Reduction and Push Technology of Cable Harness Information for

Complex Mechatronic Products based on Variable Precision Rough

Sets

Falin Wang

1

, Wenhe Liao

1

, Yu Guo

1

and Xiaofei Wang

2

1

College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics

No. 29 Yudao Street, Qinhuai District, Nanjing City, 210016, Jiangsu Province, China

2

Nanjing Research Institute of Electronics Technology, No.8, Guorui Road, Yuhuatai District, Nanjing City 210039,

Jiangsu Province, China

Keywords: Cable Harness Information, Complex Mechatronic Products, Information Reduction, Information Push.

Abstract: As energy and signal transmission medium, cable harness is widely used in complex mechatronic products,

and cable harness information are the basis and premise conditions of the flexible cable harness assembly

simulation of complex mechatronic products system. To retrieve cable harness information from the

information management system or repository effectively, a push method of cable harness information for

complex mechatronic products based on variable precision rough sets (VPRS) was proposed in this paper.

By using the cable harness information reduction method, the cable harness information repository is

simplified, and rules which can support the precise push also be distilled from the reduct cable harness

information repository. On the basis of the above approach, cable harness wiring designers, assembly

process planners and assembly process simulation designers can efficiently share cable harness information

during all design processes. Finally, a case is employed to validate the proposed method of this paper.

1 INTRODUCTION

Complex mechatronic products like aerospace

vehicles, satellites, aircraft engine, rocket engine,

missile and automobile are the complex systems,

which composed of mechanical structures, electrical

equipments, control equipments, detect equipments

(Zhong, 2007), etc. Involved in many disciplinary,

complex manufacturing processes, more test links,

and long development cycle are the main

characteristics of those products. Developing

complex mechatronic products requires intensive

collaboration between engineers of the mechanical,

electronic, control, and software domains in a design

team (Bolón-Canedo et al., 2013, Wang et al., 2002,

M, 2002). Moreover, the complex mechatronic

products design is a typical information or

knowledge-intensive process, and involved in

complicated interactions among multidisciplinary

design teams in a distributed, heterogeneous and

dynamic environment, including cooperation,

coordination, and communication(Chen et al., 2008,

Shen et al., 2000).

As energy and signal transmission medium,

cable harness is widely used in complex mechatronic

products in fields such as aviation, aerospace,

automobile and shipbuilding industry, it is the “link”

between electrical equipments and every extension

module, the quality of the cable harness wiring has

become an important indicator to treasure overall

performance and reliability of products (Ning et al.,

2009, Shang et al., 2012).

In engineering applications, the cable harness has

a complex topology structure covering a lot of

geometric topology information, engineering

semantic information, management attribute

information, physical attribute information, cable

harness material information, cable harness auxiliary

material information, electrical connector

information, electrical function information and

decentralized wiring information, et al. Each class of

the above information contains additional sub-

information, such as physical attribute information

of cable harness contains cable harness weight, cable

harness density, bending property, tensile property

and minimum bending radius, et al.

As is well know, enterprises often occurring

263

Wang F., Liao W., Guo Y. and Wang X..

Reduction and Push Technology of Cable Harness Information for Complex Mechatronic Products based on Variable Precision Rough Sets.

DOI: 10.5220/0005538002630270

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 263-270

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

“massive information” and “information flood”

phenomenon frequently due to the increasing of

cable harness wiring information, and some

information in the repository are redundant and not

important for the designers. Consequently, designers

spent more and more time to retrieve information

from the information management system, and even

difficult to retrieve information that meets the design

requirements, which are adverse to the cable harness

wiring design information sharing and reuse, and

also hindered improvement design efficiency and

level of the designers (Ji et al., 2013). How to

manage the existing cable harness wiring design

information effectively and extract guiding

significant rules accurately from the vast amounts of

cable harness wiring design information have

become the key point for enterprises to improve

complex mechatronic products development speed

and shorten the development cycle.

Information reduction of cable harness is one of

the processing techniques, and different methods and

tools have been proposed for effective and efficient

reduction of information (Farahat et al., 2013, Dai et

al., 2013, Ramentol et al., 2012, G et al., 2007). The

aim of reduction is to find a minimal attribute subset

of the original datasets that is the most informative,

and all other attributes can be deleted from the

databases with the minimal information loss. Then,

on this base, implement the right cable harness

wiring designer with the right information in the

right place at the right time and at the right cost(Li

and Yin, 2009, Naeve, 2005), that is realize the

precise information pushing.

2 CABLE HARNESS

INFORMATION MODEL AND

COLLABORATIVE DESIGN

WORK MODEL

2.1 Cable Harness Information Model

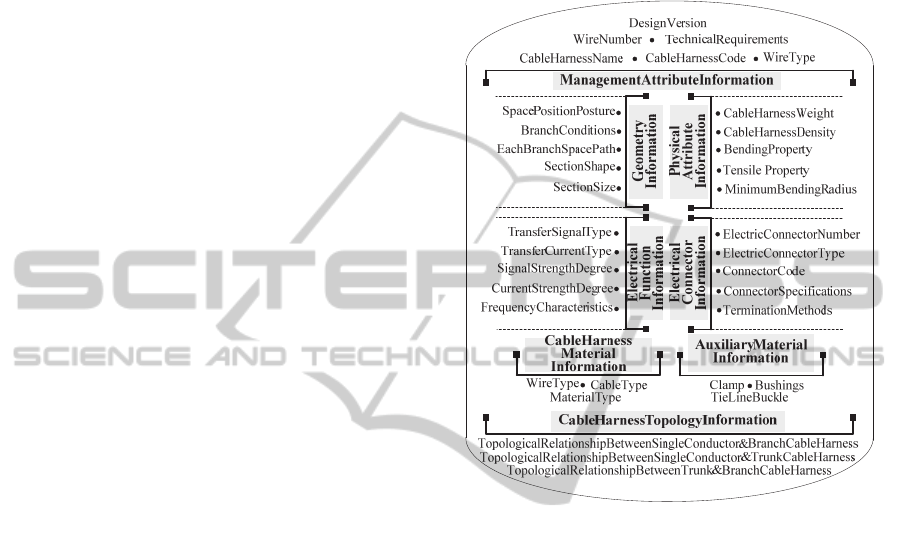

The cable harness information model (as shown in

Figure 1) mainly describes the relevant information

of cable harness properties, such as cable harness

geometry information, cable harness physical

attribute information, cable harness topology

information, cable harness electrical functional

information, etc.; each kind of information

represents the actual working state information

content of cable harness.

In the assembly simulation of complex

mechatronic products system of flexible cable

harness, wiring design determines the assembly

process, assembly process is the basis of assembly

process simulation, while cable harness information

model is the basis and premise conditions of the

above works, and also is the data source which

required for each above phase.

Figure 1: Cable harness information model of complex

mechatronic products.

2.2 Collaborative Design Work Model

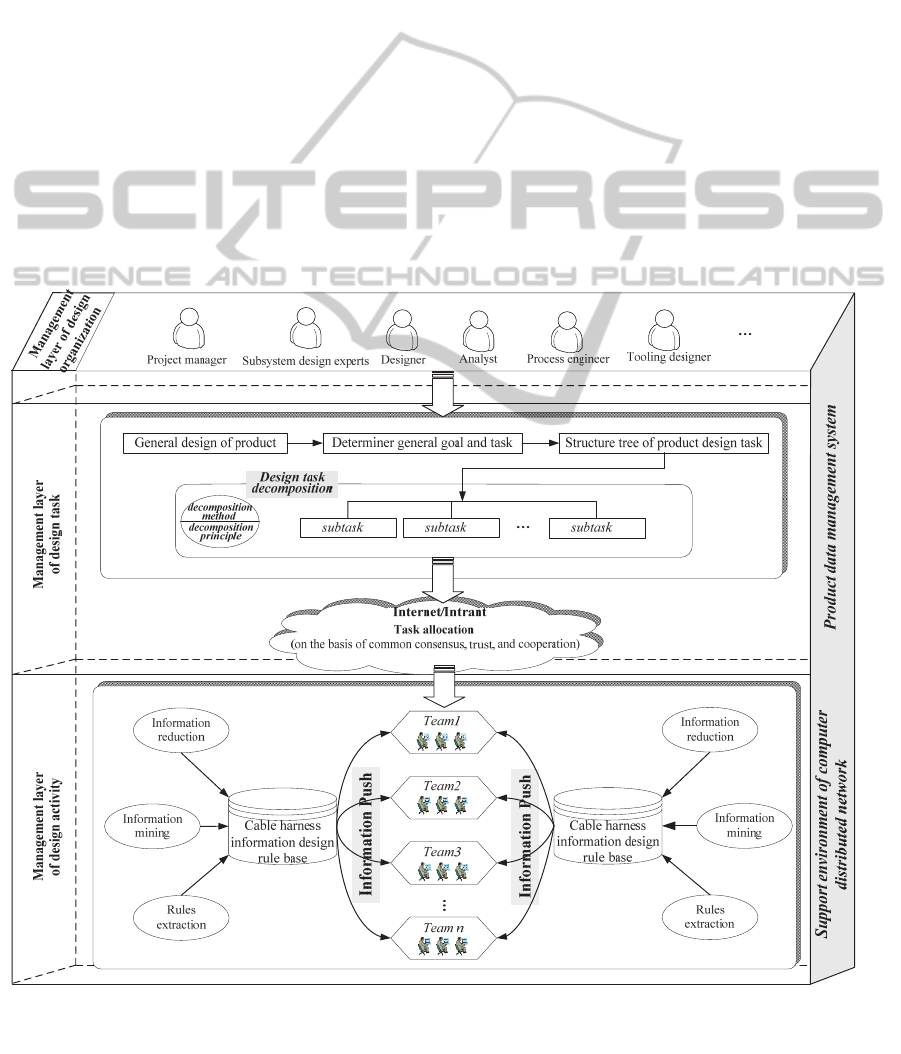

In this paper, we have built a collaborative design

work model for complex mechatronic products, and

shown in Figure 2. In this model, we transform the

collaborative design task into a whole problem

solving task. By applying the task decomposition

method and principle, the whole problem solving

task will be decomposed into several

subtasks:

12

,,,

n

TT T

; then allocate these subtasks to

the multi-design teams which are set up on the basis

of common consensus, trust, and cooperation. Each

design team solve its own subtask and composite all

the sub solutions ultimately.

The collaborative design work model established

in this paper mainly composed of three layers (as

shown in Figure 2.): management layer of design

organization, management layer of design task and

management layer of design activity. The detail

description of each layer as follows.

(1) Management Layer of Design Organization:

to complete the task and realize the goal of the

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

264

organization, the project manager must develop a

practical and effective form of organization structure

according to the situation of the enterprise and the

project itself combine each subsystems design

experts, designer, analyst, and other participants.

(2) Management Layer of Design Task: the main

responsibility of this layer is to determine the overall

goals and tasks of the product design, and

decompose the overall tasks into a series of subtasks

combine relevant decomposition principles. The

reasonable allocation of those subtasks also finished

in this layer.

(3) Management Layer of Design Activity: in this

layer, each collaborative design team completes the

allocated subtask on the collaborative work

platform, and implement the task that pushes the

design information to the designer in accordance

with certain design rules. During the whole design

process, collaborative design teams will share and

reuse the design information or resources in real

time among each other.

Collaborative work platform is the basic

foundation for the complex mechatronic products

design; it has the necessary hardware and software

environment, and also includes the design

specifications, resource library and information or

knowledge base, covering multiple aspects of the

personnel organization, resource allocation, process

management and design results concentration, etc.

The designers can share the product data material

and design resources through the collaborative work

platform, and thereby discuss and modify the design

solutions.

3 CABLE HARNESS

INFORMATION REDUCTION

AND PUSH METHOD

The variable precision rough sets model (VPRS),

firstly proposed by Ziarko (W., 1993), is an effective

mathematical tool with an error-tolerance capability

to handle uncertainty problem. Basically, the VPRS

2

T

n

T

1

T

Figure 2: Collaborative design work model for complex mechatronic products.

ReductionandPushTechnologyofCableHarnessInformationforComplexMechatronicProductsbasedonVariable

PrecisionRoughSets

265

is an extension of Pawlak’s rough set theory

(Pawlak, 1991, Pawlak, 1982), allowing for partial

classification. By setting a confidence threshold

value

, the VPRS cannot only solve classification

problems with uncertain data and no functional

relationship between attributes, but also relax the

rigid boundary definition of Pawlak’s rough set

model to improve the model suitability. Due to the

existence of

, the VPRS can resist data noise or

remove data errors (Śle¸zak and Ziarko, 2005). In

this paper, we use the approach of VPRS to

implement cable harness information reduction and

push.

3.1 Roughening Description of Cable

Harness Information Push based on

VPRS

In this section, we introduce the roughening

description method of cable harness information

push based on VPRS, and briefly review some

notions related with VPRS which can be found in

(Ye et al., 2014, Li and Yin, 2009, Mi et al., 2004,

GY, 2001, W, 1993).

In form, a quadruple

,,,SUAVf

is an

information system (or called a cable harness

information push decision system). Where,

12

{, , , }

n

Uxx x

is a non-empty finite set of

objects called the universe; each object of universe

U

represents a case of design (or browsing history

of cable harness information) in complex

mechatronic products design process.

A

is a non-

empty finite set of attributes, and

A

CD

;

where

C

represents condition attribute set,

{}

D

d

is

decision attribute set,

CD

; here, we let the

condition attribute set

C

as the cable harness

information attribute, and let the decision attribute

set

{}

D

d

as the design proposal that the designer

will be referenced in a new product development

task. An attribute can be defined as

:

a

aU V

for

every

aA

, where

a

VV

and the set

a

V

is called

the value set of

a

.

:

f

UA V

is an information

function such as for any

aA and

x

U

,

,

a

f

xa V

.

f

defines the mapping

relationship between the cable harness information

and its attribute values.

Definition 1 (Indiscernibility Relation). Let

,,,SUAVf

be a cable harness information push

decision system, then with any

BA

there is

associated an equivalence relation:

2

() {(,) | (,) (,), }

A

IND B x y U f x a f y a a B

(1)

Where

()

A

I

ND B

is called the

B

indiscernibility

relation. The equivalence classes of the

B

indiscernibility relation are denoted

[]

B

x

or

()UINDB

, it can be abbreviated as

UB

.

Definition 2 (Lower Approximations and Upper

Approximations). Let

,,,SUAVf

be a cable

harness information push decision system and

let

,

X

UB A

, we can approximate

X

using

only the information contained in

B

by constructing

the

B

lower and

B

upper approximations of

X

,

denoted

()

B

RX

and

()

B

RX

respectively, where

( ) { |[] } {[]|[] }

BBBB

R

XxUx X xx X

(2)

and

( ) { |[] } {[]|[] }

BB BB

RX xU x X x x X

(3)

The lower approximation

()

B

RX

is the set of

objects that belong to

X

with certainty, while the

upper approximation

()

B

RX

is the set of objects that

possibly belong to

X

.

Definition 3 (Consistent and Inconsistent Cable

Harness Information Push Decision System). Let

,,,SUAVf

be a cable harness information push

decision system,

C

represents condition attribute set,

{}

D

d

represents decision attribute set, denote

equivalence relation:

{( , ) | ( ) ( ), }

Cijcicj

RxxfxfxcC

(4)

and

{( , ) | ( ) ( ), }

dijdidj

R

xx f x f x d D

(5)

If

Cd

R

R

, then

,,,SUCDVf

is called

consistent cable harness information push decision

system, otherwise it is called inconsistent cable

harness information push decision system.

Definition 4 (Discernibility Matrix of Consistent

Decision System). Let

,,,SUAVf

be a cable

harness information push decision system,

C

represents condition attribute set,

{}

D

d

represents decision attribute set, denote:

{[ ] | }

CiCi

UR x x U

(6)

{[ ] | }

didi

UR x x U

(7)

and

([ ] ,[ ] ) { | ( ) ( )}

diC jC k ki kj

D

x x a Cfx fx

(8)

Where,

[] [ ]

id jd

xx

. When

[] []

id jd

xx

,

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

266

([ ] ,[ ] )

diCjC

Dx x

, then

([ ] ,[ ] )

diCjC

Dx x

is

called decision discernibility set about

[]

iC

x

and

[]

jC

x

, while,

(([],[])|[],[] )

diCjC iCjC C

D

Matrix D x x x x U R

(9)

is called the discernibility matrix of consistent

decision system.

Definition 5 (Probability Distribution Function).

Let

,,,SUAVf

be a cable harness information

push decision system and

B

C

. Denote:

{( , ) | ( ) ( ), }

Bijkikjk

R

xx f x f x c B

(10)

and

{[ ] | }

BiBi

UR x x U

(11)

12

{, , , }

dr

UR PP P

(12)

Where,

[] { |(, ) }

iB j i j B

x

xxx R

. For

,

i

x

U

let

( []) [] [],( )

jiB j iB iB

PP x P x x j r

, then,

define

12

() (( []),( []), ,( []))

B i iB iB r iB

xPPxPPx PPx

(13)

is the probability distribution functions of the

d

UR

.

Definition 6 (

Lower and Upper Approximations).

Let

,,,SUAVf

be an inconsistent cable harness

information push decision system.

Let

(0.5,1]

,

A

CD

,

B

C

, for

XU

,

denote:

(){ |( [] }

Bi iB

RX x UPXx

{[ ] | ( [ ] }

iB iB

xPXx

(14)

(){ |( [])1 }

Bi iB

RX x UPXx

{[ ] | ( [ ] ) 1 }

iB iB

xPXx

(15)

()

B

RX

and

()

B

R

X

are called

lower

approximation and

upper approximation,

respectively. Where

()PXY X Y Y

if

0Y

,

and

()1PXY

otherwise.

X

is the cardinality of

the set

X

.

Definition 7 (

Upper and Lower Distribution

discernibility matrices). Let

,,,SUCDVf

be

an inconsistent cable harness information push

decision system.

12

{, , , }

Cm

UR CC C

. Denote:

*

1

{([ ] ,[ ] ) | ( ) ( )}

CC C C

D

xy MxMy

(16)

*

2

{([ ] ,[ ] ) | ( ) ( )}

CCC C

DxyGxGy

(17)

Where,

() { | ( )},

C

Cj j

M

xPxRPxU

;

() { | ( )},

C

Cj j

Gx PxRP xU

. Denoted by

(,)

ik

f

Ca

the value of

k

a

about the objects in

i

C

.

Define

(, )

lij

DCC

{|(,)(,)},

kikjk

aCfCa fCa

*

(, ) ,

ij l

CC D

*

(, ) ,

ij l

CC D

1, 2.l

,C

(18)

then

1

(, )

ij

DCC

and

2

(, )

ij

DCC

are the

upper and

lower distribution discernibility attribute sets

respectively. Here, we denote:

11

((,)|, )

ij

DMatrix D C C i j m

(19)

and

22

((,)|, )

ij

DMatrix D C C i j m

(20)

and they are called

upper and lower distribution

discernibility matrices respectively in the cable

harness information push decision system.

Definition 8 (Decision Matrix). Let

,,,SUCDVf

be a cable harness information

push decision system,

() , ,, ,

B

SB U B DV f

(0.5,1]

is an attribute reduction decision table after

attribute reduction. Let

(1,2,,)

i

Xi p

and

(1,2,,)

j

X

jq

represent the equivalence class of

the relation

()

RB

. Where,

(),

iBrj

XPosPX

()

B

r

Neg P

, then, define the decision matrix

( ) ( 1,2, , ; 1,2, , )

ij p q

M

ci pj q

(21)

as

{( , ( , )) | , ( , ) ( , )}

ij i i j

cafXaaBfXafXa

(22)

Given an equivalence class

i

X

, take each element of

M

as a Boolean expression, then the decision rule

sets can be expressed as the following Boolean

function

i

()

ij

c

ij

c

(23)

Hence, we can calculate the minimal disjunctive

normal form, and get the rule sets of

r

P

. The rule’s

support can also be calculated out.

3.2 Rules Generate and Cable Harness

Information Push Method based on

VPRS

Rule extraction is one of the major forms of data

ReductionandPushTechnologyofCableHarnessInformationforComplexMechatronicProductsbasedonVariable

PrecisionRoughSets

267

mining and is perhaps the most common form of

cable harness information discovery in cable harness

information push decision systems (Li et al., 2013,

Fan et al., 2005, Mi et al., 2004). To implement rules

extraction, two definitions will be given firstly.

Definition 9 (decision rule). Given a decision table:

,,,SUCDVf

. Let

(),XUINDC

(),YUINDD

,

x

X

() (,())

C

cC

des X c c x

(24)

represents the description of the equivalence

class

X

;

,yY

() (,())

D

dD

des Y d d x

(25)

represents the description of the equivalence class

Y

.

Define

:() (),

CD

r des X des Y Y X

(26)

is the decision rule from

X

to

Y

.

Definition 10 (support of rule r). Let

,,,SUCDVf

be a cable harness information

push decision system,

U

is called the universe. For

each rule

:() ()

Ci Dj

rdes X des Y

, the support can be

defined as:

()

ij

Sup r X Y U

(27)

4 CASE STUDY

To implement the cable harness information push,

we designed a decision table like Table 2, and the

meaning of each symbol represents can see in Table

1.

Table 1: The meaning of each symbol represents.

Symbol Meaning Symbol Meaning

1

a

stray electromag-

netic field

1

capacitance

weakness

2

a

cable harness

insulation strength

2 capacitance strong

3

a

degree of coupling

crosstalk

3

low degree of

coupling crosstalk

4

a

distributed capacita

n-ce

4

general degree of

coupling crosstalk

d

wiring quality of

cable harness

5

high degree of

coupling crosstalk

1

Q

high quality 6

300M

2

Q

general quality 7

100 300M

3

Q

low quality 8

100M

Table 2: Decision table of cable harness information push.

U

C

D

1

a

2

a

3

a

4

a

d

1

x

1 4 5 8

1

Q

2

x

2 3 6 7

2

Q

3

x

1 4 6 8

3

Q

4

x

2 3 5 7

3

Q

5

x

1 4 6 8

3

Q

6

x

1 4 6 8

2

Q

7

x

1 4 5 8

1

Q

8

x

2 3 6 7

2

Q

According to the equivalence relation

C

R

and

D

R

on

U

, Let

11 17

[] {, },

A

Cx xx

22 28

[] {,},

A

Cx xx

33 356

[] {,,},

A

Cx xxx

44 4

[] {}.

A

Cx x

11 17

[] {, },

D

D

xxx

22 268

[] {,,},

D

D

xxxx

33 345

[] {,,}.

D

D

xxxx

The partitions on the universe

U

generated by

the equivalence relation

C

R

and

D

R

are

1234

{, , , },

C

UR CC C C

123

{, , }.

D

UR DD D

Due

to

AD

RR

, the Table 2 is an inconsistent cable

harness information push decision table according to

the definition 3. Then we use the processing method

for the inconsistent decision table to calculate the

probability distribution functions on the equivalence

class

C

UR

, and the results are

17

( ) ( ) (1,0,0)

AA

xx

,

28

() ()(0,1,0)

AA

xx

,

356

() () () (0,13,23)

AAA

xxx

,

4

()(0,0,1)

A

x

.

When the classification error

0.7

, the upper

approximation set of the set

1

D

,

2

D

and

3

D

about

the relation

R

are as follows respectively:

0.7

117

(){,},

A

R

Dxx

0.7

223568

(){,,,,},

A

RD xxxxx

0.7

33456

(){,,,}

A

RD xxxx

.

So we have

0.7 0.7

171

() (){},

AA

M

xMx D

0.7 0.7

282

() (){},

AA

M

xMx D

0.7 0.7 0.7

35623

() () (){ , },

AAA

M

xMxMx DD

0.7

43

(){}

A

M

xD

.

And the decision discernibility set is

*0.7

1 121314232434

{(,),(,),(,),(,),(,),(,)}D CCCCCCCCCCCC

.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

268

Because

0.7

1 1 2 1234

(, ){,,,},

D

CC aa aa

0.7

113 3

(, ){},DCC a

0.7

114 124

(, ){,,},

D

CC aa a

0.7

123 124

(,){,,},

D

CC aaa

0.7

124 3

(,){},

D

CC a

0.7

134 1234

(, ){,,,}

D

CC aaaa

.

So we construct the upper approximation

discernibility matrix is (

0.7

):

1234

1234 1234

0.7

1

31241234

124 3 1234 1234

{, , , }

{, , , }{, , , }

.

{} {, , } {, , , }

{,,} {} {,,,}{,,,}

aaaa

aaaa aaaa

DMatrix

aaaaaaaa

aaa a aaaa aaaa

and the upper distribution discernibility formula we

solve is

0.7

1 1234 124 3

()()

M

aaaa aa a a

13 23 34

()()().aa aa aa

From the upper distribution discernibility formula,

we know that the attribute sets

13

{, }aa

,

23

{,}aa

and

34

{, }aa

are the three distribution reduction of the

cable harness information push system (here,

accuracy is 0.7), and the attribute

3

a

is core

attribute.

To obtain the push rule sets of cable harness

information, we must construct the decision matrixes

of the set

1

D

,

2

D

and

3

D

. Select a set

13

{, }

B

R

ED a a

from the attribute reduction sets, and

its equivalence class can be denoted

as

1234

{, , , }

B

U RED C C C C

. The discernibility

matrices we solved for

1

D

,

2

D

and

3

D

are shown in

Table 3, Table 4 and Table 5.

Table 3: Discernibility matrix of decision

1

D

.

2

C

3

C

4

C

1

(,1)a

3

(,5)a

1

(,1)a

1

C

3

(,5)a

Table 4: Discernibility matrix of decision

2

D

.

1

C

3

C

4

C

1

(,2)a

1

(,2)a

3

(,6)a

2

C

3

(,6)a

Table 5: Discernibility matrix of decision

3

D

.

1

C

2

C

3

C

1

(,2)a

3

(,5)a

1

(,2)a

4

C

3

(,5)a

Table 6: Push rule sets and supports.

Rules Supports (%)

11 3 1

:( 1) ( 5) ( )ra a dQ

25

21 3 2

:( 2) ( 6) ( )ra a dQ

25

31 3 3

:( 2) ( 5) ( )ra a dQ

12.5

On the basis of discernibility matrices, the minimum

disjunctive normal form (DNF) of the Table 3, Table

4 and Table 5 can be expressed as follows:

1113 3131

()((1)(5))(5)(1)(5)(1).BDaa aaaa

1213 1313

( ) (( 2) ( 6)) ( 2) ( 6) ( 2) ( 6).BDaa aa aa

1313 13 13

( ) ( 2) ( 5) (( 2) ( 5)) ( 2) ( 5).BDaa aa aa

To sum up the above analysis, the push rule sets and

its supports of the cable harness information are

express at the Table 6. The support size of the cable

harness information rules reflects the degree of

information which the designers used. For all cable

harness information push rule sets, low support rules

should be eliminated. In practice, we can set a

threshold of support (e.g. 15%), support is less than

the threshold will be eliminated, and push the cable

harness information to designers will be more

accurately.

5 CONCLUSIONS

This research focuses on the techniques of cable

harness information reduction and push. By using

those techniques, the design repository is simplified

and we can extract rules which can support the

precise push of cable harness information. And the

methods or techniques proposed in this paper will

play an important role in the field of flexible cable

harness assembly simulation for complex

mechatronic products. Though significant progress

has been made on cable harness information

reduction and push, there is still much work to be

conducted in the future, such as ontology modelling

and representation of cable harness information,

evaluation of the effect of a cable harness

information push, among others.

ReductionandPushTechnologyofCableHarnessInformationforComplexMechatronicProductsbasedonVariable

PrecisionRoughSets

269

ACKNOWLEDGEMENTS

This research work was supported by Funding of

Jiangsu Innovation Program for Graduate Education

and the Fundamental Research Funds for the Central

Universities (Grant no. KYLX_0311).

REFERENCES

Bol N-Canedo, V., S Nchez-Maro O, N. & Alonso-

Betanzos, A. 2013. A Review of Feature Selection

Methods on Synthetic Data. Knowledge and

Information Systems, 34, 483-519.

Chen, Y.-J., Chen, Y.-M. & Chu, H.-C. 2008. Enabling

Collaborative Product Design through Distributed

Engineering Knowledge Management. Computers in

Industry, 59, 395-409.

Dai, J., Wang, W., Tian, H. & Liu, L. 2013. Attribute

Selection Based On A New Conditional Entropy For

Incomplete Decision Systems. Knowledge-Based

Systems, 39, 207-213.

Fan, Z.-P., Feng, Y. & Sun, Y.-H. 2005. A Framework On

Compound Knowledge Push System Oriented To

Organizational Employees, First International

Workshop, Internet And Network Economics.

Farahat, A., Ghodsi, A. & Kamel, M. 2013. Efficient

Greedy Feature Selection for Unsupervised Learning.

Knowledge and Information Systems, 35, 285–310.

G, P., W, B., J, F. & Kh, G. 2007. Engineering Design: A

Systematic Approach. 3rd Ed, London (UK), Springer

London Limited.

Gy, W. 2001. Rough Set Theory and Knowledge

Discovery, Xi’an, Xi’an Jiaotong University Press.

Ji, X., Gu, X. & Dai, F. 2013. Technology for Product

Design Knowledge Push Based On Ontology and

Rough Sets. Computer Integrated Manufacturing

Systems, 19, 7-20.

Li, F. & Yin, Y. 2009. Approaches To Knowledge

Reduction Of Covering Decision Systems Based On

Information Theory. Information Sciences, 179, 1694-

1704.

Li, J., Mei, C. & Lv, Y. 2013. Incomplete Decision

Contexts: Approximate Concept Construction, Rule

Acquisition And Knowledge Reduction. International

Journal of Approximate Reasoning, 54, 149-165.

M, T. 2002. Mechatronics: From the 20th to the 21st

Century. Control Eng Practice, 10, 877–86.

Mi, J.-S., Wu, W.-Z. & Zhang, W.-X. 2004. Approaches

To Knowledge Reduction Based On Variable

Precision Rough Set Model. Information Sciences, 159,

255-272.

Naeve, A. 2005. The Human Semantic Web Shifting From

Knowledge Push to Knowledge Pull. International

Journal on Semantic Web and Information Systems, 1,

1-30.

Ning, R., Liu, J., Tang, C. & Zhang, X. 2009. Virtual

Assembly Technology and Its Application. Defense

Manufacturing Technology, 4, 8.

Pawlak, Z. 1982. Rough Sets. International Journal of

Computer and Information Science, 11, 341–356.

Pawlak, Z. 1991. Rough Sets: Theoretical Aspects of

Reasoning about Data, Boston, Kluwer Academic

Publishers.

Ramentol, E., Caballero, Y., Bello, R. & Herrera, F. 2012.

Smote-Rsb*: A Hybrid Preprocessing Approach Based

On Oversampling And Under Sampling For High

Imbalanced Data-Sets Using Smote And Rough Sets

Theory. Knowledge and Information Systems, 33,

245–265.

Shang, W., Ning, R., Liu, J. & Wang, Z. 2012. Assembly

Process Simulation for Flexible Cable Harness in

Complex Electromechanical Products. Journal of

Computer-Aided Design & Computer Graphics, 24, 10.

Shen, W., Norrie, D. H. & Barthes, J. P. 2000. Multi-Agent

Systems for Concurrent Intelligent Design and

Manufacturing, London, Uk, Taylor & Francis.

Śle¸Zak, D. & Ziarko, W. 2005. The Investigation of the

Bayesian Rough Set Model. International Journal of

Approximate Reasoning, 40, 81-91.

W., Z. 1993. Variable Precision Rough Set Model.

Journal of Computer and System Sciences, 46, 39-59.

Wang, L., Shen, W., Xie, H., Neelamkavil, J. & Pardasani,

A. 2002. Collaborative Conceptual Design—State Of

the Art and Future Trends. Computer-Aided Design,

34, 981-996.

Ye, M., Wu, X., Hu, X. & Hu, D. 2014. Knowledge

Reduction For Decision Tables With Attribute Value

Taxonomies. Knowledge-Based Systems, 56, 68-78.

Zhong, J. 2007. Coupling Design Theory and Method of

Complex Electromechanical System, China Machine

Press, Beijing.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

270