Transmission and Thermal Emission in the NO

2

and CO Absorption

Lines using Macroporous Silicon Photonic Crystals

with 700 Nm Pitch

D. Cardador, D. Segura, D. Vega and A. Rodríguez

Micro i Nanotecnologies, Departament d’Enginyeria Electrònica, Universitat Politècnica de Catalunya,

C/Jordi Girona, 31, 08031, Barcelona, Spain

Keywords: Photonic Crystals, Pitch, Cavity, Resonance, Transmission, Emission, Q-factor, Gas Sensor.

Abstract: Macroporous silicon photonic crystals with a cavity in the middle of their structure have been studied in

both, transmission and emission. The initial transmittance of the photonic crystals was increased form 4%-

6% up to the value of 25%-30% by performing a rear attach of the samples of approximately 160 µm. The

use of wafers with 700 nm of pitch allowed us to fabricate the optical response of the photonic crystals in

the ranges of 6.4 µm and 4.6 µm, where different gases have their absorption frequency –such as NO

2

or

CO. The fabricated samples have been also heated in order to evaluate their viability to be used as selective

emitters for gas sensing purposes. Results show a good agreement in the position of the respective peak

compared to the transmission spectrum. However, further studies have to be done to place the base of the

peak as close as possible to the 0% of emission in order to have a better selective emitter. This work is a

starting point for gas detection devices using macroporous technology in the mid-infrared, which includes

ammonia, formaldehyde, carbon monoxide or nitrous oxide, among others.

1 INTRODUCTION

Photonic Crystals (PC) are becoming increasingly

attractive for both research and market applications.

Their optical properties, obtained by creating

periodical structures of different refractive index

materials, are very interesting for a wide range of

application areas, such as optical communications or

sensing. The introduction of defects in the structure

that break the periodicity confers the PC some

interesting functionalities. They allow the creation of

resonant states within the photonic bandgap at

specific frequencies or modes -(Joannopoulos et al.

2011; Braun et al. 2006)- what can be used as

waveguides (Rinne et al. 2007), light couplers,

optical resonators (Youcef Mahmoud et al. 2012),

thermal emitters (Gesemann et al. 2010) or tuneable

filters (Neumann et al. 2008), etc.

As reported in the literature, there are several

factors that affect the photonic bandgap features:

the contrast between the high and the low reflective

index in the PC, the morphology, the light path,

etcetera (Joannopoulos et al. 2011). In the case of

introducing a defect inside the photonic crystal, it is

also important to have into account its shape to

predict the optical response of the structure. Several

articles have dealt with this issue in 1D and 2D PCs

–i.e. (Alvarado-Rodriguez 2003; Xiao et al. 2016;

Mohebbi 2015). However, the influence of the

defects morphology in the optical response of 3D

photonic crystals have not been so deeply analysed,

perhaps, because of the high dependence of the

method used to fabricate the PC (Nelson 2011;

Braun et al. 2006b). A number of different

techniques have been proposed to incorporate defect

structures within the PCs in woodpiles (Taverne et

al. 2015), synthetic opals (Massé et al. 2006;

Palacios-Lidón et al. 2004) or macroporous silicon

(Mertens et al. 2005), among others.

In this paper we focus on macroporous silicon

(mp-Si), which is a versatile material that can be

successfully fabricated through the so-called

electrochemical etching (EE). With this technique it

is possible to fabricate pores with different depth

profiles -such as sinusoidal or straight- with a planar

defect inside the crystal structure –see Fig. 1.

Previous studies reported mp-Si structures with a

cavity in the middle of the PC that had a resonant

wavelength around the 7 µm (Mertens et al. 2005).

Nevertheless, they worked with a lattice parameter –

Cardador D., Segura D., Vega D. and Rodrà guez A.

Transmission and Thermal Emission in the NO2 and CO Absorption Lines using Macroporous Silicon Photonic Crystals with 700 Nm Pitch.

DOI: 10.5220/0006120101910195

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 191-195

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

191

also called pitch- of 2 µm and a vertical periodicity

about 2.5 µm. This vertical periodicity is limited to

the lattice parameter: when approaching to the pitch

value, the vertical periodicity is more difficult to

achieve and the profile is much more difficult to

control by EE. Although some other studies reported

modulated structures in 700 nm (Langner 2008),

they did not insert a cavity in their structures,

probably because the profiles were not as good as

the ones obtained in 2 µm of pitch. In the present

study, the samples used to fabricate the macroporous

silicon PCs had a pitch of 700 nm and a vertical

periodicity around the lattice parameter, what

enabled us to place a peak and tailor it at wavelength

as short as 4.6 microns, were different gas

absorption peaks can be found.

By removing around 160 µm of bulk silicon of the

samples, we have been able to increase the

transmission percentage from values around 4%-6%

up to values between 25% and 30%. This improves

the features of the peak –i.e. transmittance and

quality factor- and, as a consequence, the sensitivity

of the final gas sensor device is enhanced. Further

improvement of the transmission could be achieved

by removing some more bulk silicon, but the risk of

damaging the photonic crystal –mechanical support

or etching of the PC structure- becomes high and

some silicon bulk has to be left to avoid these

problems. In the case of thermal emission this layer

has not an important impact in the relative

transmission amplitude of the peak –from the base to

the top of the resonant peak-, but it has a

considerable effect in the position of the base point.

Specifically, the more bulk silicon the more

radiation of the no texturized region, which is finally

reflected in a higher offset from the zero emission

point to the base point, where the emission peak

rises.

The conclusions drawn in this paper lead us to

confirm that the studied macroporous silicon

structures can be employed in gas sensing

applications. However, further work has to be done

in order to improve the amplitude and the Q-factor

of the peak, as well as to reduce the offset, either

working in transmission or emission.

2 EXPERIMENTAL

The 3D structures were obtained by electrochemical

etching of n-type (100) crystalline silicon samples in

hydrofluoric (HF) acid solution. The starting

material had a resistivity between 0.1-0.3 Ω·cm

(~3·10

16

/cm

3

phosporous-doped). An N

+

layer was

implanted on the backside of the wafer to provide a

low-resistance transparent ohmic contact. Next, the

wafer was oxidized and a nanoimprint lithography of

700 nm pitch was performed. A Reactive-ion

Etching (RIE) and a tetramethylammonium

hydroxide (TMAH) etching were done to create

inverted pyramid-shaped pits that act as nucleation

centres for the ordered pore growth. Finally, the EE

etching was carried out to control the modulation of

pore diameter which, is regulated by the applied

etching current. This method allows to design the

profile beforehand and to create smooth 3D

structures of great complexity just by applying

different etching currents.

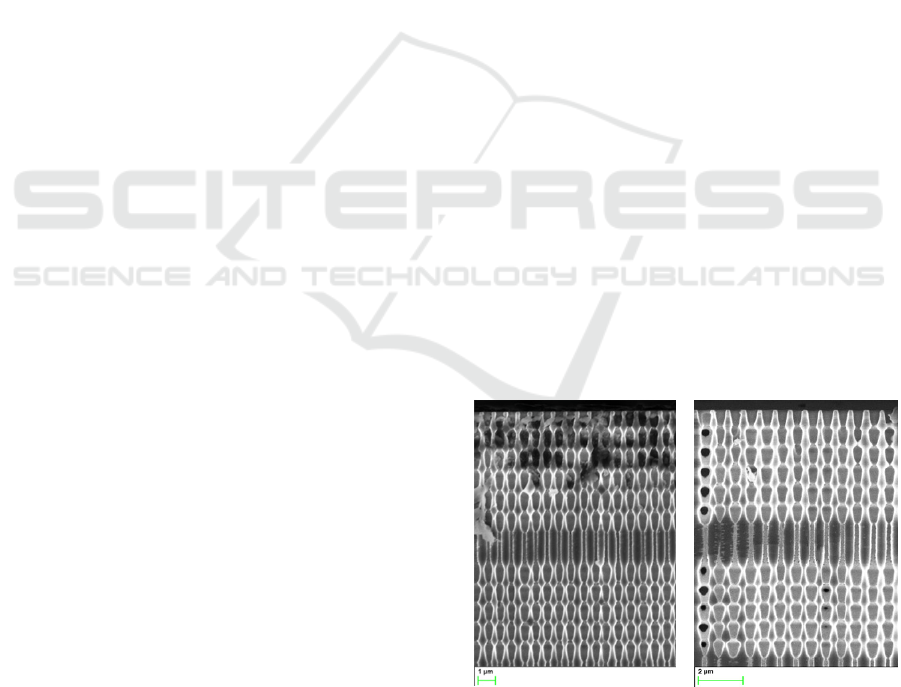

In particular, the periodical profiles attached in

Fig.1 have been generated. In the first sample (left)

the depth periodicity was set to be about 1.1-1.2 µm

what arouse a bandgap around [5-7] µm. As

depicted in the figure, a planar defect was introduced

halfway the total pore depth by suppressing one of

the modulations and leaving a constant diameter

section. The length of the cavity varied from 2.1 µm

to 2.6 µm with a diameter of 0.23 µm in all the

samples. In order to reduce the bandgap central

wavelength, and thus the position of the peak, the

vertical modulation of the pore was shortened. In

concrete, it was set to the lattice constant value

(~700nm). Thanks to that, the bandgap moved to the

range of [4-5] µm, while the defect’s length took

values in the range of [1.5-1.8] µm. The total depth

of all samples was about 12-15 micrometers. A

complete description of the process can be found

elsewhere (Lehmann 1993). The second fabricated

structure can be observed in the right image.

Figure 1: Cross sectional view of two 3-D PCs fabricated

by EE over a litography of 0.7 μm pitch. The inclusion of

a defect in the PC lattice enables a transmitted mode in 6.4

µm (left) and 4.6 µm (right). (les he reordenat en l’ordre

del text).

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

192

The transmitted response of the fabricated samples

was measured in the MIR range using a Bruker

Optic’s Vertex FT-IR spectrometer. The lattice was

aligned to the Γ – M direction (along one lattice axis

in the surface), an aperture of 1 mm and a resolution

of 4 cm

-1

was used for the calculation of the

spectrum. The measurements have been referred to

the source spectrum to normalize the results.

The emissivity was experimentally measured

using the A540 emission adapter of the FT-IR

spectrometer. This commercial setup allows normal

thermal emission measurement, with a beam

opening angle of ±7,5°, from room temperature up

to 400 °C. In this setup, the sample is clamped

vertically to a metallic surface that is at a constant

temperature. After thermalization, the sample is at a

constant and homogeneous temperature very close to

the temperature of the heater, since c-Si is an

excellent thermal conductor. In our case, the samples

were heated at the highest possible temperature in

order to obtain the maximum power of the emitter.

Finally, the emissivity values are obtained after

conducting a standard calibration with a piece of

polished Si as reference.

3 RESULTS AND DISCUSSIONS

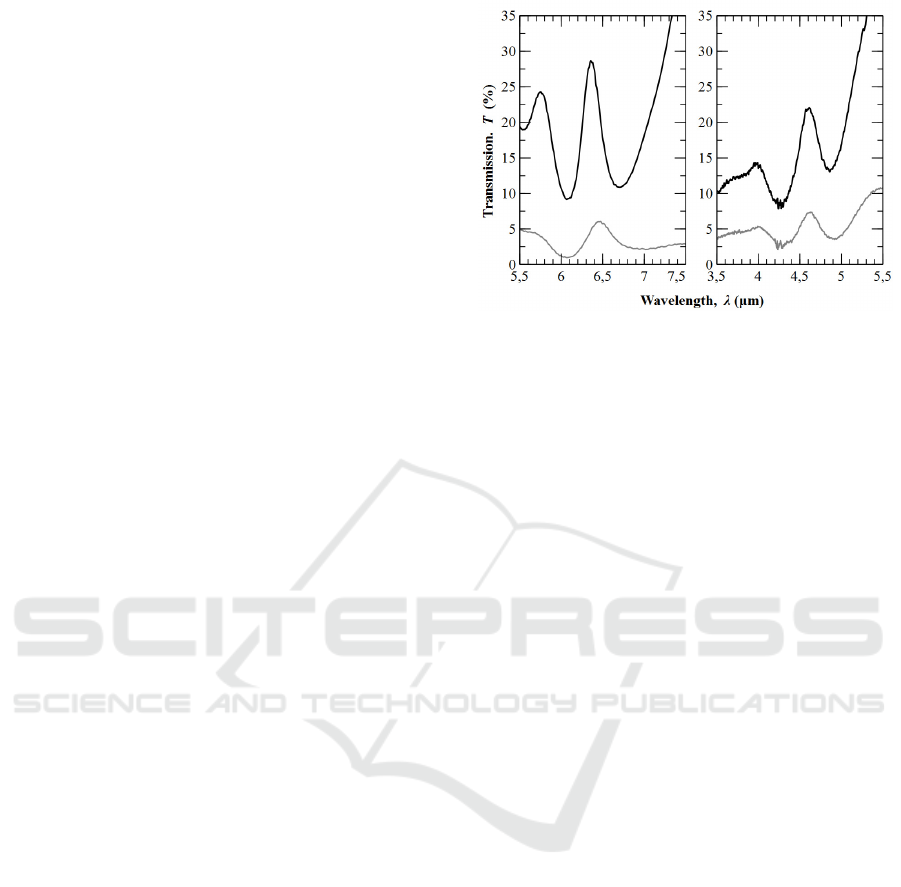

The two fabricated samples of the Figure 1: are

characterized in the FT-IR. In the Figure 2: the

sample’s transmission spectrum is shown. As

depicted in it, there is a high enhancement in the

transmission due to the reduction of, approximately,

160 µm of bulk silicon from the back side of the

wafer. In particular, the transmission percentage

rises from the value of 6% up to 29%. Previous

studies reported maximal transmission peaks of

almost 50% using mp-Si structures. Nonetheless,

their peaks were placed out of the mid-infrared

range –following the same convention as in (Byrnes

2008)- in concrete at 20 µm, far from the interesting

gas sensing mid infrared frequencies.

Figure 2: Transmittance of the samples before (grey) and

after (black) the TMAH attack for removing part of the

bulk silicon of the wafer. The different wavelength range

are achieved by controlling the vertically periodicity. Left

image corresponds to the image plotted in Fig.1(a) and the

right image to the Fig.1(b).

The values presented in this work are the best

ones reported in the mid-infrared, as far as our

research reached, in 3D mp-Si structures. Moreover,

the use of samples with 700 nm of pitch made

possible to reduce the vertical modulation and adjust

its periodicity close to the lattice constant. This

entailed a proportional translation of the entire

spectrum towards lower frequencies. An

appropriated dimensioning of the defect’s length and

width lead us to correctly place a resonant mode

inside the bandgap. Consequently, we were able to

reproduce the transmittance figure around 4.6 µm,

where the CO has its absorption lines –see Fig. 2.

As explained in the introduction, below the PC

there is some remaining bulk silicon. This silicon

reduces the amount of ideally transmitted light,

which in simulations –without any bulk silicon- can

be around 60%. However the reduction of more

silicon presents some problems. The first of them is

the risk of damaging the PC structure after some

hours of TMAH attack. The second one is that if the

attacked surface is big, some mechanical stress can

appear, completely breaking the surface as a

consequence.

One interesting fact is that by removing some

bulk silicon the quality factor of the peak is also

enhanced, improving the performance of a future gas

sensor. Nevertheless, the transmission inside the

band gap is also increased what, in turn, will result

in less sensitivity in a gas sensor. Some research

should be carried out to reduce the transmission

inside the band gap for obtaining good gas sensors.

Transmission and Thermal Emission in the NO2 and CO Absorption Lines using Macroporous Silicon Photonic Crystals with 700 Nm Pitch

193

Figure 3: Experimental emisison spectra for the samples

depicted in Fig. 1 (they are conveniently depicted. E.g.:

left image in Fig. 1 corresponds to the left image in Fig.3).

Both samples were heated at 400 ºC.

In the right image of the Fig. 2, it can be seen the

trademark of the CO

2

absorption lines at a 4.25 µm

wavelength. These marks correspond to variations of

gas concentrations referred to the background case.

If the peak is positioned on the absorption lines of a

target gas, the concentration of it can be determined

by comparing the area of the peak before and after

the gas exposure. Even more, despite using the PC

for filtering the light coming from the emitter, the

sample can be heated in order to have an emission

peak at the desired wavelengths. This would allow

replacing the optical emitter for a selective thermal

emitter, emitting in a smaller range of wavelengths,

and thus, simplifying the configuration for sensing

gases, probably without the need of an optical filter.

The lowered samples were used to evaluate their

thermal emission in the two studied wavelengths –

see Fig. 3- when the samples are heated at 400ºC.

The peaks are placed around 6.5 µm and 4.5 µm, in

good accordance with the position of the peak in

transmission. If observed insightfully a peak

broadening of about 100 nm can be seen in both

cases. A reduction of their respective amplitudes,

compared to their transmission spectrum, is also

noticeable, particularly at 4.5 µm. During the study

we have verified that there are some variations in the

pore’s morphology due to the expansion of the

silicon with the heating of the sample, which affects

the optical response of the peak; these experimental

variations, although they are of a few tens of

nanometers, modify the local refractive index what,

finally, impacts in the position and the amplitude of

the peak.

Another remarkable point is that the peaks do

not start at zero position; they have their beginning

at the emissivity of 40%-45%. Probably part of this

offset is due to the remaining bulk silicon in the

bottom of the photonic crystal, which also radiates in

the frequencies of the peak, reducing the

performance of the samples as selective thermal

emitters.

Further studies should deal with this issue in

order to obtain good selective emitters that

propagate a range of frequencies along its bandgap.

4 CONCLUSIONS

Macroporous silicon photonic crystals with a defect

inserted in the middle of the structure have been

studied. The initial transmittance of these structures

is between the 4% and the 6%. Performing a rear

attach of the sample –approximately 160 µm-, the

transmission percentage increases to the value of

25%-30%.

The use of samples with 700 nm of pitch allows

to work with sub micrometre vertical periods.

Thanks to this, peaks at lower resonant frequencies

can be placed, in concrete, we have fabricated two of

them: at 6.4 µm and 4.6 µm, what can be used to

sense different gases that have their absorption

frequency in ranges close to that values –such as

NO

2

or CO.

Both peaks been heated at room temperature of

400 ºC in order to obtain a selective emitter. Results

show a good agreement in the position of the peak

compared to the position in the transmission

spectrum. The little differences are attributable to

the variations in the shape of the pores given by the

expansion of the silicon due to higher temperatures.

Further studies have to be done to place the base of

the peak as close as possible to the 0% of emission

in order to have a real selective emitter.

This work is a starting point for gas detection

devices using macroporous technology in the mid-

infrared, which includes ammonia, formaldehyde,

carbon monoxide or nitrous oxide, among others.

ACKNOWLEDGEMENTS

This work has been founded by TEC-2013-48-147-

C6-2-R.

REFERENCES

Alvarado-Rodriguez, I., 2003. Fabrication of two-

dimensional photonic crystal single-defect cavities and

their characterization by elastic scattering. A

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

194

dissertation Doctor of philosophy in Electrical

Engineering.-Los Angeles, University of california.

Braun, P.V., Rinne, S.A. & García-Santamaría, F., 2006.

Introducing Defects in 3D Photonic Crystals: State of

the Art. Advanced Materials, 18(20), pp.2665–2678.

Byrnes, J., 2008. Unexploded ordnance detection and

mitigation. Springer Science & Business Media.

Gesemann, B., Schweizer, S.L. & Wehrspohn, R.B., 2010.

Thermal emission properties of 2D and 3D silicon

photonic crystals. Photonics and Nanostructures -

Fundamentals and Applications, 8(2), pp.107–111.

Joannopoulos, J.D. et al., 2011. Photonic Crystals:

Molding the Flow of Light, Princeton university press

(Second Edition).

Langner, A., 2008. Fabrication and characterization of

macroporous silicon. Doktorarbeit, Martin-Luther-

Universität.

Lehmann, V., 1993. The Physics of Macropore Formation

in Low Doped n-Type Silicon. Journal of The

Electrochemical Society, 140(10), p.2836.

Massé, P. et al., 2006. Tailoring planar defect in three-

dimensional colloidal crystals. Chemical Physics

Letters, 422(1-3), pp.251–255.

Mertens, G. et al., 2005. Tunable defect mode in a three-

dimensional photonic crystal. Applied Physics Letters,

87(24), p.241108.

Mohebbi, M., 2015. Refractive index sensing of gases

based on a one-dimensional photonic crystal

nanocavity. Journal of Sensors and Sensor Systems.

Nelson, E., 2011. Three-dimensional photonic crystal

optoelectronics. Diss. University of Illinois at Urbana-

Champaign.

Neumann, N. et al., 2008. Tunable infrared detector with

integrated micromachined Fabry-Perot filter. Journal

of Micro/Nanolithography, MEMS and MOEMS, 7(2),

p.021004.

Palacios-Lidón, E. et al., 2004. Engineered Planar Defects

Embedded in Opals. Advanced Materials, 16(4),

pp.341–345.

Rinne, S.A., García-Santamaría, F. & Braun, P. V., 2007.

Embedded cavities and waveguides in three-

dimensional silicon photonic crystals. Nature

Photonics, 2(1), pp.52–56.

Taverne, M., Ho, Y. & Rarity, J., 2015. Investigation of

defect cavities formed in three-dimensional woodpile

photonic crystals. JOSA B.

Xiao, X. et al., 2016. Investigation of defect modes with

Al2O3 and TiO2 in one-dimensional photonic crystals.

Optik - International Journal for Light and Electron

Optics, 127(1), pp.135–138.

Youcef Mahmoud, M. et al., 2012. Optical channel drop

filters based on photonic crystal ring resonators.

Optics Communications, 285(3), pp.368–372.

Transmission and Thermal Emission in the NO2 and CO Absorption Lines using Macroporous Silicon Photonic Crystals with 700 Nm Pitch

195