A Study on Procurement Management of China Power Enterprises

based on the Concept of Life-cycle Management

Yong Zhang

1

and Jianjun Wang

2

1

Dept. of Corporate Management Consulting, State Grid Energy Research Institute, Beijing, 102209, China

2

Policy Research Department, China Banking Regulatory Commission, Beijing, China

zhangyong@sgeri.sgcc.com.cn, asterwjj@163.com

Keywords: Procurement Management, Life-cycle Management, Power Enterprises.

Abstract: Power enterprises are typical asset-intensive businesses. Power equipments have long operating cycle, and

the health level of single equipment will seriously affect the safe and stable operation of the whole power

system. Chinese power enterprises attach great importance to power enterprise equipment procurement and

adopted a series of measures to improve the level of equipment procurement. However, due to the influence

of traditional management concepts, there are some gaps between Chinese power enterprises and the world's

most advanced enterprises in the overall strategy of equipment procurement, vendor management and asset

life cycle management. This paper diagnoses the device management situation of Chinese power

enterprises, finds problems in management practice and relative recommendations for improvement are put

forward.

1 INTRODUCTION

Power enterprises are typical asset-intensive

businesses. Power equipment has long operating

cycle, and the health level of single equipment will

seriously affect the safe and stable operation of the

whole power system. China power enterprises attach

great importance to power enterprise equipment

procurement. In recent years China power

enterprises adopted a series of measures to improve

the level of equipment procurement. However, due

to the influence of traditional management concepts,

there are some gaps between China power

enterprises and world's most advanced enterprises in

the overall strategy of equipment procurement,

vendor management and asset life cycle

management. With the continuous expansion of the

power enterprises assets, how to improve asset

management capability has become an urgent

problem to be solved by China power enterprises.

2 A DIAGNOSIS ON

PROCUREMENT

MANAGEMENT PROBLEMS

OF POWER ENTERPRISES

2.1 Diagnostic Index System of Power

Enterprise Procurement

Management

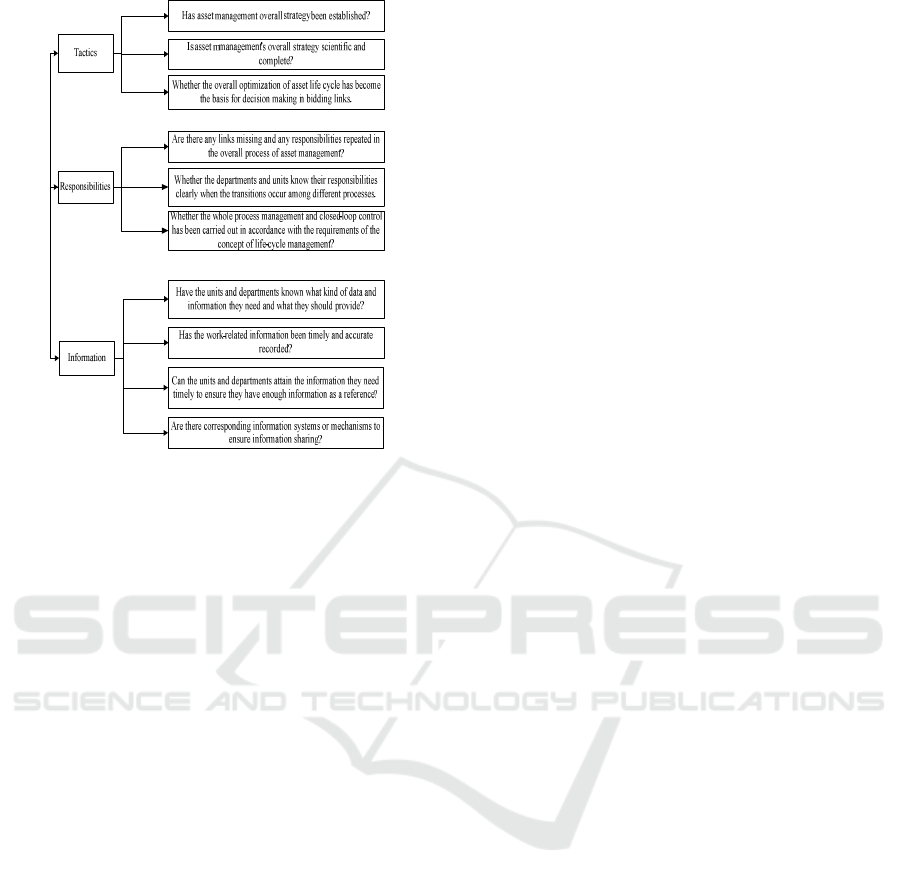

Based on the characteristics of power enterprise

procurement management, this paper establishes a

diagnostic index system of power enterprise

procurement management (see Figure 1). This

diagnostic index system includes three analysis

dimensions.

2.2 Problems Existing in the

Procurement Management of

Power Enterprises

Using the diagnostic index system of power

enterprise procurement management, this paper

analyzes China's power enterprises and finds there

are some problems.

The first problem is, asset management strategy

needs improving.

78

78

Wang J. and Zhang Y.

A Study on Procurement Management of China Power Enterprises based on the Concept of Life-cycle Management.

DOI: 10.5220/0006019400780081

In Proceedings of the Information Science and Management Engineering III (ISME 2015), pages 78-81

ISBN: 978-989-758-163-2

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

Figure 1: Diagnostic Index System of Power Enterprise

Procurement Management.

First, unified asset management philosophy is

missing. The life cycle of electrical equipments are

consists of project feasibility study, preliminary

design, bidding, equipment operation, asset

retirement. All these stages have an impact on the

healthy operation of electrical equipment assets.

Although under the current management mode, the

various stages are managed by different

departments. Different departments uphold different

management thinking and strategies, so a joint force

of asset management can’t be formed.

Second, developing equipment procurement

strategies is ignored. Business procurement mode is

closely related to many factors, such as external

policy environment for enterprise, market

environment and the company's own construction,

asset operation, etc. Once the internal and external

environment changes, companies need to assess and

adjust the existing procurement strategy timely. At

present, developing equipment procurement

strategies has not been established by majority of

China’s power enterprises. It’s hard for enterprises

to select appropriate procurement strategies in

accordance with the actual need of construction,

operation and maintenance.

Third, the existing method of bidding evaluation

doesn’t consider the asset performance throughout

the whole life cycle. At present, although power

companies take the situation of equipment operation

into account, they still take the price level as the

primary basis for purchasing decisions. From a

practical point of view, low-cost devices always

have some shortcomings, such as short maintenance

cycle, high failure rate, higher maintenance costs,

etc. It is difficult for low-cost devices to present

satisfying performance in their whole life cycle.

The second problem is, the responsibility of asset

management is not clear, and part of the

responsibility is missing.

First, the supplier management is absent.

Supplier management is an important part of

material management process, as pre-sale, sale and

after-sales stages of electric power equipment are all

in need of perfect supplier management. Currently

most electric power enterprises have not yet

established supplier evaluation system, so it is hard

to accurately evaluate vendor's comprehensive

quality of service according to the supplier's product

quality and after-sales service, and it is also hard to

use the assess results in future procurement. Second,

the operational departments and the financial sector

is still lack of effective connection in the assets

retirement. There are no clear assessment criteria

and disposal process in asset retirement

management, and retired assets cannot be disposed

in time, and the reuse of retired assets and the

recycling of asset residual are delayed.

The third problem is, asset management-related

information sharing is not implemented in a timely

manner.

First, the majority of electricity enterprises

haven’t established a unified supplier management

information system. Supplier management must be

established on the basis of accumulating large

amounts of data on supplier’s products and service.

At present, the Group's subsidiary companies have

to collect and accumulate the related data on their

own. The basic data for supplier evaluation is

inadequate, so it is difficult to provide a reference

for procurement. Second, material procurement

cannot be supported by the information from project

construction, operation and inspection, maintenance

and repair, condition assessment, technical

transformation, retirement, etc. Procurement

administration cannot grasp suppliers’ situation of

on-site service, quality and timeliness of delivery,

after-sales service. It is hard to control the service

quality of suppliers.

A Study on Procurement Management of China Power Enterprises based on the Concept of Life-cycle Management

79

A Study on Procurement Management of China Power Enterprises based on the Concept of Life-cycle Management

79

3 IMPROVEMENT

SUGGESTIONS ON ASSET

MANAGEMENT IN POWER

ENTERPRISE

3.1 Establish Unified Concept of Asset

Management, and Set up and

Improve the Management

Strategies.

First, power enterprises should carry out asset

management based on life cycle management

philosophy. The core idea of asset life cycle

management is to combine all stages of feasible

study, preliminary design, procurement, operation of

assets, asset retirement, etc. in asset management as

a whole, taking process optimization as the main

focus, using informatization as the main measure,

applying advanced decision and operation

management method such as life cycle cost (LCC)

evaluation method, condition based maintenance to

eventually realization high efficiency and low cost in

the entire life cycle of the assets.

Second, add a new stage of procurement strategy

decision to the process. Power enterprises should

create a new stage of procurement strategy

(including supplier development strategy, strategic

purchasing strategy) decision in the procurement

process according to overall demand and schedule

arrangement of the purchasing, and timely adjust the

procurement strategy according to internal and

external environment of the enterprise to ensure the

quality of the equipment under the premise to reduce

costs.

Third, establish LCC bid evaluation method

suitable to the characteristics of power equipment.

Not only the equipment purchase cost, but also the

operation and maintenance costs, failure costs and

retirement costs of equipment in its whole life cycle

are included in the calculation. And the LCC value

should be regarded as key basis of bid evaluation

decision-making to realize the optimal life cycle cost

of the equipment. In order to use LCC bid evaluation

method in bid evaluation, the following questions

should be paid attention to in the preparation of

technical specification books and commercial code

books:

a. Formulating complete procurement technical

specification standard to realize the asset life cycle

cost optimization, putting equipment operation data

under certain operating mode into the technical

standard of equipment, to provide decision-making

support of the equipment.

b. The economy of the equipment not only

reflects the investment cost, but also relates to the

reliability of the equipment to guarantee the normal

production, safety and stability, and reduce the loss

of the fault shutdown. Therefore, it is important to

determine in equipment procurement business

specification the economic characteristics of

equipment reflected by the equipment reliability

level. Using the life cycle cost method, the economic

characteristics should be converted and used in the

decision-making process of equipment procurement.

3.2 Establishing a Sound Supplier

Management Process.

First, power enterprises should add a new stage of

supplier evaluation, including supplier pre-

assessment, supplier post-evaluation and supplier

interaction management, in the procurement process

to improve procurement process. Second, power

enterprises should strengthen the horizontal

coordination between operation department and

finance department, and discuss and formulate asset

retirement evaluation criteria and the disposal

process. Once the assets retired, evaluation process

should be immediately started to timely re-

utilization and residual recovery and avoid the loss

of the residual assets value.

3.3 Accelerating the Construction of

Information Sharing Channels for

Asset Management.

First, a unified supplier management system should

be established to realize the dynamic relationship

between supplier management system and other

management information systems. The unified

supplier management system can provide timely and

accurate data support for supplier management.

a. Supplier management system and production

management system (PMS) should be linked up, so

that the supplier management module can extract the

original defects data of equipment from the

equipment standing book of PMS. At the same time,

PMS can also get the basic information of the

suppliers and equipment from the supplier

management module.

b. Supplier management system and the asset

management module should be linked up, so the

LCC calculation data in supplier management

module can be provided to the asset management

module of the ERP.

ISME 2015 - Information Science and Management Engineering III

80

ISME 2015 - International Conference on Information System and Management Engineering

80

c. Supplier management system and the material

management module should be linked up, so power

enterprises can collect information of the suppliers

and supply timeliness from the materials

management module in ERP.

Second, power enterprises should establish

information sharing channels between the

procurement process and spare parts process, so

power enterprises can get access to kinds, types,

quantity, state information of spare parts. When

making the procurement plan, fully consideration

should be paid to the assets which have been

processed as a spare part, so as to avoid waste

caused by repeat purchase.

4 CONCLUSIONS

Improvement on quality of electric power equipment

is the key to the healthy and stable operation of the

power system. Although traditional philosophy of

asset management can reduce procurement costs, a

lot of equipment operation maintenance cost,

maintenance cost and failure cost were brought

forward due to quality problems of the equipment.

Therefore, power enterprises should innovate their

management modes and carry out asset life cycle

management. Power enterprises should use

equipment’s performance in the whole life cycle as

the basis of optimization decision, and eventually

raise the level of equipment procurement in the

power enterprise of our country.

REFERENCES

Moore, R., Lopes, J., 1999. Paper templates. In

TEMPLATE’06, 1st International Conference on

Template Production. SCITEPRESS.

Smith, J., 1998. The book, The publishing company.

London, 2

nd

edition.

Zhang Yong, Wei bin,2008. The power grid enterprises

LCAM thinking. Energy technology and economy, (4).

Ma Jun, Jiang Yimin, 2006. Analysis of the full life cycle

cost of transformers. Transformers, (12).

Guo Qing, 2007. Discussion on the full life cycle

management of transmission line construction project

. Shanxi power.

Ahmed N.U, 1995. A design and implementation model

for life cycle cost management system. Information &

Management, Volume 28, Number 4, April 1995.

Joachim Schneider,et al(2006). Asset management

techniques. Electrical Power and Energy Systems,

(28).

Han Liqiang(2002). Application of CALS system in the life

management of weapon equipment and Its Revelation

[J]. Information theory and exploration, (6).

A Study on Procurement Management of China Power Enterprises based on the Concept of Life-cycle Management

81

A Study on Procurement Management of China Power Enterprises based on the Concept of Life-cycle Management

81