Towards Multi-functional Robot-based Automation Systems

Andreas Angerer

1

, Michael Vistein

1

, Alwin Hoffmann

1

, Wolfgang Reif

1

, Florian Krebs

2

and Manfred Schnheits

2

1

Institute for Software & Systems Engineering (ISSE), University of Augsburg, Augsburg, Germany

2

Center for Lightweight Production Technology, Institute of Structures and Design,

German Aerospace Center, Stuttgart, Germany

Keywords:

Cooperating Robots, Industrial Automation and Robotics, Robot Programming, Modelling and Simulation.

Abstract:

Multi-functional robot cells will play an important role in smart factories of the future. Equipped with flexible

toolings, teams of robots will be able to realize manufacturing processes with growing complexity. However, to

efficiently support small batch sizes and a multitude of process variants, powerful software tools are required.

This paper illustrates the challenges that developers face in multi-functional robot cells, using the example of

CFRP production. The vision of a new programming environment for such future flexible automation systems

is sketched.

1 INTRODUCTION

According to the International Federation of Robotics

(2014), the automotive industry is currently the

largest operator of industrial robots. This is mainly

due to the large batch sizes and, thus, a high num-

ber of repetitive tasks which allows for a more eco-

nomic integration of robots compared to other indus-

tries. However, there is a trend to apply robotic sys-

tems also for small batch production and for com-

plex manufacturing processes (cf. euRobotics aisbl,

2014). Especially with the Internet of Things and

Services and strategic initiatives such as Industry 4.0

in Germany (cf. Kagermann et al., 2013), the idea

of smart factories with intelligent machinery – re-

ferred to as cyber-physical systems (cf. Geisberger

and Broy, 2012) – and a highly customized produc-

tion is emerging. The products incorporate the knowl-

edge of how they need to be processed and, moreover,

they communicate directly with the machinery. As

cyber-physical systems, they know their skills and of-

fer them as services in a smart factory.

From our point of view, multi-functional robot

cells will play an important part in future smart facto-

ries. Industrial robots are flexible machines that can

perform a broad variety of tasks using different end-

effectors. Moreover, dynamic teams of cooperating

robots can together handle complex tasks if required.

Until today, there is a strong focus on knowledge-

based manufacturing systems or cyber-physical sys-

tems consisting of a single robot. However, when re-

garding dynamic teams of robots, the available skills

depend on the composition of the team. Cyber-

physical systems must be able to occasionally form

a new system with an extended set of skills and ser-

vices which poses new challenges for research.

The production of carbon fiber-reinforced plas-

tics (CFRP) is an interesting example where multi-

functional robot cells are important. CFRPs are be-

coming more and more important for many modern

products, e.g. for airplanes or helicopters, but also for

the automotive industry. Today, the production is of-

ten done manually, which is a very tedious and stren-

uous task, therefore it is worthwhile to automate this

process. However, the dimensions of CFRP parts can

vary tremendously depending on the product: Some

aircraft structures can be only a few centimeters in

size whereas others can be in the range of several

dozens of meters. Thus, a single industrial robot in

a static, fixed configuration will not always be suffi-

cient for handling the parts.

This paper introduces the challenges as well as a

possible road map for modeling, programming and

simulating dynamic robot teams in multi-functional

cells. Section 2 delivers a detailed view of both the

production process for CFRP and the multi-functional

robot cell built at the Center for Lightweight Pro-

duction Technology (ZLP) of the German Aerospace

Center (Deutsches Zentrum f

¨

ur Luft- und Raumfahrt,

DLR) in Augsburg. In Section 3, the current ap-

438

Angerer A., Vistein M., Hoffmann A., Reif W., Krebs F. and Schönheits M..

Towards Multi-functional Robot-based Automation Systems.

DOI: 10.5220/0005573804380443

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 438-443

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

Table 1: Cutpiece distribution for the demonstration pro-

cess.

Cutpiece class #

Skin “tile” (regular shape) 40

Skin “tile” (irregular on margins) 16

Frame thickness extension (regular shape) 40

Frame thickness extension (irregular) 16

Stringer base (large) 48

Stringer base (small) 48

Sum 208

proaches are described and challenges for applica-

tion development in such large scale environments are

identified. Novel approaches for efficient software de-

velopment for large teams of robots and peripheral de-

vices are introduced in Section 4. The paper is con-

cluded with Section 5.

2 CASE STUDY

To motivate the challenges that have to be faced in

multi-functional robot cells, we would like to address

the automated production of CFRP structural compo-

nents for aerospace applications. Many processes for

the production of CFRPs exist such as advanced fiber

placement, resin transfer molding, or vacuum assisted

resin infusion (VARI). An overview over these tech-

niques can be found in Baker et al. (2004). In the fol-

lowing, the VARI process will be shortly introduced

to understand the process requirements. A first auto-

mated solution is described afterwards.

2.1 Vacuum Assisted Resin Infusion

The VARI process basically uses dry textile cutouts

laid into a mold at specific positions. Afterwards the

mold is sealed with an airtight foil and other auxil-

iary materials. The whole layup is then evacuated and

subsequently infused with resin. To fully leverage the

weight saving potential of CFRPs, fibers are mainly

oriented along the major axis of tensile loads. In other

words, more material is placed in areas where high

loads are expected and less in other areas. Ultimately,

this leads to a very complex design of cutouts – often

referred to as cutpieces – in which many cutpieces

are unique within the layup. The whole layup is doc-

umented in a plybook

1

which specifies the shape of

each cutpiece and where it should be placed in the

layup. In aerospace applications, these plybooks usu-

ally contain hundreds of individual cutpieces.

1

A ply is a set of cutpieces forming a layer in a layup.

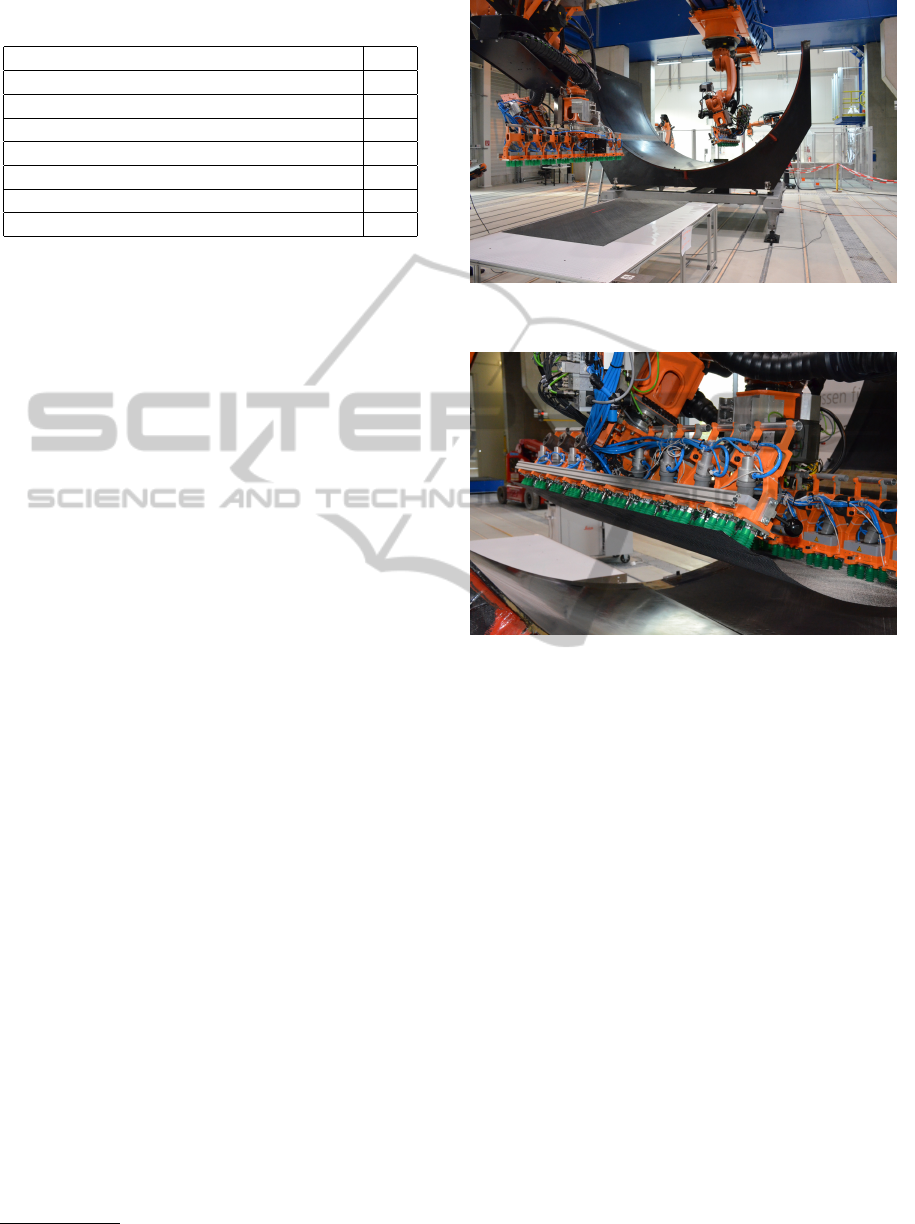

Figure 1: The experimental setup for the layup in the multi-

functional cell.

Figure 2: Both robots gripping a cutpiece.

2.2 Experimental Setup

In 2014, the DLR in Augsburg implemented an au-

tomated demonstration for this process on site, using

a section of an aircraft fuselage. This component is

basically a half-cylinder with a radius of ∼1.8 meters

and roughly a length of 2.5 meters. To illustrate the

automation process, a simplified plybook was created

consisting of 208 mostly uniform cutpieces. Table 1

summarizes the different ply classes. After plybook

design, a rough layout of the process in the robot cell

was drafted. The DLR’s multi-functional cell (Krebs

et al., 2014) was chosen as a platform.

This cell is intended for the evaluation of auto-

mated production processes for CFRP parts and con-

sists of two industrial 6-DOF arms on a common lin-

ear track in overhead configuration, and three XYZ-

portals spanning a workspace of roughly 30 x 15 x 7

meters. For this application, only the two central in-

dustrial arms were used (cf. Figure 1). The validation

of cooperative layup of single cutpieces was one of

the main objectives of this setup. Therefore the larger

cutpieces were handled using the KUKA.RoboTeam

technology which allows multiple robots to act coop-

TowardsMulti-functionalRobot-basedAutomationSystems

439

eratively. Three modes of operation are possible:

• Synchronized start: all robots start a process step

at the same time

• Synchronized motion: both the start and the finish

times of a step occur simultaneously for all robots

• Motion cooperation: one robot acts as a master

while the other robots follow in a geometrically

linked fashion

On each end-effector, a gripper was mounted that was

able to hold an edge of the fabric (cf. Figure 2). One

gripper was additionally equipped with a system to

measure the layup quality using a laser scanner.

2.3 Process Description

In a nutshell, the process is a pick&place application

that requires the cutpieces to be picked up from a ta-

ble and positioned into the mold at the proper coordi-

nates for each cutpiece. At the beginning, both robots

pick up each side of the cutpiece with their vacuum

grippers from a table together using a synchronized

motion. The following motions transfer the robots

into safe a position over the mold and include a mo-

tion of the linear track. Although this motion needs

to be synchronized as well, this cannot be carried out

by KUKA.RoboTeam since linear tracks are not fully

supported. A workaround was found by starting both

robot motions at the same time and letting them travel

the for same distance. After reaching the safe posi-

tion, the robots are geometrically linked and the mas-

ter robot leads the slave to a position just before layup.

Then, breaking the link again, each robot moves in a

synchronized motion to its individual target position,

making final adjustments along the way to compen-

sate for small deformations in the mold.

When both robots are in place, heaters are ex-

tended to melt the thermoplastic binder and temporar-

ily bond the cutpiece. After a ply has been laid up

completely, the robots move back into the safe posi-

tion. The robot without the laser scanner moves out

of the mold. After that, the measurement is started by

the second robot to verify that all cutpieces have been

positioned correctly according to the plybook. As-

suming the measurement showed no anomalies, both

robots move back into the starting configuration and

repeat the cycle until all plies have been laid.

2.4 Programming the Process

Currently available offline programming toolchains

like DELMIA (Dassault) and Process Simulate

(Siemens) lack proper support for cooperating robots

and could thus not be used directly for programming

the process. Instead, a hybrid approach was em-

ployed: The transfer from the table to the mold was

done using a classical teach-in process to define fixed

motions for both of the robots. Picking up the cut-

pieces as well as layup onto the mold was done by

using parameterized robot programs. The parameters

– mainly the gripping and target points – were gener-

ated in CPD

2

and exported manually by the program-

mers. Controlling the cooperation of the robots had to

be done by manually inserting appropriate commands

into the robot programs.

In sum, a lot of steps had to be done manually due

to the lack of appropriate support in CAD and offline

programming tools. Additional difficulties had to be

solved in dealing with KUKA.RoboTeam and online

programming as mentioned by Larsen et al. (2014).

While this experiment – dealing only with a minor

number of variations – already formed a challenge, it

is obvious that this approach will not scale to a real

world example with a multiple of individual plies.

3 CHALLENGES

Multi-functional cells like the DLR MFZ are able to

handle complex, fast-changing processes with rather

small lot sizes. The key ingredient are different types

of manipulators with the ability to cooperate, vary-

ing end-effectors as well as additional tools and fit-

tings. But still planning, programming and control-

ling processes in such robot cells remains a difficult

issue. The problem can be divided into two major

challenges, as outlined below.

3.1 Modeling, Planning and Simulation

Processes with a very high complexity and variability

cannot be fully planned and programmed manually.

Developers of the system software need tools for as-

sisted, semi- or fully automated planning of all tasks

involved in a process. Moreover, mapping tasks to a

multi-functional robot cell and determining an appro-

priate combination of robot arms, end-effectors and

sensors to reliably execute a certain task is a chal-

lenge that nowadays requires skilled and experienced

human experts.

In sum, we see challenges in the following areas:

• modeling complex processes with a large number

of interdependent tasks,

• modeling devices in a multi-functional cell and

their abilities (e.g. manipulators, end-effectors,

2

Composites Part Design, an extension for Dassault’s

CAD software CATIA.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

440

actuators, sensors, . . . ),

• modeling interaction of the devices (e.g. team and

un-team multiple manipulators on the fly),

• representing capabilities of single manipulator-

endeffector combinations,

• representing capabilities of teams of manipulators

and end-effectors

• (semi-)automated planning of process execution

in multi-functional robot cells,

• simulation and qualitative analysis of complex

processes in multi-functional cells.

For defining robot paths based on CAD data, there

exist various toolchains that are used in industry as

well as academia today. A prominent example is

the combination of Dassault Systeme’s CATIA and

DELMIA, sometimes combined with cenit’s FAST-

SURF. DELMIA can be used to perform virtual teach-

in of robot motions based on CAD input from CATIA.

FASTSURF adds support for motions along more

complex surfaces and furthermore integrates simula-

tion and analysis functionality geared towards con-

crete processes like painting. However, those tools

are rather focused on modeling single tasks and reach

their limits when it comes to modeling complex pro-

cesses with hundreds of sub-tasks like in the VARI

process. Furthermore, the support for robot teams in-

cluding different cooperation patterns is rather lim-

ited. In research, various single aspects that are rel-

evant for multi-robot systems have been treated, like

collision detection and path planning for multi-robot

systems (cf. Mediavilla et al., 1998; Larsen et al.,

2014). Only recently, research started to address the

idea as well as basic challenges regarding off-line pro-

gramming environments for multi-robot systems (cf.

Basile et al., 2012; Gan et al., 2013).

On the other hand, a lot of research has been done

in the area of process description as such as well as

(automatic) decomposition of processes into tasks (cf.

Thomas and Wahl, 2001; Ou and Xu, 2013; Huck-

aby et al., 2013). This has also been applied to the

robotics domain and has been combined with mod-

eling of devices, end-effectors and their skills (cf.

Pfrommer et al., 2013; Stenmark and Malec, 2013;

Michniewicz and Reinhart, 2014). However, research

in these areas has been focused largely on single robot

systems, and the additional challenges induced by co-

operating robot teams have not been treated in-depth.

3.2 Deployment to Real-world Systems

Similar to the physical actuators and end-effectors

in multi-functional cells, also the controller struc-

ture is very heterogeneous. Robot controllers mostly

are programmed using proprietary, manufacturer-

dependent programming languages and add-ons (e.g.

for robot cooperation). Devices utilize various tech-

nologies like field bus systems (e.g. Profinet, De-

viceNet, Ethercat) and ethernet-based protocols to

communicate. Often PLCs are used to build topolo-

gies and also to implement superordinated logic, of-

tentimes real-time deterministic and safety-critical

logic. But the PLCs typically are programmed using

proprietary tools and languages in turn.

In classical offline-programming scenarios, code

generation is often used to derive executable artifacts

from models for the target platforms (cf. Feldmann

et al., 2013; Stenmark et al., 2014). Even in a simple

robot cell, this has lots of disadvantages:

• many manual steps, e.g. exported robot programs

typically have to be moved to the robot controller

• shortcomings in flexibility, e.g. communication to

other devices is often done through generated I/O

commands in the robot program, this mostly lacks

good support for changes e.g. in I/O mapping

• ensuring overall consistency is imposed on the

user

In a multifunctional, reconfigurable robot cell, this all

gets even more tedious and error-prone to support all

of the different target platforms present.

4 TOWARDS EFFICIENT

SOFTWARE DEVELOPMENT

In order to efficiently develop software for multi-

functional robot cells, progress is needed on various

levels. This section presents areas that need be pushed

forward from our point of view (cf. Figure 3).

First of all, it is necessary to model the manufac-

turing process and break it down into single tasks.

It might be necessary to decompose tasks into fur-

ther sub-tasks. Dependencies among tasks need to be

modeled in order to determine a feasible order for ex-

ecution and parallelization. For example, in the VARI

process, the cutpieces may be produced all in parallel,

while the layup process obviously requires a certain

order of tasks. Each of the tasks has certain require-

ments that have to be fulfilled for successful execu-

tion. For example, cutpieces may be bent only to a

certain degree in order not to damage the fibers, which

has to be ensured during handling. Furthermore, a

maximum position tolerance has to be respected when

the cutpieces are laid into a mold. While some of

those requirements are mandatory for successful pro-

duction, others can be met with a certain tolerance,

TowardsMulti-functionalRobot-basedAutomationSystems

441

which influences the result quality. To judge the re-

sulting quality, the process model has to introduce

metrics for quality, which allows to predict quality of

the final result. For more accurate predictions, empiri-

cal values (e.g. known inaccuracies) should be usable

for extrapolation.

In order to map a manufacturing process to the ca-

pabilities of a multi-functional robot cell, a thorough

model of robot teams and tools is required. This

model must be able to describe not only the charac-

teristics and skills of a single robot with a specific

end-effector, but also that of different combinations

of devices, i.e. different combinations of robot arms

and end-effectors and in particular the combination of

multiple robot arms to teams as required by the task.

When multiple robot arms form a team, there are dif-

ferent cooperation patterns that fit various kinds of

tasks (e.g., uniform motion or motion relative to other

team members’ motions). The type of cooperation

pattern has an influence on how the team needs to be

represented by the model. In robot teams, different

constraints apply to the allowed operations, for exam-

ple due to the workspace of the single members or due

to physical capabilities like maximum velocities and

accelerations. On the other hand, those constraints

can depend on the initial configurations of the mem-

bers in the team. Thus, the formation of teams plays

an important role: Certain preconditions have to be

met in order to create a team from single robots.

Based on the manufacturing process model, a

CAD model of the robot cell and the model of robot

teams and tools, a unified programming environ-

ment for multi-functional robot cells becomes fea-

sible as a basis for mapping domain-specific pro-

simulate process

measure

process quality

assist in

offlineteaching

assign tasks

to robot teams

programming

environment

programming

environment

dynamic robot

team model

process model

Ͳ skills

Ͳ cooperation patterns

Ͳ constraints

Ͳ team formation

Ͳ task decomposition

Ͳ task dependencies

Ͳ task requirements

Ͳ quality metrics

deployment to realsystem

CADmodel

Figure 3: Process, CAD and robot team models should be

unified in a programming environment to assist software de-

velopment for multi-functional robot cells.

duction processes to concrete manufacturing cells.

By analyzing task composition and dependencies and

matching task requirements with robot (team) skills,

the programming environment can assist users in as-

signing tasks to robot teams. To design concrete op-

erations of a robot (team) required for a certain man-

ufacturing task, the programming environment must

assist users in offline teaching. Conventional on-line

teaching techniques are time-consuming and expen-

sive already for systems with single robots. Due to

constraints and physical dimensions of robot team se-

tups, on-line teaching becomes infeasible.

The assignment of tasks to robot teams and the

concrete task realization by robot team operations has

a strong influence on the quality of the process. A

programming environment should allow for measur-

ing the resulting process quality based on the quality

metrics inherent to the process model and the charac-

teristics of the robots and end-effectors. In this con-

text, the ability to simulate a concrete process in a

multi-functional cell is of great importance. Simula-

tion should be accurate enough to roughly conclude

about the process quality and to compare it among

different variants of a process. Simulation should

furthermore support user-defined parameters for in-

terrupting and replaying, similar to the use of break-

points in software debugging.

A crucial factor for the effectiveness of the pro-

posed offline programming system is the transition

from simulation to the real-world system. As men-

tioned before, code generation from models is the

predominant approach nowadays. In multi-functional

robot cells with complex end-effectors and very het-

erogeneous controllers, the effort for developing code

generators increases dramatically. Not only a vari-

ety of target platforms (robot controllers, tool con-

trollers, PLCs, ...) has to be supported, but also the

semantic consistency of the resulting code has to be

ensured. In order to match the required hard real-time

requirements in a cooperating robot team, further as-

pects like communication latencies have to be con-

sidered. Furthermore, modifications to the generated

code are often hard to re-integrate into the models, re-

quiring those modifications to be made over and over

again after code generation. From our point of view,

this “classical” code generation approach is no longer

feasible for multi-functional robot cells. Instead, a

shift towards open, standardized and configurable in-

terfaces of the different devices is necessary. Those

interfaces should reflect more closely the semantic

concepts of the process model. Thus, it might be-

come feasible to directly execute the models instead

of generating code, which would allow for a seamless

transition from simulation to real-world operation.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

442

First steps towards the proposed programming en-

vironment have already been made. In a first setup,

a single robot and multiple end-effectors have been

used. Based on a process model and a CAD model of

the robot cell, a semi-automatic generation of a feasi-

ble process flow is possible, including offline teaching

and simulation. Details on the architecture and setup

can be found in N

¨

agele et al. (2015).

5 CONCLUSION

This work illustrated the challenges that develop-

ers face when complex manufacturing processes

should be realized with a multi-functional robot cell.

The Multi-Functional Cell located at the DLR ZLP

in Augsburg is one of the world’s biggest multi-

functional robot cells in operation today and can be

seen as a prototype of what is yet to come accord-

ing to current research agendas. Based on a particu-

lar CFRP manufacturing process, the main challenges

that need to be solved were explained. The vision of a

programming environment for multi-functional robot

cells that unifies process, CAD and robot team models

was presented. By future joint research, the Univer-

sity of Augsburg and the DLR Center for Lightweight

Production will strive to realize this vision.

ACKNOWLEDGEMENT

The demonstration depicted in Section 2 was made

possible with the help and support of Andreas Buch-

heim, Somen Dutta, Mona Eckardt, Lars Larsen,

Thomas Schmidt, and Alfons Schuster of the DLR.

REFERENCES

Baker, A. A., Dutton, S., and Kelly, D. (2004). Composite

Materials for Aircraft Structures. American Institute

of Aeronautics & Astronautics.

Basile, F., Caccavale, F., Chiacchio, P., Coppola, J., and Cu-

ratella, C. (2012). Task-oriented motion planning for

multi-arm robotic systems. Robotics and Computer-

Integrated Manufacturing, 28(5):569 – 582.

euRobotics aisbl (2014). Strategic research agenda for

robotics in Europe 2014 – 2020.

Feldmann, S., Loskyll, M., Rosch, S., Schlick, J., Zuhlke,

D., and Vogel-Heuser, B. (2013). Increasing agility

in engineering and runtime of automated manufactur-

ing systems. In 2013 IEEE Intl. Conf. on Industrial

Technology, pages 1303–1308.

Gan, Y., Dai, X., and Li, D. (2013). Off-Line Program-

ming Techniques for Multirobot Cooperation System.

In Intl. J. of Adv. Robotic Systems. InTech Europe.

Geisberger, E. and Broy, M., editors (2012). Integrierte

Forschungsagenda Cyber-Physical Systems. acatech.

Huckaby, J., Vassos, S., and Christensen, H. I. (2013). Plan-

ning with a task modeling framework in manufactur-

ing robotics. In 2013 IEEE/RSJ Intl. Conf. on Intelli-

gent Robots and Systems, pages 5787–5794.

International Federation of Robotics (2014). World

Robotics – Industrial Robots 2014. VDMA Verlag.

Kagermann, H., Wahlster, W., and Helbig, J. (2013). Rec-

ommendations for implementing the strategic initia-

tive INDUSTRIE 4.0. Final report of the Industrie 4.0

Working Group, acatech.

Krebs, F., Larsen, L., Braun, G., and Dudenhausen, W.

(2014). Design of a multifunctional cell for aerospace

CFRP production. The Intl. J. of Adv. Manufacturing

Technology, pages 1–8.

Larsen, L., Kim, J., and Kupke, M. (2014). Intelligent path

planning towards collision-free cooperating industrial

robots. In 11th Intl. Conf. on Informatics in Control,

Automation and Robotics.

Mediavilla, M., Fraile, J., Peran, J., and Dodds, G. (1998).

Optimization of collision free trajectories in multi-

robot systems. In Robotics and Automation. Proceed-

ings. 1998 IEEE Intl. Conf. on, volume 4, pages 2910–

2915 vol.4.

Michniewicz, J. and Reinhart, G. (2014). Cyber-physical

robotics – automated analysis, programming and con-

figuration of robot cells based on cyber-physical-

systems. Procedia Technology, 15:567–576.

N

¨

agele, L., Macho, M., Angerer, A., Hoffmann, A., Vistein,

M., Sch

¨

onheits, M., and Reif, W. (2015). A backward-

oriented approach for offline programming of com-

plex manufacturing tasks. In The 6th Intl. Conf. on

Automation, Robotics and Applications.

Ou, L.-M. and Xu, X. (2013). Relationship matrix based

automatic assembly sequence generation from a CAD

model. Computer-Aided Design, 45(7):1053 – 1067.

Pfrommer, J., Schleipen, M., and Beyerer, J. (2013). PPRS:

Production skills and their relation to product, pro-

cess, and resource. In 2013 IEEE Intl. Conf. on

Emerging Tech. & Factory Automation, pages 1–4.

Stenmark, M. and Malec, J. (2013). Knowledge-based in-

dustrial robotics. In 12th Scandinavian Conf. on Arti-

ficial Intelligence, pages 265–274.

Stenmark, M., Malec, J., and Stolt, A. (2014). From high-

level task descriptions to executable robot code. In 7th

IEEE Conf. on Intelligent Systems, pages 189–202.

Thomas, U. and Wahl, F. (2001). A system for automatic

planning, evaluation and execution of assembly se-

quences for industrial robots. In Intelligent Robots

and Systems. Proceedings. 2001 IEEE/RSJ Intl. Conf.

on, volume 3, pages 1458–1464 vol.3.

TowardsMulti-functionalRobot-basedAutomationSystems

443