Numerical Analysis of a New Polymer Photonic Crystal Fiber for

Sensing Applications

Issam Haddouche and Linda Cherby

Institute of Electronics and Computer Ingeneering, USTHB University, Bab Ezzouar, Algeria

Keywords: Photonic Crystal Fiber, Optical Biosensors, Polymer, Vectorial Finite Element Method.

Abstract: In this paper a new sensor design based on the enhancement of the evanescent field of the propagating

modes is presented, the sensor is a modified Photonic Crystal Fiber (PCF) with Teflon AF used as a

background material. Assessment of the sensor's performance is made by calculating Confinement loss of

the waveguide. Full-Vector Finite Element Method is used throughout the analysis. Results show a

remarkable enhancement in the evanescent field for this sensor compared with standard PCF waveguide.

1 INTRODUCTION

Over the Past decade, Photonic Crystal Fibers (PCF)

technology earned more attention in sensing

applications, Biosensing in particular (Mescia et al.,

2009; Coscelli et al., 2010). PCFs offer more design

flexibility, remote sensing and the possibility of

greater wave field profile control thanks to the

various geometry parameters, they also possess a

wide single-mode operating wavelength range and a

very interesting light dispersion properties (Saitoh

and Koshiba, 2002).

Comparing with conventional Teflon, Teflon AF

has a very interesting feature, that is, light

transmission at infrared and visible wavelength

regions with relatively low refractive index (Yang et

al., 2008).

The design of this sensor is characterized by the

intensity of the evanescent part of the optical field,

i.e. the propagating mode inside the fiber can

interact with the outer medium (Yin et al., 2008),

and thus any disturbance in this last can be detected,

which is a very interesting feature in chemical and

Bio-sensing.

The evanescent optical power is evaluated by

calculating Confinement loss of the waveguide.

A full-vector analysis is critical in order to get

accurate and reliable results (Saitoh and Koshiba,

2002). FV-FEM was used throughout this study with

edge/nodal triangular elements (Koshiba et al.,

1994) (Koshiba and Tsuji, 2000).

In this work the performance of a Teflon AF

PCF based sensor is evaluated by calculating

Confinement loss (Cl) using a FV-FEM and a

perfectly matched layer (PML) as boundary

condition (Berenger, 1993).

2 DESCRIPTION OF THE

MODEL

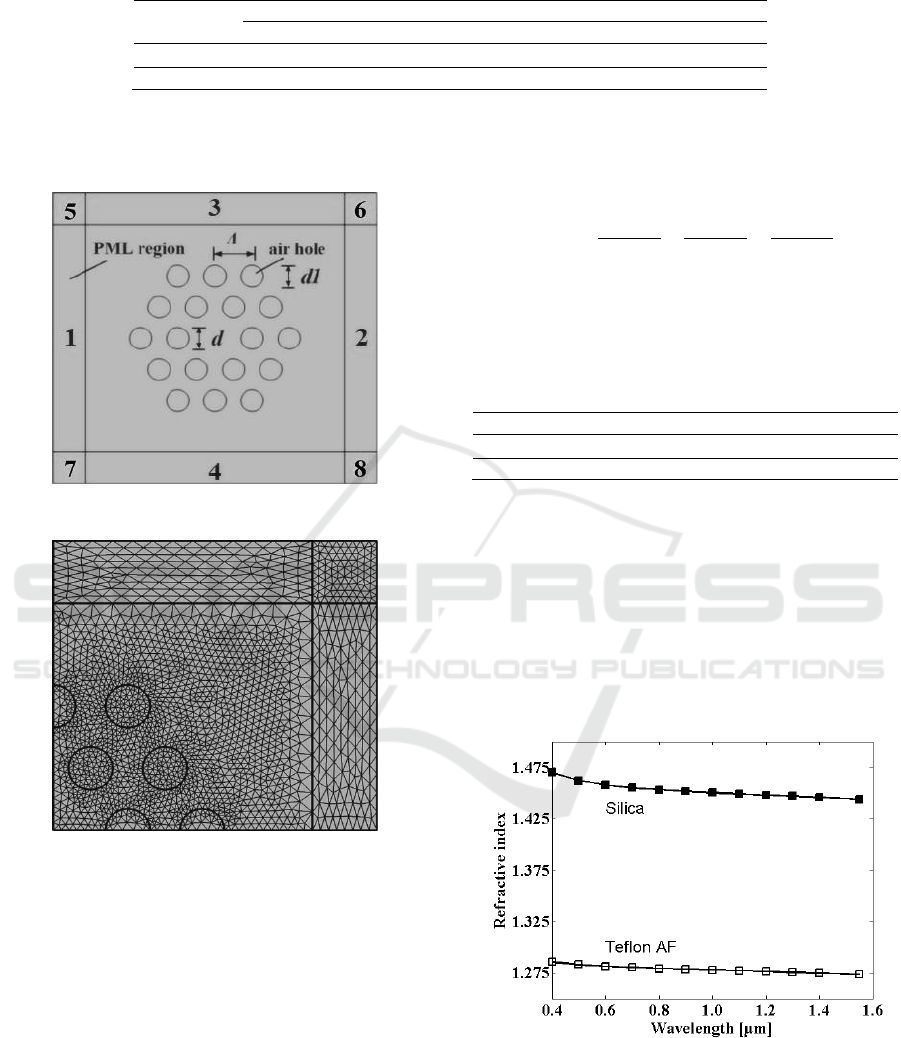

We consider in figure 1 a PCF with two rings of air

holes surrounded by a rectangular PML, with the

hole pitch denoted Λ, hole diameter of the inner ring

d and that of the outer ring d1. From Maxwell’s

equation the following vectorial wave equation is

derived (Saitoh et al., 2003):

0

(1)

where is the electric field, k

0

=2π/λ is the free

space wavenumber, λ is the wavelength, n is the

refractive index, [s] is complex and depends on s

i

(i

= 1...4) inside the PML region and equals the

identity matrix elsewhere (Saitoh et al., 2003):

⁄

00

0

⁄

0

00

(2)

s

x

and s

y

are given in table 1 for each PML region

with:

1

(3)

where i refers to zone 1...4 in the PML region, α

i

is

directly related to electrical conductivity and

Haddouche I. and lynda C.

NUMERICAL ANALYSIS OF A NEW POLYMER PHOTONIC CRYSTAL FIBER FOR SENSING APPLICATIONS.

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1: PML parameters.

PML

parameter

PML region

1 2 3 4 5 6 7 8

s

x

s

1

s

2

1 1 s

1

s

2

s

1

s

2

s

y

1 1 s

3

s

4

s

3

s

3

s

4

s

4

reflection coefficient (Viale et al., 2005), ρ is the

distance from the beginning of the PML and t

i

is

thickness of the PML layer.

Figure 1: PCF surrounded by rectangular PML.

Figure 2: Computational window with meshing.

Taking advantage of the model’s symmetry only

one quarter is discretised into edge/nodal elements

as illustrated in figure 2, which saves some

computation time, memory and enhances accuracy.

The following eigenvalue equation is derived

(Koshiba and Tsuji, 2000):

0

(4)

where [K] and [M] are the FEM global matrices, n

eff

is the effective index of the propagating modes.

The PML layer will be used to calculate the

confinement loss [dB/m] of the propagating modes

using the following relation (Saitoh et al., 2003):

8.686

(5)

Im stands for imaginary part.

Refractive indices of silica and Teflon AF are

modeled using Sellmeier equation (Yang et al.,

2008) (Paschotta).

1

(6)

The values of B

i

and C

i

are summarized in table

2.

Material Dispersion of silica and Teflon AF are

illustrated in figure 3.

Table 2: Sellmeier Equation parameters.

material B

1

C

1

B

2

C

2

B

3

C

3

Silica 0.696 0.005 0.4 0.0135 0.897 97.93

Teflon AF 0.181 0.014 1 159.28 0 0

3 RESULTS AND DISCUSSION

The confinement loss is calculated for two kinds of

PCF, the first PCF (conventional PCF) has

d1=d=1.38 µm however the second PCF (modified

PCF) differs from the first in that d1 is smaller than

d, each waveguide is modelled for the two

background materials silica and Teflon AF

.

Figure 3: Material dispersion of silica and Teflon AF.

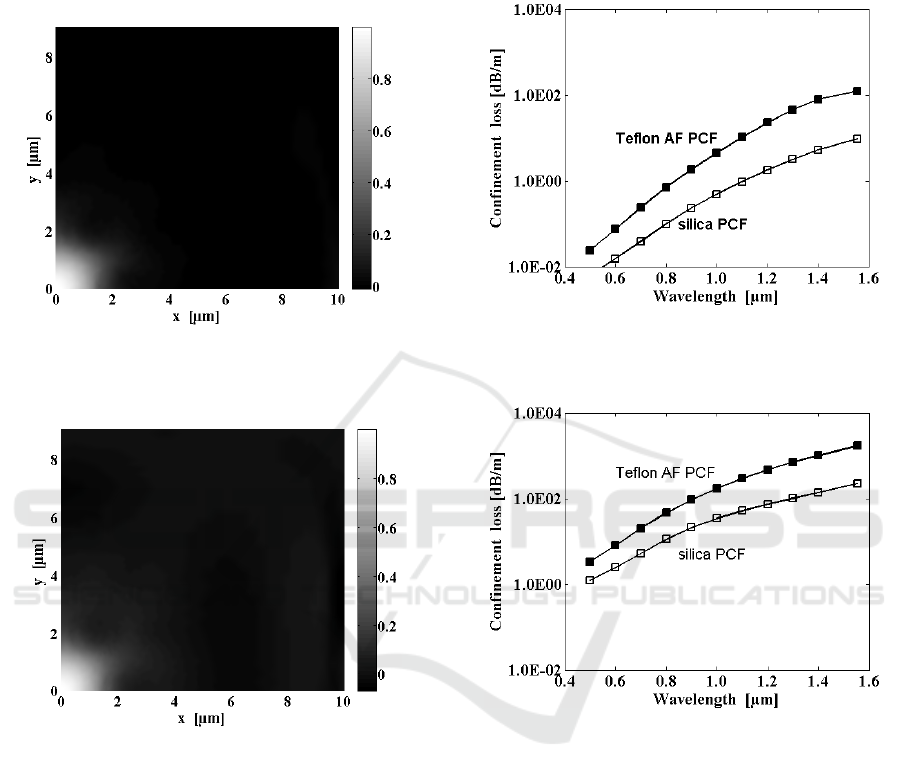

Figures 4 and 5 depict the x-component of the

electric field of the

mode of the Teflon AF

PCF for the two PCF models.

The mode field profile seems to be more

extended outside the core in the modified PCF, this

is due to the fact that the hole diameter of the outer

ring is smaller thus enhancing the evanescent field.

After solving eigenvalue equation (4), complex

n

eff

is obtained and relation (5) is used to calculate

confinement loss.

Figure 4: x-component of the electric field of the

HE

mode of the Teflon AF conventional PCF with: 18

air holes, Λ=2.3µm and d=d1=1.38µm.

Figure 5: x-component of the electric field of the

HE

mode for the modified Teflon AF PCF with: 18 air

holes, Λ=2.3µm, d= 1.38µm and d1=0.92µm.

Numerical Results are illustrated in figures 6 and

7, where confinement loss of the

mode was

calculated with respect to wavelength for

conventional and modified two rings PCFs

respectively and for two background materials. The

hole diameter of the outer ring was taken

d1=0.92µm in the modified PCF.

These results show that confinement loss

increases with wavelength, this can be explained by

the dependence of the mode field diameter (MFD)

on wavelength (Saitoh and Koshiba, 2005)

(Agrawal, 2002) i.e. the more MFD is important the

more mode profile is extended outside the core. We

can also note that Teflon AF PCF has a greater

confinement loss than that of silica PCF, this is due

to the lower index contrast in Teflon case providing

wider MFD (Saitoh and Koshiba, 2005)

(Agrawal,

2002).

Figure 6: Confinement loss plot of conventional PCF with

respect to wavelength with: 18 air holes, Λ=2.3µm,

d=1.38µm and d1=d.

Figure 7: Confinement loss plot of modified PCF with

respect to wavelength with: 18 air holes, Λ=2.3µm,

d=1.38µm and d1=0.92µm.

Reducing the hole diameter of the outer ring d1,

allows more energy to leave the core towards the

outer medium this is the reason why confinement

loss is more important in the modified PCF as

illustrated in figure 7.

4 CONCLUSIONS

A numerical study of a PCF for Biosensing

applications was presented in this paper, propagation

loss is a very important parameter in evanescent

wave based sensors, these sensors are simple, cheap

and easy to use unlike other types such as Surface

Plasmon Resonance (SPR) based sensors, and can be

used within interferometers to detect phase shift

resulting from disturbance in outer medium. As it is

well known PCFs are inherently lossy, the use of

some special materials with lower refractive indices

than silica such as Teflon AF will increase

confinement loss even more because of the lower

index contrast between the core and the cladding,

altering geometrical parameters values such as the

pitch Λ and the hole diameter d can also increase

confinement loss.

REFERENCES

L. Mescia, F. Prudenzano, L. Allegretti, 2009. Design of

silica based photonic crystal fiber for biosensing

applications, Journal of Non-Crystalline Solids 355.

Coscelli, E, M. Sozzi, F. Poli, 2010. Toward A Highly

Specific DNA Biosensor: PNA-Modified Suspended-

Core Photonic Crystal Fibers, IEEE Journal of

Quantum Electronics, Vol. 16, No. 4, 967–972.

Saitoh, K, M. Koshiba, 2002. Full-vectorial imaginary-

distance beam propagation method, IEEE Journal of

Quantum Electronics, Vol. 38, No. 7, 927–933.

Yang, M. K., R. H. French, E. W. Tokarsky, 2008. Optical

properties of Teflon® AF amorphous fluoropolymers,

J. Micro/Nanolith. MEMS MOEMS, Vol. 7, No. 3, 1–

9.

S. Yin, C. Zhan, P. Ruffin, 2008. Fiber optic sensors.

Koshiba, M, S. Maruyama, K. Hirayama, 1994. A vector

finite element method with the high-order mixed-

interpolation-type triangular elements, Journal of

lightwave technology, Vol. 12, No. 3, 495–502.

Koshiba, M, Y. Tsuji, 2000. Curvilinear hybrid

edge/nodal elements with triangular shape for guided-

wave problems, Journal of lightwave technology, Vol.

18, No. 5, 737–743.

Berenger, J., 1993. A perfectly matched layer for the

absorption of Electromagnetic waves, Journal of

computational physics, Vol. 114, 185–200.

Saitoh, K, M. Koshiba, T. Hasegawa, E. Sasaoka, 2003.

Chromatic dispersion control in photonic crystal

fibers: application to ultra-flattened dispersion, Optics

express, Vol. 11, No. 8, 843–852.

Viale, P, S. Février, F. Gérome, H. Vilard, 2005.

Confinement Loss Computations in Photonic Crystal

Fibres using a Novel Perfectly Matched Layer Design,

COMSOL Multiphysics User's Conference Paris.

R. Paschotta, Sellmeier Formula, RP Photonics,

https://www.rp-photonics.com/sellmeier_formula.html.

Saitoh, K, M. Koshiba, 2005.Numerical Modeling of

Photonic Crystal Fibers, Journal Of Lightwave

Technology, Vol. 23, No. 11, 3580- 3590, November.

G. P. Agrawal, 2002. Fiber-Optic Communications

Systems, Third Edition, Wiley, pp. 33-37.