Automated Process Model Discovery

Limitations and Challenges

Norbert Gronau and Christian Glaschke

Chair of Business Information Systems and Electronic Government, University of Potsdam, August Bebel Straße 89,

Potsdam, Germany

n.gronau@lswi.de, c.glaschke@lswi.de

Keywords: Process Mining, Process Model Discovery, Screen Capturing

Abstract: The implementation of business processes through the use of information systems (ERP, CRM, PLM and

MES) has become a key success factor for companies. For further development and optimization of

processes, many companies haven´t trusted processes for the analysis. Surveying as-is processes is complex

and only possible by manual recording. To perform this task automatically the theory shows us different

approaches (process mining, Application Usage Mining and Web Usage Mining). The target of the concepts

and tools is to complement the process of continuous improvement in the company with meaningful process

models, which can be reconstructed from protocols and user actions in the information systems. This article

focuses on the limitations of these concepts and the challenges they present and gives an outlook on how

future solutions must work to speed up the process of continuous improvement and to meet the challenges

of heterogeneity in IS - architectures.

1 INTRODUCTION

For more than 20 years business process

management has been the leading paradigm for

organizing and restructuring corporations and public

entities. Although all kinds of companies use

business process management in certain areas, there

are some challenges that require further analysis. To

name only a few:

Improving learning while performing a

business process

Making better use of person-bound knowledge

that is generated in or used during the business

process

The establishment of PDCA cycles (plan-do-

check-act) in process management, that enable

the detection and subsequent correction of

deviations without interrupting the business

process

Typically, business processes today are

supported by enterprise systems like ERP,

CRM or SCM. Normally, there are deviations

between the intended process covered, the

ERP and the actual process that is run in the

company (cf. Gronau, 2015)

The human interface is more important than

ever in most business processes, despite

automation. When the automated business

process is interrupted, it is a human that has to

decide how to propel the process further. The

description of human interfaces is by no-way

interoperable now.

A better real world awareness of the objects of

business processes (persons, information,

cases, instances and customer materials)

currently available, as well as approaches to

integrate such information into the process, is

more necessary than ever.

With respect to all these new challenges, detailed

and purpose-specific modeling is the precondition

for a purposeful analysis of the business process

necessary for its improvement. The detection of

business processes and the investigation into

necessary attributes of all objects tends to be very

time-consuming and is still incapable of being fully

automated.

There are some approaches like process mining

(cf. Van der Aalst, 2011) that can help identify

process patterns or recurrent instances, but the mere

act of modeling itself is one of the most challenging

tasks. This process also heavily influences the

quality of the results. Incorrect or missing attributes

19

Gronau N. and Glaschke C.

Automated Process Model Discovery - Limitations and Challenges.

DOI: 10.5220/0005885100190025

In Proceedings of the Fifth International Symposium on Business Modeling and Software Design (BMSD 2015), pages 19-25

ISBN: 978-989-758-111-3

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

or objects mean that the purpose of analysis and the

goal of the improvement cannot be reached.

Therefore, this paper describes ongoing research

activities to determine an approach to automatically

identify business processes and model them from the

information that can be derived from information

systems like ERP and CRM.

2 PROCESS MODEL DISCOVERY

IN TIME FROM INTERNET OF

THINGS

In this section, the topic of process model discovery

in the area of a total digital integration is discussed.

Current trends, such as the internet of things,

industrial internet and digitalization (cf. Kagermann,

2014) are some of the main drivers for the

development of new concepts and technologies in

the area of business process modeling. At the center

of these approaches lies the question of how it is

possible to attain more efficient and transparent

business processes. Hence, there is great demand for

a current and trustworthy as-is process model (Houy

et. al., 2011). Such a model is necessary to decide

how to optimize or reengineer the process. Inquiries

to determine as-is processes are very complex and

labor intensive, and are typically carried out by

manual forms of observation and data collection.

The main question of the present paper is: How

can as-is processes in a corporation or a public entity

be determined automatically for further analysis?

This question has tackled in the past by using a

variety of different viewpoints. For instance, there

are techniques that use either certain properties of

technologies (Web Usage Mining, cf. Zhong, 2013)

or log files from enterprise systems to reconstruct

as-is processes. This approach is called Application

Usage and Process Mining. These tools and methods

have to be integrated into what are today more

heterogeneous application landscapes with variable

technologies and application systems (cf. Huber,

2015). This trend will be even more intense in the

future when more system elements from the Internet

of Things are incorporated within the application

landscape. Given that this development will occur in

the near future, the research question of this

contribution can be stated as follows: What kind of

information about the environment and the

enterprise are necessary in order to be able to

discover processes automatically? To answer this

question, current research approaches are described

and their limitations analyzed. Additionally,

solutions that allow for the use and analysis of the

available data are outlined, and the existing

challenges facing the development of a new method

are illustrated. At the end, an outlook for further

research is given.

3 EXISTING PROCESS

DISCOVERY APPROACHES

AND THEIR LIMITATIONS

A well-known approach for process discovery is the

concept of process mining that was developed by

Van der Aalst and his research group at Technical

University of Eindhoven (The Netherlands). This

approach uses log files from application systems (for

instance ERP systems) to reconstruct processes. To

be successful in that effort, the application system

has to deliver the needed information in a specific

manner (as shown in table 1).

Table 1: Example for a logfile.

PID Activity Worker Timestamp

452 registration 55

2011-12-24,

11:10:21

452 investigation 56

2011-12-24,

11:15:21

452 consulting 33

2011-12-24,

12:17:10

452 dismissal 55

2011-12-24,

12:47:11

453 registration 55

2011-12-24,

11:16:35

453 investigation 56

2011-12-24,

11:27:12

453 consulting 12

2011-12-24,

11:52:37

453 dismissal 55

2011-12-24,

11:59:54

454 registration 55

2011-12-24,

11:11:21

454 investigation 55

2011-12-24,

11:15:21

454 registration 56

2011-12-24,

12:17:00

An important component of this listing of

process instances is the process identification

number (PID). This number is used to create a

process diagram based on more than one process

instance (cf. Van der Aalst, 2012). In the

background, petri networks are used to be able to

Fifth International Symposium on Business Modeling and Software Design

20

generate process diagrams, to describe the different

conditions of the process and to create a graph for

visualization and analysis (cf. Van der Aalst, 2011 &

Accorsi et.al. 2012).

Another approach that uses more than one input

source is Application Usage Mining. In this

approach, the log files are complemented by

additional data from the data-base of the information

system: for instance on the users, workflows and

functions of the system. This information is used to

further enrich the models. In the background of this

approach petri networks are also used to describe the

logic of the process and to summarize the possible

states of a system (cf. Kassem, 2005).

Both approaches rely on the assumption that a

system that is able to generate data about business

processes and to deliver log files in the necessary

quality exists. This assumption is not valid for

enterprises with a huge number of information

systems, for instance best of breed solutions,

federated ERP systems or combinations of different

system classes (PLM and ERP and DMS and MES)

that are used together in the business process.

Furthermore, customizing the application systems is

very time consuming and a very high level of

expertise is required. One feature that complicates

this approach is that the functions executed by the

application system are used as a first hint for

classification and instance creation. Hence, the

relevant process tasks and functions have to be

known before the customizing of log files can take

place.

Another possibility to record the interactions

between user and system are log files of web-based

systems. This approach is called Web Usage Mining.

Here the access point for the process recording is the

technology used (PHP, HTML, Javascript, ...). As in

the process mining approach, the server can record

user requests and results into logs. The session ID is

used as process ID (cf. Bhart, 2014). This principle

is typically used for analyzing the user‘s behavior

and not for reconstructing business processes, but an

adaptation for web-based application systems seems

to be at least possible.

Starting from the preconditions that for a

successful execution of business processes more

than one application system and different

technologies are used and that some of the tasks are

performed outside of the information systems, a new

approach is necessary to be able to automatically

discover and record business processes.

To sum up, it can be said that existing

approaches for the data collection either have

specific knowledge about the process or concentrate

on only one application system or one single

technology. As information about real objects,

locations and movements are not taken into account,

these methods can only achieve a limited degree of

accuracy. Hence, we formulate another research

question: How can the user and his surrounding

likewise be taken into account for process model

discovery?

4 IDENTIFIED POSSIBILITIES

FOR DATA CAPTURING

This section shows possibilities to collect data from

performed processes without being dependent on

specific application systems or technologies.

Another aim of this section is to describe which

information user and environment can deliver and

how this information can be captured.

4.1 Screen Capturing and Optical

Character Recognition

A main point of criticism about the approaches

presented in section 3 is that a lot of work is

necessary to configure the log data, and that meta

information for the enrichment of log files in a

structured manner has to be available. To obtain this

information without any knowledge about the

business process, an approach is needed which

works independently from application systems.

Application systems are ideally closed systems with

complex interactions with clients that use different

data formats.

There is only one object that shows all the

interactions between user and system, the screen. To

be able to use this valuable source of information,

screen captures can be analyzed by an OCR software

(Shekappa et. al., 2015). From this information a

matrix can then be derived (table 2). The lines are

the clients where the software captures the screen

content. The columns are the different points in time

when the screen capturing took place. Every cell is

the result of an OCR recognition f(t) at a certain

moment (for instance t1). Available screen capturing

software is also able to capture the cursor positions

and mouse clicks of the user (cf. Huang et. al, 2011

& Johnson et. al., 2012). Therefore, it is also

possible to analyze table cells in an application

system selected by the user. This approach delivers

data about the interactions of the user with a

terminal that is sorted by date but unstructured. It is

also possible to find out the cursor position,

Automated Process Model Discovery: Limitations and Challenges

21

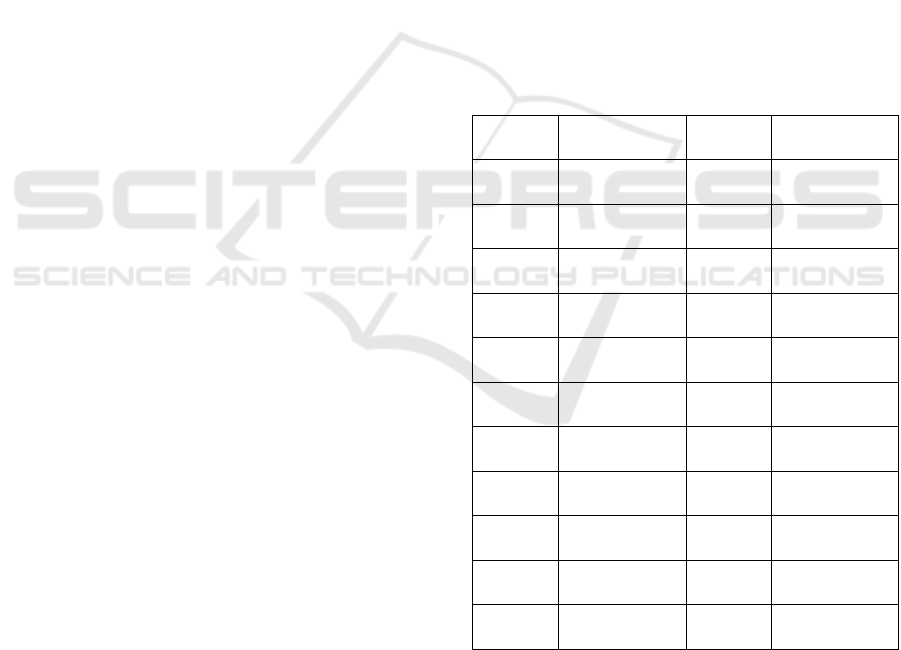

Table 2: Results table for OCR recording.

t1 t2 t3 t4 t5 t6 t7 t8 t9 t10 t11 t12 t13

Client 1

f(t1) f(t2) f(t3) f(t4) f(t5) f(t6) f(t7) f(t8) f(t9) f(t10) f(t11) f(t12) f(t13)

Client 2

f(t1) f(t2) f(t3) f(t4) f(t5) f(t6) f(t7) f(t8) f(t9) f(t10) f(t11) f(t12) f(t13)

Client 3

f(t1) f(t2) f(t3) f(t4) f(t5) f(t6) f(t7) f(t8) f(t9) f(t10) f(t11) f(t12) f(t13)

Client 4

f(t1) f(t2) f(t3) f(t4) f(t5) f(t6) f(t7) f(t8) f(t9) f(t10) f(t11) f(t12) f(t13)

Client 5

f(t1) f(t2) f(t3) f(t4) f(t5) f(t6) f(t7) f(t8) f(t9) f(t10) f(t11) f(t12) f(t13)

and to analyze which fields were selected by the user

and which functions were performed.

4.2 Operating System Information

Another point of criticism concerning the

approaches presented in section 2 is the exclusive

focus on application systems. Other software

running on the computer also delivers data that can

be used for the reconstruction of processes and the

generation of meta information.

Aside from the user entries, the operating system

can also deliver other valuable information. This

might include log-in credentials, the program used

and the data entered. Additionally, the operating

system is responsible for file operations and network

access (cf. Tanenbaum, 2003). Using this

information it is possible to determine which file

was opened or processed.

4.3 Process ID in Application Systems

The process ID makes a substantial contribution to

the discovery of a process. It makes it possible to

distinguish between different process instances.

From that structure, in turn, a process model can be

reconstructed. In application systems, a huge set of

distinct numbers for different kinds of data and

levels of detail exist. Execution data exist for the

accomplishment of business processes. This data, for

instance, reveals the change of storage data when a

delivery document changes the stored amount of an

item by a booking process. This delivery document

has a unique number and also points to its logical

predecessors. The offer number can be found in the

order; the order number is mentioned on a factory

order or on a delivery document. The document flow

that can be created from these numbers can be

reconstructed or read from the leading application

systems supporting this process. Additionally, these

numbers are also available when corresponding with

a client, for instance ticket numbers or invoice

numbers. Master data identifies a business object

(product resource, storage facility) uniquely by a

number. In some cases, not only are the products

identified, but also the object instances. Therefore, a

serial number or batch number is used. These

numbers are typically printed onto the product and

are used for traceability of every single item or batch

job in logistics and manufacturing.

4.4 Tracking of Business Objects

Another approach to collect information about the

environment and the user utilizes technologies to

spatially locate users and objects. Different

approaches, such as RFID or GPS, exist for this

purpose. A movement profile can be derived from

this data. These movements can be used to follow

processes when an object is moved and to define

interactions between users and business objects (cf.

Sultanow, 2015 & Gronau, 2014).

4.5 Summary

Four approaches can be used to collect data about

business processes in corporations. The next task is

to use that information to reconstruct the underlying

business processes.

5 CHALLENGES DURING THE

DEVELOPMENT OF A

METHOD

Combining the information from the different

approaches in section 4 leads to different challenges

for further research. In this section, the problems are

elaborated with the help of an exemplary scenario.

This scenario is described at first to depict the

challenges. A special emphasis is put on the aspects

of the existing approaches Process Mining,

Application Usage Mining and Web Usage Mining

that constitute weaknesses.

Fifth International Symposium on Business Modeling and Software Design

22

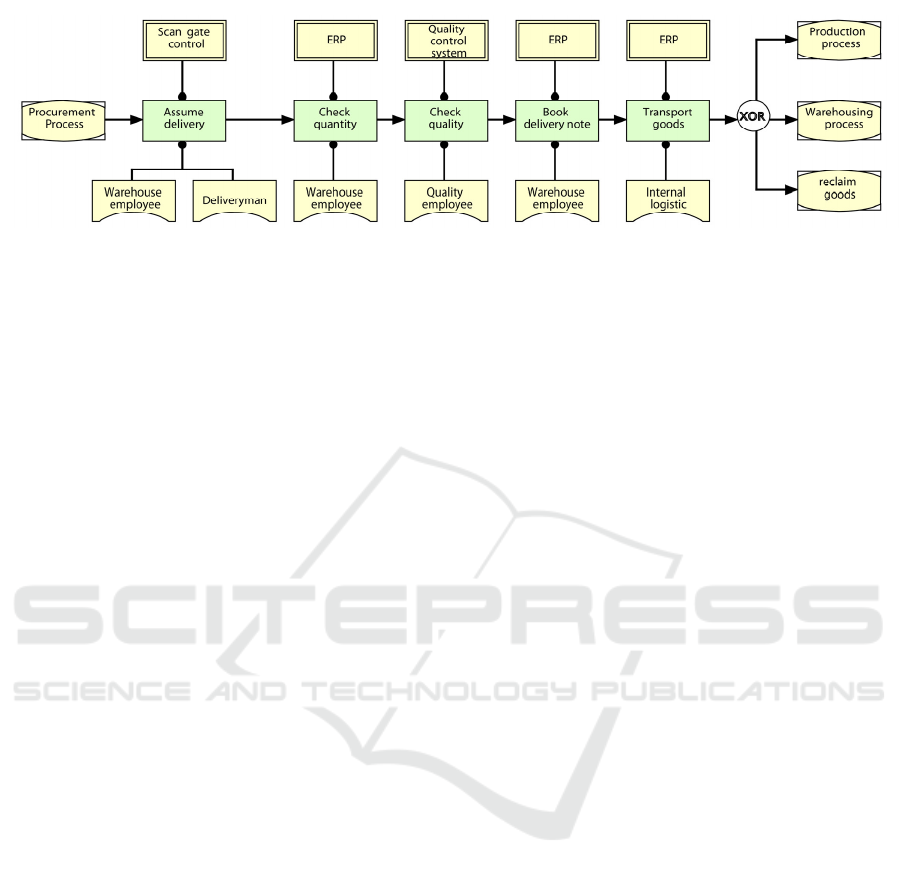

Figure 1: Product entry process.

5.1 The Example of the Data Entry

Process

To be able to describe the challenges a scenario was

developed, in which a product entry process is

performed. In figure 1, the process is illustrated in

the KMDL process view (Gronau, 2005).

The process goes as follows: after a successful

order from the procurement process (process

interface), the goods are delivered. The delivery is

accepted and driven through a scan gate. The

information system „scan gate control“ shows the

warehouse employee (role) the listing of the

delivered parts on a client computer and shows the

serial, order and supplier numbers from the RFID

tags of the packages. After checking that

information, the warehouse employee approves the

delivery document for the delivery man and in the

scan gate control Software the parts list. The data

from the scan gate control system is entered into the

ERP system as a quality control system. In the ERP

system, a new bill of delivery is generated that

contains the articles and their amounts. The

warehouse employee unpacks the goods and gets the

bill of delivery in the ERP system in order to check

the quantities. After confirming the amount, the ERP

bill of delivery is handed over for inspection to the

Quality Control System, which creates a test order,

which includes the different properties of the

articles. The Quality employee checks the properties

per serial number and deposited a test result. Some

parts are identified as unsuitable. This has to be

entered into the quality control system. Most articles

pass the amount check successfully. Acknowledging

that the ERP system has been checked automatically

produces the results of the quality assurance task and

generates a storage location for every serial number

of the delivered goods in the bill of delivery. Good

parts are now transported to the manufacturing

storage, bad parts into a reclaim storage yard.

Articles marked as consumables are stored in the

warehousing process. In process step book delivery

note the articles in different charge carrier / transport

units are separated. Then, the delivery will be

booked. The ERP system generates from a transfer

order, which is processed by the logistics depart-

ment. Hence, the goods are stored in different

locations.

5.2 Challenges of Automated Process

Model Discovery

The first challenge for the approaches from section 3

is to recognize that the procurement process is the

trigger for the warehouse entry process. In the

process “assume delivery,” the order number is the

only connection between these two processes. This

connection has to be recognized and assigned to the

order process. This is the main result to expect from

the method to be developed. Therefore, the

recognition mechanism has to find out that the same

order number is now used during the delivery, and

has to interpret this as a unique number.

Using the statements above we can formulate

some requirements for the necessary recognition

mechanism.

The method has to reliably find out the unique

identifiers by screen capturing and OCR.

A second challenge can be derived from the

“assume delivery” process. Here it is necessary to

find out that the serial numbers indicate the different

flows of goods. To achieve this, the products that are

equipped with RFID tags at different locations

(storage, quality control, ...) show the serial numbers

and the current location belonging to that serial

number. Of course, the information about the

locations of the RFID reader stations must be

known. Second challenge: The method must

combine information from the screen capturing with

the determined location of the goods.

Another challenge is the assignment of roles and

information systems to the steps of the process. The

warehouse employee logs himself into the system

with his mobile device and connects himself to the

scan gate control system. The operating system then

captures the user group or the log-in name. With

Automated Process Model Discovery: Limitations and Challenges

23

other information systems the process is performed

in a similar manner. The operating system registers

the usage of the scan gate control software and

allocates this software to the process. The only role

in the exemplary process that cannot be captured in

this manner is the delivery man. Third challenge:

The method must be able to recognize the external

and internal roles involved in the process.

The next challenge is it to differentiate between

the different process steps. In the example, the

differentiation between the process steps “assume

delivery” and “check quantity” can be performed by

different information systems. When the process

transfers from “check quantity” to “check quality”,

different roles and different systems allow one to

find out that different process steps are performed. A

differentiation on that level is at any rate impossible.

An example of this can be seen in the work of a

sourcing employee who works with an ERP system

and does everything in the sourcing process, from

ordering to invoice checks, on his or her own. Fourth

challenge: The method must discover the different

process steps and be able to see the limit of one

process step and the beginning of another one.

The fifth challenge is to find out the description

of the process. To that end, a lot of information is

collected from OCR or screen capturing, but their

interpretation is difficult. An example is the “check

quantity” process, and the question: how can we

derive that term? One approach would be to assign

the function to the location; another approach would

be to use the window title of the ERP system

(“delivery note”). Sometimes this task can be done

by manual configuration, or by screen capturing.

The fifth challenge is, therefore, that the method

must be able to determine the name of a process

step.

The sixth challenge is to recognize different

target locations (storage locations in the logistic

process) from logistics and from the transport of

goods. Therefore, these different locations have to

be distinguished in the process by using different

process interfaces. To meet this challenge, the

master data of the storage in the warehouse

management system could be used to help

understand the structure of the storage groups and

their functionality in the process. Another possibility

is to assign this information to the different

locations. When this information is available for

differentiation, the process interfaces into the storage

area can be reconstructed. The sixth challenge is:

The method must have knowledge that specifies the

environment.

6 CONCLUSION AND OUTLOOK

The contribution has shown that an automated

discovery of process models is possible when some

new approaches are applied. The investigation of

current approaches showed that systems and

technologies deliver valuable information about the

process flow, but a configuration for a case of

specific use is necessary. The main gap in the

research is the lack of consideration of human tasks

and environmental data.

For the research task to develop a new integrated

approach, a couple of challenges must be dealt with.

One of the most important requirements of a new

method is to see the corporation and its data sources

in an integrated manner. Another important topic is

the collection of data according to location, time and

their connection to the process model. No

satisfactory answer could be given to the research

question concerning which information about the

user and the environment has to be collected in order

to be able to sufficiently discover process models.

On one hand, information about location must be

available (for instance which task is performed

where), while on the other hand, the master data that

holds that information has to be investigated. In any

case, the demand for and benefit of that kind of input

can be shown. Finally, there remains the question of

how the recognition mechanism uses semantic

techniques. Here it might be possible that the user

has to assist the recognition mechanism to describe

the process models.

An open issue after creating process models is to

interpret these semi-formal models. To reach an

understanding about a process solely by using a

model is very difficult. The authors thinks that

human beings, too, will have to participate in that

process in the future.

REFERENCES

Accorsi R., Stocker T. (2012). On the Exploitation of

Process Mining for Security Audits: The Conformance

Checking Case. ACM Symposium on Applied

Computing. doi:10.1145/2245276.2232051

Bhart, P. (2014). Prediction Model Using Web Usage

Mining Techniques. IJCATR, Volume 3, Issue 12,

827-830. doi: 10.7753/IJCATR0312.1015

Gronau, N. (2015). Trends and Future Research in

Enterprise Systems. Lecture Notes in Business

Information Processing, Volume 198, 271-280.

Gronau, N., Müller, C., & Korf, R. (2005). KMDL –

Capturing, Analysing and Improving Knowledge-

Fifth International Symposium on Business Modeling and Software Design

24

Intensive Business Processes. Journal of Universal

Computer Science, 11(4), 452-472.

Gronau, N., Sultanow, E. (2014). Echtzeitmeldung und

Analysen über Wissensereignisse. IM+io Fach-

zeitschrift für Innovation, Organisation und

Management. 01/2014. 80-87

Houy C., Fettke P., Loos P., Van der Aalst WMP.,

Krogstie J. (2011). Business process management in

the large. Business Information System Engineering 3,

385-388. doi:10.1007/s12599-011-0181-5.

Huang, J., White, R. W., Dumais, S. (2011). No Clicks, No

Problem: Using Cursor Movements to Understand

and Improve Search. Proceeding CHI '11 Proceedings

of the SIGCHI Conference on Human Factors in

Computing Systems, pp. 1225-1234. doi: 10.1145/

1978942.1979125

Huber, S., (2015). Informationsintegration in dynamischen

Unternehmensnetzwerken – Architekturen, Methoden

und Anwendungen. Springer. doi: 10.1007/978 -3-658-

07748-8

Johnson, A., Mulder, B., Sijbinga, A., Hulsebos, L.

(2012). Action as a Window to Perception: Measuring

Attention with Mouse Movements. Applied Cognitive

Psychology, Appl. Cognit. Psychol. 26, 802-809.

doi:10.1002/acp.2862

Kagermann, H., (2014). Chancen von Industrie 4.0 nutzen.

Industrie 4.0 in Produktion, Automatisierung und

Logistik. Springer. 603-613. doi: 10.1007/978-3- 658-

04682-8

Kassem, G., Rautenstrauch, C. (2005). Application Usage

Mining to Improve Enterprise Workflows: ERP

Systems SAP R/3 as Example. IDEA Group

Publishing, In:Proceedings of the 2005 Information

Resources Management Association International

Conference.

Krogstie, J. (2015). Capturing Enterprise Data Integration

Challenges Using a Semiotic Data Quality

Framework. BISE, 57(1). 27-36

Schemm, J. W. (2009). Zwischenbetriebliches Stamm-

datenmanagement. Springer Verlag.

Shekappa B., Mallikarjun, A., Shivarama, J. (2015). Best

Practices in Digitization: Planning and Workflow

Processes. In International Conference on the theme

Emerging Technologies and Future of Libraries:

Issues and Challenges. 332-340

Sultanow, E., Cox, S., Brockmann, C., Gronau, N. (2015).

Real World Awareness via the Knowledge Modeling

and Description Language. In M. Khosrow-Pour

(Ed.), Encyclopedia of Information Science and

Technology, Third Edition, 5224-5234.

doi:10.4018/978-1-4666-5888-2.ch516

Tanenbaum, A. S. (2003). Moderne Betriebssysteme.

Pearson Studium, Auflage 2.

Tiwari, A. Turner, C.J., Majeed, B. (2008). A review of

business process mining: state of the art and future

trends. Business Process Management Journal. Vol. 14

Iss: 1. 5-22.

Van der Aalst, WMP. (2011). Process Mining –

Discovery, Conformance and Enhancement of

Business Processes. Springer.

Van der Aalst, WMP., Accorsi R., Ullrich M. (2012).

Process Mining. Retrieved April 29, 2015, from

http://www.gi.de/nc/service/informatiklexikon/detaila

nsicht/article/process-mining.htm

Zhong, N., Liu, J.,Yao Y. (2013). Web Intelligence. Web

Log Mining. Springer. 173-198.

Automated Process Model Discovery: Limitations and Challenges

25