Empowering Industrial Maintenance Personnel with Situationally

Relevant Information using Semantics and Context Reasoning

David H

¨

astbacka

1

, Pekka Aarnio

2

, Valeriy Vyatkin

2

and Seppo Kuikka

1

1

Department of Automation Science and Engineering, Tampere University of Technology,

Korkeakoulunkatu 3, 33720 Tampere, Finland

2

Department of Electrical Engineering and Automation, School of Electrical Engineering, Aalto University,

Otaniementie 17, Espoo, Finland

Keywords:

Industrial Maintenance, Knowledge Management, System Integration, Semantic Web, Contextual Reasoning.

Abstract:

Industrial maintenance is a complex discipline requiring experience and know-how. Information such as main-

tenance work orders are usually provided through mobile devices to field personnel. There are also other in-

formation sources with manuals, documented history, contact information etc. that is of value supporting the

tasks at hand but typically this needs to be retrieved manually. The challenge is how to utilize information

originating from heterogeneous information sources that, in addition, may change e.g. for outsourced mainte-

nance service providers taking care of different sites. To facilitate the use of supporting materials an ontology

knowledge management approach is developed that integrates data and documents, and provides relevant in-

formation for the task at hand using context and semantics based reasoning. Results from early prototyping

show that the approach can improve utilization of information in existing systems through adapter layers and

complement existing mobile as well as upcoming augmented reality applications by automatically providing

situationally relevant information.

1 INTRODUCTION

In industrial production environments the availability

of equipment and machines is critical to the efficiency

of production. Maintenance is a key factor in this

for achieving high reliability and required precision of

operation. As a discipline maintenance is knowledge-

intensive and requires expertise in executing demand-

ing tasks of servicing machines and equipment.

In their work maintenance technicians follow

tasks assigned to them using work orders. Although

this information is in digital form there are seldom

accessible paths to other information that would be

of use to support the task at hand. Such supporting

information is, for example, service manuals, operat-

ing instructions, and documentation from similar pre-

vious tasks. This is partly due to the heterogeneous

nature of those information sources. Even though this

information would exist it is not always easy to find

and productive time may be lost.

The challenges, and associated costs, are becom-

ing more evident with outsourced maintenance ser-

vices putting a price tag on individual maintenance

tasks. Having access to relevant information is also a

challenge for typical service providers having multi-

ple sites at their responsibility (Murthy et al., 2015),

e.g. with differing practices as well as different infor-

mation systems. This is not only a problem of inexpe-

rienced personnel but also for experienced personnel

that need to handle a broader range of tasks. It can be

claimed that information is not exchanged as it was

before and that especially the transfer of tacit knowl-

edge can be reduced due to this model of operation.

The paper presents research how industrial field

service personnel (FSP), i.e. maintenance techni-

cians, can be supported with situationally relevant in-

formation. The aim is to develop an integration plat-

form that using semantics based reasoning combines

and makes better use of existing information. In this

paper the focus is on conceptualizing the knowledge

management solution, defining a system architecture

and evaluating implementation technologies.

The paper is structured as follows. Section 2 pro-

vides an overview of background information and re-

lated work. Section 3 outlines characteristics and cur-

rent challenges based on interviews and discussions

with companies. Based on this, in section 4, a concept

is developed what kind of information is provided and

from which systems. In section 5 the use of Seman-

tic Web technologies is discussed to manage different

182

Hästbacka, D., Aarnio, P., Vyatkin, V. and Kuikka, S..

Empowering Industrial Maintenance Personnel with Situationally Relevant Information using Semantics and Context Reasoning.

In Proceedings of the 7th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2015) - Volume 3: KMIS, pages 182-192

ISBN: 978-989-758-158-8

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

data sources with information related to the mainte-

nance. In the approach Semantic Web technologies

are used to classify content, adapt different metadata,

and to reason and combine knowledge with regard

to the current context of the maintenance technician.

Discussion is provided in section 6 before concluding

the paper with future work in section 7.

2 RELATED WORK AND

BACKGROUND

2.1 E-maintenance

During the last decade the working environment of

maintenance technicians has developed rapidly along

with ICT technology evolution. Especially, the In-

ternet, new web technologies and wireless networks

have enabled this development to a new level often

called as e-maintenance. E-maintenance is defined in

(Campos et al., 2009) as the ability to monitor plant

floor assets, link the production and maintenance op-

eration systems, collect feedback from remote cus-

tomer sites, and integrate its upper level enterprise ap-

plications. The most preferred e-maintenance strategy

is condition based maintenance (CBM), which can be

advanced by the introduction of new technology.

These new technologies have changed the way

how maintenance functions are carried out and pro-

vide new tools and access interfaces for FSPs. They

have enhanced data collection (e.g. Radio-frequency

identification (RFID) & smart tags, micro sensors)

and data analysis functions implemented as web ser-

vices. Wireless networks enable mobile communica-

tion with advanced interfaces and computation power

(smartphones, tablets). For instance, RFID smart

tags enable fast identification of machines using mo-

bile devices and easy access to maintenance related

data stored in them, such as, location, spare parts,

tools and even information about the past mainte-

nance actions. The e-maintenance concept address

also the requirement of enhanced system interop-

erability and information integration by widely ac-

cepted data model standards, such as, Mimosa (Ma-

chinery Information Management Open System Al-

liance) OSA-CBM (Open System Architecture for

Condition Based Maintenance)(MIMOSA, 2010) and

ISA-95 (IEC, 2013). (Holmberg et al., 2010)

Many of these new technologies have already ma-

ture deployments and are in daily use by maintenance

technicians. In a near future, maintenance systems are

expected to enable more intelligent use of collected

data from remote distributed sources through sensor

hubs and cloud computing; wearable computing and

augmented reality (AR) services will enable to relay

detailed guidance to inexperienced maintenance tech-

nicians at remote sites. (Holmberg et al., 2010)

Many challenges are still related to information

integration and knowledge management in the main-

tenance domain (Ruiz et al., 2013). Semantic Web

technologies, as seen for e-maintenance, are enabling

technologies that can provide new solutions also for

this area. For example, they enable flexible and ex-

pressive knowledge representation by ontology mod-

els, advanced search capabilities, information integra-

tion at semantic level, ontology and rule based rea-

soning capabilities, etc. Semantic Web technology

standards managed by W3C are an important set of

complementary standards for e-maintenance.

2.2 Contextual Computing

The fast development of mobile and sensor technolo-

gies has enabled implementing smart mobile plat-

forms with enough computing power for context-

aware applications. Its importance in providing in-

telligence to new applications will grow in the future

together with other technologies supporting the Inter-

net of Things (IoT) and Services (IoTS) paradigms.

Recent survey papers about context-aware com-

puting are (Perera et al., 2014; Hong et al., 2009). The

notion of context in general has been studied in (Dey,

2001; Abowd and Mynatt, 2000). Definition of the

concept has been further refined and categorization

of context-aware computing provided in (Soylu et al.,

2009). Review and categorization of contextual rea-

soning and modeling approaches have been presented

in (Perera et al., 2014; Nalepa and Bobek, 2014).

Generic context models and ontologies have been

developed in (Soylu et al., 2009; Wang et al.,

2012; Gundersen, 2014; Wang et al., 2004; Chen

et al., 2005; Mettouris and Papadopoulos, 2013). A

practical design and implementation of a rule-based

context-aware system for health care domain is pre-

sented in (Wang et al., 2012).

Examples of industrial applications of contextual

computing are (Gundersen, 2014; Pistofidis et al.,

2014; Zhu et al., 2015). (Gundersen, 2014) apply

contextual computing in a situation assessment pro-

cess for oil well drilling operations. (Pistofidis et al.,

2014) define a model for failure context to support di-

agnostic and maintenance services. The generic con-

text ontology defined in (Wang et al., 2004) has been

extended in (Zhu et al., 2015) to support AR assisted

maintenance systems.

Empowering Industrial Maintenance Personnel with Situationally Relevant Information using Semantics and Context Reasoning

183

2.3 Industrial Semantic Web

A semantic data integration system has been stud-

ied by (Kunz et al., 2010) focusing on data federa-

tion to enable IoTS. For operational decision making

and run-time data acquisition an ontological frame-

work has been developed by (Mu

˜

noz et al., 2012).

In another approach to increase interoperability of

dynamic manufacturing networks an interoperability

framework has been presented (Figay et al., 2012).

To improve use of engineering information and in-

teroperability an approach based on ontologies has

been proposed in a model-driven development con-

text (Chungoora et al., 2013). These, however, do not

target needs presented in this paper but due to a sim-

ilar basis they provide efficient means for connecting

such information to the approach of this paper.

3 INFORMATION EXCHANGE

CHALLENGES

Maintenance in production environments can be car-

ried out based on a number of strategies but the

maintenance intervals and practices applied depend,

among other factors, on the target, its role and criti-

cality in the system, and the expertise and know-how

required. Maintenance may also include remote work

but remote monitoring is not in the scope of this paper.

The challenges discussed are based on feedback

and discussions with industry professionals. Themed

free-form questionnaires were sent out to a small

number of chosen industry professionals. Addition-

ally, also observations were made during workshops

discussing these and related topics.

3.1 Fragmented into Different Systems

A large number of information systems are used in in-

dustrial operations, especially in large production en-

vironments. The following information systems can

be identified of importance to maintenance activities:

• Plant or device model information systems: Plant

or device asset data stored typically as a logical hi-

erarchical structure including attributes and char-

acteristics. Usually the result of the engineering

phase and its master data is often stored in enter-

prise resource planning (ERP) level systems.

• Maintenance information systems: Data related

to active maintenance tasks, previously performed

maintenance actions and service history which ac-

cumulate during the lifecycle for e.g. a production

facility or an individual device.

• Condition monitoring systems: Data representing

the health and operational conditions of individ-

ual devices and assets actively monitored e.g. by

dedicated measurements. These systems are often

third-party provided and device specific. Aggre-

gating condition monitoring systems are also used

especially for communicating alarm event infor-

mation to human machine interfaces (HMI).

• Control systems: Control systems operate a wide

range of devices and equipment in the daily pro-

duction. Complex distributed control systems

(DCS) often include advanced monitoring fea-

tures as well as information on operation status

that reflect the current state of the machinery.

• Device catalogs and supporting documents: De-

vice vendors and equipment manufacturers typi-

cally provide datasheets, manuals and other sup-

porting instructions for their devices through ded-

icated portals or in-house support channels.

A key issue for maintenance services is that a

significant amount of this information is linked and

required for assessing and performing the required

maintenance activities efficiently. In a typical sce-

nario the FSP use information of assets to be main-

tained from the plant model information system, e.g.

the exact location identifier for the correct target as

well as for accounting the related costs. The deci-

sion whether to do a maintenance action, on the other

hand, can be based on a periodic schedule in the main-

tenance information system or by some degraded con-

dition indicated by a condition monitoring system.

Similarly the control system can provide such infor-

mation with alarms as well as the status of the ma-

chinery to decide whether the maintenance task can

be carried out safely. To perform the maintenance

task the person might need device specific supporting

documents and manuals.

Most of this information is available but retrieved

manually and communicated by emails and direct

conversation. This consumes valuable time as well

as hinders the full utilization of information. In man-

ual or poorly integrated systems it is not uncommon

that some other maintenance task escapes one’s atten-

tion that could have easily been performed at the same

time. This is obviously costly when downtime is in-

creased when maintenance efforts are not optimised.

The aforementioned systems are often heteroge-

neous facing the typical integration challenges for

building effective solutions. This means that apart

from the different types of communication protocols

also the information semantics vary.

KMIS 2015 - 7th International Conference on Knowledge Management and Information Sharing

184

3.2 Information Management

In production environments it can be argued that as-

set information becomes over time more important

than the physical asset itself. An example of this is

maintenance history that is critical for the overall op-

eration of some machinery. Having a spare device

does not help if production is unexpectedly stopped

resulting in lost production easily exceeding the mon-

etary value of the failing device. Maintenance affects

the OEE indicator (Overall Equipment Efficiency =

Availability x Performance Efficiency x Rate of Qual-

ity) especially through availability and quality.

Management of information in industrial produc-

tion facilities is challenging also due to the large num-

ber of devices and equipment installed. A processing

facility, for example, can contain hundreds or up to

thousands of devices that depending on the manufac-

turer have their information and attributes differently

in the plant model information system. Fortunately

for industrial informatics there are several standards

that facilitate the communication such as Mimosa for

maintenance activities, ISA-88 and ISO 15926 for

production equipment structuring and attributes, and

ISA-95 for manufacturing to enterprise communica-

tion, to name a few of the applicable standards that

can be used to harmonize information management.

A CBM system increases the knowledge of the

risk of failure, and is therefore an important means

to maximise availability and effective hours of crit-

ical components. Typically these systems continu-

ously monitor the asset of interest and based on data-

analysis from a larger set of similar devices some

threshold values can be detected when maintenance

should be performed. The know-how to interpret

these signals, e.g. deviations in vibration analysis re-

sults, switching times for internal components etc., is

often the expertise of the device manufacturer. It is

often provided as an additional billable service to the

operator or owner. From the operator perspective the

raw data is not of core interest, i.e. only the perfor-

mance indicators, while the manufacturer on the other

hand may depend on this for doing analysis on a larger

set of devices. Depending on the implementation this

information can be provided directly from the device

or as a remote service e.g. over the Internet.

A mobile remote asset, such as a crane or some

other movable device, is not similarly part of any fac-

tory network. In such cases status and condition data

is often gathered from the device to a cloud storage,

either automatically on-line or periodically between

stationings or when visited by a maintenance tech-

nician. For modern devices this can be provided re-

motely to the site over the Internet but for many older

systems this is a combination of Internet retrieved

data, e.g. maintenance history, and local information

on most recent condition developments and events.

3.3 External Service Providers

The business models have also changed and many

production facility owners, or operators, focus on

their core tasks. As a result, maintenance is often

outsourced to various service providers, e.g. generic

routine maintenance and highly specialised services.

In all cases the external service provider needs in-

formation from the various information systems pre-

viously listed. To some extent this can be reduced

with planning from the operator side and a direct link

to the plant information model system can be elimi-

nated, i.e. that being an ERP system in many cases.

The rest of the demands, however, remain. From

the service provider side the challenge and associated

system integration cost is even greater as the same

service provider may have liabilities with several cus-

tomers, i.e. several different production facilities.

A maintenance service person needs to have ac-

cess to the assigned task but also to information

on previous maintenance history. An experienced

FSP can, for instance, spot on-site a cause to some

recurring failure with knowledge of previous inci-

dents. Outsourced personnel do not necessarily pos-

sess the experience from working with the equipment

for years or the practices and methods previously ap-

plied. Supporting documents and guidelines become

important in these cases and they need to be commu-

nicated efficiently while the task is at hand.

Sometimes demanding maintenance service work

is performed by relatively inexperienced persons such

as the machine operator. In such cases the guidelines

need to be explicitly provided as the person may have

no idea where to search for such information in the

first place. However, in such cases remote monitoring

and assistance can also be used to support the work.

3.4 Tacit Knowledge in Maintenance

An important factor in maintenance work is the use

of tacit knowledge, i.e. the experience and non-

explicit know-how. An experienced FSP knows how

to troubleshoot failures efficiently, what information

is needed to perform the work and where to find it,

how to proceed with the maintenance action such as a

replacement, and what information in the work report

might benefit similar cases in the future. This can be

assisted with guidelines but creating such for diverse

tasks is laborious on its own. General challenges with

Empowering Industrial Maintenance Personnel with Situationally Relevant Information using Semantics and Context Reasoning

185

tacit knowledge is first of all identifying it and sec-

ondly explicating it so it can be used in the future.

Lack of knowledge and routines is, however, not

only a case for inexperienced maintenance techni-

cians. Especially with outsourced maintenance ser-

vices the tasks are circulated among a larger number

of persons and these persons often also have mainte-

nance tasks at different locations. This hinders build-

ing up routines as well as communication and infor-

mation exchange that e.g. used to take place sporad-

ically. For equipment that are for instance rented or

moved to remote locations it might also be that a non-

professional needs to do basic maintenance tasks (e.g.

lubing). An extreme real-world case requirement can

be that such guidance needs to be visual.

Assisting video material could be used to illus-

trate work tasks and in the future AR could signifi-

cantly help performing maintenance with augmented

instructions and object highlighting either using a mo-

bile device or wearable AR glasses. With advances

in AR technology user actions could even be cap-

tured and identified semi-automatically. This could

be used for example to capture tacit knowledge of ex-

perienced persons without interfering with their work.

Secondly, it could automatically allow extracting in-

formation on completed operations that in addition

with the known work task context could be used to

assist in reporting. The latter could help with some-

times encountered reluctance of writing reports.

Tacit knowledge as such is considered to be out of

the scope of this paper. However, utilization of ex-

plicated tacit knowledge is considered a requirement.

For example, video material that is currently already

used could easily be provided as support to the main-

tenance task at hand given that metadata is available.

3.5 Summary of Requirements

The previously listed challenges can be transformed

into the following requirements. Based on con-

structive research of design science methodology

(Crnkovic, 2010) they are projected into models and

software constructs as building blocks which enable

testing the theories and examining the new reality.

• The information provision solution needs to sup-

port gathering and integrating information from

several different sources with varying content.

• Standard based definitions should be used for or-

ganizing maintenance related information in order

to improve further knowledge utilization.

• The solutions should allow the use of adapters to

reuse once implemented adaptation for similar in-

formation types and enable classification based on

standard concepts.

• Reasoning needs to be supported to provide the

relevant supporting information with minimal

user effort.

• The context information should be reused to as-

sist and simplify reporting but also to store situa-

tional information for future analysis and support

improvements.

4 EMPOWERING TECHNICIANS

WITH SITUATIONALLY

RELEVANT INFORMATION

Providing required and supporting information rele-

vant to the maintenance task, either automatically or

semi-automatically, enables the FSP to focus efforts

on the actual value-adding work and improves con-

fidence in performing the task. Accessing support-

ing documents, manuals, previous maintenance his-

tory and other information is still highly dependent

on preparatory work that can not always be foreseen.

4.1 Architecture Overview

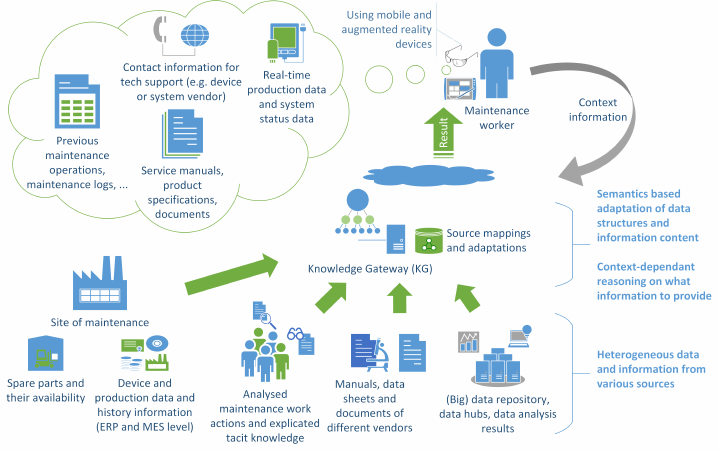

Figure 1 presents an overview of the concept how and

what kind of information is provided to the mainte-

nance technician. The lower section of the figure il-

lustrates information such as guidelines and instruc-

tions of the maintenance service company, manuals

and other documents provided e.g. by device vendors,

and information originating from data repositories as

a result of data analysis. On the bottom left of the

figure the information sources originating from the

site of maintenance are depicted. These include con-

trol systems providing runtime information but also

ERP as well as MES (Maintenance Execution Sys-

tem) level information is typically required. The lat-

ter sources typically contain site specific information

e.g. on production operations but also in-house inven-

tories of spare parts, replacements etc.

For software applications to be able to use pro-

vided information efficiently metadata is required

both for interfaces as well as the data content. Es-

pecially in cases where information sources and the

content structure change a knowledge management

solution is required. This is where the semantic inter-

face gateway, referred to as the Knowledge Gateway

(KG), acts as a key enabler in mediation. It provides a

uniform point of access to heterogeneous sources that

based on metadata allows for reasoning what is rele-

vant in different situations the maintenance technician

encounters.

KMIS 2015 - 7th International Conference on Knowledge Management and Information Sharing

186

Figure 1: The maintenance knowledge management concept is based on a knowledge gateway (KG) that combines information

from various sources in a meaningful way based on semantic descriptions and reasoning of the context.

4.2 Linking Information Sources

To achieve its goal the KG requires a basic model for

understanding the operational context as well as what

each information source and slice of data represent.

This along with mappings, and adapter layers to pro-

prietary systems, allows contextual reasoning to pro-

vide the relevant information to the maintenance task.

For static documents there are description meth-

ods and similar models are also emerging for AR and

other multimodal media material (Olmedo, 2013).

Also runtime information systems support several so-

phisticated means for providing operational data. An

example of this is OPC UA (Open Platform Com-

munications Unified Architecture) (OPC Foundation,

2009) that in addition to an acknowledged standard

protocol for accessing diverse systems also offers in-

formation modeling features e.g. for describing se-

mantics to be used in dynamic discovery.

In the concept a mobile device can automatically

provide information on previous maintenance opera-

tions, manuals, system status as well as contact infor-

mation for key persons in contrast to manual search-

ing from diverse sources. The context allows linking

the task with the targeted machine to access e.g. sup-

porting documents originating from the vendor. Sim-

ilarly the identified machine can be used to retrieve

previous maintenance history of e.g. same type of ac-

tions. Using the facility segment location other open

tasks can be automatically shown in case they can be

performed during the same stop in production.

4.3 Maintenance Technician’s Context

The meaning of context notion is difficult to capture

because of its open nature. For instance, some partic-

ular knowledge is considered to be part of context in

one setting while it is not in another setting. A gen-

eral definition often cited in literature has been pre-

sented in (Dey, 2001): “Context is any information

that can be used to characterize the situation of an

entity. An entity is a person, place, or object that is

considered relevant to the interaction between a user

and an application, including the user and applica-

tions themselves.” Accordingly, context is informa-

tion about some situation. Defining situation as a state

of an entity and its environment implies that informa-

tion about an environment is also an essential part of

context.

In this study, the scope of the context needs to be

defined for the maintenance application domain. the

basic concepts and high level context categorization

are based on the Situation Assessment Context (SAC)

model defined in (Gundersen, 2014). In this model

situation is defined as a static state of an entity and its

environment. Events can change this state creating a

new situation. The state can be described by informa-

tion elements relevant for the situation. Consequently,

situation is defined by the context elements forming

or characterizing the situation and element relations.

The SAC hierarchy is extended and specialized for

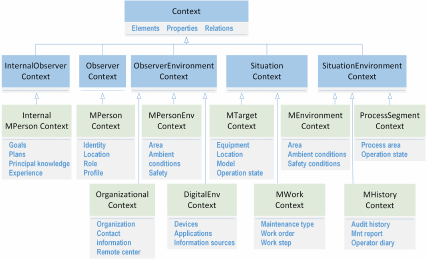

maintenance operations domain by ten new categories

represented in figure 2 as Maintenance Context (MC)

Empowering Industrial Maintenance Personnel with Situationally Relevant Information using Semantics and Context Reasoning

187

Figure 2: A class diagram presenting MaintenanceContext

classes (two lower rows) in SituationAssessment context hi-

erarchy (two upper rows). Some examples of the possible

Elements of the Context classes are listed as class members.

classes. As a result, the overall operational context

model consists of ten contexts with different sets of

elements which represent different aspects of the total

knowledge content.

In the MC model, a maintenance person (MPer-

son) represents the Observer of the SA model. MPer-

son’s maintenance work (MWork) is related to some

target machine (MTarget) which can be part of some

larger production segment (ProcessSegment) in a pro-

duction area. Maintenance work can consist of sev-

eral work steps and sub operations. After finishing

one work step and changing to the next one, the situa-

tion of the maintenance technician might also change

especially if the next task need to be done in a new

environment location. In fact, the situation dynamics

is mainly related to the dynamics of the workflow and

the accuracy it is observed and recorded.

In addition to ProcessSegment context there are

two other dimensions of the target environment (Sit-

uationEnvironment) that need to be described in the

model. MEnvironment contains elements with in-

formation about the conditions in the maintenance

area that can affect work preparations and execution.

MHistory context will provide information about the

maintenance history of the target, such as links to the

latest maintenance reports.

ObserverEnvironment context is described by

three more specific sub contexts. First, MPerson-

Environment context contains by default the same

information as MEnvironment. However, there are

situations when the environment of the maintenance

worker is different from that of the maintenance tar-

get. Second, Organizational context provides infor-

mation about the maintenance organization and peo-

ple, e.g. the contact information of experienced main-

tenance people at the site and remote support center.

Third, DigitalEnvironment context contains the list-

ing of available applications and data sources that can

be accessed for support information.

5 KNOWLEDGE MANAGEMENT

BASED ON SEMANTICS

The previous section introduced the concept of pro-

viding situationally relevant information for the main-

tenance technician based on the context to support

the task at hand. As discussed in section 3, integrat-

ing such information is challenging especially with

changing maintenance locations and varying back of-

fice information systems. For this the use of informa-

tion semantics is proposed to assist in the meaningful

interpretation and combination of knowledge.

5.1 Semantic Web Technologies

For the Semantic Web ontologies form the basis of

knowledge with descriptions expressing relationships

between objects as well as their properties. RDF (Re-

source Description Framework) and OWL (Web On-

tology Languages), that is built on top of RDF, are

commonly used W3C specifications. These ontology

concepts, i.e. classes, their instances and property

types, are denoted by unique URIs allowing sharing

and reuse of concepts. Using a triple statement mech-

anism relationships are then described between con-

cepts to form the knowledge representation.

More general ontologies, often denoted as core

ontologies, are used to map and link concepts in

different application specific ontologies. RDF and

OWL, in comparison to XML, provide computer in-

terpretable semantics. This means that using reason-

ing statements and rules new knowledge can be au-

tomatically inferred. As a result, and in combination

with ontology mappings, this also enables meaningful

interpretation of previously unencountered content.

A limiting factor in Semantic Web applications is

the open world assumption (OWA) meaning that if

something is not stated it does not mean it does not

exist (e.g. in the real world). It is simply unknown.

This means that the lack of some declaration can-

not be used to infer something opposite. In applica-

tions with known boundaries, e.g. application specific

implementations, techniques such as SPIN (SPARQL

Inference Notation) can be used to query and infer on

a closed world assumption (CWA). This also means

that SPARQL and SPIN can be used for validation of

data in comparison to standard OWL reasoning.

Ontology reasoning, especially using OWL in its

full extent, is computationally complex. Applica-

tions utilizing SWRL (Semantic Web Rule Language)

rules, for example, are often of exponential space time

complexity. This matters especially in settings com-

bining vast amounts of data. Further on, a topic of

its own is combining ontologies from diverse sources

KMIS 2015 - 7th International Conference on Knowledge Management and Information Sharing

188

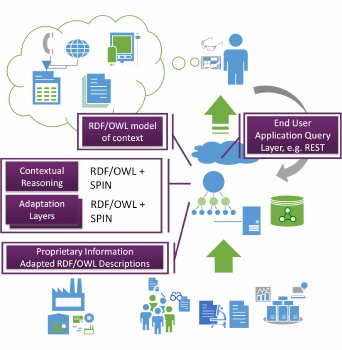

Figure 3: The knowledge management uses Semantic Web

technologies for managing information as well as for con-

textual reasoning to provide content suited the task at hand.

having embedded reasoning axioms unimaginable.

In order to overcome this the SPARQL based SPIN

mechanism can be used. SPARQL is an ontology

query language and SPIN is an application of this for

reasoning but also for construction of new knowledge.

SPARQL, however, operates on a (RDF) triple level

but the triple stores can perform inferences on their

own, e.g. using OWL reasoning. SPIN is then used

to build layers of queries and construct statements to

infer and adapt to different underlying semantics.

Figure 3 illustrates on a generic level the use of

the aforementioned Semantic Web technologies in the

concept. Unified access to originally heterogeneous

data sources is made possible by a semantic repos-

itory KB containing all information in RDF graph

format. The data access performance of advanced

repositories implemented by RDF triple store technol-

ogy is already well comparable with that of relational

databases, which make them a feasible KB solution

for the proposed concept (Aarnio et al., 2014).

Adapter solutions are needed to index proprietary

content. This is achieved either manually or by tools

performing classification resulting in semantically an-

notated metadata. Considering the current tools avail-

able (e.g. as surveyed by (Tosi and Morasca, 2015)

and (Madani et al., 2013)) a simple model is con-

sidered sufficient. The more advanced adaptation is

consider a responsibility of the RDF/OWL and SPIN

based adaptation layers. With these layers mappings

are developed to general maintenance domain ontol-

ogy concepts. Using these knowledge constructs rea-

soning is then performed. To facilitate usability of

results a REST interface for simplified access is pro-

vided for mobile and other user interface devices.

5.2 Plant and Maintenance Information

using Semantic Web Ontologies

To unify the different representations of production

facility structures and devices a plant information

model has been developed. The ontology model is

based on the IEC 62264 (ANSI/ISA-95) standard. It

provides a set of concepts for dividing the enterprise

environment into hierarchical sites, areas, segments,

units and modules. The plant information model pro-

vides target locations for maintenance tasks but also

serves as the link to surrounding components e.g. in

the same segment or unit. Additionally, the plant in-

formation model provides information and links to the

assets, and further enables linking of additional infor-

mation of individual devices and equipment.

Furthermore, a lightweight maintenance ontology

has been developed as an upper level integration

model for potential maintenance related legacy data

sources with differing structures. This model is based

on well-founded open standard Mimosa’s OSA-EAI

that covers concept definitions for several mainte-

nance areas including maintenance work orders and

activities, asset and segment hierarchies, condition

monitoring and diagnostics etc. The maintenance on-

tology has partially overlapping content with the plant

information model, which enables model linking and

integrating queries from both models.

5.3 Semantic Representation of the

Maintenance Context

The development of the context model ontology was

founded on the abstract context modeling principles

described in section 4. Design decisions were also

constrained by the need to support several functional

requirements of the KG system. The final aim is to

provide relevant situation dependent support informa-

tion for a FSP during the maintenance work. Contex-

tual information is exploited in combining, filtering

and access of information in the primary knowledge

base (KB) as well as providing links to appropriate

external services.

5.3.1 Context Model Ontology

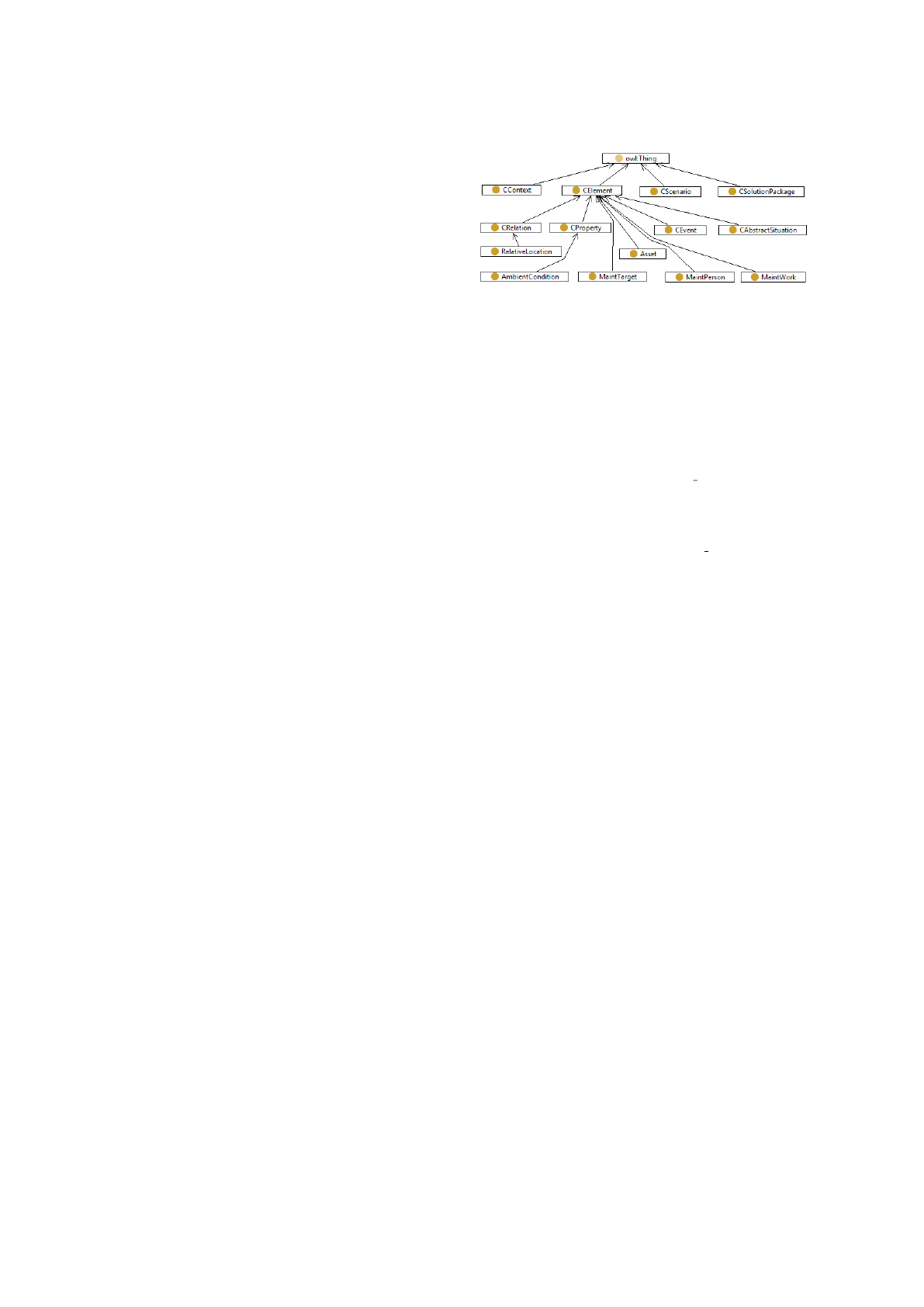

The context model ontology consists of two parts: a

small set of basic upper level concepts (represented

with prefix letter C in figure 4) and an extendable

set of domain related concepts defined as special-

izations of the upper level concepts. The names of

the maintenance domain concepts are mostly adopted

from Mimosa’s OSA-EAI model. The overall oper-

ational context model consists of several context in-

Empowering Industrial Maintenance Personnel with Situationally Relevant Information using Semantics and Context Reasoning

189

stances from different context categories each con-

taining a different set of elements and providing a dif-

ferent view to the primary knowledge in the KB.

Context consists of elements (figure 4) that rep-

resent any objects, properties of objects or relations

between objects that are considered relevant for the

description of a situation. Events that indicate possi-

ble situation change are also considered as elements.

Elements can be characterized by attributes and asso-

ciated with binary relations to other elements. Typi-

cally, an element should contain information about its

type, location and some aspect of time.

Because, the context model is a view model, do-

main specific elements may have simple data content,

but need to have references (URI, ID) to the primary

objects in the KB they represent as a kind of proxy

objects. This reference value can be used as an argu-

ment in a SPARQL query (SPIN template, rule) when

a more detailed description of the primary object is

required. Furthermore, elements can have references

to more than one KB model (named RDF graph) en-

abling information combination. For instance, the

context element Segment may represent a Segment

object in the Mimosa model, but also the correspond-

ing Equipment object in the ISA-95 based model, and

both models can be accessed through this element.

5.3.2 Contextual Reasoning

Reasoning on the context is carried out mainly at a

high conceptual level in the KG. Fast development

of intelligent mobile platforms and reasoning engines

(Motik et al., 2012) makes it soon possible to do the

most low level sensor data based contextual reason-

ing in real-time already in the user’s mobile device.

For instance, FSP’s movement can be tracked by mo-

bile devices, which can infer his relative location to

the target machine and send it as e.g. ‘near the target’

event message instead of using coordinate values.

Contextual reasoning capability is implemented

by SPIN rules. Rules can be embedded to context

and element classes enabling object-oriented style of

modeling. Four basic kinds of rules are used in the

context model: construction rules, information filter-

ing rules, modification rules and constraint rules.

(1) Element construction rules are used to initialize

the main attribute values of the created element in-

stances, such as, references to the primary informa-

tion objects in KB.

(2) Information filtering rules are used to select a rel-

evant set information objects into a solution package

to be provided for FSP. What is relevant support in-

formation depends on the context, e.g. current work

phase and expertise level of FSP.

Figure 4: The upper level class hierarchy (prefix C) of the

context ontology extended with some of the domain specific

CElement subclasses.

(3) Modification rules are used to update element

values. Situation rules explained above belong to

this category. For example, the following simplified

rule representation denotes how a new value of

an AbstractSituation element can be inferred and

updated depending on the values of other elements:

MPerson{relativeLocation(’near target’)},

WorkStep{nextActivity(’inspection’)},

MTarget{Asset{operationState(’stopped’)}},

WorkStep{permission(’granted’)}

=>AbstractSituation(’inspection started’).

(4) Constraint rules can be used to validate element

values before other rules are executed, e.g. to check

if the state of the target machine is ’stopped’ when its

service begins and otherwise generate a notification.

The context related support information is pro-

vided to FSP as a solution package that is an ag-

gregated package object containing different kinds

of guidance information for his work. For example,

it can contain the results of contextualized queries,

links to maintenance instruction documents and AR-

multimedia sources as well as addresses of mainte-

nance service function endpoints.

6 DISCUSSION

The novel solution for integrating maintenance infor-

mation relevant to the context provides the flexibil-

ity required in today’s service business environments.

The solution allows connecting information from var-

ious sources using adapting layers, and based on effi-

cient contextual reasoning automatically provide the

relevant information to the FSP. In addition, acknowl-

edged standards are used as a basis for ontology de-

velopment, thus promoting interoperability and in-

dustrial acceptance.

The KG system design based on a semantic KB

and RDF data model address the requirements of flex-

ible knowledge representation, easy data model ex-

tensions and knowledge sharing. These aspects are

highly important especially for contextual modeling.

KMIS 2015 - 7th International Conference on Knowledge Management and Information Sharing

190

Since, it might be impossible to predefine the whole

context model, it should be easily extendable with

new domain specific elements adopted and abstracted

from the most essential concepts of the existing pri-

mary information models. Further, the approach

emphasizes lightweight ontologies defined with lim-

ited complexity ontology language (OWL 2 RL) and

contextual reasoning by SPIN rules. These design

choices enable simple system implementation, when

no separate rule-based system is needed. Most of the

application logic can be hidden into supple rules and

query templates embedded into the ontology allowing

execution using standard SPARQL capable engines.

RDF is a metadata language that can be used to

represent the semantics of explicated tacit knowledge

in a resilient way. At least simple tacit knowledge pat-

terns could be recorded by an easy to use annotation

mechanism provided to system users. The idea is that

all kinds of user generated annotations, comments and

tags can be linked to any elements of a context model

and recorded. A set of predefined annotation patterns

developed in collaboration with domain experts could

improve the usability of this functionality. This func-

tionality justifies the simple and relatively flat struc-

ture of the context model, which provides element

categorization understandable to the users with basic

domain knowledge.

AR-multimedia and videos can be used to record

and transmit explicated tacit knowledge of domain ex-

perts. Context dependent search of these media re-

quires that metadata describing their content is avail-

able in RDF format. In fact, some specifications re-

lated to AR-media metadata and search are already

under development that can support this search func-

tion, such as, ARML and JPSearch. The KG sys-

tem will provide links to high level situation relevant

AR-media and information instances in the solution

package delivered to FSP’s mobile device. However,

real-time contextual reasoning required for presenta-

tion of the selected AR-media will be the responsibil-

ity of mobile AR applications and reasoners running

on FSP’s mobile devices (e.g. (Zhu et al., 2015)).

The concept development phase was supported by

preliminary evaluation of the main implementation

technologies. The basic ontology models were manu-

ally developed using an ontology editor. Data access

using query templates and contextual reasoning using

SPIN rules were tested in an editor supporting SPIN

reasoning as well as by using an application devel-

oped for this purpose with an open source SPIN API

library (Java). Consequently, these technologies were

considered feasible for the concept implementation.

7 CONCLUSION

Supporting maintenance technicians with situation-

ally relevant information can improve efficiency and

quality of work, and increase general confidence in

performing the maintenance tasks. Much of this

varying information content is scattered into different

information sources. Having information available

suited to the task at hand typically requires prepara-

tory work that is away from productive hours, and this

is emphasized in the case of external service providers

having several facilities to take care of.

The paper first presented requirements for em-

powering FSPs with situationally relevant informa-

tion to meet challenges in performing maintenance.

Based on these a knowledge management concept

was defined including methods for linking mainte-

nance information system data, supporting knowl-

edge, site equipment and other assets. For this a con-

text model was defined so that reasoning could be per-

formed automatically to provide relevant information

directly to the maintenance technician. The devel-

oped solution is based on using Semantic Web tech-

nologies such as RDF, OWL, SPARQL and SPIN to

categorize, map, adapt and perform reasoning to flex-

ibly integrate information from diverse sources. As

such, the knowledge management approach can im-

prove the utilization of existing data and augments in-

formation provided by current mobile applications the

maintenance technicians use.

Currently the knowledge management approach

and system architecture has been defined, and early

prototyping has been performed. In upcoming re-

search, live data sources will be integrated and the

adaptation means will be further developed for test-

ing in close to real production environments.

REFERENCES

Aarnio, P., Seilonen, I., and Friman, M. (2014). Seman-

tic repository for case-based reasoning in cbm ser-

vices. In Emerging Technology and Factory Automa-

tion (ETFA), 2014 IEEE, pages 1–8.

Abowd, G. D. and Mynatt, E. D. (2000). Charting past,

present, and future research in ubiquitous computing.

ACM Trans. Comput.-Hum. Interact., 7(1):29–58.

Campos, J., Jantunen, E., and Prakash, O. (2009). A

web and mobile device architecture for mobile e-

maintenance. The International Journal of Advanced

Manufacturing Technology, 45(1-2):71–80.

Chen, H., Finin, T., and Joshi, A. (2005). The soupa ontol-

ogy for pervasive computing. In Tamma, V., Crane-

field, S., Finin, T., and Willmott, S., editors, Ontolo-

gies for Agents: Theory and Experiences, Whitestein

Empowering Industrial Maintenance Personnel with Situationally Relevant Information using Semantics and Context Reasoning

191

Series in Software Agent Technologies, pages 233–

258. Birkh

¨

auser Basel.

Chungoora, N., Young, R. I., Gunendran, G., Palmer, C.,

Usman, Z., Anjum, N. A., Cutting-Decelle, A.-F.,

Harding, J. A., and Case, K. (2013). A model-driven

ontology approach for manufacturing system interop-

erability and knowledge sharing. Computers in Indus-

try, 64(4):392 – 401.

Crnkovic, G. (2010). Constructive research and info-

computational knowledge generation. In Magnani,

L., Carnielli, W., and Pizzi, C., editors, Model-Based

Reasoning in Science and Technology, volume 314

of Studies in Computational Intelligence, pages 359–

380. Springer Berlin Heidelberg.

Dey, A. K. (2001). Understanding and using context. Per-

sonal Ubiquitous Comput., 5(1):4–7.

Figay, N., Ghodous, P., Khalfallah, M., and Barhamgi,

M. (2012). Interoperability framework for dynamic

manufacturing networks. Computers in Industry,

63(8):749 – 755. Special Issue on Sustainable Inter-

operability: The Future of Internet Based Industrial

Enterprises.

Gundersen, O. E. (2014). The role of context and its el-

ements in situation assessment. In Br

´

ezillon, P. and

Gonzalez, A. J., editors, Context in Computing, pages

343–357. Springer New York.

Holmberg, K., Adgar, A., Arnaiz, A., Jantunen, E., Mas-

colo, J., and Mekid, S. (2010). E-maintenance.

Springer Publishing Company, Inc., 1st edition.

Hong, J., Suh, E., and Kim, S. (2009). Context-aware sys-

tems: A literature review and classification. Expert

Systems with Applications, 36(4):8509 – 8522.

IEC (2013). IEC 62264-1:2013 enterprise-control system

integration – part 1: Models and terminology.

Kunz, S., Brecht, F., Fabian, B., Aleksy, M., and Wauer, M.

(2010). Aletheia–improving industrial service lifecy-

cle management by semantic data federations. In 24th

IEEE International Conference on Advanced Infor-

mation Networking and Applications (AINA), pages

1308–1314.

Madani, A., Boussaid, O., and Zegour, D. E. (2013). Semi-

structured documents mining: A review and compar-

ison. Procedia Computer Science, 22(0):330 – 339.

17th International Conference in Knowledge Based

and Intelligent Information and Engineering Systems.

Mettouris, C. and Papadopoulos, G. A. (2013). Contextual

modelling in context-aware recommender systems: A

generic approach. In Haller, A., Huang, G., Huang, Z.,

Paik, H.-y., and Sheng, Q., editors, Web Information

Systems Engineering - WISE 2011 and 2012 Work-

shops, volume 7652 of LNCS, pages 41–52. Springer

Berlin Heidelberg.

MIMOSA (2010). OSA-CBM Open System Architecture

for Condition-based Maintenance v3.3.1 Production

Specification.

Motik, B., Horrocks, I., and Kim, S. M. (2012). Delta-

reasoner: A semantic web reasoner for an intelligent

mobile platform. In Proceedings of the 21st Inter-

national Conference Companion on World Wide Web,

WWW ’12 Companion, pages 63–72, New York, NY,

USA. ACM.

Mu

˜

noz, E., Cap

´

on-Garc

´

ıa, E., Espu

˜

na, A., and Puigjaner,

L. (2012). Ontological framework for enterprise-wide

integrated decision-making at operational level. Com-

puters & Chemical Engineering, 42:217 – 234.

Murthy, D., Karim, M., and Ahmadi, A. (2015). Data man-

agement in maintenance outsourcing. Reliability En-

gineering & System Safety, 142(0):100 – 110.

Nalepa, G. J. and Bobek, S. (2014). Rule-based solution

for context-aware reasoning on mobile devices. Com-

puter Science and Information Systems, 11(1):171–

193.

Olmedo, H. (2013). Virtuality continuum’s state of the art.

Procedia Computer Science, 25(0):261 – 270. 2013

International Conference on Virtual and Augmented

Reality in Education.

OPC Foundation (2009). OPC unified architecture specifi-

cation part 5: Information model v.1.01.

Perera, C., Zaslavsky, A., Christen, P., and Georgakopoulos,

D. (2014). Context aware computing for the internet

of things: A survey. Communications Surveys Tutori-

als, IEEE, 16(1):414–454.

Pistofidis, P., Emmanouilidis, C., Papadopoulos, A., and

Botsaris, P. N. (2014). Modeling the semantics of fail-

ure context as a means to offer context-adaptive main-

tenance support. Second European Conference of the

Prognostics and Health Management Society, pages

8–10.

Ruiz, P. A. P., Kamsu-Foguem, B., and Noyes, D.

(2013). Knowledge reuse integrating the collaboration

from experts in industrial maintenance management.

Knowledge-Based Systems, 50(0):171 – 186.

Soylu, A., Causmaecker, P., and Desmet, P. (2009). Context

and adaptivity in pervasive computing environments:

Links with software engineering and ontological engi-

neering. Journal of Software, 4(9).

Tosi, D. and Morasca, S. (2015). Supporting the semi-

automatic semantic annotation of web services: A sys-

tematic literature review. Information and Software

Technology, 61(0):16 – 32.

Wang, H., Mehta, R., Chung, L., Supakkul, S., and Huang,

L. (2012). Rule-based context-aware adaptation: a

goal-oriented approach. Int. Journal of Pervasive

Computing and Communications, 8(3):279–299.

Wang, X., Zhang, D. Q., Gu, T., and Pung, H. (2004). On-

tology based context modeling and reasoning using

OWL. In Pervasive Computing and Communications

Workshops, 2004. Proceedings of the Second IEEE

Annual Conference on, pages 18–22.

Zhu, J., Ong, S., and Nee, A. (2015). A context-aware

augmented reality assisted maintenance system. In-

ternational Journal of Computer Integrated Manufac-

turing, 28(2):213–225.

KMIS 2015 - 7th International Conference on Knowledge Management and Information Sharing

192