Angular Arrangement Optimization of the Support Racks of Gas

Turbine Engine to Reduce the Circumferential Unevenness

of Gas Flow

Grigorii M. Popov, Daria Kolmakova and Aleksandr O. Shklovets

Institute of Propulsion and Power Systems, Samara State Aerospace University (SSAU), Samara, Russian Federation

Keywords: Circumferential Distortion, Axial Compressor, Rotor Blades, Support Racks.

Abstract: This work is motivated by the necessity to reduce the effects of the flow circumferential distortion in the

flow passage of the aircraft gas turbine engine (GTE). During the presented research, another principal of

reduction of the flow circumferential distortion was chosen. Firstly, the variants of upgrading the existing

support racks were found. Secondly, the new design of support was offered. Both version of the support

design variation took into account the availability of technological and structural limitations associated with

the location of oil pipes, springs and others elements in the support racks. Investigations of modified design

showed that the support with altered racks provides a reduction of dynamic stresses by 20% at resonance

with the most dangerous harmonic, and the new design of support can give the decrease of 30%.

1 INTRODUCTION

Many problems that are currently faced by

researchers and engineers cannot be solved

analytically or require huge costs for the

experimental realization. Often, the only possibility

to carry out the express analysis of engineering

problems is a computer and mathematical

simulation. Progress in the development of

numerical methods significantly increased the

number of tasks available for analysis (Popov, et al.,

2014.). The obtained results based on these methods

are used in almost all fields of science and

technology.

The finite element method finds its most

important application in the design analysis. At the

same time, bridges, buildings, marine hulls, aircraft

components, machine parts, pistons, tools, i.e. any

engineering construction are understood under

“construction” in the design analysis.

Turbomachinery impellers are very critical parts

of gas turbine engines. The reliable engine operation

and flight safety of the aircraft depend on their

reliable operation of impellers to a large extent

(Shabliy and Cherniaev, 2014).

The possibility of appearance of variable

dynamic stresses in the impellers associated with the

action of the changing in time loads on it. One of the

main types of dangerous oscillations are forced.

Forced oscillations are due to the impact of

external forces on the object, time-varying, which do

not depend on dynamic behaviour of a vibrating

object and do not change under the assumption of

object non-deformable. In turbomachines these

forces associated with circumferential uniform of

flow incident on the rotating impeller. The

circumferential distortion is transformed into power

load that varies in time.

2 CALCULATION METHOD OF

FORCED OSCILLATIONS

Circumferential nonuniformity of the gas stream

flowing around the blades is the main source of

vibration excitation of the gas turbine engine rotor

wheels (RW). It appears in the form of

nonuniformity of the velocity and pressure fields in

the stream before and after the RW. Nonuniformity

leads to the fact that the gas load intensity in the

circumferential and radial directions is inconstant

around the circumference of the flow passage. The

integrated gas-dynamic force Q

g

changeable in value

acts on any of the blades during RW rotation.

383

M. Popov G., Kolmakova D. and O. Shklovets A..

Angular Arrangement Optimization of the Support Racks of Gas Turbine Engine to Reduce the Circumferential Unevenness of Gas Flow.

DOI: 10.5220/0005570403830388

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 383-388

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

Since the gas-dynamic force Q

g

is a periodic

value, i.e. Q

g

() = Q

g

(+2), it can be expanded in

a Fourier series:

∑

∙ cos

(1)

where Q

m

– the amplitude of the component

harmonic; m

e

– harmonic number;

– center angle,

γ

m

– phase shift along the circumference.

Expansion (1) allows presenting the gas load

having a complex distribution along the

circumference as a sum of component harmonics.

Each of them represents a succession of load waves

that fit around the circumference of flow passage.

For rotating impeller, any of the components in

(1) is exciting harmonic, which is the backward

running waves succession. The load rotates with an

angular velocity ω, which equal to the angular

velocity of RW. Thus, the circumferential gas flow

nonuniformity for rotor wheels is equivalent to an

effects of infinite set of exciting harmonics, each of

which represents a succession

e

m

of backward

running waves of load oscillates in time with

frequency f

e

= m

e

n

s

, where

To determine the dynamic stresses in the blade

airfoil, Ansys software was used. Gas dynamic load

force on the blades is determined in static CFD-

calculation. Using APDL programming language,

the program was written that imports the load

distribution from finite element model of blade row

in CFX to finite element model of the blade row in

Ansys Mechanical APDL. Then, the load is

decomposed in Fourier series at congruent nodes of

blades and is represented as a backward running

wave. Campbell diagram is used to determine the

most dangerous engine modes, and correspondingly,

the most dangerous harmonics. Dynamic stress

analysis is carried out only with the most dangerous

harmonic. This method is described in detail in

(Ermakov et al., 2014).

Damping in the system is defined on the basis of

experimental data as a viscous in material. Thus we

cannot state that this calculation method allows

evaluating the quantitative dynamic stresses in the

blade at the design stage. However, this method is

acceptable for qualitative assessment of changes of

dynamic stresses during the optimization.

3 IMPLEMENTATION OF

METHOD

Practical implementation of the method is discussed

in (Ermakov, Shklovets, Popov, Kolmakova, 2014).

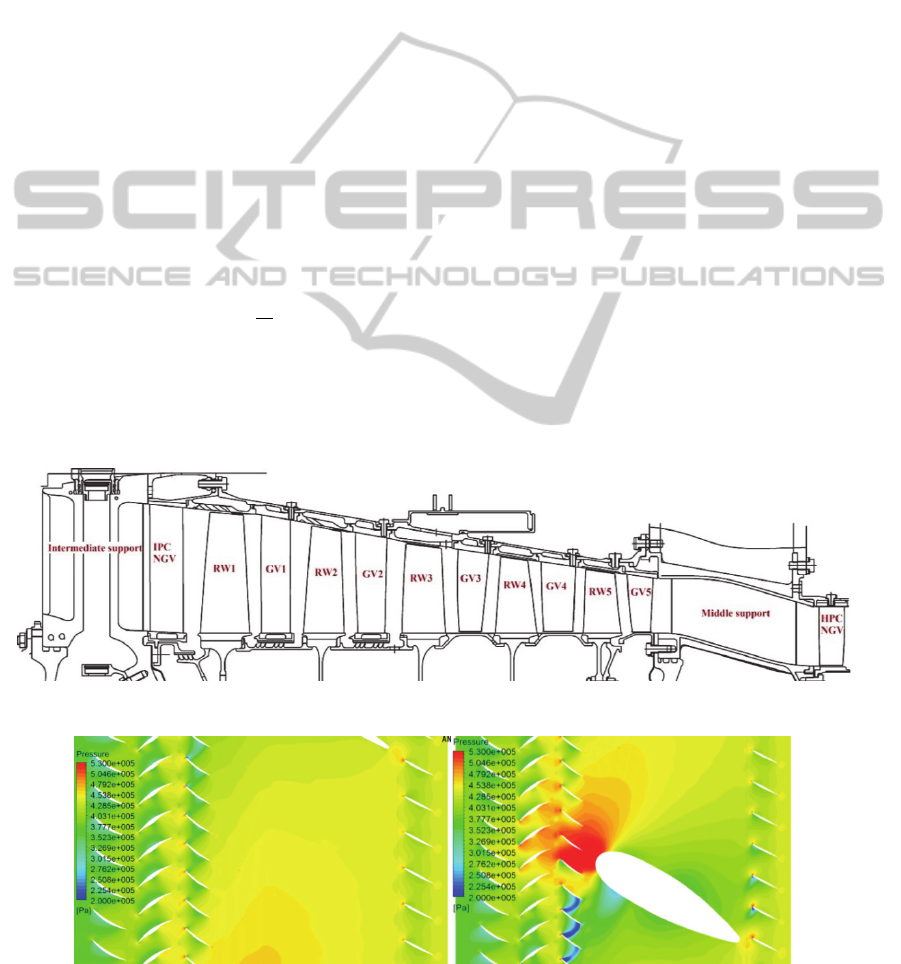

The object of the investigation is fifth stage rotor

wheel blade of medium pressure compressor (IPC)

of GTE (Figure 1). Downstream the fifth stage of the

IPC, the middle GTE support is located.

Figure 1: The diagram of the investigated compressor.

a) b)

Figure 2: Pressure fields between support rack (a) and close to racks (b).

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

384

Seven racks of different cross-sections are

unevenly distributed in the flow passage of support

casing. These racks cause the circumferential

variation of the gas flow in gas-turbine engine flow

passage, which leads to increased dynamic stresses

in the fifth rotor wheel blades, as a consequence, to

its breakage (Figure 2).

As the number of support racks is 7, the blade

was detuned from the dangerous seventh harmonic

at the design stage. The natural frequency of the RW

blade vibrations is selected so that the resonance is

possible with the eighth harmonic and higher.

Seventh harmonic is beyond the engine operating

conditions. Experimental research revealed the

destruction of the rotor blade of compressor stage at

resonance with the 12

th

harmonic.

On the basis of the above-described method of

calculation of blade forced oscillations, the

maximum alternating stresses were defined in the

fifth stage rotor blade of IPC reference design

operating in the conditions of gas flow

circumferential distortion.

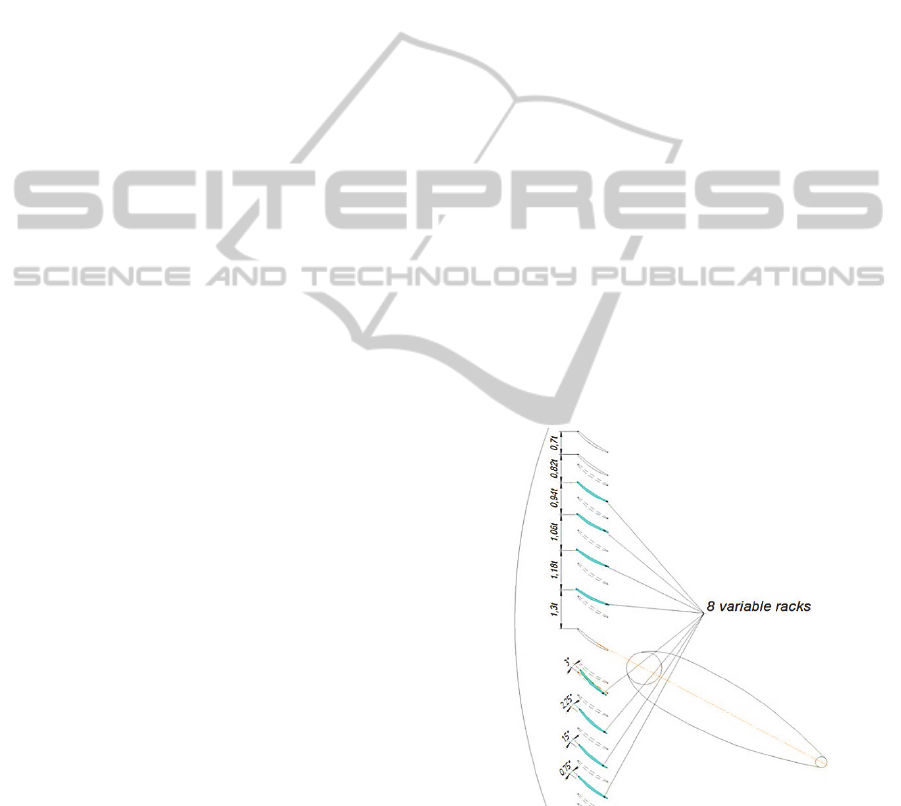

To reduce the circumferential distortion of the

flow, stagger angles and pitch of fifth stage guide

vanes were changed to non-uniform around the

circumference of the rotor wheel (Figure 3). At the

same time, CFD-calculation qualitatively coincides

with the experiment.

As a result, the optimal variant of the design was

chosen, in which the amplitude of the dangerous

12th harmonic was reduced by 2 times, while the

number of changeable guide vane (GV) blades was

equal to 14 (total blade number is 76).

4 EFFECT OF SUPPORT DESIGN

ON CIRCUMFERENTIAL

DISTORTION

4.1 Changing Angular Location of

Support Racks

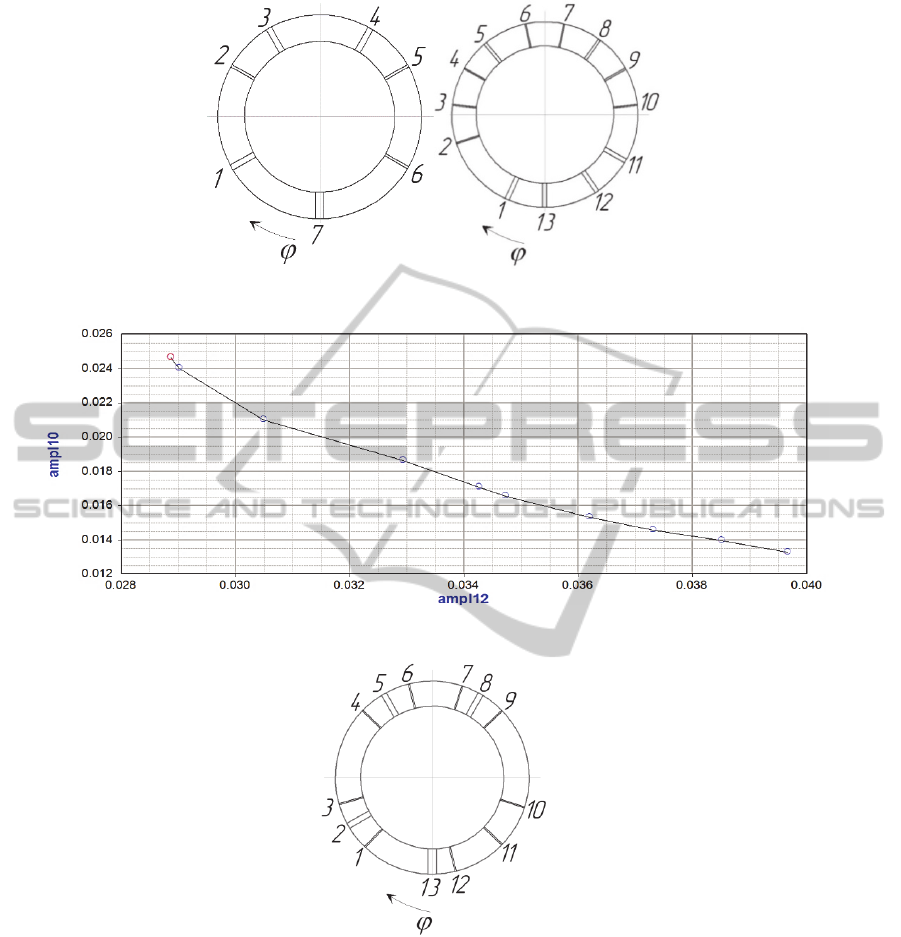

Technologically, changing the stagger angle of the

guide vane blade is challenging, so it was decided to

change the configuration of the support rack.

Therefore, the experimental variant of support with

13 racks instead of standard support with seven

racks was considered at the next stage of the

research (Figure 4). The experimental tests were

conducted by JSC "Kuznetsov" (Samara, Russia) –

the enterprise of aviation and space propulsion

engineering. (JSC "Kuznetsov", 2014).

It was revealed that the mean amplitude of

dangerous 12th harmonic decreased by 2 times in

the computational studies (experimental data

confirm this). The coincidence of obtained results

with experimental data confirms the adequacy of

computational models and techniques. There was a

significant decrease in the amplitudes of all

dangerous harmonics.

The rack thickness, in which the engine systems

are located, and their angular disposition were

changed in the 13-racks experimental support.

Therefore, such support cannot be applied at

modernized engine. Consequently, one of the

conditions was to keep unchanged the racks 1, 3, 4,

and 7 of standard 7-racks the support (Figure 4)

when optimizing the angular arrangement of racks.

For this, the optimization technique of the

angular position of support racks was developed.

Angular position of racks was represented as a

periodic function. Function was provided in the form

of discrete data array containing the nominal

pressure before each rack, which was equal to one.

The array contained 180 values; each value

corresponded to the angle of the circumferential

location of the rack. Then the function value was 0 if

there was no the rack and the value was 1 if there

was rack is. Changing the angular arrangement of

free racks, decrease of dangerous harmonics

amplitude can be achieved.

Figure 3: The algorithm of introduction of different

stagger angle and pitch.

Reduction in the amplitude of the 12

th

harmonic

was performed using optimization methods

implemented in the software package IOSO

(Egorov, Kretinin, Leshchenko, Kuptzov, 2002.).

The goal of optimization was to decrease the

amplitudes of 10

th

and 12

th

harmonics.

AngularArrangementOptimizationoftheSupportRacksofGasTurbineEnginetoReducetheCircumferential

UnevennessofGasFlow

385

Figure 4: Scheme of standard 7-racks support and modified 13th-racks support.

Figure 5: The Pareto set of multicriteria optimization.

Figure 6: Location of support racks corresponding to the point of the Pareto set.

Consequently, the optimization criterion was the

amplitudes of 10

th

and 12

th

harmonics.

Angles of the 1, 3, 4, 6, 7, 9-12 racks were used

as variable parameters. In formulation of

optimization problem, the restrictions on the

amplitude values of 8, 9, 11 and 13 harmonics were

imposed. These restrictions were assigned so that the

amplitude values of these harmonics obviously did

not lead to the destruction of the blades.

During the optimization, the Pareto front was

obtained - the set of unimprovable solutions, a

compromise between the decrease in the amplitude

of 10

th

and 12

th

harmonics (Figure 5). A unique array

of angular location of 1, 3, 4, 6, 7, 9-12 racks

corresponded to each point of the Pareto set.

For further analysis, the leftmost point of Pareto

front was selected (Figure 5). This point corresponds

to the maximum possible reduction in the amplitude

of the 12

th

harmonic, as the most dangerous.

Location of the racks, shown in Figure 6,

corresponds to this point of the Pareto set.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

386

4.2 Changing Position of Support

Racks Relative to Blades of

Upstream Guide Vane

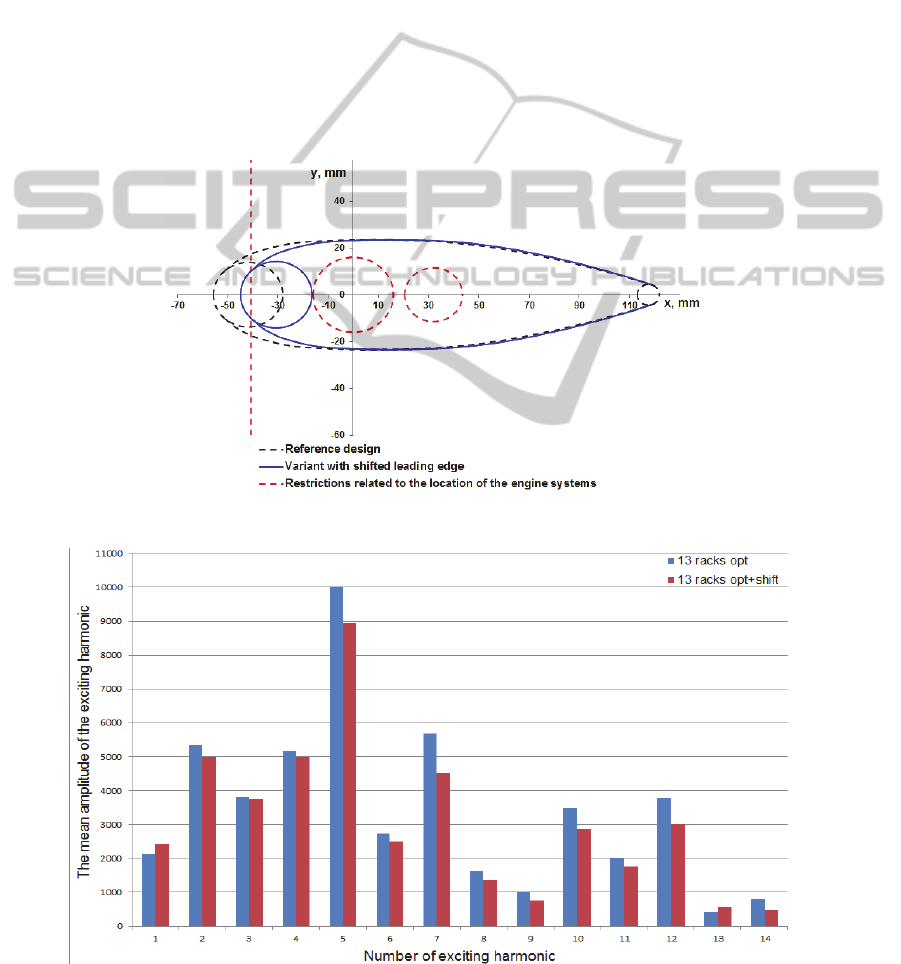

There are experimental studies that prove that the

lattice, which is located in front of the cylinder,

streamlined by the flow, enhances the upstream

transmission of the high pressure zone (Saren,

1984).

The results of that research allow us to offer an

additional way to reduce the dynamic stresses. It

represents a change in the form of support racks due

to remoteness of the leading edge of support racks

(cylinder) from the trailing edges of GV blades of

fifth stage (lattice). At the same time, the internal

cavities of racks remain unchanged for the

placement of engine systems (Figure 7) (Pechenin,

Bolotov, Rusanov, 2014).

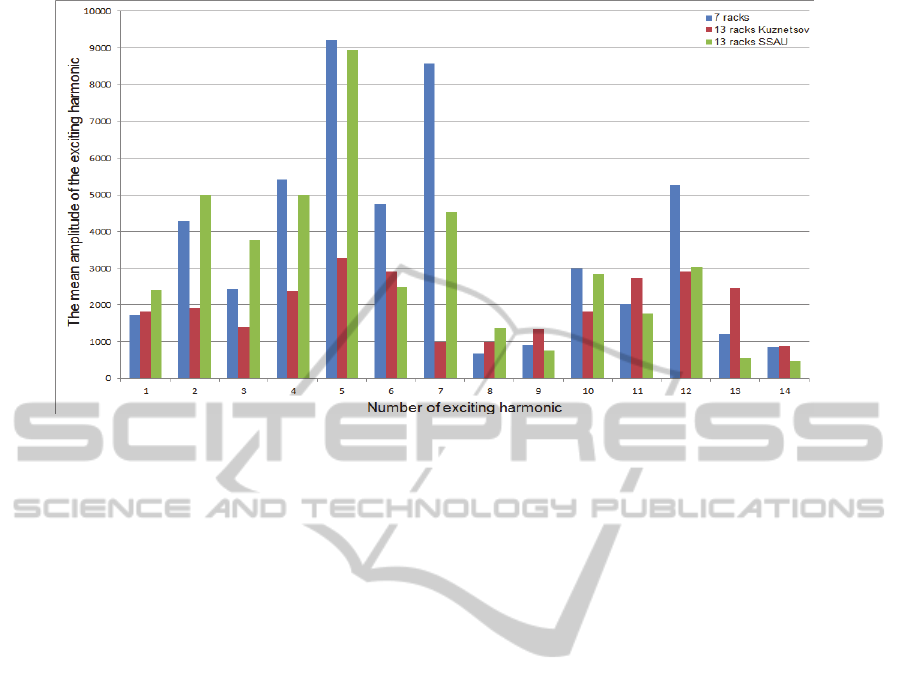

Figure 8 shows a comparison of the harmonic

amplitudes of the optimized 13-racks support

without shifting the leading edges and with shifted

leading edges of racks. Figure 9 shows a comparison

of harmonic amplitudes of the 7-racks support, the

reference design of 13-racks support (by JSC

“Kuznetsov”) and optimized 13-racks support with

shifted leading edges (by SSAU).

Thus, the implementation of optimized 13-racks

support with shifted leading edges reduces the

amplitude of the most dangerous harmonic in 1.8

times, while the position of four the support racks

with engine systems remains unchanged.

Figure 7: The algorithm of shift of the rack leading edge.

Figure 8: Mean amplitude of the exciting harmonics of the 13-racks support with and without shifted leading edges.

AngularArrangementOptimizationoftheSupportRacksofGasTurbineEnginetoReducetheCircumferential

UnevennessofGasFlow

387

Figure 9: Mean amplitude of the exciting harmonics of the 7-racks support, reference 13-racks support (Kuznetsov) and

optimized 13-racks support with shifted leading edges (SSAU).

5 CONCLUSIONS

The high level of circumferential distortion of the

gas flow in aircraft engine is caused by many

factors. One of the major is the presence of support

racks in the flow passage.

Change in the angular position of support racks

allows redistributing and reducing the amplitude of

the exciting harmonics.

During the research, the optimization technology

of angular arrangement of support racks was

developed by the software IOSO due to the discrete

representation of a response from the rack.

This allowed obtaining the optimum racks

location of 13-racks support, providing decrease in

the amplitude of 12

th

harmonic in 2 times.

Furthermore, the variant of variable dynamic

stresses reduction was proposed due to shape

correction of support racks (shift of the rack leading

edges relative to the trailing edges of GV blades

located in front of the support).

This method provided a decrease in the

amplitude of the 12

th

harmonic in 1.8 times.

ACKNOWLEDGEMENTS

This work was supported by the Ministry of

Education and Science of the Russian Federation in

execution of the order №218 from 09.04.2010

(theme code 2013-218-04-4777).

REFERENCES

Popov, G., Baturin, O., Kolmakova, D. Krivcov, A., 2014.

Improvement Results of TK-32 turbocompressor

turbine with gas-dynamics and strength CAE-systems.

In International J. of Engineering and Technology

Vol. 6, pp. 2297-03.

Shabliy, L.S., Cherniaev, A.V., 2014. Optimization of

compressor blade geometry for efficiency and pressure

ratio under strength constraint. In Proc. of ASME 2014

Gas Turbine India Conference, GTINDIA 2014,

GTINDIA2014-8132.

Ermakov, A., Shklovets, A., Popov, G., Kolmakova, D.,

2014. Investigation of the effect of the gas turbine

compressor supports on gas flow circumferential

nonuniformity. In Research J.l of Applied Sciences,

vol. 9, pp. 684-690.

JSC "Kuznetsov", Accessed October 10, 2014.

http://www.kuznetsov-motors.ru/en.

Egorov, I., Kretinin, G., Leshchenko, I., Kuptzov, S.,

2002. IOSO Optimisation Toolkit - Novel Software to

Create Better Design. In Proc. 9th AIAA/ISSMO

Symposium on Multidisciplinary Analysis and

Optimisation.

Saren, V., 1984. Flow around irregular lattice of plates

placed in front of the cylinder, Technical Report,

Central Institute of Aviation Motors, Moscow.

Pechenin, V.A., Bolotov, M.A., Rusanov, N.V., 2014.

Method of evaluation of profile form and shaped

surfaces with application of wavelets. In Research

Journal of Applied Sciences, Vol. 9 (11), pp. 820-824.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

388