Laser-based Soldering Technique for Hermetical Sealing of the

Calibration Target for the Exomars’ Raman Instrument

Thomas Burkhardt

1

, Michael Seifert

1

, Pol Ribes

1,2

, Nicolas Lange

1

, Guillermo Lopez-Reyes

3

,

Andoni Moral-Inza

4

and Antonio Sansano

3

1

Fraunhofer Institute for Applied Optics and Precision Engineering IOF, Albert-Einstein-Str. 7, 07745 Jena, Germany

2

Institute of Applied Physics IAP, Friedrich-Schiller University Jena, Max-Wien-Platz 1, 07743 Jena, Germany

3

Unidad Asociada UVA-CSIC-CAB, Universidad de Valladolid, Parque Tecnológico Boecillo, 47151 Valladolid, Spain

4

Instituto Nacional del Tecnica Aerospacial INTA, Ctra Ajalvir Km4, 28850 Torrejón de Ardoz, Spain

Keywords: ExoMars Raman Laser Spectrometer, Calibration Target, Laser-based Soldering, Solderjet Bumping,

Hermetical Sealing.

Abstract: We propose the laser-based Solderjet Bumping as a full inorganic joining technique for the hermetical

sealing of a possible calibration target container for the ExoMars Raman Laser Spectrometer. This

technique allows the adhesive free bonding in a flux free and localized soldering process. We show a finite

elements analysis based optimization of a soldering adapted design for the calibration target container.

Current experimental results document hermetical sealing of a stainless steel tube with BK7 and D263

windows with a helium leakage rate down to 5·10

-6

mbar·l·s

-1

.

1 INTRODUCTION

1.1 Motivation

In 2018 ESA/Roscosmos will launch the ExoMars

Rover mission. The main target of this mission is to

study the Martian environment and to test new

technologies paving the way for a possible Mars

return mission in the 2020s. Raman spectroscopy is

a tool for the chemical and structural identification

of (sub-)surface materials and organic analysis to

address the scientific objective of the Pasteur

payload to search for evidence of past and present

life on Mars (Rull Pérez and Martinez-Frias, 2006;

Escudero et al., 2008). The Raman Laser

Spectrometer (RLS) is together with the MicrOmega

(IR spectrometer) and the Mars Organic Molecule

Analyzer (MOMA) part of the rover’s analytical

laboratory drawer (ALD). They are key exobiology

experiments on the ExoMars rover mission to

examine the chemical composition of geological

samples acquired from depths of up to two meters,

where possible organic molecules may be protected

from destructive cosmic radiation and/or oxidative

chemical reactions (Arevalo et al., 2015). For

calibration of the RLS on board the rover, a

calibration target (CT) will be included. This allows

periodic calibration of the instrument for high

precision and to evaluate the health of the system

during the mission (Sansano et al., 2014). During

each analysis (several hours), at least 20 spectra at

different points of the sample will be acquired.

Before each experiment cycle, the CT will be used

to assess the calibration status of the whole

instrument in an end-to-end calibration, including

the laser optical head, harness, spectrometer, and

electronics. There will be at least 22 experimental

cycles, each of them with a different sample.

As the CT will be located in the ultra clean zone

(UCZ) of the ALD, the CT container is to be

suitably sealed. It needs to comply with planetary

protection requirements to prevent biological

contamination of Mars to preserve its pristine nature

and also to prevent the corruption of the mission’s

experiments. To achieve this ambitious protection

and contamination control COSPAR Cat IVb

classification measures are implemented to avoid the

terrestrial contamination of the analyzed samples.

According to Richter et al. (2015) this addresses the

whole Sample Processing and Distribution

Subsystem (SPDS) and includes the pressurized

UCZ (pressurized during launch, transfer, and

landing), sterilization of the ALD sample chain, ultra

Burkhardt, T., Seifert, M., Ribes, P., Lange, N., Lopez-Reyes, G., Moral-Inza, A. and Sansano, A.

Laser-based Soldering Technique for Hermetical Sealing of the Calibration Target for the Exomars’ Raman Instrument.

DOI: 10.5220/0005653200550061

In Proceedings of the 4th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2016), pages 57-63

ISBN: 978-989-758-174-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

57

cleaning of the ALD sample chain components, and

integration of the hardware in a high cleanliness

environment.

1.2 Solderjet Bumping Technique

We propose the laser-based Solderjet Bumping as a

full inorganic joining technique for the hermetical

sealing of a possible CT container candidate. It

allows the adhesive free bonding of heterogeneous

materials, e.g. metals with glass, in a flux free

process. The soldered assembly is therefore

completely free of undesired organic compounds.

Furthermore the solder joints are able to withstand

high thermal loads during sterilization and high

energetic radiation, e.g. cosmic radiation during

transfer of the lander to and its mission on Mars.

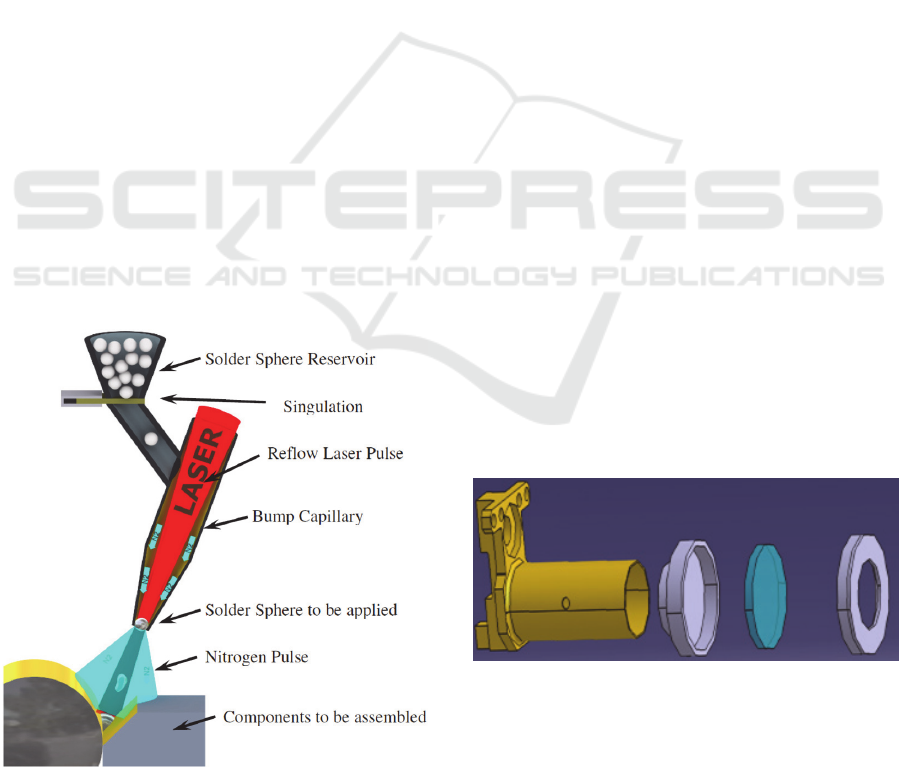

Solderjet Bumping (Figure 1) is a laser-based

soldering process that is especially well suited for

the joining of optical components made of fragile

and/or brittle materials like glasses or ceramics.

Spherical solder preforms that consist of soft solders

alloys, e.g. tin-based lead-free solders or eutectic

gold-tin, are used in a diameter range of 60 µm to

760 µm. These spheres are transferred from a

reservoir to a placement capillary next to the joining

geometry of the components to be bonded together.

After positioning, the material is molten by a fiber-

coupled, infrared laser pulse and jetted out of the

capillary. Nitrogen is used as an inert gas flow. The

liquid solder droplets account for a very good

thermal contact of the alloy with the components.

Figure 1: Solderjet Bumping operation principle (Beckert

et al., 2010).

We have demonstrated the versatility of this

technique for the high accuracy packaging of

photonic micro-systems (Beckert et al., 2010).

Hermetical sealing of biomedical devices (Beckert et

al., 2011) and the vacuum compatibility of soldered

assemblies for the use in electron beam lithography

(Burkhardt et al., 2011) have been proven. We

presented Solderjet Bumping for optical

instrumentation in aerospace applications (Burkhardt

et al., 2015). The technique has been used for the

manufacturing of a compact and robust, solid-state

laser for the ExoMars mission and was tested at

thermal and radiation (proton and gamma) loads

(Ribes et al., 2015).

2 DESIGN AND OPTIMIZATION

2.1 Requirements

The CT consists of a cylindrical, stainless steel

container of 5..6 mm diameter. A cavity in the

container will be covered by a thin glass window,

fused silica and BK7 will be discussed as candidates.

The window will contain the calibration sample and

needs therefore to be hermetically sealed to prevent

organic molecular contamination of the UCZ. A

mixture of powdered standard compounds (both

organic and inorganic) with a known spectral Raman

response covering the entire spectral range will be

filled in this sealed envelope (Sansano et al., 2014).

Regarding the calibration sample both an

encapsulated mixture – a pill with diameter 4 mm

and thickness 3 mm – and non-encapsulated powder

are discussed. The main laser characteristics during

calibration are continuous operation at 532 nm, with

50 mW optical output power that is focused on

50 µm diameter spot on the sample.

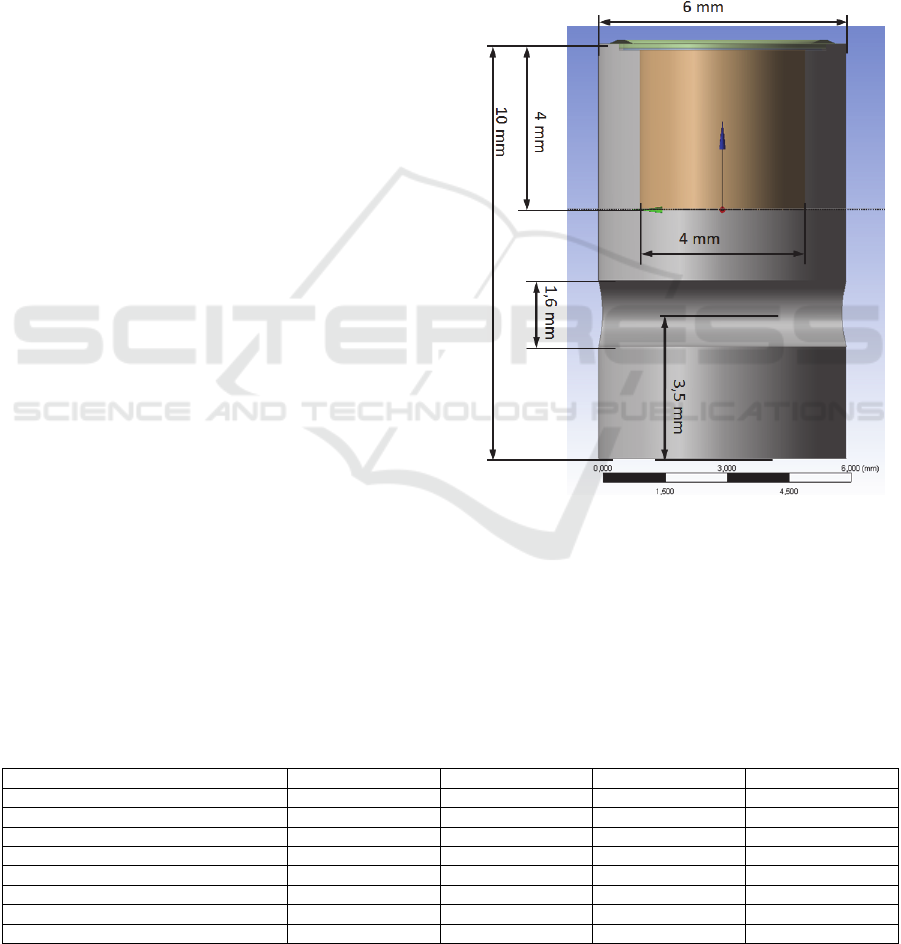

Figure 2: Design proposal of CT holder elements (Sansano

et al., 2014).

BK7 is selected over its radiation resistant

counterparts (e.g. BK7G18) for multiple reasons.

These include availability as thin glass sheets and

manufacturability to the designed shape, its

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

58

thermomechanical properties with respect to the

stainless steel receptacle. A trade-off in BK7’s

preferability for space applications in terms of

radiation damage is accepted as radiation

obscuration is well characterised for ionising and

non-ionising doses is accepted for a known Raman

signature of the material. Given that the window of

the CT container would be placed very deep inside

the ALD of the rover the expected radiation levels

should not to be a major concern for the obscuration

of the window.

Due to obvious weight restrictions the maximum

required weight is 9 g with a further decrease to 4 g

during STM (structural and thermal model) design.

Figure 2 shows the design proposal of a CT and

holder elements as a basis for the design

considerations of a CT suitable for Solderjet

Bumping. The required envelope, including the

support, is the one contained in a parallelepiped of

13×26.3× 10.9 mm³.

The thickness of the glass window is required to

be 100 µm maximum. A maximum height difference

between the top surface of the window and the

solder joint of 50 µm is permitted. This is necessary

for the CT to be within the agreed envelope for

avoiding any interference with the rover’s carrousel

powdered sample flattener.

2.2 Design and FEA Results

Based on the requirements of the CT a model of the

receptacle is developed to simulate and evaluate

thermomechanical, shock, acceleration, and

vibrational loads. Different solder joint geometries

are investigated and optimized according to the

results of the finite elements analysis (FEA).

Figure shows the model and initial dimensions

used in FEA simulations and optimization. The

simplified model omits the enclosed powder sample

as thermomechanical simulations will not be

affected as there is no transfer of forces or momenta.

In dynamic simulations the powder would act as an

additional mass, dampening the response behavior of

the whole receptacle thus the simulated empty

system shows the worst case results.

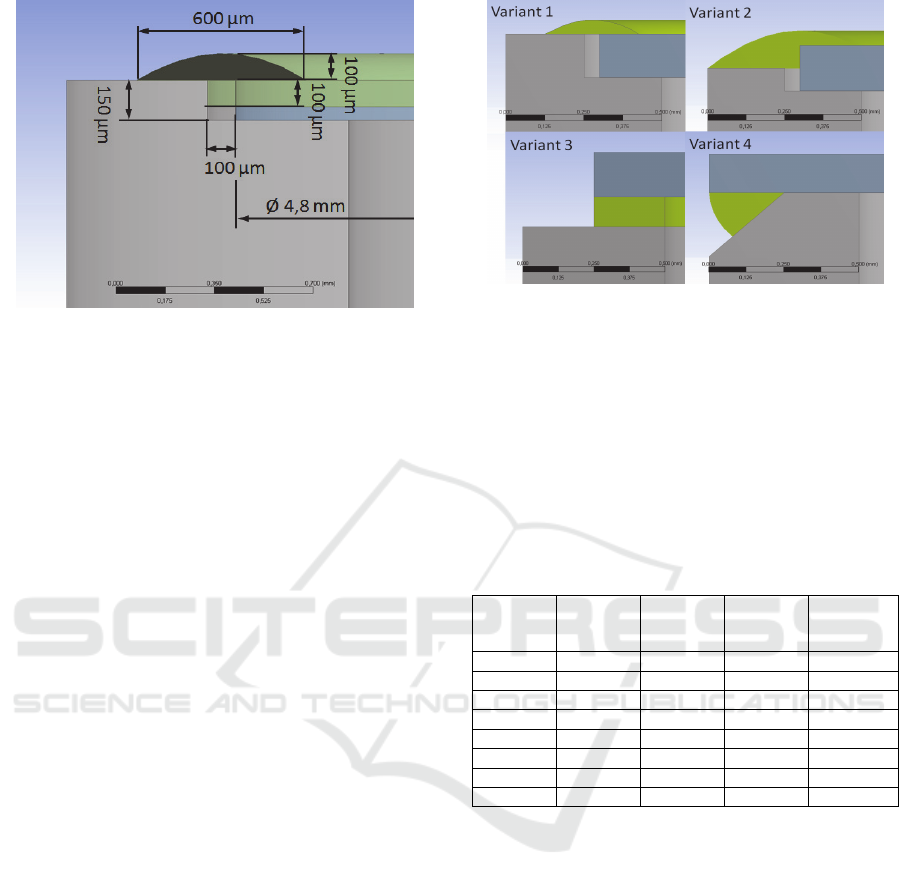

Details of the solder joint showing the receptacle,

the window, and the solder itself are depicted in

Figure 4. A gap of 100 µm between receptacle and

window is assumed to accommodate for

manufacturing tolerances. Initial simulations

assumed the shown 600 µm width and 100 µm

height of the solder joint to bridge this gap. These

values could be achieved using a solder sphere

diameter of 400 µm, overlapping placement, and

typical, experimentally validated wetting behavior.

Figure 3: Simulated receptacle with dimensions.

Material parameters used for the simulations for

the stainless steel, the window (both fused silica and

BK7), and the solder alloy (SAC305 = Sn3Ag0.5Cu)

are listed in Table 1. The equivalent Von-Mises

stresses as well as the total deformation are

evaluated in all three individual parts: receptacle,

glass window, and solder ring.

Table 1: Material parameters used for FEA simulations.

Stainless Steel Fused Silica BK7 SAC305

Young’s Modulus / GPa 193 73.2 82 44

Poisson’s Ratio 0.31 0.17 0.21 0.36

Density 7.75 2.02 2.2 7.4

CTE / 10

-6

·K

-1

17 0.56 7.1 22.4

Thermal Conductivity / W·m

-1

·K

-1

15.1 1.4 1.1 56.3

Specific Heat / J·kg

-1

·K

-1

480 750 858 283

Yield Strength / MPa 207 N/A N/A N/A

Ultimate Tensile Strength / MPa 586 50 63.5 45

Laser-based Soldering Technique for Hermetical Sealing of the Calibration Target for the Exomars’ Raman Instrument

59

Figure 4: Detail of the solder joint of the receptacle with

initial design values.

2.3 Design Optimization

2.3.1 First Iteration

First thermomechanical simulations according to the

model presented in Figure 3 and Figure 4 and a

temperature range from -60 °C to +130 °C show

maximum stresses in the solder of 229 MPa and in

the window (fused silica) of 133 MPa. Both

significantly exceed the ultimate tensile strength

(UTS) of these materials (see Table 1) which is

mainly caused by the large mismatch of the

coefficient of thermal expansion. Static structural

acceleration, transient structural shock, harmonic

load, and random vibration simulation all show

acceptable stress levels with a minimum safety

factor of 8.5. The results are not presented here as

the model had to be refined to improve the thermal

behavior.

To avoid damage to the solder and window a

design optimization is investigated. Besides a

reduction in differential thermal expansion (DTE) a

few concepts are followed and simulated

accordingly. A promising approach is a changed gap

between the components, a thicker glass material, a

cylindrical geometry with reduced stiffness at the

top of the receptacle, and a change in geometry of

the solder joint.

A refined geometry with reduced stiffness at the

top of the receptacle minimizing DTE to relief stress

uses a reduced wall thickness of the cylinder of

0.5 mm compared to initial 1 mm. The gap between

cylinder wall and window is decreased – a measure

that requires tighter tolerances for the experimental

samples. Furthermore the solder joint size is

decreased both in width and thickness, which will

experimentally be realized by using smaller solder

spheres (diameter 100 µm or 150 µm).

Figure 5: Refined geometries of iteration 1.

In addition to the changed geometry the

simulations were done with Fused Silica as well as

BK7 as glass material. The advantage is the

significantly increased CTE of BK7, lowering the

DTE with respect to the steel tube, and the increased

UTS compared to Fused Silica (see Table 1). Four

geometries are investigated as shown in

Figure.

Table 2: Maximum Von-Mises stresses in solder joint and

glass window for thermal load of 130 °C and calculated

minimum safety factors (FS denotes Fused Silica).

Type

Solder

Stress /

MPa

Solder

Safety

Factor

Window

Stress /

MPa

Window

Safety

Factor

V1, FS 378 0.12 240 0.21

V1, BK7 232 0.19 162 0.39

V2, FS 381 0.12 155 0.32

V2, BK7 258 0.18 109 0.58

V3, FS 209 0.22 158 0.32

V3, BK7 138 0.33 109 0.58

V4, FS 1380 0.03 269 0.19

V4, BK7 881 0.05 183 0.35

Table 2 lists the resulting maximum Von-Mises

stresses for a thermal load of 130 °C and the

respective minimum safety factors using UTS values

as listed in Table 1. While the stresses in the solder

and the glass window still significantly exceed the

materials UTS an improvement due to the use of

BK7 can be observed. This is traced back to the CTE

which is 12 times higher for BK7 than for Fused

Silica and the 13.5 MPa higher UTS. Variants 1, 2,

and 4 show stress distributions with very localized

peaking that indicate a potential improvement by

refining the geometry.

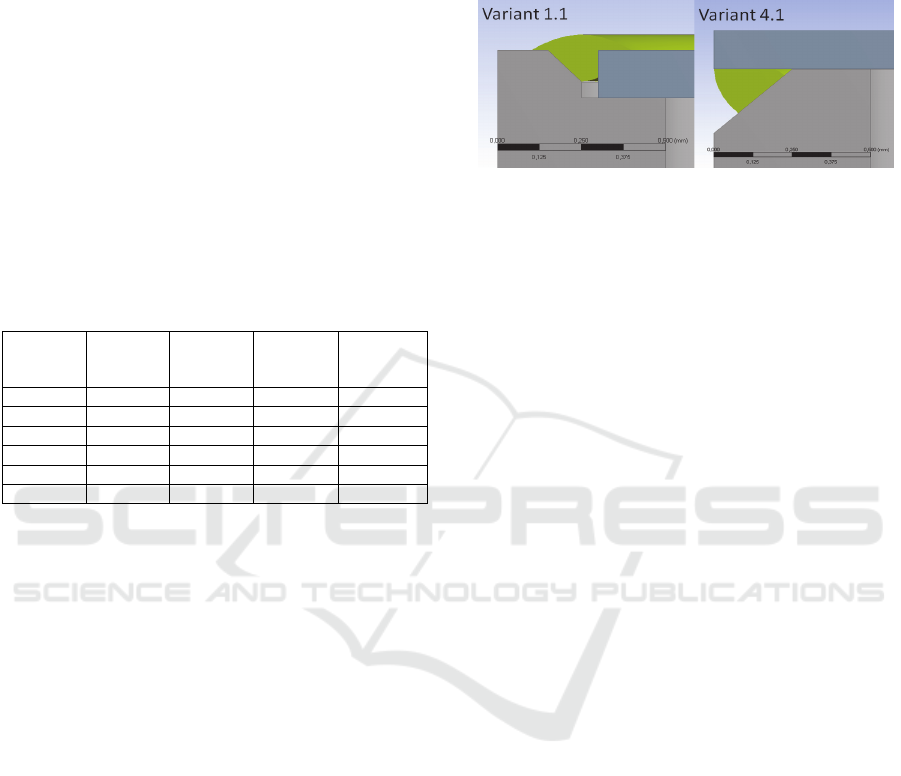

2.3.2 Second Iteration

Based on the results for the four variants discussed

in the previous sub subsection, the geometries for

three variants are further refined and simulated again

under the same conditions. Due to overall low

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

60

stresses variant 2 will not be refined further.

Variants 1, 3 and 4 on the other hand are showing

potential for further improvements and are therefore

further investigated. In addition plasticity of the

solder alloy is added to the model to create a more

realistic representation. Figure 6 shows the improved

geometries 1.1 and 4.1 with rounded edges to

minimize stress. Variant 3.1 is similar to variant 3 as

depicted in Figure 5 with a decreased solder layer

thickness of 50 µm. Table 3 lists the maximum Von-

Mises stresses for a thermal load of 130 °C

respective minimum safety factors using UTS values

as listed in Table 1 for the improved designs both for

elastic and plastic modelling of the solder.

Table 3: Maximum Von-Mises stresses in solder joint and

glass window for thermal load of 130 °C and calculated

minimum safety factors for second design iteration.

Calculations using plasticity are marked with an asterisk.

Type

Solder

Stress /

MPa

Solder

Safety

Factor

Window

Stress /

MPa

Window

Safety

Factor

V1.1 238 0.2 101 0.6

V1.1 * 51 0.9 75 0.8

V3.1 163 0.3 110 0.6

V3.1 * 48 0.9 85 0.8

V4.1 259 0.2 167 0.4

V4.1 * 52 0.9 113 0.6

The plasticity allows the solder alloy to balance

and even out the occurring stresses in the

components, thus increasing the minimum stresses

but decreasing the maximum stresses. As a result the

minimum safety factors increase and the maximum

safety factors decrease (note that only minimum

safety factors are listed in Table 3). Considering

these changed stress and safety factor conditions,

variant 1.1 (as calculated with plasticity) shows the

optimal compromise of a sufficiently high minimum

and maximum safety factor in all three components.

In addition variant 1.1 has the best prerequisites for

the technological realization in contrast to the more

complicated solder process required for variant 3.1

and 4.1. With refining the geometries of the three

chosen variants the occurring stresses could be

further reduced. By introducing the plasticity to

material formulation of the solder alloy said stresses

were successfully smoothed and balanced in all three

components, reducing the extreme values.

All evaluations were done with the absolute

maximum stress values that occur at each

component representing the worst case. The average

stress in each component is expected to be

significantly lower and indicates the possible use of

soldering the proposed assemblies. Transient and

dynamic mechanical load cases were simulated for

the optimized models and show minimum safety

factors of 14.5 and a first Eigenfrequency of 50 kHz.

Considering these mechanical loads an assembly of

the CT using Solderjet Bumping seems feasible.

Figure 6: Refined geometries of iteration 2.

3 EXPERIMENTAL RESULTS

As suggested by the results variants 1 and 1.1 are the

most promising candidates for successful soldering.

Furthermore variants 3.x and 4.x require

significantly more elaborate handling equipment.

Experimental verification as reported in this paper is

therefore using samples made according to design

variants 1 and 1.1.

Due to commercial availability one batch of

experiments was conducted using D263 glass which

shows similar thermomechanical properties as BK7

especially an equivalent CTE but is available as thin

sheet glass (thickness 145 µm). These samples were

prepared at IOF from sheets. The second batch of

experiments was done using BK7 windows with a

thickness of 175 µm. These samples were also

prepared at IOF from sheets. A third batch of BK7

samples was procured from Laser Optex, China,

with a thickness of 150 µm ± 2 µm.

Both the windows and the stainless steel cylinder

are covered by a solderable thin film metallization. It

is provided by physical vapor deposition and

consists of three layers: titanium, platinum, and

gold. The metallization system has an overall

thickness of approx. 500 nm. Titanium acts as

adhesion promoter, platinum as diffusion barrier,

and the wettable, non-oxidizing gold finish supports

the required flux-free processing to achieve a clean

solder joint. (Banse et al., 2005) reported this system

among others as a suitable and well adhering

metallization for glass materials.

3.1 Soldering and Optical Inspection

Soldering is conducted using a solder sphere

diameter of 100 µm and 150 µm according to the

optimized design of the solder joints. Relevant

Laser-based Soldering Technique for Hermetical Sealing of the Calibration Target for the Exomars’ Raman Instrument

61

parameters for the laser-based Solderjet Bumping

are the reflow energy governed by laser pulse width

and laser current. Using glass slides these parameter

sets are evaluated to find proper wetting of the

solder in the substrate while preventing damage to

the glass. The latter is especially an issue with

soldering as thermal shock can cause cracks to form

and propagate in the glass leading to failures of the

bond. We found suitable parameters as listed in

Table 4. The increased necessary energy

corresponds well to increased solder volume and

mass (approx. factor 3.4). These investigations show

the limited parameter space for soldering thin sheet

glass and the possible issues with soldering near the

edges of said glass sheets.

Table 4: Laser reflow parameter sets.

Solder

Sphere

Diameter /

µm

Laser

Current /

mA

Laser Pulse

Width /

ms

Puls Energy

/

mJ

100 1500 1 7.4

150 1700 2.4 22.5

Glass windows are inserted in the stainless steel

tube, adjusted for an even and symmetrical

distribution of the gap around the circumference,

and kept in place by application of vacuum. A bond

height – the distance of the Solderjet’s placement

capillary to the soldered components – of 350 µm

for 100 µm solder spheres and 550 µm for 150 µm is

used. These distances are selected to provide

undisturbed application of the liquid solder droplet

with minimized deviation of placement accuracy.

Soldering is a sequential process to subsequently

place multiple overlapping bumps. We investigated

different placement strategies, e.g. an interlaced

placement scheme and multiple turns to

accommodate for a larger gap between window and

tube due to issues with tolerances. We did not find a

significant influence of the placement scheme on

leakage rate as long as a completely closed solder

joint is achieved and no holes are observable by

visual inspection. Placement of solder droplets is

done in an automated system using a vision system

and a circular fit to adjust the machine’s tool path

with the outline of the sample. A total of 288 bumps

per turn are placed at a solder sphere diameter of

100 µm and 232 bumps per turn for 150 µm preform

diameter, respectively.

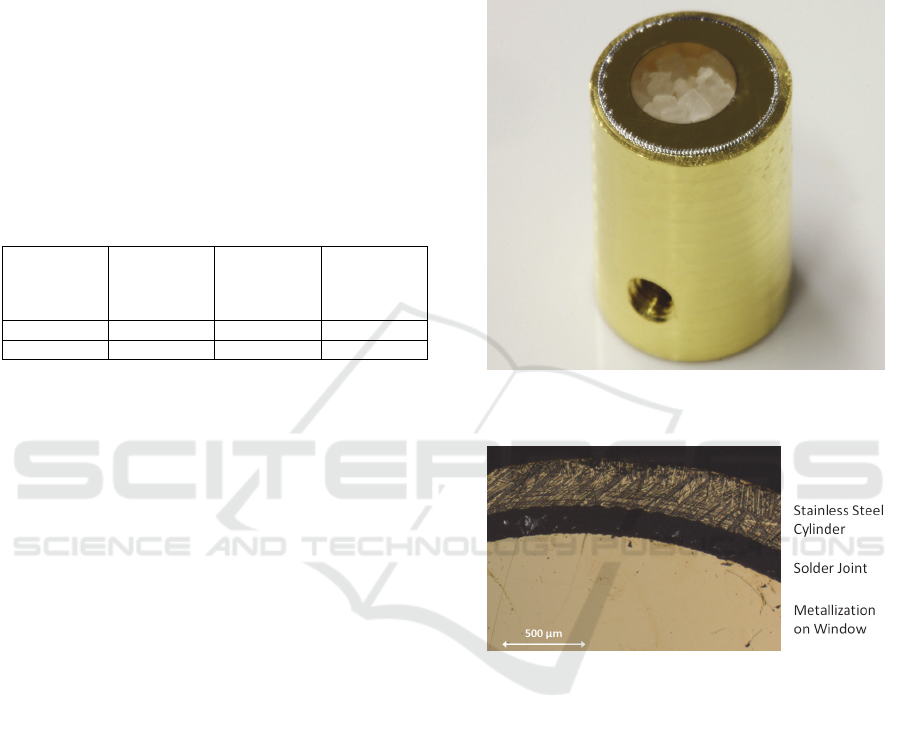

Figure 7 shows a sealed CT filled with mock-up

sample compound. The total weight of the sample is

less than 2 g within the STM design limit. A total

height of the solder joint of less than 50 µm is

achieved using solder droplet diameters of 100 µm.

Figure 8 shows a top view photomicrograph of the

sample and the solder joint. It illustrates clearly the

regular and clean overlapping placement of multiple

solder droplets in the bond zone to provide proper

mechanical fixation of the window as well as

hermetical sealing.

Figure 7: Sealed calibration target filled with mock-up

sample compounds and BK7 window.

Figure 8: Photomicrograph of solder joint.

3.2 Helium Leakage Testing

For measuring the leakage rate a Leybold Inficon

UL200 was used. Minimum detectable leakage rate

in vacuum mode is 5·10

-11

mbar·l·s

-1

. For testing, the

cylinders were fixed with an adapter to the leak

tester and evacuated. The soldered windows were

then sprayed with Helium and the leakage rate was

measured.

For batch one using D263 glass, thickness

145 µm, out of seven samples we found one sample

exceeding 5·10

-6

mbar·l·s

-1

, three samples exceeding

10

-4

mbar·l·s

-1

, and one sample exceeding 10

-2

mbar·l·s

-1

.

With BK7 glass, thicknesses of 175 µm and

150 µm, out of eight samples we found two samples

exceeding 10

-4

mbar·l·s

-1

, two samples exceeding

PHOTOPTICS 2016 - 4th International Conference on Photonics, Optics and Laser Technology

62

10

-3

mbar·l·s

-1

, and three sample exceeding 10

-2

mbar·l·s

-1

. A major issue is the surface quality of the

window’s edges. We observe the formation of

micro-cracks during soldering which in turn

significantly increase leakage rate. While the

procured windows show a very narrow thickness

tolerance, the edges are not polished and therefore

susceptible to crack induced by thermal shock.

4 CONCLUSIONS

We have shown the hermetical sealing of a multi-

material assembly for the possible use as a

calibration target container for the ExoMars Raman

Laser Spectrometer. Proof-of-concept samples made

of stainless steel and D263 achieved leakage rates of

5·10

-6

mbar·l·s

-1

. The bonding is completely

inorganic and therefore suitable for high cleanliness

and contamination free applications, e.g. under

COSPAR planetary protection requirements.

A FEA tool chain and models were set up for

optimization of joint geometries and were used to

provide appropriate design recommendations for

minimized stresses. Mechanical and

thermomechanical load cases were investigated by

numerical simulations. A minimized differential

thermal expansion is found to be necessary to

achieve acceptable stress levels in the solder joint.

Although the presented design of the container

and therefore the proposed bonding will not be used

for the RLS CT the results show the adequacy of

Solderjet Bumping for hermetical sealing and

aerospace applications. The development activities

continue and the technology is kept as a backup plan

for the ExoMars RLS CT.

Further improvements of leakage rate and

reduced failures during bonding are expected with

optimized sample geometries, improved surface

quality of the windows’ circumferential side faces,

and adapted tolerances between receptacle and

window. A goal would be to achieve a helium

leakage rate better than 10

-8

mbar·l·s

-1

. Experimental

qualifications based the mechanical and thermal load

cases considered for the numerical optimizations

have to be conducted with further samples.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge funding from

MINECO, Spain, through project ESP2013-48427-

C3-2-R.

REFERENCES

Arevalo, R., Brinckerhoff, W., van Amerom, F., Danell,

R., Pinnick, V., Xiang Li, Getty, S., Hovmand, L.,

Grubisic, A., Mahaffy, P., Goesmann, F., Steininger,

H., 2015, Design and demonstration of the Mars

Organic Molecule Analyzer (MOMA) on the ExoMars

2018 rover, in: Aerospace Conference, 2015 IEEE.

Banse, H., Beckert, E., Eberhardt, R., Stöckl, W., Vogel,

J., Laserbeam soldering– a new assembly technology

for micro optical systems, Microsyst. Technol. 11,

186–193 (2005).

Beckert, E., Burkhardt, T., Hornaff, M., Kamm, A.,

Scheidig, I., Stiehl, C., Eberhardt, R., Tünnermann, A.,

2010, Submicron accuracy optimization for laser beam

soldering processes, Proc. SPIE 7585, 758505.

Beckert, E., Wippermann, F., Walther, S., Burkhardt, T.,

Messerschmidt, B., Bartnitzek, T., Vahrenkamp, T.,

Eberhardt, R., Gäbler, D., Tünnermann, A., 2011,

Autoclaveable miniaturized video endoscopes with

simplified flip-chip assembly, Proc. SPIE 7893,

78930B.

Burkhardt, T., Mohaupt, M., Hornaff, M., Zaage, B.,

Beckert, E., Döring, H.-J., Slodowski, M., Reimer, K.,

Witt, M., Eberhardt, R., Tünnermann, A., 2011,

Packaging Technology of Multi Deflection Arrays for

Multi-Shaped Beam Lithography, Proc. of IMAPS 44

th

International Symposium on Microelectronics.

Burkhardt, T., Hornaff, M., Kamm, A., Burkhardt, D.,

Schmidt, E., Beckert, E., Eberhardt, R., Tünnermann,

A., 2015, Low-strain laser-based solder joining of

mounted lenses, Proc. SPIE 9574, 9574-21.

Escudero-Sanz, I., Ahlers, B., Bazalgette Courrèges-

Lacoste, G., 2008, Optical design of a combined

raman–laser-induced-breakdown-spectroscopy

instrument for the european space agency exomars

mission, Opt. Eng., vol. 47, no. 3, pp. 033001-1–

03301-11 .

Ribes, P., Burkhardt, T., Hornaff, M., Kousar, S.,

Burkhardt, D., Beckert, E., Gilaberte, M., Guilhot, D.,

Montes, D., Galan, M., Ferrando, S., Laudisio, M.,

Belenguer, T., Ibarmia, S., Gallego, P., Rodriguez, J.

A., Eberhardt, R., Tünnermann, A., 2015, Solderjet

bumping technique used to manufacture a compact

and robust green solid-state laser, Proc. SPIE 9520,

952009.

Richter, L., Carianni, P., Durrant, S., Hofmann, P.,

Mühlbauer, Q., Musso, F., Paul, R., Redlich, D., 2015,

Progress Report on Development of the Exomars 2018

Sample Processing and Distribution Subsystem

(SPDS) and related OHB Sample Handling Studies,

Astra 2015 ESTEC.

Rull Pérez, F., Martinez-Frias, J., 2006, Raman

spectroscopy goes to Mars, Spectroscopy Europe, vol.

18, pp. 18–21.

Sansano, A., Navarro, R, Lopez-Reyes, G., Rull, F., 2014,

Development of the Calibration Target for ExoMars’

Raman Instrument (RLS), 45

th

Lunar and Planetary

Science Conference.

Laser-based Soldering Technique for Hermetical Sealing of the Calibration Target for the Exomars’ Raman Instrument

63