A 2 Dimensional Dynamical Model of Asphalt-roller Interaction

during Vibratory Compaction

Syed Asif Imran

1

, Sesh Commuri

1

and Musharraf Zaman

2

1

School of Electrical and Computer Engineering, University of Oklahoma, W. Boyd St, Norman, Oklahoma, U.S.A.

2

School of Civil Engineering and Environmental Science, University of Oklahoma, W. Boyd St, Norman, Oklahoma, U.S.A.

Keywords: Intelligent Compaction, Vibration Analysis, Asphalt Pavements, Roller Dynamics, Construction Engineering.

Abstract: The quality and longevity of an asphalt pavement is influenced by several factors including, the design of the

mix and environmental factors at the time of compaction. These factors are difficult to control during the

construction process and often result in inadequate compaction of the pavement. Intelligent Compaction (IC)

technologies address this issue by providing continuous real-time estimation of the compaction level achieved

during construction. This information can then be used to address quality issues during construction and

improve the overall quality of the pavement. One of the goals of IC is the dynamic adjustment of the

compaction effort of the vibratory roller in order to achieve uniform density and stiffness of the pavement.

However, complex dynamics of the compaction process and lack of computationally tractable dynamical

models hamper the development of such controllers of vibratory rollers. In this study, the interaction between

the vibratory roller and the underlying pavement is studied. A two-dimensional lumped element model that

can replicate the compaction in the field is developed and its parameters are determined using the visco-elastic

plastic properties and the shear deformation properties of the asphalt mix. Numerical simulation results show

that the model is capable of capturing the coupled vibration dynamics of the asphalt-roller system in both the

vertical and longitudinal direction. Comparison of numerical studies with the field compaction data also

indicates that the model can be helpful in the development of control algorithms to improve the quality of

pavements during their construction.

1 INTRODUCTION

Asphalt pavements constitute an important part of the

transportation infrastructure. The long term

performance of these pavements depends largely on

the quality of compaction achieved during their

construction. Compaction is a process of reducing the

volume of air in hot mix asphalt (HMA) by using

external forces and vibrations to reorient the

constituent aggregate particles into a more closely

spaced arrangement. This reduction of air volume in

a mixture produces a corresponding increase in HMA

unit weight, or density. Several studies have indicated

compaction to be the greatest determining factor in

dense graded pavement performance (Brown, 1984;

Scherocman and Martenson, 1984). Proper and good

quality compaction increases the service life of

pavement by improving its load bearing capacity,

temperature stability and fatigue life.

The compaction of an asphalt pavement is influenced

by numerous factors related to the properties of

asphalt mixture, environmental effect and

construction process (Lenz, 2011). The mechanistic

properties of the asphalt mixture such as viscosity and

stiffness are largely affected by its temperature. The

volumetric properties such as gradation, size,

angularity of aggregates and chemical property of the

binder also affect the compaction. The environmental

factors include temperature and stiffness of the

underlying layer, ambient temperature, wind speed,

and solar radiation etc. Several construction related

factors such as rolling pattern, applied vibratory force

and speed of the roller, thickness of the lift being

compacted also play significant roles during

compaction process. Therefore any change in the

influential factors during construction can result in a

variation in the compaction characteristics of asphalt

pavement and can require different compaction effort

to achieve the same level of compaction everywhere.

In the traditional construction process, it is assumed

that the environmental and material properties do not

vary during compaction. Therefore, a roller operating

533

Asif Imran S., Commuri S. and Zaman M..

A 2 Dimensional Dynamical Model of Asphalt-roller Interaction during Vibratory Compaction.

DOI: 10.5220/0005536405330540

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 533-540

ISBN: 978-989-758-122-9

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

at constant speed and frequency is used during

compaction of the pavement along a pre-determined

path. However, material and environmental

variability results in non-uniform compaction of the

mix. Investigations carried out during field

compaction have shown as much as 2% variation in

density in locations less than a meter apart from each

other (Beainy et al., 2011). Intelligent Compaction

(IC) technologies attempt to address this variability in

compaction quality by providing continuous real-

time quality control by monitoring the level of

compaction of the pavement and adjusting the amount

of compaction energy applied by the roller in order to

obtain uniform density.

IC solutions have been developed by Original

Equipment Manufacturers (OEMs) with the goal of

providing real-time estimation of the level of

compaction (Arasteh, 2007; Briaud and Seo, 2003;

Rakawoski, 2008). However, these approaches were

hampered by limited understanding of the roller

dynamics and the lack of adequate mathematical

models and have met with limited success.

Several attempts have been made in recent years

to study the dynamical interaction between the roller

and the underlying material. Huerne (2004)

developed a constituent model of asphalt mixture

using critical state theory adopted from the soil

mechanics and used this model to study compaction

using a static roller. Koneru et al. (2008) developed a

constitutive model using a thermodynamic

framework to study the compaction of asphalt mixes.

In this method, the notion of multiple natural

configurations assumed by a body was used to

analyze compaction of asphalt mixes using laboratory

equipment. Masad et al (2010) used a

thermodynamics based nonlinear viscoelastic model

of the asphalt mix. A finite element based numerical

scheme was developed to simulate the response

during laboratory and field compaction. The

developed model was able to predict the influence of

material properties such as binder viscosity,

aggregate shape characteristics, and aggregate

gradation during the static compaction of asphalt

specimen. Chen (2011) formulated a Discrete element

Method based model of asphalt compaction taking

into account the viscoelastic property of the mix as

well as the slippage and interlocking of the aggregates

during compaction. While these results are

encouraging, significant work is still required to

develop a simple and computationally tractable

model to implement and study real-time closed loop

control algorithms.

Researchers have also studied analytical models

such as Maxwell, generalized Maxwell, Kelvin–

Voigt, generalized Kelvin, Huet–Sayegh, and Burger

models to represent asphalt pavement as a

combination of simple mechanical elements such as

spring and damper (Nillson et al., 2002; Pronk, 2005;

Xu and Solaimanian, 2009). These models are used

mostly to study the long term behavior of the

pavement under traffic loads. Their ability in

representing the pavement during field compaction is

not studied. Among the analytical models, Burger’s

model is simple and can represent the viscoelastic

behavior of an asphalt pavement (Liu and You, 2009;

Liu et al., 2009). Beainy et al. (2013) used Burger’s

model to represent the dynamical properties of

asphalt pavement in his model for studying the

asphalt-roller interaction during compaction. The

model captures the coupled dynamics of the static

vibratory interaction between the roller and asphalt

pavement in the direction normal to the surface of the

pavement. The movement of the roller along the

pavement and the vibration of the roller drum in the

longitudinal or lateral direction are not taken into

account. Imran et al. (2014) incorporated the motion

of roller to the Beainy’s model to demonstrate its

applicability in emulating the field compaction

process that uses a conventional rolling pattern. In

their study, the asphalt pavement was considered to

be a collection of small independent blocks of

Burger’s material. At any given time, the roller was

assumed to be interacting with one set of blocks. This

model also was limited to study the vibration in the

vertical direction only. The effect of shear resistance

of the asphalt pavement was not taken into account.

This paper extends the work of Imran et al. (2014) by

incorporating the effect of shear strength between the

adjacent blocks in the longitudinal direction. The

model is aimed to capture the dynamics of the

vibratory compaction in both the vertical and the

longitudinal direction.

2 DEVELOPMENT OF THE

MODEL

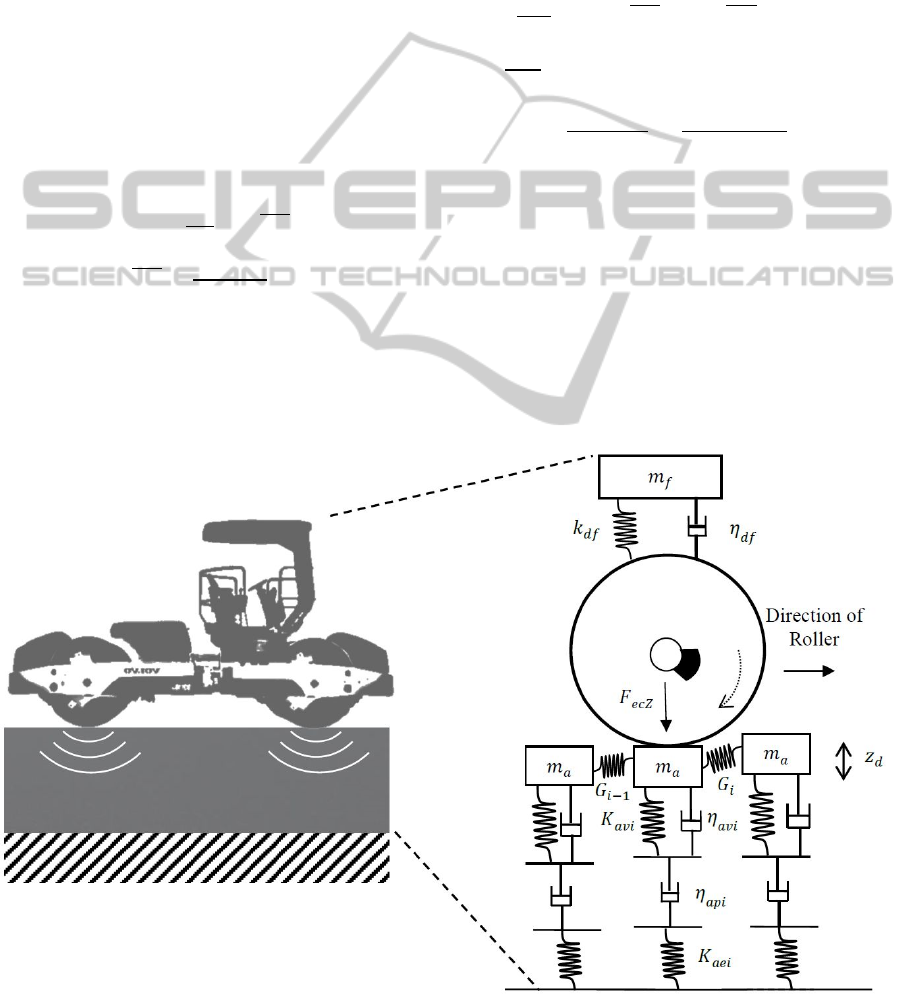

The work of Beainy et. al (2013) and Imran et. al

(2014) is extended in this study for the development

of a model that can represent the asphalt-roller

interaction during compaction process. In this model,

the vibratory roller drum and the underlying

pavement are considered to form a coupled system.

The roller is considered to be in continuous contact

with the asphalt pavement. The dynamics due to

bouncing or loss of contact is not taken into account.

The vibration dynamics in both the vertical and

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

534

longitudinal directions are studied. No lateral

movement due to vibration is considered.

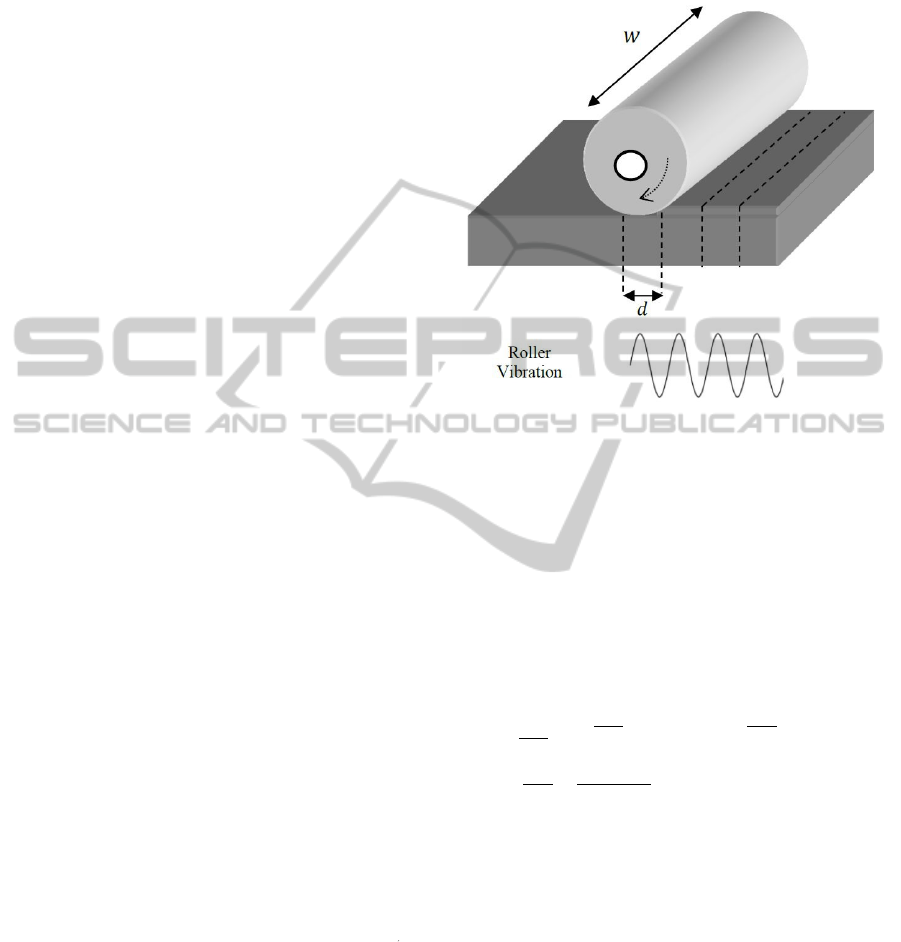

The asphalt mat is assumed to be placed on top of

a rigid base. The pavement is modelled as a collection

of small blocks of Burger’s material placed in a grid

wise manner adjacent to each other. At any given

cycle of vibration the roller interacts with only one

block. The dimensions of each block depend on the

geometry of the drum and asphalt layer, and, the

velocity of the roller. Its height is equal to the

thickness of the pavement layer. The width

corresponds to the width of the drum. The length is

the distance the roller travels along the pavement

while making one impact. At the beginning of each

impact cycle the drum moves on top of a new block.

The interaction between the roller and the block

continues for one cycle of the vibration. Then in the

next cycle the roller moves to the next block (Figure

1). The blocks along the direction of roller motion

(longitudinal) are assumed to be connected to each

other through a spring indicating the shear stiffness of

the asphalt mat. The blocks in the lateral direction are

considered to be independent of one other. The

parameter values of each block are dependent on the

density and temperature of the block.

A vibratory roller uses a combination of static

forces (drum and frame weights) and impact force

(drum eccentric vibrations) to compress the asphalt

mix. The eccentric force is directly related to the mass

of the rotating weight and to the rotational speed. It

acts radially and can be expressed as

(1)

Where,

is the moment of the eccentric mass

and

is the angular frequency of rotation.

The eccentric force can be divided into two

components, a vertical force that acts normal to the

asphalt surface and a horizontal component that acts

tangentially to it. The vertical component of the

eccentric force is expressed as

sin

,

(2)

and the horizontal component is expressed as

cos

.

(3)

The coupling between the drum and the fame of the

roller is modelled as a parallel combination of a linear

spring and a linear dashpot element.

The underlying asphalt pavement is modelled as a

collection of blocks of Burger’s material arranged in

a grid wise manner. The Burger’s material

encompasses the viscoelastic, instantaneous and

permanent deformation experienced by the asphalt

mat during compaction. They are represented as a

combination of linear spring and damper elements

and shown in Figure 2.

Figure 1: Block representation of asphalt pavement.

Vertical Vibration

The total vertical deformation occurring in each (th)

block of the asphalt pavement due to stress

applied

by the roller consist of an instantaneous elastic

deformation ‘

’, a delayed viscoelastic deformation

‘

’, and a permanent deformation ‘

’. The

constitutive equation of the vertical strain can be

expressed as

(4)

Here,

and

indicate the stiffness of the spring

elements and,

and

indicate the damping

coefficient of the dampers used in the th asphalt

block.

, and

are constants that represent the

boundary conditions.

The interaction between the roller and the

underlying asphalt block due to the vertical

component of vibration can be formulated as follows.

Drum Vibration:

sin

(5)

Frame Vibration:

A2DimensionalDynamicalModelofAsphalt-rollerInteractionduringVibratoryCompaction

535

(6)

where

is the displacement of the asphalt layer;

is the vertical reaction force of the asphalt block;

is the reaction force due to shear component;

is

the displacement of the drum;

is the displacement

of the frame;

is the drum-frame stiffness

coefficient;

is the velocity of the drum;

is the

velocity of the frame;

is the drum-frame damping

coefficient;

is the asphalt weight;

is the vertical

acceleration of the drum;

is the vertical

acceleration of the asphalt block;

is the

acceleration of the frame.

The vertical reaction force of the asphalt block

is the force exerted by each block opposing the

compaction force of the roller. It can be expressed as

(7)

is the force generated by the shear spring

component

between the current block and the

block next to it and can be represented as,

(8)

Boundary Conditions:

In the th cycle of vibration, the shear spring

component will generate an equal amount of force

to the next block that will be compacted in the 1

th cycle. For simplicity of calculation, if we consider

to be a constant force in the th cycle, then, the

constants

and

can be determined as follows,

1

(9)

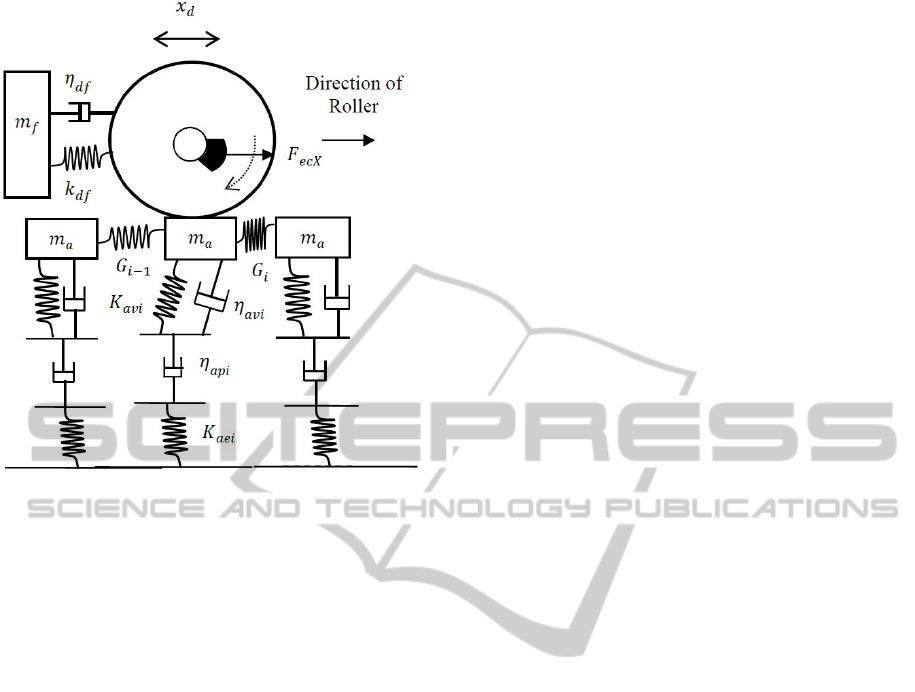

Horizontal Vibration:

The dynamics of interaction between the roller and

the asphalt mat in the longitudinal direction can be

formulated as

Figure 2: Interaction between vibratory roller and asphalt pavement in the vertical direction.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

536

Figure 3: Asphalt-roller interaction in horizontal direction.

Drum Vibration:

cos

(10)

Frame Vibration:

(11)

Where,

,

and

are the displacement, velocity

and acceleration of the drum in the longitudinal

direction respectively.

,

and

are the

corresponding displacement, velocity and

acceleration of the frame.

3 MODEL PARAMETERS

The model parameters can be divided into two sets,

the asphalt material parameters and the roller

parameters. Asphalt material parameters mostly

include the stiffness and damping coefficients of the

Burger’s material. They are dependent on the type

and gradation of the mixture, type of the binder used,

temperature and air void contents of the pavement

during compaction. They also depend on the

dimension and velocity of the drum and the frequency

of vibration. A systematic procedure was developed

in previous studies to estimate these parameters from

the laboratory complex modulus test. A detailed

information regarding the estimation of these

parameters can be found elsewhere (Beainy et al.,

2013a; Imran et al., 2014). The parameters are

adjusted according to the dimension of each block.

The height of each block is equal to the depth of the

asphalt layer. Its length is equal to the length of the

drum and the width is assumed to be equal to the

distance the roller covers during one cycle of

vibration.

One important inclusion of this model from the

previous study (Imran et. al., 2014) is the

incorporation of shear component. Unfortunately,

due to limited resources, it was not possible to

estimate the shear stiffness as a function of asphalt

material properties for this research. However, it is

found in the literature is the shear modulus values are

approximately 30-40% of the dynamic modulus

values for asphalt cores (Pellinen and Xiao, 2006). In

this research, the shear stiffness is considered to be

30% of the Burger’s material stiffness at the

compaction temperature.

The roller parameters include mass of the drum

and frame, width and diameter of the drum, stiffness

coefficient and damping coefficient of drum-frame

coupling, rotational frequency of eccentrics and the

eccentric moment. These parameters can be

determined from some previous studies and the

manufacturer’s specifications of the roller.

4 NUMERICAL SIMULATION

Simulations are performed to study and evaluate the

ability of the model in replicating the field response.

The compaction of a 76.2 mm thick layer of asphalt

mix with a nominal maximum aggregate size of

12.5mm and PG 76 -28 binder is studied. An IR

DD118HF smooth drum vibratory roller is considered

for compaction of the asphalt mix. The roller is

assumed to be operating at a rated frequency of 56 Hz

and moving at a constant speed of 6.4km/h

throughout the simulation process. The compaction of

a single pass on the asphalt pavement with an initial

density of 90% of the maximum theoretical density is

simulated. The model is developed and simulated in

Matlab/Simulink environment for this study.

The parameters of the asphalt block depend on the

density and temperature of asphalt mix, as well as the

operating frequency of the roller. At each simulation

step, the roller operating frequency, the temperature

and air void content of the pavement for each block is

monitored and the parameter values are adjusted

accordingly. The temperature of the asphalt mix is

considered to be constant at 150

0

C during simulation.

A2DimensionalDynamicalModelofAsphalt-rollerInteractionduringVibratoryCompaction

537

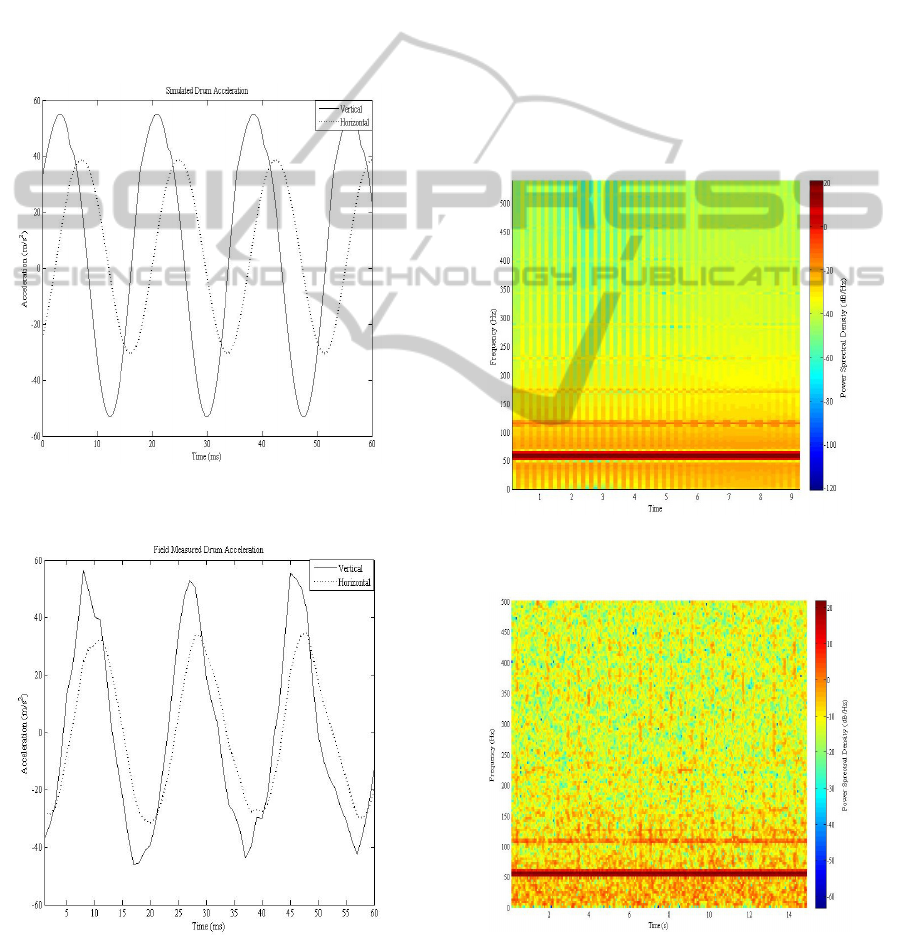

Figure 4 show the simulated drum acceleration in the

vertical and horizontal direction. The simulation

results are compared with the data measured during

field construction. A Crossbow CXL10HF3 triaxial

accelerometer is used to measure the vibration of an

IR DD 118HF roller during construction of US 77 in

Noble, Oklahoma. Both the vertical and the

horizontal vibration were measured. Figure 5 show

the drum acceleration measured during field

compaction. The field data is filtered in order to

reduce the high frequency noise. Comparison

between the model vibration data and the field

vibration data show that the model is able to capture

Figure 4: Simulated drum acceleration in vertical and

longitudinal direction.

Figure 5: Drum acceleration in vertical and longitudinal

direction collected from field.

the response of the roller drum in both the vertical and

horizontal direction.

From the field data, it is evident that, the

amplitude of the horizontal vibration is less than that

of the vertical vibration. Besides, the horizontal

vibration lags its vertical counterpart. This is due to

the effect of rotating radial force exerted by the

eccentric masses. The model is capable of addressing

this dynamics. However, the phase difference

between the vibrations is found higher in the

simulated results than in the field data. This can be

attributed to the fact that the shear component of the

asphalt pavement is represented by a spring in the

model. The viscous behavior of asphalt in the

horizontal direction is not taken into consideration.

This results in variation in the delayed response from

the actual field data.

Figure 6: Simulated roller vibration spectrum

(longitudinal).

Figure 7: Field measured roller vibration spectrum

(longitudinal).

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

538

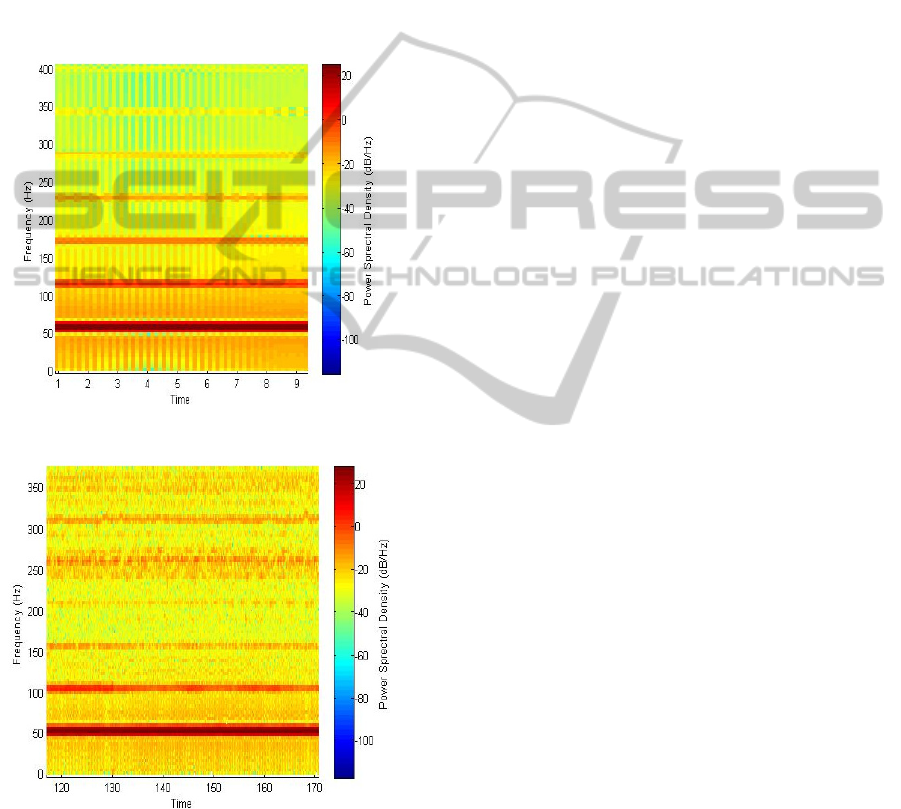

The spectrogram of the vibrations obtained using

numerical simulations is shown in Figure 6 and

Figure 8. Figure 7 and Figure 9 show the

corresponding spectrogram of the vibrations of the

roller observed during field compaction. The power

spectral density of the drum accelerations in each

frequency band is presented in these figures using a

color-coded map. The comparison of the spectral

analysis show that the model presented in this paper

captures not only the response of the roller at the

fundamental frequency (frequency of the eccentrics),

but also the response at the harmonics.

Figure 8: Simulated roller vibration spectrum (vertical).

Figure 9: Field measured roller vibration spectrum

(vertical).

5 CONCLUSIONS

A dynamical model of asphalt-roller interaction

during compaction is presented in this paper. The

dynamics of vibration in both the vertical and

horizontal direction is incorporated in the model. The

2 dimensional coupled dynamics between a moving

vibratory roller and the underlying asphalt pavement

is studied for the first time to the best of the

knowledge of the authors. The visco-elastic property

as well as the shear resistance of the asphalt pavement

is taken into account. The model parameters are

derived considering some important properties that

affect the compaction process. These are the

temperature and density of the mixture during

compaction, gradation of the mix, type of the binder,

layer thickness, frequency of the vibratory force and

several roller properties etc.

The ability of the model in emulating the real time

compaction process is studied. Comparison between

simulations results and field measured compaction

data showed that the model is capable of capturing the

coupled vibration dynamics between the roller and

the asphalt mat in both the vertical and horizontal

direction. The results indicate that the model can be a

simple and tractable mathematical representation of

the complex compaction dynamics. The model can

also serve as a preliminary step towards the

development closed loop control algorithms for the

compaction process.

The model was developed based on certain

assumption such as rigid base, fixed contact area

between roller drum and asphalt pavement, and

constant speed of the roller during compaction. The

effect of shear resistance is considered for

longitudinal direction only. The lateral shear flow of

asphalt is not taken into account. Future research is

aimed at relaxing these assumptions.

REFERENCES

Arasteh, M. 2007. Innovations in Compaction Control and

Testing. Intelligent Compaction 2007 Construction

Conference, Federal Highway Administration,

Bishmark, ND.

Beainy, F., Commuri, S., and Zaman, M. 2011. Quality

assurance of hot mix asphalt pavements using the

intelligent asphalt compaction analyser. ASCE Journal

of Construction Engineering and Management, 138(2),

178-187.

Beainy, F., Commuri, S., Zaman, M., & Imran, S. 2013.

Viscoelastic-Plastic Model of Asphalt-Roller

Interaction. ASCE International Journal of

Geomechanics, 13(5), 581-594.

Briaud, J. L.; and Seo, J. 2003. Intelligent compaction:

Overview and research needs. Texas A&M Univ.,

College Station, TX.

Brown, E. R. 1984.Experiences of Corps of Engineers in

Compaction of Hot Asphalt Mixtures. Placement and

A2DimensionalDynamicalModelofAsphalt-rollerInteractionduringVibratoryCompaction

539

Compaction of Asphalt Mixtures, F.T. Wagner, Ed.

ASTM Special Technical Publication 829. American

Society for Testing and Materials. Philadelphia, PA.

Chen, J. 2011. Discrete Element Method (DEM) Analyses

for Hot-Mix Asphalt (HMA) Mixture Compaction.

PhD Dissertation, University of Tennessee.

Huerne, H. L. 2004. Compaction of Asphalt Road

Pavements. PhD Dissertation, University of Twente,

Netherlands.

Imran, S., Beainy, F., Commuri, S., and Zaman, M. 2014.

Dynamical Model of Asphalt-Roller Interaction During

compaction. 11th International Conference on

Informatics in Control, Automation and Robotics, 559-

567.

Koneru, S., Masad, E., and Rajagopal, K. R. 2008. A

thermo-dynamical framework for modeling the

compaction of asphalt mixes. Mechanics of Materials,

40(10), 846–864.

Lenz, R. 2011. Pavement Design Guide. Texas Department

of Transportation.

Liu, Y., and You, Z. 2009. Determining Burger’s Model

Parameters of Asphalt Materials using Creep-recovery

Testing Data. Pavements and Materials: Modeling,

Testing, and Performance. ASCE Geotechnical Special

Publication, 184, 26-36.

Liu, Y., Qingli, D., and You, Z. 2009. Viscoelastic Model

for Discrete Element Simulation of Asphalt Mixtures.

ASCE Journal of Engineering Mechanics, 135(4), 324-

333.

Masad, E., Koneru, S., Scarpas, T., Kassem, E., and

Rajagopal, K. 2010. Modeling of Hot-Mix Asphalt

Compaction: A Thermodynamics-Based Compressible

Viscoelastic Model. Texas Transportation Institute,

Office of Acquisition Management, Federal Highway

Administration, Washington, D.C.

Nillson, R., Hopman, P., and Isacsson, U. 2002. Influence

of different rheological models on predicted pavement

responses in flexible pavements. Road Materials and

Pavement Design: An International Journal, 3, 117-

149.

Pellinen, T. K., and Xiao, S. 2006. Stiffness of Hot-Mix

Asphalt. Publication FHWA/IN/JTRP-2005/20. Joint

Transportation Research Program, Indiana Department

of Transportation and Purdue University, West

Lafayette, Indiana.

Pronk, A. 2005. The Huet–Sayegh model: a simple and

excellent rheological model for master curves of

asphaltic mixes. Lytton Symposium on Mechanics of

Flexible Pavements, Baton Rouge, LA.

Rakowski, S. 2008. Intelligent Compaction CCV IC.

Presentation, Sakai, Dallas, TX: Transportation Pooled

Fund Intelligent Compaction Systems initial-Task

Working Group meeting.

Scherocman, J. A. and Martenson, E. D. 1984. Placement

of Asphalt Concrete Mixtures. Placement and

Compaction of Asphalt Mixtures, F.T. Wagner,

Ed. ASTM Special Technical Publication

829. American Society for Testing and

Materials. Philadelphia, PA. 3-27.

Xu, Q., and Solaimanian, M. 2009. Modelling linear

viscoelastic properties of asphaltconcrete by the Huet–

Sayegh model. International Journal of Pavement

Engineering, Taylor & Francis, 10(6), 401-422.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

540