Experimental Analysis and Modeling of NO

x

Emissions in

Compression Ignition Engines Fueled with Blends of Diesel and Palm

Oil Biodiesel

Adriana Patricia Villegas Quiceno

1

, Ramón Fernando Colmenares Quintero

1

, Simona Silvia Merola

2

,

Adrian Irimescu

2

and Gerardo Valentino

2

1

Research Group TERMOMEC, Universidad Cooperativa de Colombia, Medellín, Colombia

2

Istituto Motori CNR, Napoli, Italy

Keywords: Compression Ignition Engine, Modeling, NO

x

Emissions, Blends, Diesel, Biodiesel.

Abstract: In this work, theoretical and experimental studies about the effects of the blends of diesel and palm oil

biodiesel on NO

x

formation in compression-ignition engines were developed. Experiments were conducted

using commercial diesel, palm oil biodiesel and blends at 5% (B5), 20% (B20) and 50% (B50) as fuels. A

phenomenological semi-empirical model that uses the information obtained from thermodynamic diagnostics

was used for determining the theoretical NO

x

formation. The model shows the high sensitivity of NO

x

formation to the temperature and the operating conditions. Effects associated to the operating conditions of

the engine were evaluated and the results indicate that high engine loads and low speeds lead to the NO

x

formation. However, it was not possible to determine with precision, the effect of the type of fuel, because of

the high sensitivity of the NO

x

formation with respect to the operating conditions of the engine.

1 INTRODUCTION

Nowadays, biodiesel has received considerable

attention given its potential use as a substitute for

petroleum diesel. In general terms, the current

technology is easily adapted for the use of such a fuel,

since its implementation does not require significant

changes in the control strategy of diesel engines.

Biodiesel is a renewable fuel that reduces greenhouse

emissions, such as particulate matter, carbon

monoxide, and total hydrocarbons among others

(Agudelo et al., 2010) (Sun et al., 2010).

However, the effect of the biodiesel and its blends

with diesel fuel on NO

x

formation is still a topic of

discussion in the literature. (Lapuerta et al., 2008) and

(Sun et al., 2010) classify the literature regarding the

effect of the biofuels on NO

x

production in five

groups: group 1: NOx increase, group 2: NO

x

increase

under certain operating conditions and blends, group

3: little or no difference, group 4: NO

x

decrease and

group 5: uncertain or no comment. The increase in

NO

x

emissions generates serious problems for public

health and the environment as these chemical species

contribute to the production of ozone. High levels of

ozone at low altitude cause respiratory diseases and

damage to the vegetation among others. On the other

hand, nitric oxides increase the level of acid rain and

contribute to the production of photochemical smog

(Turns, 1996). Also, NO

x

affects the development of

the biofuels industry due to the stringent restrictions

for these emissions in American and European

regulations. Several factors could increase or

decrease the NO

x

formation in blends of diesel and

biodiesel: adiabatic flame temperature, ignition delay

(Eckerle et al., 2009) and injection timing, as well as

fuel chemistry (Ban-Weiss et al., 2007). These factors

are determinant in the process of NO

x

formation and

should be analyzed as an overview rather than as

individual effects (Ban-Weiss et al., 2007). Adiabatic

flame temperature is affected by the fuel chemistry.

Increased aromatic content produces higher flame

temperatures that can promote NO

x

formation

through the thermal mechanism. This effect is most

significant for modes of combustion dominated by

diffusion, which mainly occur a high engine load

operation (Eckerle et al., 2009).

Ignition delay is defined as the time between the

start of injection and start of combustion; this

parameter is generally shorter for biodiesel compared

to petroleum diesel (Sun et al., 2010). The cetane

Quiceno, A., Quintero, R., Merola, S., Irimescu, A. and Valentino, G.

Experimental Analysis and Modeling of NO

x

Emissions in Compression Ignition Engines Fueled with Blends of Diesel and Palm Oil Biodiesel.

In Proceedings of the International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2016), pages 245-252

ISBN: 978-989-758-185-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

245

number is an indicator of the ignition delay time;

higher values correspond to shorter ignition delay

times (Ban-Weiss et al., 2007). It has been reported

that the sensitivity of NO

x

to changes in Cetane

number is higher at low load than at high load

(Lapuerta et al., 2008) which could reduce NO

x

emissions at low load. Advanced injection timing

could produce higher NO

x

emissions as the

combustion stars earlier, and thus the residence time

of the burning mixture in the cylinder is increased. An

advance in injection timing for biodiesel with respect

to petroleum diesel is caused by its higher bulk

modulus of compressibility for the biodiesel (Ban-

Weiss et al., 2007).

In this paper, a theoretical and experimental

analysis of the NO

x

production using diesel and palm

oil biodiesel blends is discussed The mechanism of

formation of NO

x

through the thermal mechanism is

presented and a semi-empirical model is applied to

determine the NO

x

formation in the combustion

diffusion phase.

2 METHODOLOGY

2.1 Modeling of NO

x

Emissions in

Diesel Engines

During combustion of fuels that do not contain

nitrogen in their structure, nitrogen monoxide (NO) is

formed from three mechanism: the thermal

(Zeldovich), the prompt (Fenimore) and fuel-bound

nitrogen (Sun et al., 2010). The thermal mechanism is

presented during high temperatures in the combustion

chamber when the reaction between the oxygen and

the nitrogen is carried out (Miller and Bowman,

1989). The thermal mechanism represents the most

important source in the NO

x

formation (Ban-Weiss et

al., 2007) and it is represented by three reactions: O +

N

2

↔ NO + N, O + O

2

↔ NO + O and O + OH ↔ NO

+ H (Sun et al., 2010). Some simplifications have

been applied to these equations in order to obtain the

general dynamic expression for NO

x

production

presented as d[NO] / dt = 6 · 10

16

/ T

0.5

exp(-69.09 /

T) · [O

2,eq

]

0.5

· [N

2,eq

] (Sun et al., 2010) (Fernando et

al., 2006) (Park et al., 2013). The first assumption is

that the nitrogen chemistry can be de-coupled from

combustion reactions due to the reactions rate of non-

nitrogenated species generally occur much faster than

that of the nitrogen chemistry, The second approach

implies that the concentrations of O, O

2

, OH, H and

N

2

can be approximated to the equilibrium

temperature. Finally, it is assumed that the radical N

is in its steady state. An approach for solving the

equation for calculating d[NO] consists in applying a

calculation scheme that takes into account the main

kinetics aspects for the formation and destruction of

NOx in the combustion chamber, which is linked to

the engine operating conditions. The main variables

include the instant pressure in the combustion

chamber, the fuel mass burned rate (FMB), the

adiabatic flame temperature (T

ad

) and the heat release

rate (HHR) which are obtained from thermodynamics

diagnostics (Timoney et al., 2005) (Park et al., 2013)

(Guardiola et al., 2011).

Based on the model developed by (Dec, 1997), it

is possible to confirm that the premixed combustion

phase does not show NO

x

formation as the higher

equivalent ratio reduces the amount of available

oxygen. This situation implies that the most important

processes for NO

x

formation occur in the flame front

during the combustion by diffusion.

Bearing this in mind, the theoretical NO

x

production is determined in the combustion diffusion

phase and the adiabatic flame temperature is the

characteristic temperature. The combustion diffusion

phase is taken from the values of heat release rate

curves between the start of combustion (SOC) and the

end of diffusion phase (EOD) (Timoney et al., 2005).

The approximated values of adiabatic flame

temperature for the biodiesel and their blends with

diesel are taken from (Glaude et al., 2010). The

equilibrium concentrations are estimated under

stoichiometric conditions and constant pressure. The

NASA simulation program “Chemical Equilibrium

Program” was used for calculating the equilibrium

concentrations.

Taking into account all the above considerations

(Timoney et al., 2005), a final expression for the

determination of NOx in each operating point is as

follows: e

NOx

= k Σ

SOC

EOC

T

ad

0.5

·ΔFMB · n

-1

· P

-1

·

exp(-0.69 / T

ad

) · [O

2,eq

]

0.5

· [N

2,eq

] · ΔCAD, where

constant k = Ru 6 · 10

16

· (1 + SFAR) / (6 NSTEP M

W

b

), with FMB calculated based on the rate of heat

release, with the lower heating value of each fuel

NSTEP and ΔCAD corresponding to the angular

resolution.

2.2 Experimental Setup

Test were carried out in a bench-mounted and

instrumented automotive diesel engine (Table 1). The

engine was coupled to a 230 kW Eddy current

dynamometer. Air and fuel consumptions were

measured with a hot-wire sensor and an electronic

balanced mass flow sensor, respectively. NO

x

were

measured with chemiluminescense analyzer. In-

cylinder combustion diagnostics was carried out

SFFEV 2016 - Special Session on Simulation of flex fuel engines and alternative biofuel vehicles

246

using a two species (air and combustion products),

single-zone model, based on the approach proposed

by (Lapuerta et al., 1999). For recording the

instantaneous in-cylinder pressure, a piezoelectric

pressure transducer installed on the glow plug and a

Kistler 5011B charge amplifier were used. The

instantaneous piston position was determined using

an angular encoder with a resolution of 1024

pulses/revolution coupled to the crankshaft at the

opposite end of the fly-wheel. The angle of start of

injection was measured with a clamp-on transducer.

Table 1: Engine specifications.

Reference ISUZU 4AJ1

Type Turbocharged, direct injection,

rotating pump

Swept volume 2499cm

3

Configuration 4 in-line cylinders

Bore x stroke 93mm x 92mm

Compression ratio 18.4

Rated Power 59kW at 4100 rpm

Maximum torque 170Nm at 2300 rpm

Tests were performed using palm oil biodiesel

(BP100), commercial grade diesel fuel and three

diesel biodiesel blends (BP5, BP20, BP50). The

properties of fuels are presented in Table 2. For each

fuel, twelve operation modes, each one characterized

by an effective torque (20, 40, 60 and 80 Nm) and

engine speed (2000, 2250 and 2500 rpm) were tested,

with NO

x

emission measurements performed in

steady state conditions.

3 RESULTS AND ANALYSIS

3.1 Experimental Analysis of NO

x

Emissions

In Table 3, the experimental results of the NO

x

measurements at different operating conditions and

blends of diesel and palm oil biodiesel are presented.

The trends in NO

x

emissions were evaluated using

statistical software. The Analysis of variance

(ANOVA) shown in Table 4 and the confidence

intervals given in Table 5 indicate that the type of

biodiesel, speed and torque affect significantly on the

NO

x

emissions.

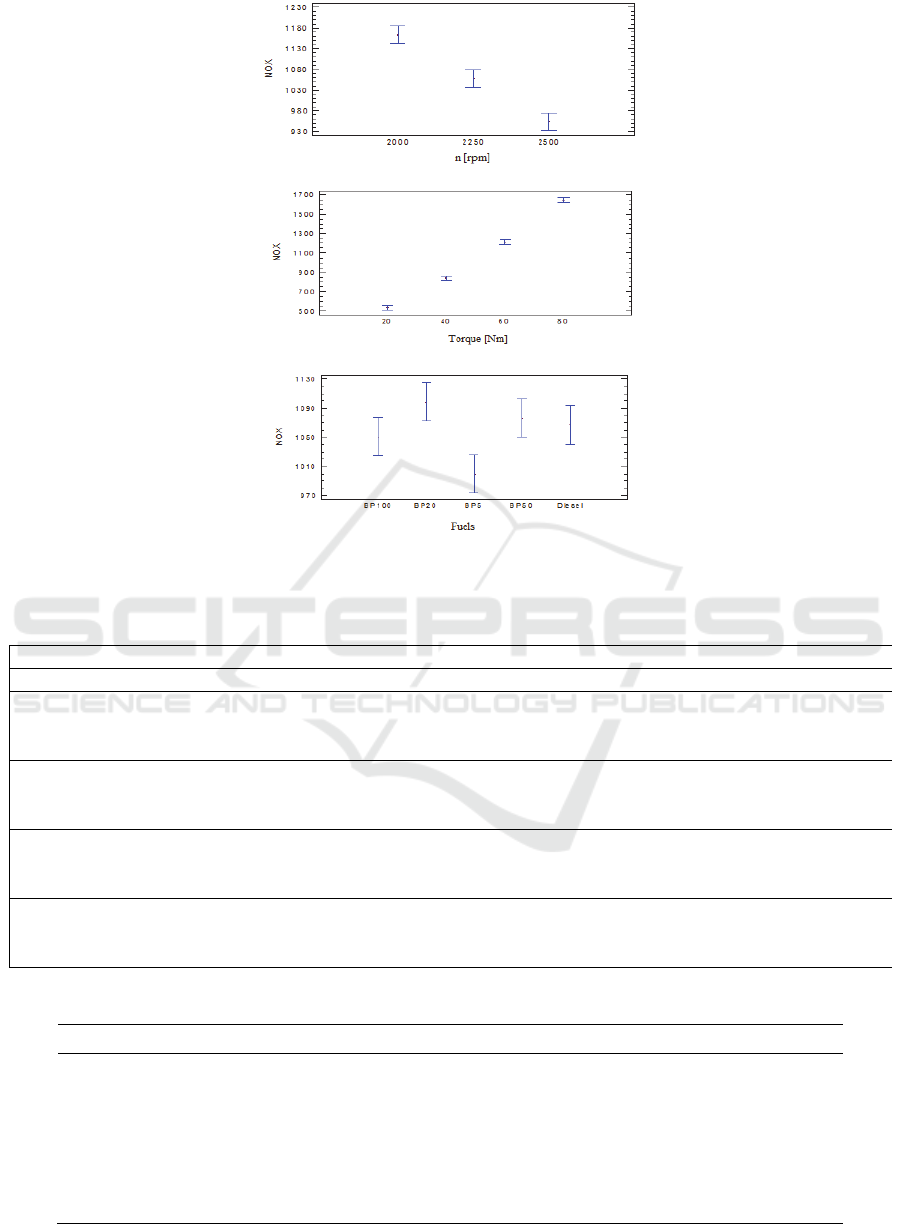

Figure 1 (a) suggests that the NO

x

formation

decreases with an increase of the engine speed for all

fuels in all torque settings. Two factors could produce

this trend, the mean temperature in the combustion

chamber and the residence time of combustion gases.

Table 6 shows the highest mean temperatures within

the combustion chamber for all operation modes and

fuel blends. Although the mean maximum

temperature increases with the engine speed at the

same load, the time of the residence of the

combustion gases decreases leading to low values of

NO

x

in the range of speeds evaluated.

It is important to highlight at this point, that in the

work of (Agudelo et al., 2010) it was observed that

the NO

x

increases with the speed of the engine in

regions near to the maximum torque of the engine (i.e.

170 Nm at speeds lower than 1750 rpm).

As it can be seen in Figure 1(b), The NO

x

formation increases as the Torque goes up. This

Table 2: Fuel properties.

Fuel Chemical Formula

(b)

Molecular

weight

(b)

[kg/kmol]

Density at

15°C [kg/m

3

]

Lower Heating

Value [kJ/kg]

(a)

Stoichiometric

air/fuel ratio

()

(c )

Diesel

.

.

.

208.2 853.4 41568 14.8

BP100

.

.

283.5 879.7 37920 12.8

BP005

.

.

.

211.1 854.7 41444 14.5

BP020

.

.

.

220.1 858.7 41075 14.2

BP050

.

.

.

237.3 866.6 40387 13.9

(a)

calculated from ultimate composition and measured gross heating value

(b)

calculated from fatty acid methyl esters profile

(c)

calculated from composition

Experimental Analysis and Modeling of NO

x

Emissions in Compression Ignition Engines Fueled with Blends of Diesel and Palm Oil

Biodiesel

247

(a)

(b)

(c)

Figure 1: Results of variance analysis for NO

x

. Means and 95% of Fisher LSD.

Table 3: NO

x

emissions at different operating conditions and blends of biofuels.

NO

x

emissions [ppm]

Torque [Nm] n [rpm] Diesel BP5 BP20 BP50 BP100

20

2000 568 601 619 602 565

2250 537 516 566 564 497

2500 468 485 491 491 486

40

2000 940 897 979 956 856

2250 854 867 862 836 805

2500 753 759 802 724 730

60

2000 1358 1159 1412 1402 1359

2250 1234 1089 1247 1228 1183

2500 1089 1079 1111 1105 1092

80

2000 1827 1508 1879 1900 1898

2250 1663 1631 1682 1646 1646

2500 1515 1409 1534 1461 1495

Table 4: Variance analysis for NO

x

emissions.

Source Sum of squares Gl Medium square F-Ratio P-Value

Principal effects

A Fuel 65783,6 4 16445,9 4,03 0,0066

B:[rpm] 442289, 2 221144, 54,19 0,0000

C:Torque [Nm] 1,03112E7 3 3,43708E6 842,22 0,0000

Residuals 204049, 50 4080,98

Total (Correction) 1,10234E7 59

SFFEV 2016 - Special Session on Simulation of flex fuel engines and alternative biofuel vehicles

248

Table 5: Mean and least squares for NO

x

emissions with confidence intervals of 95%

Level Cases Means Error Est. Lower Bound Upper Bound

Means Global 60 1058.62

Fuel

BP100 12 1051.0 (1.51%) 18.4413 1013.96 1088.04

BP20 12 1098.67 (-2.86%) 18.4413 1061.63 1135.71

BP5 12 1000.0 (6.29%) 18.4413 962.959 1037.04

BP50 12 1076.25 (-0.84%) 18.4413 1039.21 1113.29

Diesel 12 1067.17 18.4413 1030.13 1104.21

n [rpm]

2000 20 1164.25 14.2846 1135.56 1192.94

2250 20 1057.65 14.2846 1028.96 1086.34

2500 20 953.95 14.2846 925.259 982.641

Torque [Nm]

20 15 537.067 16.4944 503.937 570.197

40 15 841.333 16.4944 808.203 874.463

60 15 1209.8 16.4944 1176.67 1242.93

80 15 1646.27 16.4944 1613.14 1679.4

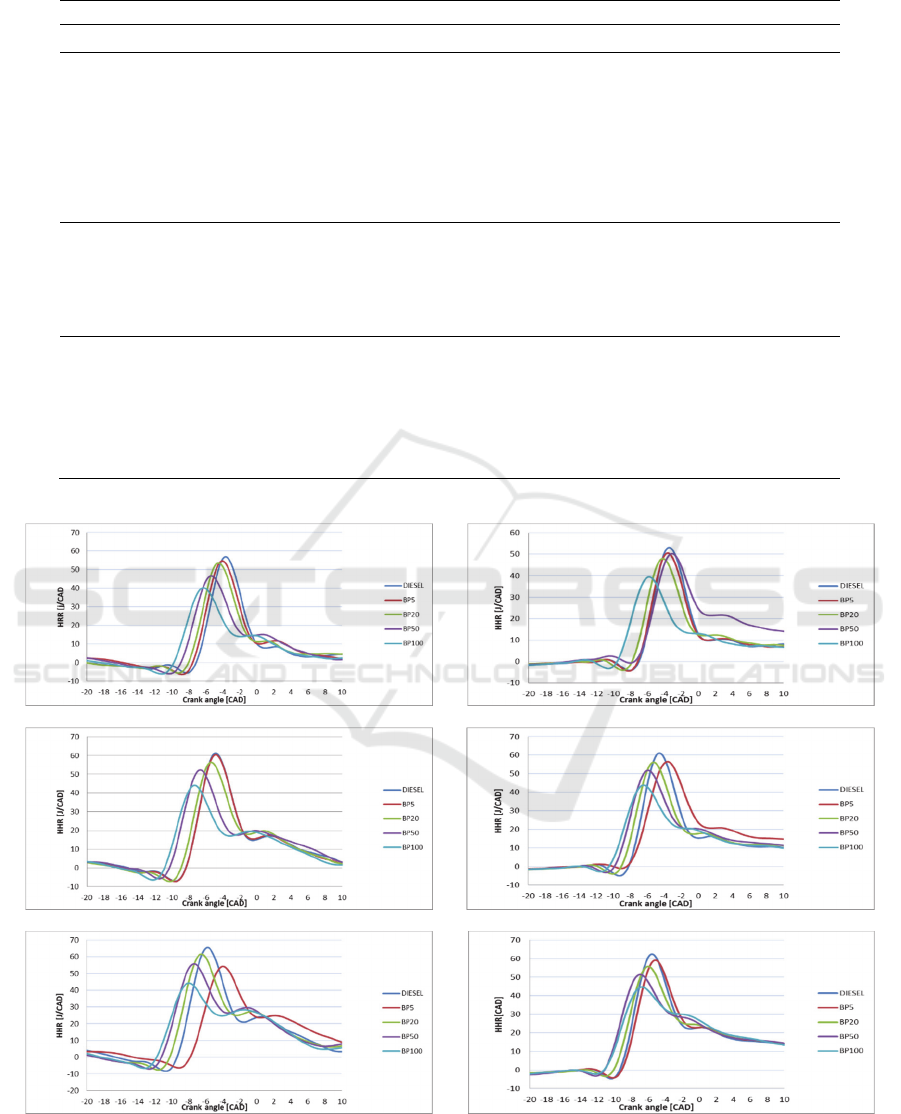

(a) (d)

(b) (e)

(c) (f)

Figure 2: Heat release curves at low loads operating conditions: 20 Nm at (a) 2000 rpm, (b) 2250 rpm, (c) 2500 rpm, and 40

Nm at (d) 2000 rpm, (e) 2250 rpm, (f ) 2500 rpm.

Experimental Analysis and Modeling of NO

x

Emissions in Compression Ignition Engines Fueled with Blends of Diesel and Palm Oil

Biodiesel

249

Table 6: Maximum mean temperature in the combustion chamber.

Maximum Mean Temperature [K]

Torque [Nm] n [rpm] Diesel BP5 BP20 BP50 BP100

20

2000 1277.23 1259.62 1310.14 1339.17 1293.06

2250 1390.79 1365.97 1419.92 1462.61 1413.00

2500 1482.81 1420.41 1542.48 1568.07 1513.18

40

2000 1291.93 1254.99 1313.07 1518.04 1300.15

2250 1423.00 1493.65 1442.08 1494.96 1429.33

2500 1550.60 1503.25 1562.17 1607.92 1544.56

60

2000 1334.43 1318.25 1339.76 1376.44 1316.89

2250 1481.05 1450.43 1503.72 1545.67 1487.73

2500 1659.09 1115.52 1605.96 1608.45 1621.06

80

2000 1531.19 1512.34 1576.29 1407.86 1575.24

2250 1634.31 1611.54 1607.21 1617.11 1595.88

2500 1688.41 1611.54 1673.49 1751.85 1681.67

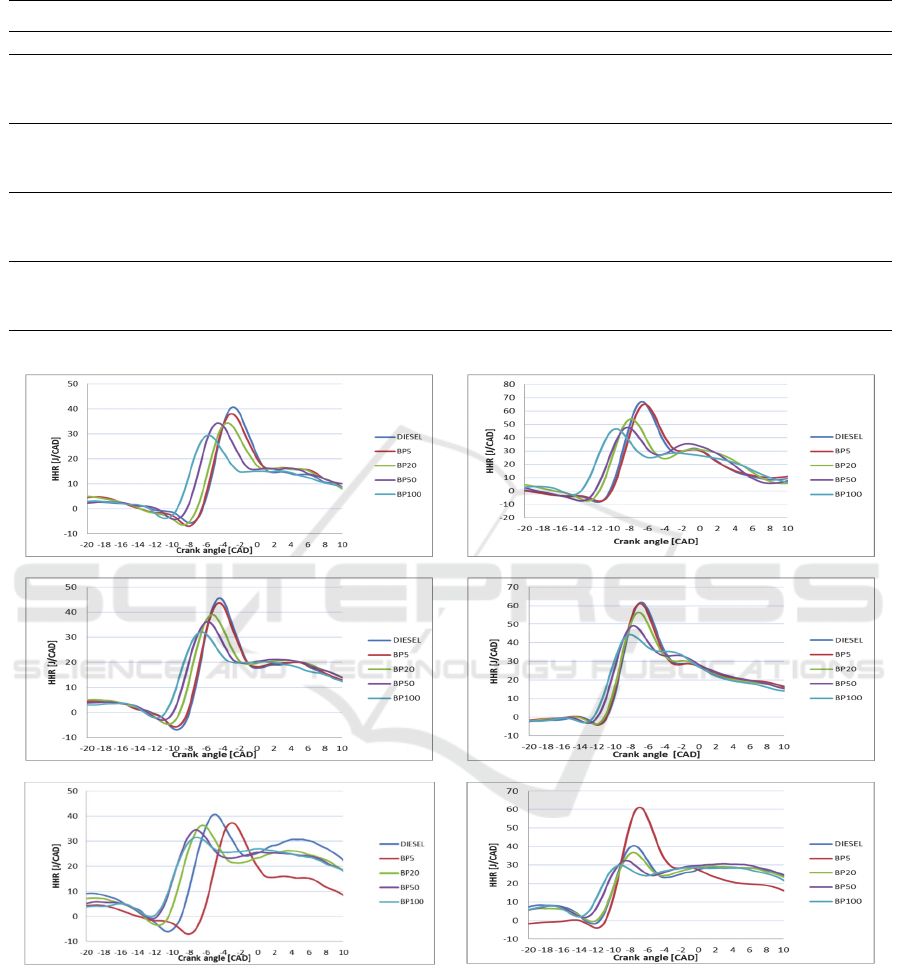

(a) (d)

(b) (e)

(c) (f)

Figure 3: Heat release curves at high loads operating conditions: 60 Nm at (a) 2000 rpm, (b) 2250 rpm, (c) 2500 rpm, and 80

Nm at (d) 2000 rpm, (e) 2250 rpm, (f ) 2500 rpm.

behavior is due to the increase of the maximum mean

temperature in the combustion chamber as shown in

Table 6. The rise of this mean temperature causes the

NO

x

formation and high loads as presented in the heat

release rate curves given in Figures (2) and (3).

Figure 2 presents the heat release rate curves at

low engine loads. As observed in this Figure, the

combustion premixed phase is predominant for all

speeds. As the load increases, the combustion

diffusion phase is dominant as presented in Figure 3,

in which according to (Dec, 1997) the highest

emissions of NO

x

are produced.

Finally, the effect of the fuel in NO

x

formation did

not present a unique trend due to the high sensitivity

SFFEV 2016 - Special Session on Simulation of flex fuel engines and alternative biofuel vehicles

250

of the engine to the operating conditions for the

blends with palm oil biodiesel. For this reason, it is

recommended for future work to determine other

physical and chemical properties such as: viscosity,

Cetane number and bulk modulus so that the effect of

type of fuels blends with palm oil biodiesel can be

better understood.

3.2 Semi-empirical Model for NO

x

Formation

The equation developed by (Timoney et al., 2005) has

been used to establish the theoretical NO

x

formation

in the combustion diffusion phase.

Table 7: NO

x

formation.

Fuel

Experimental

NO

x

[ppm]

Theoretical

NO

x

[ppm]

% discrepancy

Diesel 1515 1390 8.25

BP20 1534 1220 20.47

BP50 1461 1420 2.81

BP100 1495 1770 15.54

The operating point at 2500 rpm and 80 Nm was

used for calculating the NO

x

production thermal

mechanism due to its higher combustion diffusion

phase. The correlation was not used in the case of fuel

BP5 owing to its low combustion diffusion phase. In

Table 7 the results are summarized.

4 CONCLUSIONS

Palm oil biodiesel and its blends with diesel produce

variations in the NO

x

emissions, which increase or

decrease according to the engine operation

conditions. In general, at high loads the NO

x

emissions are increased. This behavior can be

explained for the high component of the diffusion

combustion phase. At low loads, the premixed

combustion phase is predominant, thus resulting in a

decrease of NO

x

emissions.

The correlations for determining the NO

x

formation should include parameters such as: Cetane

number, Iodine number in order to get a better

estimations taking into account the chemical and

physical features of the fuels used.

The combustion processes in diesel engines is

highly complex due to the high number of physical

and chemical interactions that occur during the

operation of the engine. Each phenomenon occurs in

tridimensional fluxes, turbulent and non-stationary,

interacting with a fuel conformed by complex chains

of hydrocarbons. In addition, a detailed chemistry

mechanism is unknown for the combustion of palm

oil biodiesel.

Lastly, it is necessary to implement optimization

techniques for parameter calibration between the

experimental and modeled values.

ACKNOWLEDGEMENTS

We would like to thank the GIMEL research group of

the Universidad de Antioquia in Medellin for the use

of the experimental facilities and advice. Also, we

would like to express our acknowledgments to

Universidad Cooperativa de Colombia and Istituto

Motori of the CNR for their financial support under

the project No. 1510 and the Cooperation Agreement

No. 0000720. COST (European Cooperation in

Science and Technology) Action FP1306 support is

also gratefully acknowledged.

REFERENCES

Agudelo, A. F., Agudelo, J. R. Benjumea, P. N., 2007.

Diagnostico de la combustion de biocombustibles en

motores, Universidad de Antioquia.

Agudelo, J., Bunjumea, P., Villegas, A. P., 2010.

Evaluation of nitrogen oxide emissions and smoke

opacity in a HSDI diesel engine fuelled with palm oil

biodiesel. Revista Facultad de Ingeniería Universidad

de Antioquia, 62-71.

Ban-Weiss, G. A., Chen, J. Y., Buchholz, B. A., Dibble, R.

W., 2007. A numerical investigation into the anomalous

slight NO

x

increase when burning biodiesel; A new

(old) theory. Fuel Processing Technology, 88, 659-667.

Dec, J. E., 1997. A conceptual model of di diesel

combustion based on laser-sheet imaging*. SAE

technical paper 970873, doi: 10.4271/970873.

Eckerle, W. A., Lyford-Pike, E. J., Stanton, D. W.,

Lapointe, L. A., Whitacre, S. D., Wall, J. C., 2009.

Effects of Methyl Ester Biodiesel Blends on NO

x

Emissions. SAE International Journal of Fuels and

Lubricants, 1, 102-118.

Fernando, S., Hall, C., Jha, S. 2006. NO

x

Reduction from

Biodiesel Fuels. Energy & Fuels, 20, 376-382.

Glaude, P.-A., Fournet, R., Bounaceur, R., Molière, M.,

2010. Adiabatic flame temperature from biofuels and

fossil fuels and derived effect on NO

x

emissions. Fuel

Processing Technology, 91, 229-235.

Guardiola, C., López, J. J., Martín, J. García-Sarmiento, D.,

2011. Semiempirical in-cylinder pressure based model

Experimental Analysis and Modeling of NO

x

Emissions in Compression Ignition Engines Fueled with Blends of Diesel and Palm Oil

Biodiesel

251

for NO

x

prediction oriented to control applications.

Applied Thermal Engineering, 31, 3275-3286.

Lapuerta, M., Armas, O., Hernández, J. J., 1999. Diagnosis

of DI Diesel combustion from in-cylinder pressure

signal by estimation of mean thermodynamic properties

of the gas. Applied Thermal Engineering, 19, 513-529.

Lapuerta, M., Armas, O., Rodríguez-Fernández, J., 2008.

Effect of biodiesel fuels on diesel engine emissions.

Progress in Energy and Combustion Science, 34, 198-

223.

Miller, J. A., Bowman, C. T., 1989. Mechanism and

modeling of nitrogen chemistry in combustion. Progress

in Energy and Combustion Science, 15, 287-338.

Park, W., Lee, J., Min, K., Yu, J., Park, S., Cho, S., 2013.

Prediction of real-time NO based on the in-cylinder

pressure in Diesel engines. Proceedings of the

Combustion Institute, 34, 3075-3082.

Sun, J., Caton, J. A., Jacobs, T. J., 2010. Oxides of nitrogen

emissions from biodiesel-fuelled diesel engines.

Progress in Energy and Combustion Science, 36, 677-

695.

Timoney, D. J., Desantes, J. M., Hernández, L., Lyons, C.

M., 2005. The development of a semi-empirical model

for rapid NO

x

concentration evaluation using measured

in-cylinder pressure in diesel engines. Proceedings of

the Institution of Mechanical Engineers, Part D:

Journal of Automobile Engineering, 219, 621-631.

Turns, S. R., 1996. An introduction to combustion,

McGraw-hill New York.

SFFEV 2016 - Special Session on Simulation of flex fuel engines and alternative biofuel vehicles

252