Energy Efficiency of a Multizone Office Building:

MPC-based Control and Simscape Modelling

Farah Gabsi

1

, Frederic Hamelin

1

, Remi Pannequin

1

and Mohamed Chaabane

2

1

Centre de Recherche en Automatique de Nancy - University of Lorraine, Vandoeuvre-les-Nancy, France

2

Laboratoire des Sciences et Techniques de l’Automatique et de l’informatique industrielle - ENIS, Sfax, Tunisia

Keywords:

Energy-efficient Buildings, Simscape

TM

Models, Model Predictive Control, Multi-room Building Model.

Abstract:

This paper deals with the problem of modelling and controlling a multi-zone office building to ensure its

thermal comfort by an optimal and cost effective management of the energy consumption. A thermal behaviour

analysis of the building is carried out using the Simscape

TM

library in MATLAB/Simulink

R

environment

that leads to a multi-model representation. Based on this modelling, the Yalmip toolbox in the MATLAB

programming environment or an iterative optimization algorithm can be used to solve the control optimisation

problem. The design of a model predictive control associated with a wise choice of the cost function makes it

possible to obtain in simulation substantial energy benefits.

1 INTRODUCTION

Over the last years, a large number of researchers

have been interested in controlling strategies for en-

ergy saving of buildings (Scherer et al., 2014), (Atam

and Helsen, 2016). Indeed, the construction sector,

especially electrical energy, is the largest energy con-

sumer. It represents approximately 40% of the total

energy consumption between all sectors of the econ-

omy in France and in the US (Agbi, 2014). One of

possible approaches to reduce energy consumption in

buildings is to use advanced control tools to effec-

tively monitor all the building actuators to ensure its

hygrothermal comfort (Goyal et al., 2013), (Privara

et al., 2011).

In this paper, a thorough methodology of mod-

elling/controlling a building part is proposed to ensure

the thermal comfort of its inhabitants while minimiz-

ing energy consumption. It uses the Simscape

TM

tool-

boxes to model the thermal behaviour of the build-

ing (Lapusan et al., 2016), and an iterative algorithm

(or Yalmip (Lofberg, 2004)) to solve the optimization

problem related to the synthesis of a predictive con-

trol. The applied target is the “Eco-safe” platform

(CRAN Nancy, France) that fits in a global context

of smart home. The developed Simscape

TM

model is

based on a physical description of the building. This

approach allows the description of the system as a

physical structure rather than by abstract mathemat-

ical equations. Furthermore, the differential equa-

tions that describe the thermal behaviour of the sys-

tem can be directly generated from the Simscape

TM

model. This modelling step in the form of a state-

space representation is essential for the development

of a predictive control model (MPC) (Camacho and

Bordons, 2007). This type of control is favoured be-

cause it has the advantage of taking into account the

disturbance predictions that greatly influence the inte-

rior comfort of a building (outside temperature, sun-

shine, occupations of parts) while anticipating their

effects (Ma et al., 2011), (Oldewurtel et al., 2012),

(Privara et al., 2011). Knowing that each control ac-

tion is associated with a different state-space model of

the system, the predictive control used is considered

as a hybrid type (Le et al., 2014). In view of the con-

trol objectives, the associated optimization criterion

is defined to integrate the energy cost of each actuator

in kWh, the resolution of the optimization problem is

executed using the Yalmip tool of Matlab or an itera-

tive algorithm for important prediction horizon.

The first part of this work is focused on the thermal

modelling of a set of building parts because few works

have been interested in this issue. The validation of

the model and the control will be conducted on the

“Eco-safe” platform. Next a model predictive control

is put in order to ensure the thermal comfort of the

rooms of the platform with a minimum of energy con-

sumption. Tests of simulation with various scenarios

were developed to exhibit the energy benefits.

Gabsi, F., Hamelin, F., Pannequin, R. and Chaabane, M.

Energy Efficiency of a Multizone Office Building: MPC-based Control and Simscape Modelling.

DOI: 10.5220/0006305002270234

In Proceedings of the 6th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2017), pages 227-234

ISBN: 978-989-758-241-7

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

227

2 PLATFORM DESCRIPTION

The “Eco-safe” platform consists of 6 rooms and a

corridor (Figure 1). The rooms are equipped with sen-

sors and actuators to model their thermal behaviour

and control their comfort. Regarding the area, the

platform is characterized by two main activity rooms:

“a room of research and development” (R&D,

1

) of

51m

2

and a piece of applications

5

of 34m

2

. Four

other rooms, 17m

2

each, allow to store tools and var-

ious materials (parts

2

+

4

) or to have an estimate

of the rooms temperature located in the upper and

lower floors (

3

+

6

), because with the same neutral

behaviour. The platform consists of heterogeneous

equipment architecture such as the sensors needed for

the modelling of its thermal response, the equipment

contributing to the thermal comfort of the rooms and

a weather station that integrates several sensors. To

ensure the thermal comfort of this platform by imple-

menting a predictive control based on the minimiza-

tion of energy consumption, it is necessary to deter-

mine a model for the thermal behaviour of the plat-

form. The following paragraph provides an answer to

this objective through the definition of a simulator.

Figure 1: The “Eco-safe” deck plans.

3 THERMAL MODELLING OF

THE PLATFORM

The simplified physical model we aim to establish has

the role to predict the thermal behaviour of the whole

platform. The latter is decomposed piece by piece

taking into account their orientation in order to fur-

ther simulate the influence of the solar radiation. Each

room consists of different elements (walls, ceiling,

floor, windows), some of which benefit from some

solar energy inputs. The temperature of the R&D

room, (

1

) and applications (

5

) is also influenced

by a main source of energy which is a reversible heat

pump to produce the heat and cold. In addition, air

flow is provided between these same rooms through

two controlled mechanical ventilation (CMV). Over-

all, the energy balance for each of the rooms can be

translated by the following equation:

C

int

dT

int

dt

= f

ext

(T

ext

,T

int

) +

n

∑

i=1

f

i

(T

int

,T

int,i

)

+θ

occupancy

+ θ

energy

(1)

with:

• C

int

: heat capacity (J/K) of the considered room;

• T

int

, T

ext

and T

int,i

: temperature (K) of the consid-

ered room, of outside and of the adjacent rooms;

• θ

energy

and θ

occupancy

: energy contributions (W )

and heat generated by the inhabitants of the room;

• f

ext

(T

ext

,T

int

) and f

i

(T

int

,T

int,i

): functions reflect-

ing the thermal behaviour of interfaces between

the room and the outside or adjacent rooms.

In order to establish the complete thermal model

of the “Eco-safe” platform, we use a physical ap-

proach based on the Simscape

TM

tool (Lapusan et al.,

2016) in the environment Simulink

R

. The global

model of the platform is the result of the integration of

all room models. Each room includes walls and win-

dows that are interacting with the external environ-

ment and neighbouring rooms by each mode of heat

transfer. While this issue is the subject of the section

that follows, the energy sources influencing the room

thermodynamics are modelled in the last paragraph.

3.1 Thermal Modelling of a Room

The room model is developed using the thermal el-

ements library of Simscape

TM

. If a correspondence

is established between the flow of heat and electric

power as well as between the temperature and the

potential difference, it is conventional to establish

thermoelectric analogies (Achterbosch et al., 1985).

This analogy will be used in the transcript of the

Simscape

TM

model of the platform to a state-space

model.

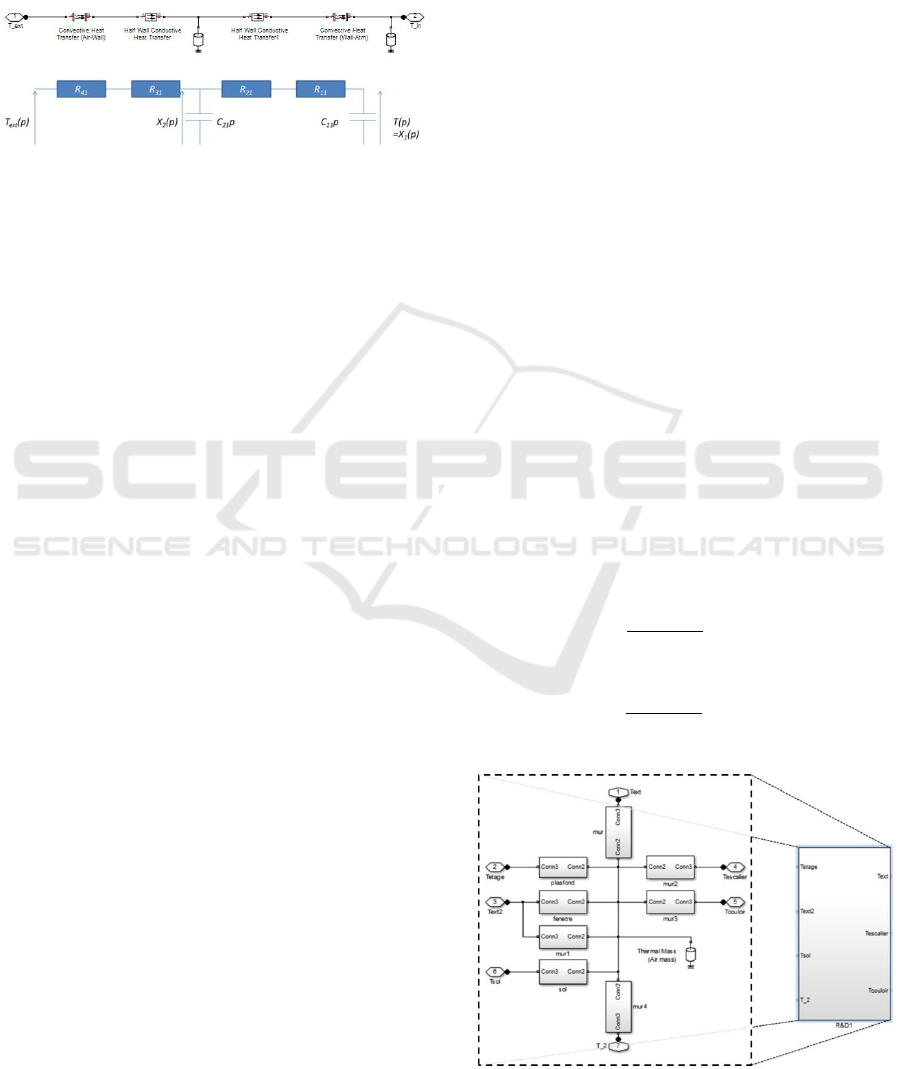

3.1.1 Models of a Wall and a Set of Windows

Wall: The thermal equilibrium is established tak-

ing into account the convective exchange between the

wall and the air that surrounds it on each side. In-

side the wall, the heat is transferred through con-

duction phenomenon. The wall model developed on

Simscape

TM

model is presented in Figure 2a, in which

it is assumed that the wall is the interface between the

inside of a room and the outside air. By electrical

analogy, the wall can also be described by a 2R1C

model (2 resistors and 1 capacitor) and schematically

represented in Figure 2b, which presents the follow-

ing notations:

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

228

• X

1

(p), X

2

(p), T

ext

(p): temperature (K) of the

room, in the middle of the wall and of outside;

• (R

11

, R

41

) and (R

21

, R

31

): thermal resistances

(K/W ) of convection and conduction;

• C

11

, C

21

: heat thermal capacities (J/K) of the

room and of the exterior wall.

Figure 2: Model of a wall (a) by Simscape

TM

(b) by electri-

cal analogy.

Set of windows: To model the thermal behaviour of

all windows in a room, we assumed that it was iden-

tical to consider a single window of equivalent sur-

face. Knowing that the windows in the rooms are all

double glazed, their modelling requires to take into

account not only the surface/superficial resistance of

inside and outside exchange (transfer by convection/

convective transfer) but also transfers by conduction

within the two glass panes and the air space between

them (see Figure 3a). By analogy, a 4R3C model is

used to determine the associated state-space represen-

tation (see Figure 3b). with:

• X

0

1

(p), X

0

2

(p), X

0

3

(p) and X

0

4

(p): temperature (K)

of the room and in the middle of the inner glass,

of the air space and of the outer glass;

• (R

12

, R

82

) and (R

22

, R

32

,..., R

62

, R

72

): thermal

resistances (K/W ) of convection and conduction;

• C

22

, C

32

, C

42

: heat thermal capacities (J/K) of the

glass and of the air space/blade;

The state-space representations of a wall and of a set

of windows are then obtained by the application of

Millman’s theorem.

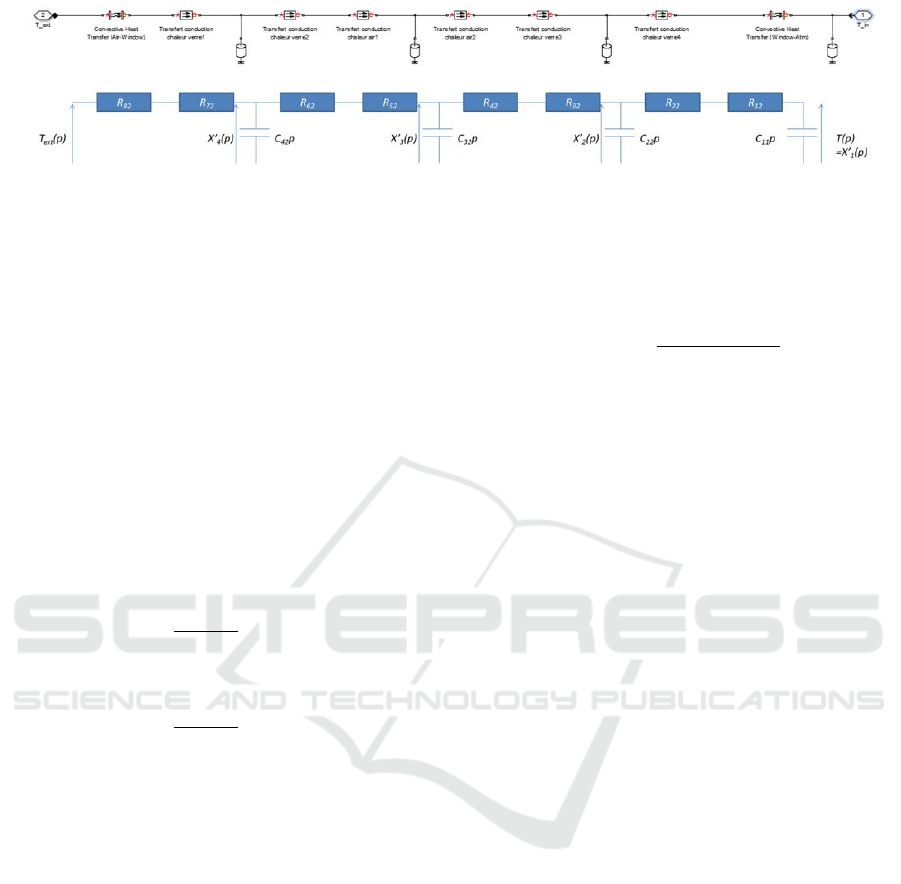

3.1.2 Models of a Room and “Eco-safe”

Platform

Room: A room being made up of several walls, a

slab, a ceiling (whose thermal behaviour is similar

to that of a wall in our case) and possible windows,

the one-room model is obtained by the integration of

the models of each of these elements within a unique

state-space representation. Considering the R&D

room (

1

) of the platform “Eco-safe” represented in

Figure 4, the state-space model thus obtained is of

order 11 (5 adjacent walls (order 1) + 1 ceiling (order

1) + 1 ground (order 1) + 1 set of windows (order 3)

+ heat capacity of the room (order 1)).

“Eco-safe” Platform: The platform is modelled by

a set of rooms delimited by the walls that are in ther-

mal contact with the outside environment and neigh-

bouring rooms. Applying the same technique of mod-

elling than for room

1

, we get a state-space represen-

tation of order 72 to simulate the thermal behaviour of

the platform. In this model, the temperature values of

the upper and lower floors are considered to be iden-

tical to those of the reference rooms (

3

+

6

).

3.2 Modelling of Energy Sources

The most important elements that produce the heat or

cold inside the building are the reversible heat pump,

the ventilation system and sun radiation. These differ-

ent equipments/contributions of energy are modelled

in this paragraph to be integrated in the simulator. The

model also takes into account the effect of the people

inside the platform and that of different electrical ap-

pliances that generate heat.

3.2.1 CMV

The CMV is used to circulate the air between rooms

1

and

5

(see Figure 1). It is assumed that the air

taken in the ‘source’ room is replaced by the outside

air through the openings at the level of the windows.

On the other hand, air received by the ‘destination’

room replaces a part of its air that is equally displaced

through the openings at the level of the windows. If

we take the example that the air flows from room

5

to room

1

, the energy flows generated by the CMV

are at the level of the ‘source’ room:

φ

CMV 1

(t) =

ρc

1

D

CMV

3600

(T

ext

(t) − T

5

(t)) (2)

and at the level of the ‘destination’ room:

φ

CMV 2

(t) =

ρc

1

D

CMV

3600

(T

5

(t) − T

1

(t)) (3)

Figure 4: Model Simscape

TM

exhibit R&D (

1

).

Energy Efficiency of a Multizone Office Building: MPC-based Control and Simscape Modelling

229

Figure 3: Model of a set of windows (a) by Simscape

TM

(b) par electrical analogy.

with c

1

= 1005.4 J/kg/K the specific heat of air ; ρ =

1.204 kg/m

3

the density of air ; D

CMV

= 150 m

3

/h the

air flow of the CMV ; (T

ext

, T

1

, T

5

) the tempera-

tures (K) of outside atmosphere, of rooms

1

and

5

.

3.2.2 Reversible Heat Pump (HP)

A heat pump is a thermodynamic device that allows

capturing heat from outdoor air and transmitting it in-

side the building. Being reversible, the HP air – water

of the platform is capable of providing air condition-

ing in the summer. It starts running in heating mode

in the order of 312K and 290K into cooling mode.

Essentially, and without taking into account the tran-

sitional aspects, the equation translating this energy

flow is in the heating mode:

φ

HP1

(t) =

ρc

1

D

HP

3600

(312 − T

i

(t)) (4)

and in air conditioning mode:

φ

HP2

(t) =

ρc

1

D

HP

3600

(290 − T

i

(t)) (5)

with D

HP

= 5000 m

3

/h the air flow of the HP and T

i

the room temperature (K) in which the HP is used.

3.2.3 Modelling of the Occupation

Each individual has a sensible heat (by his/her body

at 37

◦

C) and a latent heat (by his/her production of

steam in breathing and perspiration). Different values

are given in the literature (ASHRAE, 2013). A person

generates about 100W . By multiplying this value by

the number of people in a room, we get the energy

released by them.

3.2.4 Inputs of Energy by Solar Radiation

The sun provides heat that greatly influences the tem-

perature within the platform rooms. The estimated

brought solar energy requires to instantly follow the

positioning of the sun and to take into account the ra-

diation so that diffuse direct. In order to understand

the calculations to quantify the global radiation, it is

important to define not only the various solar compo-

nents, but also the different angles used for calcula-

tions (Antonic, 1998). The energy related to the direct

radiation is such that:

S = 1230exp(−

1

3.8sin(h + 1.6)

)cos(β) (6)

where h is the height of the sun and β is the angle

between the normal to the windows and the solar rays.

They depend on the the latitude, the hour angle, the

solar declination and the solar azimuth. As for the

energy associated to the diffused radiation energy, it

is calculated by the relationship :

D = 125(sin(h)

0.4

)((1 + cos(i))/2)

+alb(((1 + cos(i))/2)(1080(sin(h)

1.22

) (7)

−125(sin(h)

0.4

)))sin(h) +125(sin(h)

0.4

)(1 −sin(h))

where alb = 0.2 is the albedo and i = 90 corresponds

to the inclination of the windows according to the hor-

izontal.

3.3 Simulation Results

The simulator is implemented by integrating the set

of energy sources described in the previous paragraph

to the Simscape

TM

model of the “Eco-safe” platform.

The associated state-space representation is deter-

mined by adding these different energy sources on the

equivalent electrical schemas/diagrams in terms of the

correspondence between a heat flow and an electric

current. The use of the CMV or HP has the effect of

changing the state-space model of the system. Con-

sidering different scenarios of following control, it is

possible to define 6 state-space models of the plat-

form:

• Scenario 0: no action on the system,

• Scenario 1: CMV switched room

5

to

1

,

• Scenario 2: CMV switched room

1

to

5

,

• Scenario 3: HP operated in the room

1

,

• Scenario 4: HP operated in the room

5

,

• Scenario 5: 2 HP operated in rooms

1

and

5

.

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

230

For simulation, continuous time models are finally

discretized with a 5-mn sampling period. They be-

come:

x(k + 1) = A

sim

i

x(k) + B

sim

i

d(k)

y(k) = C

sim

x(k)

(8)

with:

• i ∈ {0,..., 5}: the type of implemented control on

the system identically to the number of scenario;

• A

sim

i

and B

sim

i

: state and input matrices associated

with the number of scenario; C

sim

: output matrix;

• x(k) ∈ R

72

: state vector grouping all temperatures

of walls, windows and rooms of the platform.

• d(k) =

T

ext,k

Occ

k

Sol

west

k

Sol

east

k

T

HP,k

T

;

• y(k) =

T

1

,k

T

2

,k

T

corridor,k

T

4

,k

T

5

,k

T

;

• T

ext,k

: outside temperature (K);

• Occ

k

: energy brought by occupants of room

1

;

• Sol

west

k

and Sol

east

k

: energy provided by solar ra-

diation for rooms

1

,

2

,

3

and

4

,

5

,

6

resp.;

• T

HP,k

: temperature of the air forced through the

HP, T

HP,k

=290K (cold mode) or 312K (hot mode).

Parameters R

i j

and C

i j

of the simulator were calcu-

lated from the nature and characteristics of the dif-

ferent materials used in the wall dividers, walls and

windows of the platform. They have been adjusted

from the temperature curves actually observed on the

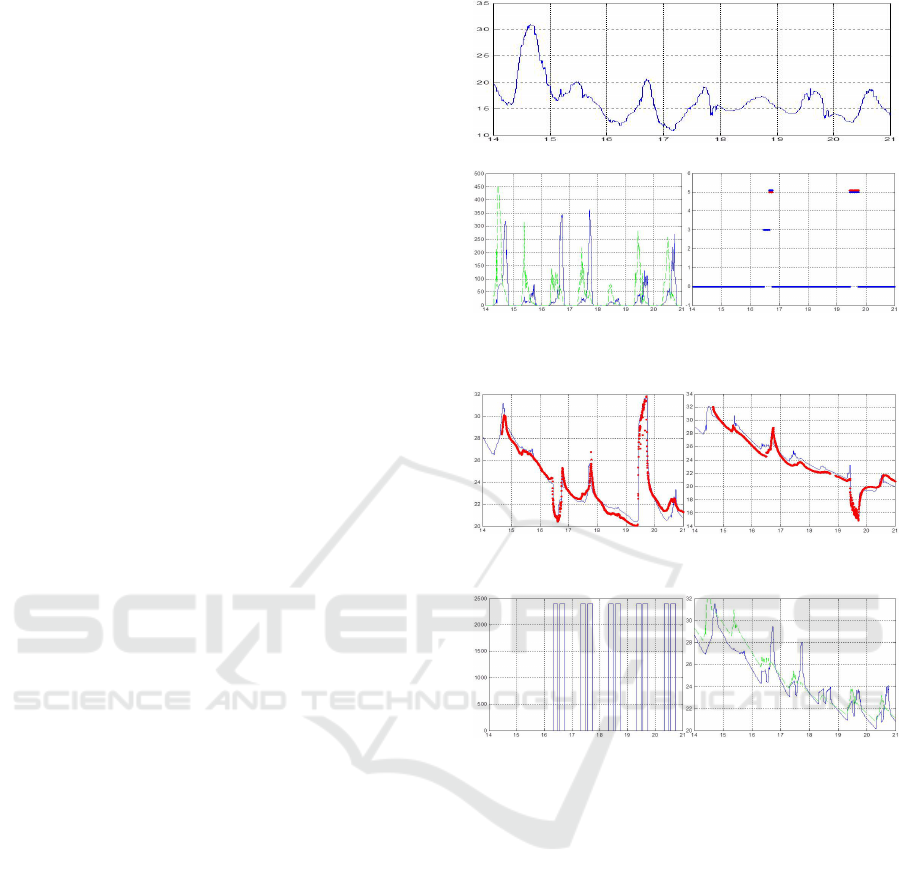

system. According to figures 7a and 7b, it appears

that the profiles of actual and estimated temperature

values are found to be very similar. The simulated

curves were generated according to the different sce-

narios of control represented in Figure 6b and from

the entries T

ext,k

(Figure 5), Sol

west

k

and Sol

east

k

(Fig-

ure 6a), which are the data issued from the meteorol-

ogy station over the period 14/09/2016 - 20/09/2016.

Figure 8b represents the temperature estimated by the

simulator within rooms

1

and

5

in scenario 0. In ad-

dition to the previous inputs, the energy released from

occupancy Occ

k

(figure 8a) is also considered. The

latter represents approximatively the energy genera-

ted by 24 people in room

1

assuming their presence

all the open days from 8h to 12h and from 14h to 18h.

The following paragraph aims to implement a con-

trol law on the platform, which is capable of ensuring

thermal comfort in the occupied rooms while mini-

mizing energy consumption. A predictive control is

used on the basis of the simulator of the platform.

4 PREDICTIVE CONTROL

The principle of the predictive control (Camacho and

Bordons, 2007) is to optimize a cost function allow-

ing to describe the aim of control over a finite time

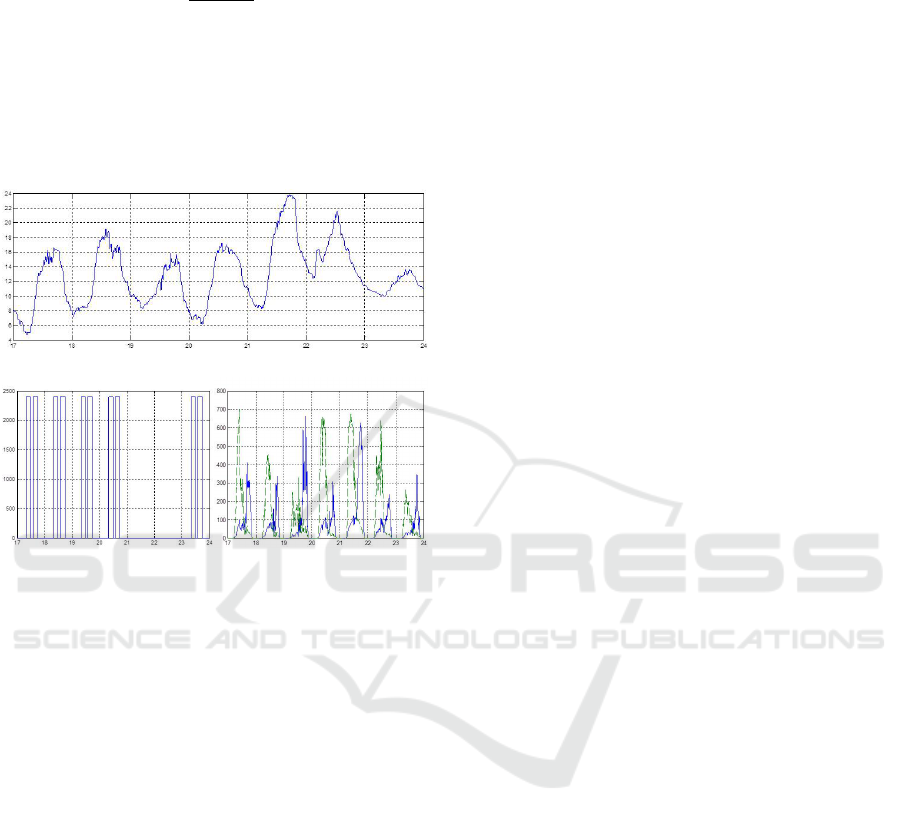

Figure 5: Outside temperature (14/09 - 20/09/2016).

Figure 6: (a) Solar energy (W ) Sol

west

k

(green) and Sol

east

k

(blue), (b) Control scenarios: HP in cold mode on 16/09 and

hot mode on 19/09 in room

1

(inversely for room

5

).

Figure 7: Actual (in red line) and estimated (in blue line)

temperature values of (a) room

1

, (b) room

5

.

Figure 8: (a) Occ

k

, (b) estimated temperature in rooms

1

(T

1

,k

in green) and

5

(T

5

,k

in blue).

horizon. To calculate the sequence of controls that

minimizes this cost function, we offer the platform

“Eco-safe” a multi-model linear representation to pre-

dict its behaviour. At each moment, an optimal con-

trol sequence is calculated to minimize the cost func-

tion on a prediction horizon. Only the first element is

applied to the system. As part of our application, this

procedure is repeated every 5 minutes.

4.1 Cost Function and Constraints

Since the objective is to ensure the thermal comfort

with a minimum of energy consumption, the cost

function must reflect these performances in a math-

ematical formulation. In the light of the European

thermal regulation ISO7730 and ASHRAE 55 stan-

dard, which define the thermal comfort as a temper-

ature interval defined by a lower limit and an upper

limit and according to the nature of the models of the

Energy Efficiency of a Multizone Office Building: MPC-based Control and Simscape Modelling

231

platform, the cost function is chosen such that:

J

1

= min

i

1

...,i

N

N

∑

j=1

||

y

i

j

(k + j) −y

re f

||

2

Q

+cost(k + j) (9)

where:

• y

min

≤ y

i

j

(k+ j)

≤ y

max

; y

re f

=

y

min

+y

max

2

•

x

0

(k + 1) = A

com

i

j

x

0

(k) + B

com

i

j

b

d(k)

y

i

j

(k) = C

com

x

0

(k)

cost(k) = α

i

j

•

b

d(k) =

h

d

T

ext,k

[

Occ

k

\

Sol

west

k

\

Sol

east

k

[

T

HP,k

i

T

includes all the estimations of the disturbances.

d

T

ext,k

,

\

Sol

west

k

and

\

Sol

east

k

are issued from mete-

orological forecasts in the short term (

\

Sol

west

k

and

\

Sol

east

k

require a basic calculation according to the

orientation of the windows and predicted solar ra-

diation).

[

Occ

k

is a prediction based on a planning

of the energy generated by the people in the room

1

.

[

T

HP,k

depends on the value of i

j

(see below).

• i

j

∈

0,...,8

represents the used control scenario

(cf. part 3.3) and α

i

j

the associated energy cost:

- i

j

=0: Scenario 0, α

0

=0W h and

[

T

HP,k

=0,

- i

j

=1: Scenario 1, α

1

=30W h and

[

T

HP,k

=0,

- i

j

=2: Scenario 2, α

2

=30W h and

[

T

HP,k

=0,

- i

j

=3: Scenario 3, α

3

=1000W h and

[

T

HP,k

=290K,

- i

j

=4: Scenario 4, α

4

=1000W h and

[

T

HP,k

=290K,

- i

j

=5: Scenario 5, α

5

=2000W h and

[

T

HP,k

=290K,

- i

j

=6: Scenario 3, α

6

=1000W h and

[

T

HP,k

=312K,

- i

j

=7: Scenario 4, α

7

=1000W h and

[

T

HP,k

=312K,

- i

j

=8: Scenario 5, α

8

=2000W h and

[

T

HP,k

=312K.

• Matrices A

com

i

, B

com

i

and C

com

are such that they

define a reduced-order model of the simulator for

0 ≤ i ≤ 5, whereas we have A

com

i

= A

com

i−3

and

B

com

i

= B

com

i−3

for 6 ≤ i ≤ 8 considering that the en-

ergy consumption of HP in warm mode is exactly

the same as in cool mode. Indeed, the order of

the simulation system, being important (72), the

calculations that would require the development

of an optimal control would become very compli-

cated and time consuming. Without immersing

into the theoretical details of this model reduc-

tion, matrices A

com

i

, B

com

i

and C

com

are obtained

through the determination of balanced state-space

realizations. Furthermore, in order not to overly

complicate the synthesis of the control law that

normally requires the development of state ob-

servers to switch from one model to another, we

have imposed on the systems of reduced order to

be all of the order 5 (the number of temperature

sensors). This allows, for a simple basic change,

C

com

= I

5

and initial state condition

d

x

0

(0) = y(0).

4.2 Optimization Problem

To minimize criterion J

1

, the Yalmip software (in the

Matlab environment) can be used (Lofberg, 2004). It

turns out however that the design load increases with

the horizon of prediction N. Also, due to the combina-

torial explosion in computation time, for a number of

control scenarios equal to 9 (i

j

∈

0,...,8

), the value

of N may not exceed 6. For larger values of N, us-

ing the Yalmip software no longer makes it possible

to obtain a digital solution to the optimization prob-

lem. Yet, it can be very interesting to consider a more

important prediction horizon. Indeed, a scenario of

optimal control on a low prediction horizon may be-

come inappropriate on a larger horizon. This happens

especially when the heating and/or cooling capabili-

ties of the building are modest or y

min

and y

max

are

time-dependent. It is important to specify that tempo-

ral changes in y

min

and y

max

are beneficial in a context

of minimization of the energy cost because the con-

straints in temperature of the parts of a building are

not the same in the absence or in the presence of peo-

ple.

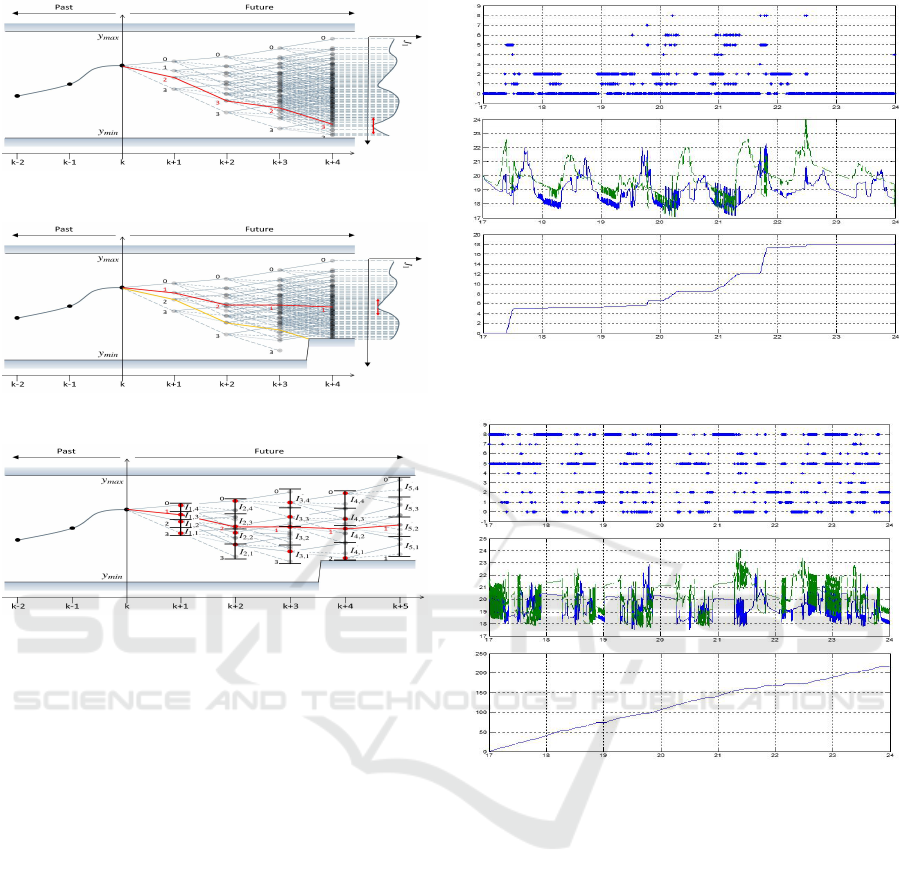

Figures 9 and 10 illustrate this phenomenon in the

simple case of a number of control scenarios equal

to 4 and when y

min

and y

max

are time-dependent. Fig-

ure 9 shows in red the control scenario predicted from

k + 1 until k + 4 (in agreement with the cost function

J

1

plotted vertically to the right of the figure) for y

min

and y

max

constant. It is characterized by the sequence

of controls i

1

= 2, i

2

= 3, i

3

= 2 and i

4

= 3. In the

case of y

min

and y

max

become time-dependent (figure

10), it should be noted that the sequence of optimal

controls becomes i

1

= 1, i

2

= 2, i

3

= 1 and i

4

= 1 (al-

ways in agreement with J

1

plotted to the right of the

figure). Therefore, in this example, if the prediction

horizon N is chosen equal to 1, 2 or 3, the optimal

control scenario to be applied at time k is associated

to i

1

= 2 whereas it is associated to i

1

= 1 for N = 4

and greater. In order to consider a prediction horizon

up some hours, we will subsequently use an iterative

approach. Its goal is to approach the best scenario of

optimal control on a given prediction horizon while

controlling the design load. The idea is to subdivide

at iteration j interval I

j

defined by:

I

j

= [max (y

min

,min

i

j

ˆy

i

j

(k + j)| ˆy(k + j − 1)),

min(y

max

,max

i

j

ˆy

i

j

(k + j)| ˆy(k + j − 1))] (10)

in an ordered set of n small-intervals I

j,l

with the same

width:

I

j

=

[

l

I

j,l

(11)

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

232

Figure 9: Control scenario predicted from k + 1 until k + 4

for y

min

and y

max

constant.

Figure 10: Control scenario predicted from k +1 until k + 4

for time-dependent y

min

and y

max

.

Figure 11: Control scenario predicted for time-dependent

y

min

and y

max

using an iterative approach.

In this expression, ˆy(k)=y(k) and ˆy

i

j

(k+ j)| ˆy(k+j−1)

represents n predictions of y at k + j from the model

associated with control scenario i

j

and from n parti-

cular predictions of y made the iteration before ( j−1).

At each of the intervals I

j,l

is joined a set of pre-

dictions ˆy

i

α

(k + j). In order to remove the control

scenarios associated to a more important energy cost

than others, it keeps only a unique prediction ˆy(k + j)

per interval I

j,l

. It corresponds to the smallest value

of ˆy

i

α

(k + j). Figure 11 represents the principle of

the proposed iterative approach on the same example

as before with n = 4, N = 5, i

j

∈

0,...,3

= I and

|I| = 4: number of members of I. At every moment of

prediction, the n best predictions ˆy(k + j) (in the sense

of cost function J

1

) are represented in red on the dia-

gram. It can be observed that the scenario of optimal

control i

1

= 1, i

2

= 2, i

3

= 1 and i

4

= 1 is the same

as one obtained by considering all the control scenar-

ios in a comprehensive way. On the other hand, the

computational load is greatly reduced with the itera-

tive algorithm. Indeed, if the number of calculations

to predict ˆy(k + j) is of |I|(nN − n + 1) for this al-

gorithm when dim (y) = 1, it becomes maximum of

(|I|

N+1

− |I|)/(|I| − 1) by exhaustive research.

Figure 12: (a) Control scenarios, (b) temperature of rooms

T

1

,k

(blue) and T

5

,k

(green), (c) kW h energy cost for Q =

0 and N = 30.

Figure 13: (a) Control scenarios, (b) Temperature of rooms

T

1

,k

(blue) and T

5

,k

(green), (c) kW h energy cost for Q =

diag([10

4

0 0 0 10

4

]) and N = 3.

4.3 Simulation tests

Aiming to illustrate the above approach and know-

ing that the main rooms of the platform are

1

and

5

rooms, the vectors y

min

and y

max

are chosen

such that y

min

=

18 16 16 16 18

and y

max

=

23 25 25 25 23

. Figures 12 - 13 represent the

evolution of temperatures T

1

,k

and T

5

,k

as well as

the different scenarios of the control with their as-

sociated energy cost in kWh over the period 17/05 -

23/05/2016 for different values of N and Q. The in-

puts of the simulator are T

ext,k

(Figure 14), Sol

west

k

and Sol

east

k

(figure 15b) and Occ

k

(figure 15a). By

these different simulations, the effect of the term

∑

N

j=1

||

y

i

j

(k + j) − y

re f

||

2

Q

can be clearly seen on the

optimal order scenario. The more

k

Q

k

is important,

the more actuators with high power energy are so-

Energy Efficiency of a Multizone Office Building: MPC-based Control and Simscape Modelling

233

licited (HP in our case) in on-off (hot-cold) control

in order to maintain the temperature of the rooms

1

and

5

close to y

re f

=

y

min

+y

max

2

= 20.5

◦

C. This type

of scenario is highly energy-consuming (see Figure

13c compared to Figure 12c). Similarly, a low predic-

tion horizon N makes the control more pre-emptive,

resulting in a slight increase in the cost of energy in

kW h. N equal to 30 samples (equivalent to 150 min-

utes) seems to be the best adapted in view of the abil-

ity of cooling/warming of the two HP.

Figure 14: Outside temperature (17/05 - 23/05/2016).

Figure 15: (a) Occ

k

, (b) Solar energy (W ) Sol

west

k

(green)

and Sol

east

k

(blue).

5 CONCLUSION

In this paper, a whole simulator of the thermal be-

haviour of a building platform has been established.

In a relatively high order (72), this simulator inte-

grates the behaviours of the set of the partitions wall

dividers/walls/windows of the platform rooms and all

energy sources (solar radiation, temperature, rooms’

occupancy, ventilation (CMV), heat pumps). Based

on a multi model representation of the building and

on an energy cost function in kWh, a predictive con-

trol has been successfully implemented to ensure the

thermal comfort of the platform rooms with a mini-

mum of energy consumption.

ACKNOWLEDGEMENTS

This work was supported by the 7th Framework Pro-

gramme FP7-NMP-608981 ”Energy IN TIME” and

has financial support from the Contrat de Plan Etat-

R

´

egion (CPER) 2015-2020, project ”Mat

´

eriaux, En-

ergie, Proc

´

ed

´

es”.

REFERENCES

Achterbosch, G. G. J., Jong, P. P. G. D., Krist-Spit, C. E.,

Meulen, S. F. V. D., and Verberne, J. (1985). The de-

velopment of a convenient thermal dynamic building

model. Energy and Buildings, 8:183–196.

Agbi, C. (2014). Scalable and Robust Designs of Model -

Based Control Strategies for Energy - Efficient Build-

ings. Dissertations, Carnegie Mellon University -

http://repository.cmu.edu/dissertations/333.

Antonic, O. (1998). Modelling daily topographic solar radi-

ation without site-specific hourly radiation data. Eco-

logical modelling, 113(1-3):31–40.

ASHRAE (2013). ASHRAE Handbook - Fundamentals (SI

Edition). American Society of Heating, Refrigerating

and Air-Conditioning Engineers, Inc.

Atam, E. and Helsen, L. (2016). Control-oriented thermal

modeling of multizone buildings: Methods and issues:

Intelligent control of a building system. IEEE Control

Systems, 36(3):86–111.

Camacho, E. F. and Bordons, C. (2007). Model predictive

control. Advanced textbooks in control and signal pro-

cessing. Springer-Verlag London.

Goyal, S., Ingley, H. A., and Barooah, P. (2013).

Occupancy-based zone-climate control for energy-

efficient buildings: Complexity vs. performance. Ap-

plied Energy, 106:209–221.

Lapusan, C., Balan, R., Hancu, O., and Plesa, A. (2016).

Development of a multi-room building thermody-

namic model using simscape library. Energy Proce-

dia, 85:320–328.

Le, K., Bourdais, R., and Gueguen, H. (2014). Optimal

control of shading system using hybrid model predic-

tive control. In 2014 European Control Conference

(ECC), pages 134–139, Strasbourg, France.

Lofberg, J. (2004). Yalmip: a toolbox for modeling and

optimization in matlab. In 2004 IEEE International

Symposium on Computer Aided Control Systems De-

sign (CACSD), pages 284–289, Taipei, Taiwan.

Ma, Y., Borrelli, F., Hencey, B., Coffey, B., Bengea, S.,

and Haves, P. (2011). Model predictive control for the

operation of building cooling systems. IEEE Transac-

tions on Control Systems Technology, 20(3):796–803.

Oldewurtel, F., Parisio, A., Jones, C. N., Gyalistras, D., Gw-

erder, M., Stauch, V., Lehmann, B., and Morari, M.

(2012). Use of model predictive control and weather

forecasts for energy efficient building climate control.

Energy and Buildings, 45:15–27.

Privara, S., Siroky, J., Ferkl, L., and Cigler, J. (2011). Model

predictive control of a building heating system: The

first experience. Energy and Buildings, 43(2-3):564–

572.

Scherer, H., Pasamontes, M., Guzman, J., Alvarez, J., Cam-

ponogara, E., and Normey-Rico, J. (2014). Effi-

cient building energy management using distributed

model predictive control. Journal of Process Control,

24(6):740–749.

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

234