-4

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(Matthaei and Maurer, 2015), (Tas et al., 2016) do not

comprehensively cover the aspect of legacy systems.

The presented functional architectures mainly focus

on the automated driving or ADAS domain. There-

fore, focusing on assisting and automating functional

aspects and applying hierarchization without consi-

deration of the relevant conditions of adjacent dom-

ains. A comprehensive approach for the abstraction

and description of the functional architecture with re-

spect to different level of integration and complexity

of features is required.

To overcome these impediments, we present a

taxonomy for existing automotive customer features

across all domains, structuring them into different le-

vel of complexity. The taxonomy forms a basis to

provide a systematic approach for systems engineer-

ing with a focus on functional aspects. This systema-

tic approach can be further elaborated to consider the

impact on development processes.

The paper is structured as followed: Section 2

presents the state-of-the-art of systems engineering

and automotive architectures. Our cross-domain taxo-

nomy for current and upcoming electric/electronic fe-

atures is elaborated in Section 3. Our proposed ap-

proach for logical architectures and hierarchization is

given in Section 4. Section 5 demonstrates the appli-

cability of the approach on exemplary automotive fe-

atures. A conclusion and outlook on further activities

is presented in Section 6.

2 STATE OF THE ART

Systems engineering is a discipline to ”guide the engi-

neering of complex systems” (Korsiakoff et al., 2011).

The term ”System” is widely spread across different

fields and application domains and several approaches

for development are established. Within the automo-

tive area, the system ”Vehicle” is partitioned into dif-

ferent domains structuring the mechanical key com-

ponents of the vehicle (Weber, 2009). In the con-

text of this paper, we focus on automotive E/E sys-

tems engineering, which consists of several different

fields such as architectures, management, modeling

and operation research (Korsiakoff et al., 2011). In

the automotive domain, the management of develop-

ment processes if commonly based on the V-Model.

The AutomotiveSPICE (Automotive-SIG, 2015) spe-

cifies an established process reference that integrates

the V-Model approach. In this contribution, we fo-

cus on the architecture and structuring of automotive

embedded systems to facilitate the process of systems

engineering.

2.1 System Architecture

Several approaches and methods for the structural

description of system architectures (ATESST2 Con-

sortium, 2013), (Pohl et al., 2012), (Vector Informatik

GmbH, 2016) follow a model-based approach. The

principle of abstraction contributes to reduced com-

plexity (Korsiakoff et al., 2011) and facilitate system

understanding (Bhave et al., 2011). It enables the

structured analysis of specific topics, such as functi-

onal safety (Adler et al., 2012). Common abstraction

layers of automotive embedded systems are Logi-

cal Architecture, Software Architecture and Technical

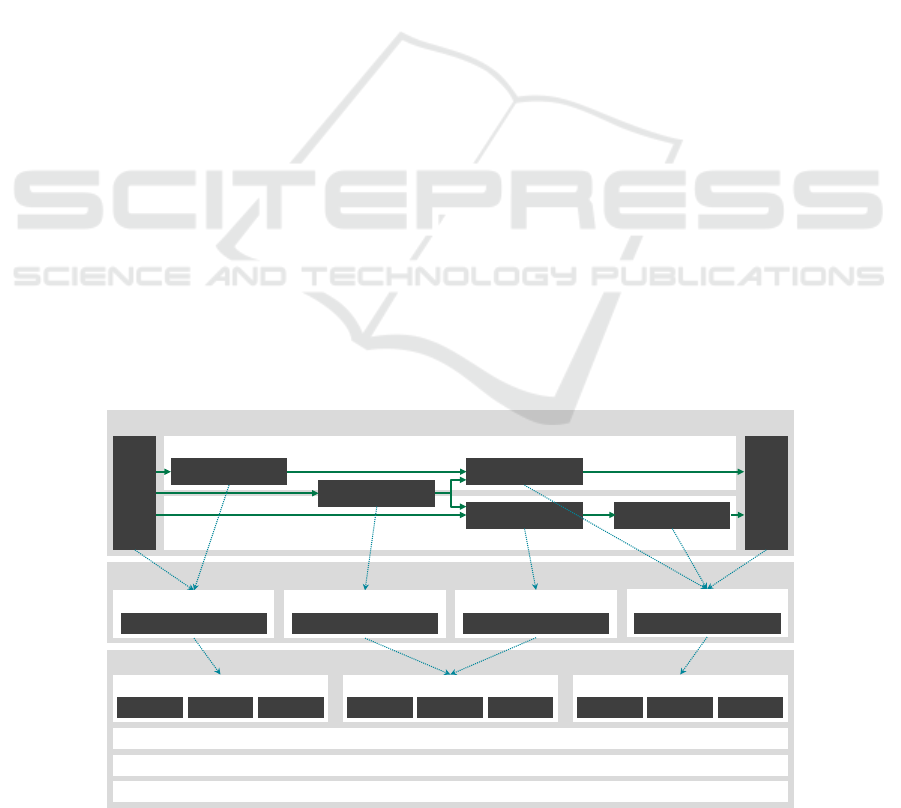

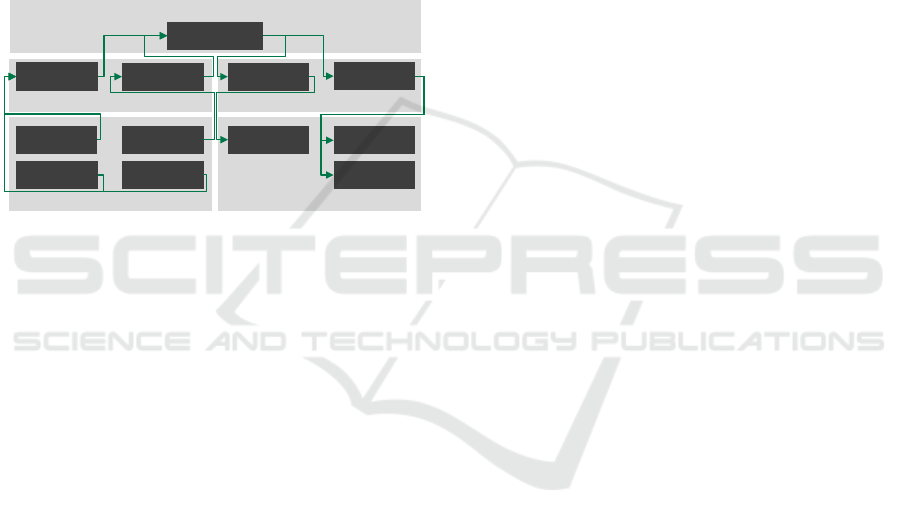

Architecture. A basic overview is given in Figure 1.

The abstraction layers provide a partial descrip-

tion of the system based on different perspectives

Logical Architecture

Software Architecture

Technical Architecture

Chain of Effects - Feature A

Chain of Effects - Feature B

Perception

Action

Function 2

Function 3

Function 4 Function 5

Function 1

Software Component A

Implementation

Software Component B

Implementation

Software Component C

Implementation

Software Component D

Implementation

Electronic Control Unit 1

ADC/DAC CPU Memory

Electronic Control Unit 2

CPU 1 CPU 2 Memory

Electronic Control Unit 3

ADC/DAC CPU Memory

Communication Network

Electric Circuits

Wiring Harness

Figure 1: Three abstraction levels of the automotive system architecture and mapping of functional behavior to software

components and electronic control units. Depiction referring to (Broy et al., 2009) and (Sch

¨

auffele and Zurawka, 2012).

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks

91

(Zhan and Krishnan, 2011), using the principle of

modularization of blocks and connections. Also hier-

archization and encapsulation of artifacts to describe

different levels of detail is intended. Between the arti-

facts of different abstraction layers, interconnections

and relations with distinct semantic are present (Pohl

et al., 2012). The example in Figure 1 depicts relati-

ons, which describe the partitioning of functional en-

tities into software components for integration on dis-

tinct Electronic Control Unit (ECU)s.

2.1.1 Logical Architecture

The logical architecture is a breakdown of a feature

”into interacting functional components” (Pretschner

et al., 2007). It represents the functional decomposi-

tion of a system into functional elements, which pro-

vide the functionality described in the corresponding

requirements. The logical architecture focuses on the

functional aspects, the logical interfaces and the co-

herence between the functional elements. It is com-

pletely independent from technical considerations or

software specific issues. A common approach in the

automotive area for the structuring of logical archi-

tectures is the usage of chains of effect to describe an

overall approach from sensing to acting (Sch

¨

auffele

and Zurawka, 2012). Demands for more elabora-

ted concepts to improve the structuring of increasing

complex features are initially addressed in (Holder

et al., 2012) and (Pretschner et al., 2007). Descrip-

tion of the functional element’s internal behavior is

highly depending on the associated domain and not in

scope of this contribution.

2.1.2 Software Architecture

The software architecture describes the different

software components and the partitioning of the

functional elements, including basic software (ope-

rating system and middleware) and communication

(Sch

¨

auffele and Zurawka, 2012). A standardized

middleware for software components allows reuse of

the basic elements, for automotive embedded sys-

tems this is given by the AUTomotive Open System

ARchitecture (AUTOSAR) (AUTOSAR development

cooperation, 2015). It specifies a software frame-

work and architecture consisting of basic software

elements, a run-time environment (RTE) and appli-

cation software components to enable reuse and sca-

lability.

Improvements and extensions for AUTOSAR in-

troduce adaptive deployment, service-oriented com-

munication and dynamic scheduling and applica-

tion execution as well as integration in new high-

performance processor architectures. The related spe-

cification under the term ”AUTOSAR adaptive” is

currently under development within the AUTOSAR

partnership (Fuerst, 2015).

2.1.3 Technical Architecture

The technical architecture specifies the integration le-

vel, which contains the hardware units to execute

the defined software components (Pretschner et al.,

2007). This comprises the ECU, actuators and sensors

and their interconnections. In automotive systems

engineering, the technical architecture is commonly

further refined to represent specific E/E aspects, such

as electric circuits and the wiring harness. The techni-

cal system architecture is based on a comprehensive

E/E topology containing a segmentation into previ-

ously introduced domains, such as body, chassis and

comfort. The current E/E architectures often reflect

the organizational structure introduced by segmenta-

tion of the car’s mechanical structure. Historically,

single ECUs were introduced to perform indepen-

dent functionality (Leen and Heffernan, 2002), con-

nected with a single centralized gateway (Streichert

and Traub, 2012) .

With increasing complexity and an increasing

number of ECUs, domain-controlled E/E architectu-

res with centralized domain-controllers were introdu-

ced (Reinhardt and Kucera, 2013), (Stolz et al., 2010).

This trend was an initial reflection to expanding sy-

stem boundaries, more complex functional chains and

higher integration of features. For each domain, mas-

ter controllers were introduced to facilitate domain-

comprehensive features. The evolution of technical

system architectures is thus tightly coupled with the

increasing interaction and networking of the logical

architecture. The current development leads to centra-

lized cross-domain E/E architectures based on high-

performance computing units (Navale et al., 2015),

(Haas and Langjahr, 2016).

2.2 Architecture Concepts for

Automated Driving

Research in the field of automated driving provides

various approaches to describe the system architec-

ture of research concepts. Stiller (Stiller et al., 2007)

provides a cognitive oriented approach of percep-

tion, planning and action tasks. Different layers clas-

sify the abstract representation of functional elements.

The architecture concept provided by Bauer (Bauer

et al., 2012) is categorized into a mission layer, a

coordination layer and a behavior layer. Each layer

consists of elements of the world model class, the

planning class and the HMI class. The utilized sen-

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

92

sors, actuators and the driver form the system envi-

ronment. The influence of human-machine interacti-

ons on system architecture is discussed by Flemisch

(Flemisch et al., 2014). Based on the psychological

categorization of the Dynamic Driving Task (DDT)

into navigation, guidance and control, the automation

system provides an interface on each level. Matt-

haei (Matthaei and Maurer, 2015) proposes a ”functi-

onal system architecture for an autonomous on-road

motor vehicle”. It applies a similar categorization

into a strategic level, a tactical level and an operati-

onal level and a further distinction between localiza-

tion, perception and mission accomplishment. An im-

plemented system architecture for automated driving,

using production vehicle sensors and additional pro-

totyping sensors, was presented by Aeberhard (Ae-

berhard et al., 2015). Buechel (Buechel et al., 2015)

presents the prototype of an automated electric vehi-

cle. The proposed software architecture consists of

the three components data fusion, trajectory planning

and trajectory controller, which is mapped to a cen-

tralized E/E architecture.

3 TAXONOMY FOR CURRENT

AND UPCOMING

ELECTRIC/ELECTRONIC

FEATURES

Todays technical compendiums of carmakers are

crammed with a high variety of customizable featu-

res. A significant proportion of those features is based

on E/E functionality. With rising complexity of and

dependencies between features, the established auto-

motive systems engineering methods and abstraction

concepts are reaching the limits of their capability. To

identify boundaries and necessary extensions of cur-

rent systems engineering methods we start with es-

tablishing a comprehensive overview of current and

upcoming E/E features. Our goal is to integrate well-

established features of the automotive industry and

current concepts of research groups within one con-

sistent taxonomy.

Our proposed taxonomy distinguishes features by

three main categories. Integrated features are closely

related to a specific mechanical domain of the vehi-

cle. They represent the E/E content necessary to ac-

complish the targeted operation of physical compo-

nents of the vehicle. Distributed features combine in-

dividual components of different domains to enable

additional capabilities. These features do not neces-

sarily require additional mechanical hardware com-

ponents. Their functional behavior can be expres-

sed as the sequential combination of available infor-

mation and usable actuators to provide added value.

Cross-linked features connect various functional ele-

ments and depend on the joined manipulation of the

behavior of independent and domain separated com-

ponents. They conflate various sources of informa-

tion to achieve a comprehensive representation of the

vehicle’s state and surroundings. This representation

forms the basis for cognitive and predictive features,

including but not limited to high automation levels.

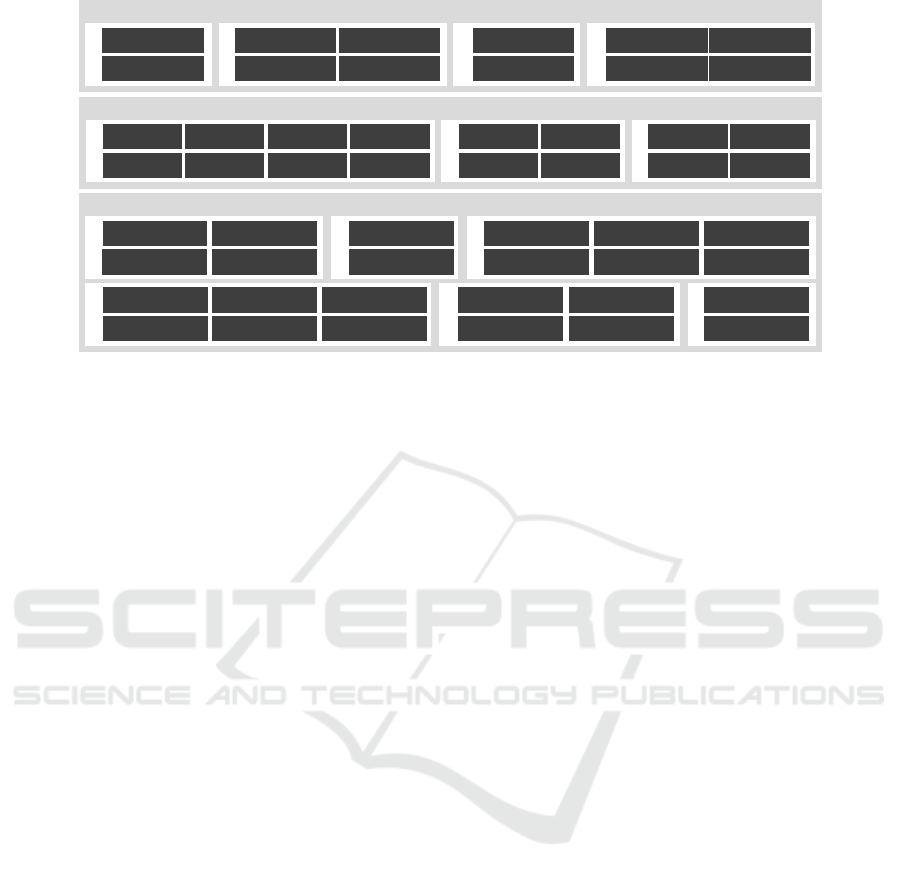

Figure 2 depicts our proposed taxonomy. It classi-

fies and combines vehicular features of existing series

cars and features of current research. The taxonomy’s

features available in series cars represent an abstrac-

ted set of the offered features of major car companies.

We analyzed the online presence of BMW

1

, Daim-

ler

2

, Ford

3

, Peugeot

4

, Toyota

5

and VW

6

to select the

most common features. Research features were se-

lected to cover a range as wide as possible.

3.1 Integrated Features

As stated above, the integrated feature level subsumes

the E/E content to operate the physical components of

the vehicle. This entails a close proximity to specific

mechanical units and commonly involves the usage

of a dedicated ECU. Most sensors and actuators re-

quired for the assigned task of the feature are directly

attached to the dedicated ECU. Integrated features are

mainly based on proprioceptive sensors. Propriocep-

tive sensors obtain information about the internal state

of the vehicle (Bengler et al., 2014).

Our taxonomy differentiates the integrated featu-

res into the established vehicle domains. Weber (We-

ber, 2009) defines five of the six domains we ap-

ply. The powertrain domain contains ”all functions

controlling the generation of driving power and its

conversion into propulsion”. The taxonomy includes

the features automatic transmission, engine control,

1

BMW Technology Guide, Bayeris-

che Motoren Werke Aktiengesellschaft,

http://www.bmw.com/com/en/insights/technology/

technology guide/index.html

2

Welcome to the Mercedes-Benz TechCenter, Daimler

AG, https://techcenter.mercedes-benz.com/en/index.html

3

Advanced technology at your fingertips, Ford Motor

Company, http://www.ford.com/cars/focus/features/#page=

FeatureCategory4

4

Technologies & Innovations, Automobiles Peugeot,

http://www.peugeot.com/en/technology

5

Toyota Technology, Toyota Motor Sales, U.S.A., Inc.,

http://www.toyota.com/technology/

6

Technik auf den Punkt gebracht., Volkswagen

AG, http://www.volkswagen.de/de/technologie/technik-

lexikon.html

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks

93

Cross-Linked Features

Automating

Advisory

Assisting

Distributed Features

Advisory

Supporting

Assisting

Integrated Features

Infotainment

PowertrainBody

Safety

Chassis

Anti-lock braking

Traction

Control

Automatic

Transmission

Airbag Control

Engine

Control

Hill Assist

Stability Control

Automated Valet

Parking

Traffic Jam Pilot

Highway Pilot

Adaptive Cruise

Control

Lane Keeping

Assist

Blind Spot

Monitor

Adaptive High

Beam

Eco-Drive

Advice

Navigation

Full Driving

Automation

Park Assist

Range

Estimation

Power Steering

Audio and Video

Communication

HMI

Access Management

Anti-Theft System

Air Conditioning and

Heating

Seat Belt Tensioner

Windows and Wipers

Seats and Comfort

Rear Axle Steering

Power Grid

Battery Management

Converter Control

Damping and

Suspension Control

Lights and Interieur

Adaptive Bend

Lighting

Lane Departure

Warning

Collision

Warning

Speed Limit

Warning

Adaptive

Aerodynamics

Trailer Assistant

Traffic Adaptive

Routing

Start-Stop

System

Park Distance

Warning

Road Condition

Warning

Green Light Speed

Advisory

Predictive Cruise

Control

Lane Change Assist

Rear Impact

Protection

Supporting

Emergency Call

Collision Mitigation

Range Optimization

Recuperation

Control

Figure 2: Taxonomy of current and upcoming E/E features. Integrated features are grouped by vehicle domains, distributed

and cross-linked features by level of interference.

traction control and hill assist as a representative fea-

ture set of the powertrain domain. The safety domain

on integrated feature level includes the passive safety

features airbag control and seat belt tensioner. More

sophisticated active safety features are classified as

distributed features. The chassis domain includes fea-

tures to control the vehicle dynamics, providing a safe

and attractive driving experience. Stability control,

anti-lock breaking and power steering describe featu-

res that mainly support safe and comfortable driving.

Rear axle steering, damping and suspension control

and adaptive aerodynamics particularly support agi-

lity. The body domain encompasses all features atta-

ched to the vehicle body, like lights, windows, wipers,

seats and air conditioning as well as the car’s access

management and anti-theft system. The infotainment

domain is the fifth vehicle domain based on Weber’s

definition. It summarizes the features for navigation,

communication, audio and video entertainment and

Human Machine Interface (HMI). To take advancing

electrification into account, the power grid domain

completes the integrated features. Battery manage-

ment and converter control represent features that are

part of 48 volt grids of hybrid electric vehicles as well

as high voltage grids of fully electric vehicles.

3.2 Distributed Features

Most of the currently available ADAS are represen-

ted by the distributed features class. The functio-

nal behavior of distributed features resembles a chain

of effects, the aforementioned sequential combination

of available information and usable actuators. The

functionality of distributed features is based on the

connection of different domains. They often intro-

duce and utilize exteroceptive sensors that provide

information about the surroundings of the vehicle

(Bengler et al., 2014).

The taxonomy categorizes distributed features by

level of interference into the three classes advisory,

supporting and assisting features. Assisting features

are specified by SAE automation level 1 (SAE inter-

national, 2016) as features that ”perform either lon-

gitudinal or lateral vehicle motion control [...]”. To

allow distinction between passive advisory and active

supporting features on level 0, we introduce the dis-

tinctive classes.

The advisory class contains features that utilize

information of integrated features and exteroceptive

sensors to provide additional information for safe and

comfortable driving and potentially to influence the

driver’s behavior. Collision warning, lane departure

warning, blind spot monitor and park distance war-

ning depict advisory features to gain additional safety.

Speed limit warning helps to stick to regulations and

eco-drive advice intends to influence the driver’s be-

havior to achieve a sustainable driving style. Range

estimation and traffic adaptive routing support the dri-

ver’s decisions regarding the selected route and stopo-

vers.

The supporting class covers all features that acti-

vely influence the vehicle’s state, but do not perform

longitudinal or lateral vehicle motion control. It en-

compasses features such as adaptive high beam and

adaptive bend light as well as automated start-stop.

Rear impact protection represents an active safety fe-

ature that aims to decrease the damage induced to pas-

sengers during standstill, rear-end collisions. Bogen-

rieder (Bogenrieder et al., 2009) describes an appro-

ach that utilizes a backwards oriented radar sensor to

detect an imminent rear-end collision.

The park assist and trailer assistant feature per-

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

94

form lateral control of the vehicle, while longitudi-

nal control always remains with the driver. Therefore,

these are automation level 1 features and part of the

assisting features class. The ACC feature performs

longitudinal control and the LKA feature performs la-

teral control. While operated individually, both fea-

tures represent automation level 1. If both systems

are activated simultaneously, the feature combination

represents automation level 2, ”Partial Driving Auto-

mation”. Consequentially, level 2 automation features

are included in the assisting features class.

3.3 Cross-linked Features

In the presented taxonomy, cross-linked features uti-

lize sensor networks to derive information or to influ-

ence several actuators. These features span functio-

nal networks in distinction to the sequential functio-

nal chains of distributed features. They are based on

the fusion of proprioceptive and exteroceptive sensor

information to obtain a realistic and complete model

of the vehicle’s internal state and surroundings. Si-

milar to distributed features, cross-linked features are

grouped into advisory, supporting and assisting clas-

ses with the addition of the automating class. It com-

prises features from automation level 3 upwards. By

SAE definition, these features perform the complete

DDT with or without fallback and within or without a

specific Operational Design Domain (ODD).

The road condition warning feature in the advis-

ory class is described in the Car2Car communication

consortium manifesto (Baldessari et al., 2007). Se-

vere road conditions are propagated via Car2Car com-

munication or back end service between road users.

The green light speed advisory feature is also defined

by the Car2Car consortium. It interacts with the road

infrastructure and provides an optimal speed advice,

averting an otherwise necessary red light stop. Both

features require lane accurate positioning and access

to various internal states and the communication plat-

form of the vehicle. Therefore, they are classified into

the cross-linked feature class.

The supporting class contains two energy mana-

gement related features, the range optimization and

the recuperation control. The range optimization cal-

culates the remaining energy of the vehicle and pre-

dicts the required energy to reach the desired des-

tination. If necessary, it shuts down power hungry

comfort features like heating and air conditioning and

limits the propulsion power. The recuperation con-

trol predicts the vehicle’s energy flows and for ex-

ample reduces battery load before long recuperation

phases, to prevent waste of energy due to battery heat

protection (Woestman et al., 2002). As these featu-

res influence various actuators and require predictive

map data, traffic flow information and internal sta-

tes for optimal performance, they are classified into

the cross-linked category. Emergency call and colli-

sion mitigation round out the supporting feature class.

These are active safety features that take action before

an imminent collision and automatically call help af-

ter an accident.

Equivalent to the distributed features, the assisting

class covers features of SAE automation level 1 and

2. The predictive cruise control feature controls the

longitudinal motion of the vehicle (Wahl, 2015). It

calculates an energy optimal velocity trajectory based

on predictive map data and proprioceptive and extero-

ceptive sensor information. The included lane change

assist feature guides the driver’s lane change maneu-

ver (Cramer et al., 2015). It requires various sensors

and predicts the surrounding traffic to calculate a safe

lane change trajectory (Nilsson et al., 2016). Both

feature’s depend on several sensing, processing and

acting primitive elements and, therefore, are classified

as cross-linked features.

All features from SAE automation level 3 up-

wards belong to the automating class of cross-linked

features. The example features traffic jam pilot,

highway pilot, automated valet parking (Nordbruch

et al., 2015) and full driving automation (Ziegler

et al., 2014) perform the complete DDT. The former

three features are designed for a specific operational

domain. Depending on their characteristics and im-

plementation, all automating features utilize more or

less comprehensive environmental perception and in-

terpretation. Beside the longitudinal and lateral con-

trol of the vehicle, the features must control several

actuators to perform the complete DDT. Automating

features comprise the highest level of cross-linking.

4 COMPREHENSIVE

HIERARCHIZATION FOR

LOGICAL SYSTEM

ARCHITECTURES

As stated in Section 2.1, based on established system

architecture modeling concepts, all functional beha-

vior of the introduced features is modeled within one

level of logical system architectures. Thereby, the

differing character and integration depth of the in-

dividual functional elements is not considered. The

representation resolves the complexity of the under-

lying functional dependencies and multiple usage sce-

narios of particular functional elements only to a limi-

ted degree. Hence, the systems engineering principles

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks

95

Operation Control

Fusion and Modeling

Vehicle State

Model

Static Environment

Model

Dynamic

Environment

Model

Lateral Motion

Control

Longitudinal

Motion Control

Power

Management

Driving Mode

Management

Driver State Model

Actuators

Lights

Active

Suspension

Engine Breaks HMI

Air

Conditioning

Flaps &

Spoilers

Gearbox and

Differentials

Steering

Motor

Wipers and

Windows

Cooling

Electronic

Converters

Battery Doors Speakers

Sensors

GNSS

Odometer

Gyroscope

Accelero-

meter

Camera

Lidar

Ultrasonic

Radar

Thermo-

meter

Barometer

Rain Sensor

Force and

Torque

Interfaces

Cellular

Network

Car2X

Steering

Wheel

Pedals

HMI

Raw Information Level

Physics Level

Filtered Information Level

Interpreted Information Level

Peripheral SystemsTrafficDriver Road WeatherVehicle Dynamics

Actuation ControlPerception

Stability

Control

Body

Control

Power Grid

Control

Engine Control

Coarse Positioning

Powertrain

Control

Object

Tracking

Electronic

Horizon

Lane Tracking &

Sign Recognition

Primitive

Motion

Power Steering

Control

Internal States &

Driver Actions

Interpretation, Prediction and Planning

Scene

Understanding

Traffic Object

Prediction

Longitudinal

Motion Planning

Lateral Motion

Planning

Driver PredictionPose Prediction

Mission Control

Energy

Optimization

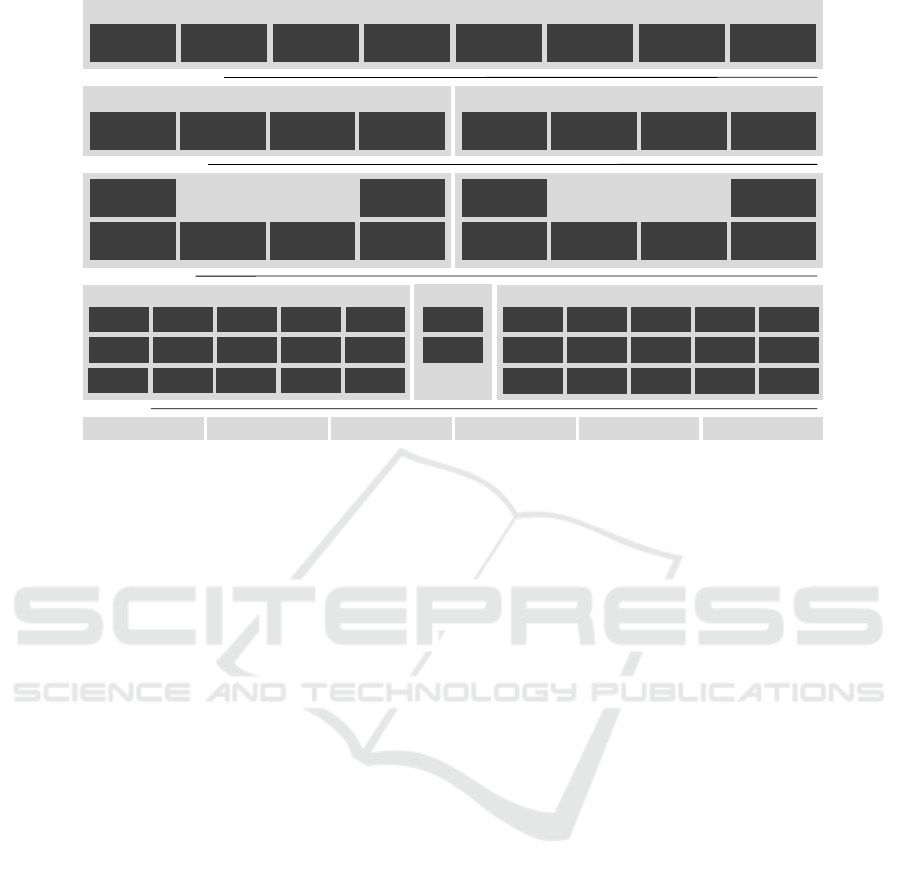

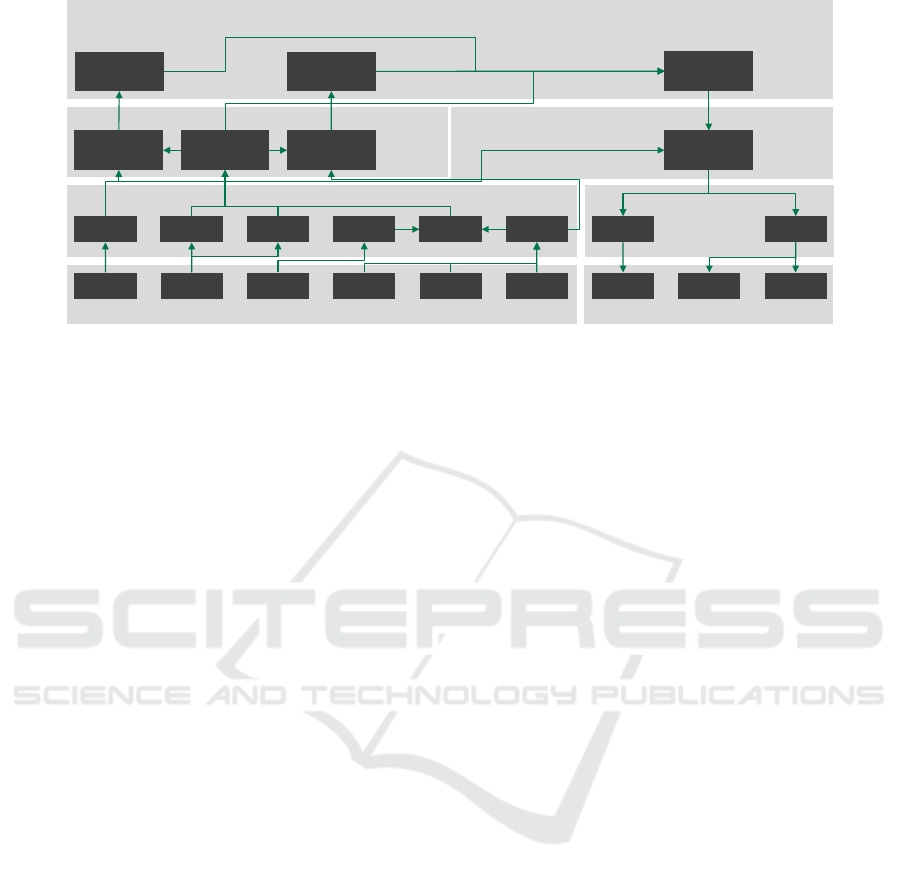

Figure 3: The proposed holistic hierarchization approach for the logical system architecture in the automotive domain.

of modularization, abstraction and hierarchization are

not employed to the full extent.

Section 2.2 outlines the approaches utilized by re-

searchers in the field of automated driving. The utili-

zation of psychological concepts offers a sound cha-

racterization for the functional components of auto-

mating features. This supports the structuring of fun-

damental sub-tasks of the DDT, but does not necessa-

rily support the entire systems engineering process.

Existing and established E/E systems were mostly

neglected by the described architecture representati-

ons. For an holistic approach we need a hierarchical

structure that supports a clear representation of the de-

pendencies between functional elements and includes

all automotive E/E features. It concurrently provides

an abstraction that facilitates adaption and association

of different shapes of systems engineering activities.

The aim of the proposed hierarchization of

functional elements is to introduce a comprehensive

domain-crossing functional architecture. The intro-

duced hierachization is based on the integration level

and the character of the processed information. This

enables a flexible description of the existing chain of

effects and their interaction with associated elements

within one systematic approach and simplifies precise

specification of interfaces. It facilitates the definition

of tailored templates for activities, such as verifica-

tion and validation, functional safety and release plan-

ning. These templates could guide developers, testers,

project and quality managers during the configuration

of function specific process implementations and the

selection of a balanced set of suitable methods and

tools.

Figure 3 depicts our newly introduced hierachiza-

tion for the logical system architecture. The classified

features of Section 3 were broken down into principal

functional elements and arranged to represent a cloc-

kwise flow of information. The layered approach pro-

vided by Stiller (Stiller et al., 2007) served as basis for

the development of the logical system architecture.

The type of information that is processed by the

respective element, is the major discrimination crite-

rion we apply to assign the elements to a particular

level. The physics level contains the functional ele-

ments to gain information from physical principles

and vice versa to influence the physics. On the raw

information level the derived raw information is filte-

red and actuation requests are processed. The filtered

information of different functional elements is combi-

ned via information fusion techniques within the fil-

tered information level and interpreted information is

used to operate the actuators. On the highest level

of the hierarchization, the interpreted information is

used to predict and abstract the state and behavior of

the system environment and the upcoming course and

actions of the vehicle are planned. In the following,

we explain these different levels, their characteristics

and possible consequences for future systems engi-

neering.

4.1 Physics Level

The physics level of the logical system architecture

is composed of sensors, interfaces and actuators and

comprises all interfaces to the system environment.

Sensors utilize physical measurement principles and

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

96

provide basis perception functions. They provide

raw information in form of discrete, unfiltered sam-

ple data. The type of supplied information ranges

from sampled physical quantities like force and tor-

que, acceleration and velocity to the raw image provi-

ded by a camera and the point cloud of a lidar sensor.

The sensors class also contains the control interfaces

of the driver and the Global Navigation Satellite Sy-

stem (GNSS) receiver.

The interfaces class enables the interaction with

affiliated technical systems. It provides access to cel-

lular networks and communication entities such as

Car2X, representing a bidirectional flow of informa-

tion.

The actuators encompass all functional elements

to affect the vehicle state and its environment as a

physical system. The powertrain elements engine, ge-

arbox and differentials influence the propulsion and

the flow of energy of the vehicle. By application of

steering torque, the steering motor affects the lateral

movement of the vehicle, but also acts as an interface

towards the driver. Active suspension and flaps and

spoilers alter the properties of aero- and vehicle dyn-

amics. Further functional elements serve a supporting

purpose (e.g. cooling, wipers or lights) and to influ-

ence the driver (e.g. HMI, speakers).

4.2 Raw Information Level

This level contains the functional elements required

for filtering and processing of raw signals and to drive

the actuators. The functions within the perception

class process the physical sensor’s raw data to derive

tangible information about the vehicle’s primitive mo-

tion and internal states. Coarse positioning is achie-

ved by interpretation of the pseudoranges in the na-

vigation satellite receiver and the electronic horizon

provides information about the upcoming road seg-

ment from an internal data storage. Images and point

clouds are processed to extract surrounding objects,

lanes and traffic signs.

The actuation control class drives and controls the

mechanical components of the vehicle via the physi-

cal actuators. It represents the basic functional com-

ponents of the integrated features that are essential

for the vehicle’s operability. The software implemen-

tation of functions on this level is subjected to hard

real-time constraints.

While the elements of the physics level represent

the functional share of mechanical and electrical har-

dware components, the raw information level contains

the functional part of the embedded software asso-

ciated with those elements. Its development should

be coupled with the processes of the physical level.

On this level, the development of components is com-

monly carried out by Tier 1 suppliers. Validation and

verification of the functional elements can mostly be

done independent of other elements. The obtained

information is commonly shared within the related

domain of the vehicle’s communication network.

4.3 Filtered Information Level

Functions on the filtered signal level perform fusion

and abstraction of the various detached information

sources and control the vehicle operation. The infor-

mation of the proprioceptive and exteroceptive sen-

sors is accumulated in the interpretation class. The

static and dynamic environment model provide a con-

densed and consistent representation of the vehicles

surroundings. The vehicle state model consolidates

all internal vehicle states and the driver state model

describes the driver’s features, such as level of atten-

tion and driving style.

The functions to control the lateral and the longi-

tudinal motion of the vehicle are the most important

items of the operation control class. Their task is to

achieve the targeted velocity and vehicle pose within

the operational limits. The driving mode management

coordinates the underlying functions to attain a well-

attuned driving experience. The power management

approves and limits power consumption of the vari-

ous components and coordinates the recuperation of

electrified vehicles.

The functions of the filtered information level are

not essential for the operability of the vehicle, but

enable distributed features. The included longitudi-

nal and lateral control elements are part of the assis-

ting and automating features. The functions on this

level are subjected to soft real-time constraints. Ve-

rification and validation of these functions is perfor-

med on the interface level. Simulation based techni-

ques require modeling of not only the vehicle physics

and environment, but also modeling of all underlying

functional elements implemented in software.

4.4 Interpreted Information Level

The interpreted information level contains cognitive

functions for interpretation, prediction and planning.

Stochastic models enable the prediction of the beha-

vior of traffic objects and driver intentions. The infor-

mation of the vehicle state model facilitates the pre-

diction of the vehicle’s pose. The functional element

scene understanding represents the interpretation of

the aggregated information. The longitudinal and la-

teral motion planning functions are based on the inter-

preted information and act on the underlying control

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks

97

functions. A dedicated element for energy optimiza-

tion enables the range optimization and the recupera-

tion control features. The mission control function is

an essential part of all automation features. It coor-

dinates the individual elements to accomplish the dri-

ving task.

The functional elements of the interpreted infor-

mation level are best suited for implementation on

a centralized, high-performance control unit, as the

amount of data necessary to provide the described in-

formation exceeds the capability of established com-

munication networks. The functional elements of

the interpreted information level resemble a service-

oriented approach. Therefore, no guarantees for real-

time constraints are given. Simulation models for ve-

rification and validation of these high level functions

do not need detailed models of the vehicle mecha-

nics or the physical background of the utilized sen-

sors. Emulation of the model based environment re-

presentation and the control behavior of the filtered

information level is sufficient.

5 REPRESENTATION OF

SELECTED FEATURES

WITHIN THE PROPOSED

LOGICAL SYSTEM

ARCHITECTURE

The elements within our proposed logical system ar-

chitecture were derived from the analysis and taxo-

nomy of existing and conceptual automotive features

in Section 3. In the following, we demonstrate the ap-

plicability by modeling selected features of all three

main categories of the taxonomy. The modeling of

established features shows the ability of our approach

to maintain legacy content. The representation of re-

search concepts proofs the ability to cope with future

demands.

5.1 Integrated Features

Of the integrated feature class, the ESC and the po-

wer steering control are modeled within our proposed

logical architecture.

5.1.1 Power Steering Control

The power steering control feature serves as an actu-

ator to influence the lateral movement of the vehicle.

It applies a torque to the steering wheel to support the

driver actuation or to achieve a given target steering

position. The power steering described by Kim (Kim

et al., 2015) supports the driver’s steering intention.

It provides a detailed description of the architecture

of a power steering control feature for driver support.

The torque applied by the driver is sensed and ampli-

fied depended on the vehicle velocity. Naranjo (Na-

ranjo et al., 2005) describes a power steering feature

for automated control of the vehicle. It applies steer-

ing torque to control the steering position. To obtain

a satisfactory control behavior, the control is operated

with a duty cycle of 10 ms.

Therefore, the power steering feature consists of

the odometer and steering wheel elements of the sen-

sors class, the power steering control function and the

steering motor of the actuators class.

5.1.2 Electronic Stability Control

The ESC feature ”is an active safety technology that

assists the driver to keep the vehicle on the intended

path and thereby helps to prevent accidents” (Liebe-

mann et al., 2004). The yaw movement of the vehicle

is stabilized by individually controlling the tire slip

of each wheel. To avoid counteracting the driver, ”it

needs to accurately interpret what the driver intends

for the vehicle motion in order to provide added di-

rectional control” (Tseng et al., 1999).

Actuation Control

ActuatorsSensors

Engine

Breaks

Gearbox and

Differentials

Odometer

Stability Control

Pedals

Steering

Wheel

Gyroscope

Accelero-

meter

Powertrain Control

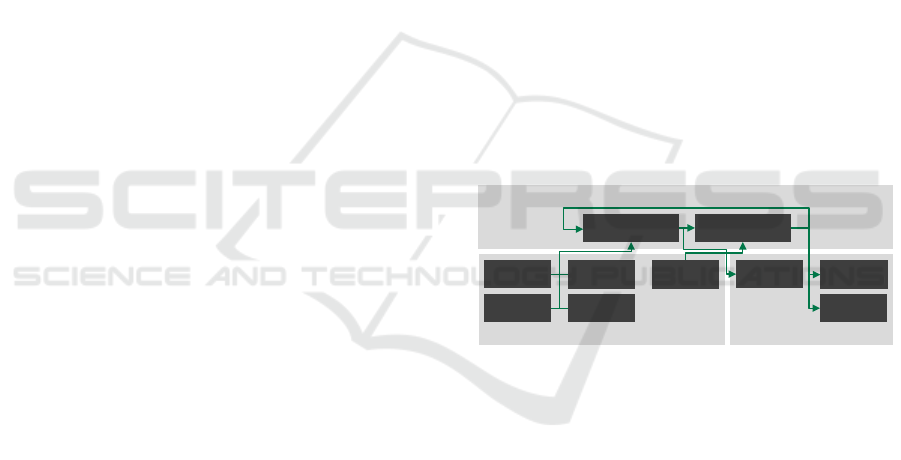

Figure 4: The chain of effects of an electronic stability con-

trol feature (Liebemann et al., 2004) described, using our

newly introduced logical system architecture abstraction.

Figure 4 depicts the logical system architecture of

the ESC. The current yaw rate and vehicle movement

is read in from a gyroscope, an odometer and an acce-

lerometer. The driver intention is derived from the

information of the steering wheel and the pedals. The

stability control functional element calculates the in-

dividual tire slips necessary to obtain a stable mo-

vement. Actuation of the brakes is directly applied,

the engine, gearbox and differentials are actuated via

the powertrain control function.

5.2 Distributed Features

To represent the distributed features class, we selected

the ACC feature as a longitudinal control feature and

the LKA feature as a lateral control feature.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

98

5.2.1 Adaptive Cruise Control

The ACC feature depicts an assisting feature that con-

trols the vehicles longitudinal velocity and adapts it

to the velocity of leading traffic. Winner (Winner

et al., 2012) provides a comprehensive overview of

the ACC feature. The radar based perception of the

area in front of the vehicle is used to calculate and

control the vehicle’s velocity. The driver inputs are

monitored to detect an override by throttle actuation

and a deactivation by brake actuation. Moon (Moon

et al., 2008) describes a two-level control structure,

where the upper level controls the vehicles speed by

requesting accelerations and the lower level controls

the acceleration by throttle and brake actuation.

Actuation Control

Perception

ActuatorsSensors

Engine

Breaks

Gearbox and

Differentials

Odometer

Stability Control

Gyroscope

Accelerometer

Powertrain

Control

Primitive Motion

Object Tracking

Radar

Operation Control

Longitudinal

Motion Control

Figure 5: The core elements of the ACC logical system ar-

chitecture.

Figure 5 depicts the logical system architecture of

an ACC feature. For comprehensibility, the elements

for driver interaction, like activation and override, are

removed and only the core elements are represented.

The primitive motion of the vehicle is estimated ba-

sed on internal sensors information. The radar sig-

nal is processed by the object tracking function and

used to calculate and control the desired time-gap in

the longitudinal motion control function. Actuation is

performed via the stability control and the powertrain

control elements.

5.2.2 Lane Keeping Assist

The lane keeping assist feature assists the driver in the

lateral control task without without assuming control

of the complete DDT. Following Ishida (Ishida and

Gayko, 2004), ”The lane keeping assistance system

consists of a camera-equipped lane recognition unit,

the LKAS control unit, and the Electric Power Steer-

ing (EPS).” The lane tracking functions extracts the

lane markings in the camera image and calculates the

lateral deviation, orientation and curvature. This in-

formation is used as control variables in the lateral

motion control function. The actuation is a steering

torque applied via the power steering control and the

steering motor.

5.3 Cross-linked Features

Of the cross-linked feature class we selected the Pre-

dictive Cruise Control (PCC) feature of the assisting

class. Wahl (Wahl, 2015) describes the PCC as a fea-

ture for optimal longitudinal control. The ACC is ex-

tended to adapt the velocity to the road topology and

speed limits besides leading traffic. Figure 6 depicts

the logical architecture of the PCC feature.

The environmental perception of the ACC is ex-

tended by a camera system for lane tracking and

traffic sign recognition. A GNSS receiver provi-

des coarse positioning, which is used to provide the

upcoming road topology via the electronic horizon

function. A consistent model of the static environ-

ment, the vehicle state and the dynamic environment

is formed on the interpretation level.

The feature implements a model predictive cont-

rol strategy. Therefore, the pose of the vehicle and

the movement of the traffic object are predicted and

passed on. Bauer (Bauer and Gauterin, 2016) splits

up the control task of the PCC into two levels. This

approach maps to the longitudinal motion planning

element and the longitudinal motion control.

6 CONCLUSIONS

In this contribution, we presented a taxonomy for ex-

isting and upcoming automotive customer features. It

provides a broad overview of the current automotive

cosmos and facilitates the analysis of current challen-

ges to systems engineering practice.

To handle increasing functional complexity, we

introduced an hierarchical structure to the logical sy-

stem architecture. The classification is designed to

cover all vehicle domains and enable representation

of functional chains and networks. The structure pro-

vides a neat general view and simplifies assignment of

properties and interface specification. The systematic

approach allows combination of new and legacy ele-

ments to derive innovative features. Following on the

presented approach, future work involves the analysis

of the influence and potential benefit to product deve-

lopment. The structured representation of functional

elements allows a level-specific allocation of process

quality gates. Adaption of the subsequential align-

ment of process actions to the different hierarchy le-

vels fosters a harmonic feature ramp-up and enables

introduction of agile practices. Association of aligned

strategies for verification and validation and functio-

nal safety with the structured and holistic view on the

logical system architecture should provide a substan-

tial benefit.

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks

99

Actuation Control

Operation Control

Fusion and Modeling

Vehicle State

Model

Dynamic

Environment

Model

Static Environment

Model

Longitudinal

Motion Control

Interpretation, Prediction and Planning

Traffic Object

Prediction

Longitudinal

Motion Planning

Pose Prediction

Actuators

Breaks Engine

Gearbox and

Differentials

Sensors

GNSS Odometer Gyroscope

Accelero-

meter

CameraRadar

Basis Perception and Actuation

Stability

Control

Powertrain

Control

Coarse

Positioning

Object

Tracking

Electronic

Horizon

Traffic Sign

Recognition

Lane

Tracking

Primitive

Motion

Figure 6: The chain of effects of a predictive cruise control feature described, using our newly introduced logical system

architecture abstraction.

REFERENCES

Adler, N., Hillenbrand, M., M

¨

uller-Glaser, K. D., Metzker,

E., and Reichmann, C. (2012). Graphically notated

fault modeling and safety analysis in the context of

electric and electronic architecture development and

functional safety. In 2012 23rd IEEE International

Symposium on Rapid System Prototyping (RSP), pa-

ges 36–42.

Aeberhard, M., Rauch, S., Bahram, M., Tanzmeister, G.,

Thomas, J., Pilat, Y., Homm, F., Huber, W., and Ka-

empchen, N. (2015). Experience, results and les-

sons learned from automated driving on germany’s

highways. IEEE Intelligent Transportation Systems

Magazine, 7(1):42–57.

ATESST2 Consortium (2013). EAST-ADL Domain Model

Specification, 2.1.12 edition.

Automotive-SIG (2015). Automotive SPICE Process Asses-

sment / Reference Model. VDA QMC, Berlin, Ger-

many, 3.0 edition.

AUTOSAR development cooperation (2015). Specification

of RTE. Munich, 4.2.1 edition.

Baldessari, R., B

¨

odekker, B., Brakemeier, A., Deegener,

M., Festag, A., Franz, W., Hiller, A., Kellum, C.,

Kosch, T., Kovacs, A., Lenardi, M., L

¨

ubke, A., Me-

nig, C., Peichl, T., Roeckl, M., Dieter, S., Markus,

S., Stratil, H., V

¨

ogel, H.-J., Weyl, B., and Zhang, W.

(2007). CAR 2 CAR Communication Consortium Ma-

nifesto. CAR 2 CAR Communication Consortium,

Brussels, 1.1 edition.

Bauer, E., Lotz, F., Pfromm, M., Schreier, M., Cieler, S.,

Eckert, A., Hohm, A., L

¨

uke, S., Rieth, P., Abendroth,

B., Willert, V., Adamy, J., Bruder, R., Konigorski, U.,

and Winner, H. (2012). Proreta 3: An integrated ap-

proach to collision avoidance and vehicle automation.

at - Automatisierungstechnik, 60:755–765.

Bauer, K.-L. and Gauterin, F. (2016). A two-layer approach

for predictive optimal cruise control. In SAE Technical

Paper 2016-01-0634.

Becker, J., Aranda Colas, M., Nordbruch, S., and Fausten,

M. (2014). Bosch’s vision and roadmap toward fully

autonomous driving. Road Vehicle Automation, Lec-

ture Notes in Mobility, pages 49–59.

Bengler, K., Dietmayer, K., F

¨

arber, B., Maurer, M., Stiller,

C., and Winner, H. (2014). Three decades of driver

assistance systems. IEEE Intelligent Transportation

Systems Magazine, 6(4):6–22.

Bhave, A., Krogh, B. H., Garlan, D., and Schmerl,

B. (2011). View consistency in architectures for

cyber-physical systems. In Cyber-Physical Systems

(ICCPS), 2011 IEEE/ACM International Conference

on, pages 151–160.

Bogenrieder, R., Fehring, M., and Bachmann, R. (2009).

Pre-safe in rear-end collision situations. In Procee-

dings 21st International Technical Conferrence on the

Enhanced Safety of Vehicles, Stuttgart.

Broy, M., Gleirscher, M., Kluge, P., Krenzer, W., Merenda,

S., and Wild, D. (2009). Automotive architecture fra-

mework: Towards holistic and standardised system ar-

chitecture description. Technical report, Technische

Universit

¨

at M

¨

unchen.

Buechel, M., Frtunikj, J., Becker, K., Sommer, S., Buckl,

C., Armbruster, M., Marek, A., Zirkler, A., Klein, C.,

and Knoll, A. (2015). An automated electric vehicle

prototype showing new trends in automotive architec-

tures. In 2015 IEEE 18th International Conference on

Intelligent Transportation Systems, pages 1274–1279.

Cramer, S., Lange, A., and Bengler, K. (2015). Path plan-

ning and steering control concept for a cooperative

lane change maneuver according to the h-mode con-

cept. In 7. Tagung Fahrerassistenzsysteme.

Flemisch, F. O., Bengler, K., Bubb, H., Winner, H., and

Bruder, R. (2014). Towards cooperative guidance

and control of highly automated vehicles: H-mode

and conduct-by-wire. Ergonomics, 57(3):343–360.

PMID: 24559139.

Fuerst, S. (2015). Autosar the next generation - the adaptive

platform. In CARS Critical Automotive applications:

Robustness & Safety in 11th EDCC European Depen-

dable Computing Conference.

VEHITS 2017 - 3rd International Conference on Vehicle Technology and Intelligent Transport Systems

100

Haas, W. and Langjahr, P. (2016). Cross-domain vehicle

control units in modern e/e architectures. In 16. Inter-

nationales Stuttgarter Symposium, pages 1619–1627.

Holder, S., Hoerwick, M., and Gentner, H. (2012). Funk-

tionsbergreifende szeneninterpretation zur vernetzung

von fahrerassistenzsystemen. In AAET - Automatisier-

tes und vernetztes Fahren.

Ishida, S. and Gayko, J. E. (2004). Development, evaluation

and introduction of a lane keeping assistance system.

In Intelligent Vehicles Symposium, 2004 IEEE, pages

943–944.

Kim, J.-W., Lee, K.-J., and Ahn, H.-S. (2015). Development

of software component architecture for motor-driven

power steering control system using autosar methodo-

logy. In Control, Automation and Systems (ICCAS),

2015 15th International Conference on, pages 1995–

1998.

Korsiakoff, A., Sweet, W. N., Seymour, S. J., and Biemer,

S. M. (2011). Systems Engineering Principles and

Practice. John Wiley & Sons, Inc.

Leen, G. and Heffernan, D. (2002). Expanding automotive

electronic systems. Computer, 35(1):88–93.

Liebemann, E. K., Meder, K., Schuh, J., and Nenninger, G.

(2004). Safety and performance enhancement: The

bosch electronic stability control (esp). SAE Paper,

20004:21–0060.

Matthaei, R. and Maurer, M. (2015). Autonomous driving

- a top-down-approach. at - Automatisierungstechnik,

63(3):155–167.

Moon, S., Yi, K., and Moon, I. (2008). Design, tuning and

evaluation of integrated acc/ca systems. In 17th World

Congress of the International Federation of Automatic

Control (IFAC 2008), volume 41 of IFAC Proceedings

Volumes, pages 8546–8551.

Naranjo, J. E., Gonzalez, C., Garcia, R., de Pedro, T., and

Haber, R. E. (2005). Power-steering control architec-

ture for automatic driving. IEEE Transactions on In-

telligent Transportation Systems, 6(4):406–415.

Navale, V. M., Williams, K., Lagospiris, A., Schaffert, M.,

and Schweiker, M.-A. (2015). (r)evolution of e/e

architectures. SAE Int. J. Passeng. Cars Electron.

Electr. Syst., 8(2):282–288.

Nilsson, J., Br

¨

annstr

¨

om, M., Coelingh, E., and Fredriksson,

J. (2016). Lane change maneuvers for automated vehi-

cles. IEEE Transactions on Intelligent Transportation

Systems, PP(99):1–10.

Nordbruch, S., Quast, G., Nicodemus, R., and Scheiger, R.

(2015). Automated valet parking. In 7. Tagung Fahre-

rassistenzsysteme.

Pohl, K., Hoenninger, H., Achatz, R., , and Broy, M. (2012).

Model-Based Engineering of Embedded Systems - The

SPES 2020 Methodology. Springer-Verlag Berlin Hei-

delberg.

Pretschner, A., Broy, M., Krueger, I. H., and Stauner, T.

(2007). Software engineering for automotive systems:

A roadmap. In FOSE Future of Software Engineering.

Reinhardt, D. and Kucera, M. (2013). Domain controlled

architecture - a new approach for large scale software

integrated automotive systems. In 3rd International

Conference on Pervasive Embedded Computing and

Communication Systems, pages 221–226.

SAE international (2016). Taxonomy and definitions for

terms related to driving automation systems for on-

road motor vehicles.

Sch

¨

auffele, J. and Zurawka, T. (2012). Automotive Soft-

ware Engineering - Grundlagen, Prozesse, Methoden

und Werzeuge effizient einsetzen. Springer Fachme-

dien Wiesbaden GmbH, 5 edition.

Stiller, C., F

¨

arber, G., and Kammel, S. (2007). Coopera-

tive cognitive automobiles. In Proceedings of the 2007

IEEE Intelligent Vehicles Symposium, pages 215–220.

Stolz, W., Kornhaas, R., and Sommer, T. (2010). Dom-

ain control units the solution for future e/e architec-

tures? In SAE Technical Paper 2010-01-0686, pages

221–226.

Streichert, T. and Traub, M. (2012). Elektrik/Elektronik-

Architekturen im Kraftfahrzeug - Modellierung und

Bewertung von Echtzeitsystemen. Springer Berlin

Heidelberg.

Tas,

¨

O. S., Kuhnt, F., Z

¨

ollner, J. M., and Stiller, C. (2016).

Functional system architectures towards fully automa-

ted driving. In 2016 IEEE Intelligent Vehicles Sympo-

sium (IV).

Tseng, H. E., Ashrafi, B., Madau, D., Brown, T. A., and

Recker, D. (1999). The development of vehicle sta-

bility control at ford. IEEE/ASME Transactions on

Mechatronics, 4(3):223–234.

Vector Informatik GmbH (2016). PREEvision User Manual

Version 8.0. Stuttgart.

Wahl, H.-G. (2015). Optimale Regelung eines pr

¨

adiktiven

Energiemanagements von Hybridfahrzeugen. PhD

thesis, Karlsruher Institut fr Technologie.

Weber, J. (2009). Automotive Development Process.

Springer-Verlag.

Weber, M. and Weisbrod, J. (2002). Requirements engi-

neering in automotive development - experience and

challenges. In IEEE Joint International Conference

on Requirements Engineering (RE’02).

Winner, H., Danner, B., and Steinle, J. (2012). Hand-

buch Fahrerassistenzsysteme, chapter Adaptive Cruise

Control, pages 478–521. Vieweg+Teubner Verlag,

Wiesbaden.

Woestman, J., Patil, P., Stunz, R., and Pilutti, T. (2002).

Strategy to use an on-board navigation system for

electric and hybrid electric vehicle energy manage-

ment. US Patent 6,487,477.

Zhan, R. and Krishnan, A. (2011). Using delta model for

collaborative work of industrial large-scaled e/e archi-

tecture models. Model Driven Engineering Langua-

ges and Systems, 14th International Conference, MO-

DELS 2011, pages 16–21.

Ziegler, J., Bender, P., Schreiber, M., Lategahn, H., Strauss,

T., Stiller, C., Dang, T., Franke, U., Appenrodt, N.,

Keller, C., Kaus, E., Herrtwich, R., Rabe, C., Pfeif-

fer, D., Lindner, F., Stein, F., Erbs, F., Enzweiler, M.,

Knoppel, C., Hipp, J., Haueis, M., Trepte, M., Brenk,

C., Tamke, A., Ghanaat, M., Braun, m., Joos, A., Fritz,

H., Mock, H., Hein, M., and Zeeb, E. (2014). Ma-

king bertha drive - an autonomous journey on a his-

toric route. IEEE Intelligent Transportation Systems

Magazine, 6(2):8–20.

A Taxonomy and Systematic Approach for Automotive System Architectures - From Functional Chains to Functional Networks

101