Design of Firing Impulse Simulator and Analysis of Its Key Research

and Development Technologies

Chi He

1

, Guangling Dong

2,3

, Hongquan Wu

3

, Qiang Li

3

and Kun Lu

3

1

School of Mechatronic Engineering, CUST, 7089 Weixing Road, Changchun, China

2

School of Astronautics, Harbin Institute of Technology, 92 Xidazhijie Street, Harbin, China

3

Department of Test Technology, Baicheng Ordnance Test Center of China, Mailbox 108, Baicheng, China

Keywords: Weapon System, Approval Test, Firing Impulse Simulator, Impulse Waveform Simulation, Key

Technology.

Abstract: A key technology problem with respect to approval testing is that of simulating firing impulse in large

calibre weapon systems without firing live ammunition with many problems as high cost, strict

environmental conditions, large numbers of staffing, wide test field, etc. There are two main methods in use

at present: the first method is to carry out numerical simulation of gun firing dynamics with modelling and

simulation (M&S) technology; the second method is to conduct hardware-in-the-loop simulation test with

firing impulse simulator (FIS). The latter types of methods generate impulse effect to simulate gun live

firing from power sources of gunpowder, gas, or liquid. FIS with gunpowder or gas as power source take on

problems as low control precision, complicated operating process, and poor safety. In this paper, a FIS

which transfer test data via CAN (Control Area Net) bus was designed and developed. System composition

and working principle are introduced based on analyzing features of similar products, where key

technologies as counter-recoil analysis, mass and speed choice of pounding head, system safety design are

studied with emphasis. The research results indicate that FIS can be used as an effective supplementary to

live firing in approval test of weapon system.

1 INTRODUCTION

Operational requirements in future wars are making

newer and higher requests on gun weapon system.

Constitutes of modern gun is growing more complex

with higher technology integration level, which

make the utilization of new theory, technology and

materials become an inexorable trend. Improvement

in overall operational effectiveness of gun increases

the cost of development and tests rapidly, which also

causes a longer and longer deployment cycle. In

order to solve this problem, it has become an

inevitable tendency to change the traditional mode

of "manual design to trial-manufacture to test

validation" with new techniques of simulation,

computer and experimental testing, which also

improves development level, shortens development

cycle and saves life cycle expense.

Simulation technology has been used widely in

development and test fields of gun weapon system at

present. The U.S. Army is also applying advanced

simulation technologies, real-time data-sharing

processes and communication architectures to be

able to test multiple weapon systems from different

locations, simultaneously. To make that possible, the

Army’s Developmental Test Command is focusing

on “virtual proving ground” technologies, which rely

on modelling and simulation to create realistic

testing environments (Cast, 2001). The FIS can

simulate the recoil, trunnion loads and ballistic

shock effects for tank and howitzer cannons. Thus, it

can be used to check mechanical structure strength

of weapon system and electrical system reliability,

examine mechanism action, stress-strain in critical

parts of gun carriage, transient response for recoil

and counter-recoil of gun, and inspect the

operational reliability of recoil mechanism,

dependability of trunnion, electrical apparatus, and

other accessories (Sanders and Patenaude, 1996).

In the field of gun firing impulse simulation

technology, experts and scholars focus mainly on

four aspects. The first is utilization and effectiveness

study on gun firing impulse simulation, such as

research report from the U.S. army Aberdeen test

453

He C., Dong G., Wu H., Li Q. and Lu K..

Design of Firing Impulse Simulator and Analysis of Its Key Research and Development Technologies.

DOI: 10.5220/0005511604530460

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 453-460

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

center “Army Combat Systems Test Activity - Best

Manufacturing Practices” (Aberdeen Test Center,

1994) analyzed the economic efficiency of FIS.

James G. Faller (1997) from Army test and

evaluation command of APD analyzed the

convenience of using FIS. The second is design

research on FIS, such as Lang (2012) developed a

shooting simulation device for multi types of

launcher, which could adjust loading attitude and

strength according to launcher type. The third is

testing technology study on key parameters of recoil

mechanism , such as Zhao (2003) realized

measurements for parameters as working pressure

and recoil resistance of recoil mechanism. The

fourth is key technology study on simulator design

and numerical simulation. Professor Yao (2001) and

Dr. Di (2012a) introduced the basic principle of gun

recoil simulation test system, and built numerical

simulation model of recoil dynamics with combined

calculation of gun recoil and interior ballistic

according to system features, where two different

types of gun are simulated to realize dynamics

simulation of recoil and counter recoil. Dr. Di

(2012b) established mechanical model and nonlinear

model of bumper, and calculated its kinematic

equation with fourth-order Runge-Kutta method in

Matlab, which is used to analyze the influences of

impulse mass, impulse speed, bumper linear rigidity,

nonlinear rigidity, and damp on recoil acceleration

of gun barrels. This research provided theoretical

basis for development of gun simulation test

mechanism.

In this paper, we mainly carry out three studies;

the first is on implementation of FIS, where

composition and working principle of controllable

hydraulic technology based FIS are introduced. The

second is on analyzing key techniques in developing

of FIS. The third is about simulated effect validation

of FIS with live firing results. In this way, practical

application problems of simulation in test and

evaluation of gun are solved.

2 SYSTEM DESIGN OF FIS

2.1 Implementation of FIS

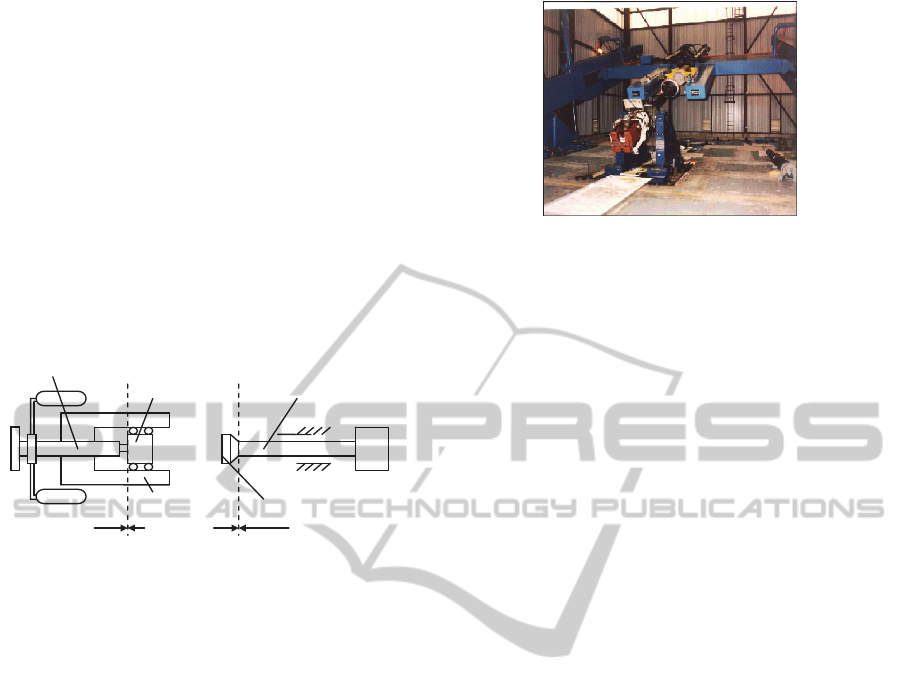

2.1.1 FIS with Gunpowder Power Source

Simulation test system is composed of impulse

generator (1), centering mechanism (2) and pedestal

(3). Its structural representation is shown in Figure

1.

As the kernel component of simulation test

Figure 1: Structural representation of simulation test

system.

and piston, which takes on the function of simulating

system, impulse generator is composed of noumenon

gunpowder gas pressure of interior barrel at live

firing, and provides motive force of recoil motion

for gun under test. Centering mechanism guarantees

exact alignment of impulse generator piston axis and

gun-bore axis for reliable, safe, and stable recoil

motion.

As the support platform of simulation test system,

pedestal bears the gravity of testing machine and

resistance to recoil. Impulse generator takes on

elastic fixing instead of rigid connection to pedestal

via a suit of counter recoil mechanism, which

provides elastic and brake force for recoil part of

impulse generator.

Working principle of impulse generator is shown

in Figure 2 (Gao et al, 2014). It is similar to general

gun weapon system except the loaded informal pills

of blank ammunition with minor-caliber and little

dosage, which fires the recoil part of gun instead of

standard ammunition.

Figure 2: Working principle of impulse generator.

In simulation firing test, firing device (1) ignites

gunpowder in combustor (2) first. Then, the

generated propellant gas pushes piston component (3)

to drive the motion of gun muzzle (6) connected on

the other end of piston rod, which realizes the recoil

motion of gun in test. When the front face of piston

moves to vent hole (5) on noumenon, powder gas is

exhausted to atmosphere, which decreases pressure

rapidly. The driving force on piston component

drops down and stops motion by resistance to realize

separation from gun muzzle. After that, recoil part of

gun in test proceeds with inertial recoil and counter

recoil motion. On the other hand, recoil part of

impulse generator is driven to the opposite direction

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

454

by pressure of propellant gas, whose buffer and reset

are realized through combined action of its recoil

apparatus and recuperator.

2.1.2 FIS with Power Source from Strikes of

High Speed Mass Block

As hydraulic power transmission is an easy way to

realize automatic control of high precision

movement with heavy load, it is often adopted as

power source of FIS. Composition diagram of

simulation test device is shown in Figure 3 (Liu et

al, 2011).

The test device is mainly composed of hydraulic

power subsystem and impulse subsystem. Where,

Hydraulic cylinder

Mass

Supporting

frame

Gun muzzle

Impact wave

generator

Hydraulic power

subsystem

Impulse

subsystem

System under test

Figure 3: Diagrammatic sketch of simulating test facility.

hydraulic power subsystem takes on the effect of

generating major flow rate in a short time, hydraulic

cylinder drives mass block to move with high speed.

At certain speed, piston rod and load would separate.

Impulse subsystem is composed of mass block and

bumper, which transmits kinetic energy to recoil part

via strikes of mass block and muzzle bumper. In this

way, it provides energy for recoil motion of gun.

Then, mass block reset under the effect of return

device for next strike. The purpose of above

program is to realize strong transient impulse, which

is centered on by subsystem designing.

2.1.3 FIS in Aberdeen Test Center of U.S.

Army

In 1990s, dynamic simulation test device of gun has

been used in Aberdeen test center of U.S. army in

test and approval process of main battle tank type

M1A2, which took full advantage of simulation test

technology, just as shown in Figure 4 (Aberdeen

Test Center, 2010).

Compared with live firing test, simulated firing

with dynamic simulation test device saved over 20

million dollars in the same year. Therefore, U.S.

military standard MIL-M-45976 stipulates clearly

that “Simulator can be used to carry out test and

evaluation”.

Figure 4: FIS of Aberdeen Proving Ground U.S. army.

The system takes on the following features

(Aberdeen Test Center, 2010):

Facility for testing the mechanical and hydraulic

components (recoil systems, bearings, seals, etc.)

of large caliber weapon systems without firing

live ammunition;

Inputs a repeatable force (up to 3 million pounds-

force) to the system under test to replicate actual

and projected firing loads at elevation from 0° to

85°;

Can be used to conduct life cycle wear, fatigue,

and reliability, availability, maintainability and

durability (RAM-D) tests of weapon systems or

cannon and recoil on a test mount;

Rate-of-fire is dependent upon the impulse level

and test item mounting configuration;

The FIS is also applicable to shock/impulse tests

of mounted electrical components, isolation

mounts, and shock absorption systems;

Indoor facility reduces test costs and

environmental impulse, and eliminates weather

delays;

On-site 32-channel analog and digital Data

Acquisition System is expandable to meet any

test requirement.

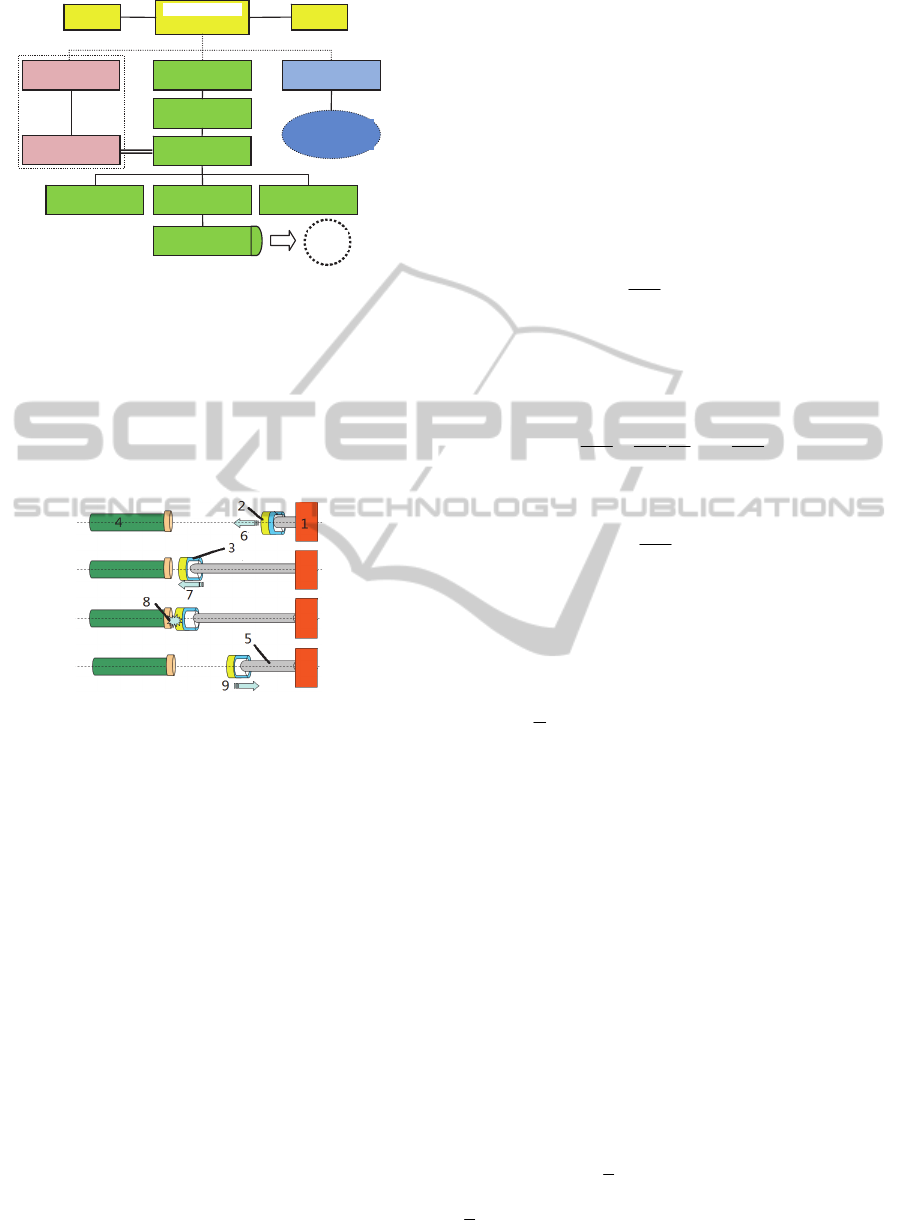

2.2 System Composition and Working

Principle of FIS

2.2.1 System Composition

FIS is designed as a distributed control and

measuring system based on CAN bus, which is

mainly composed of the following four parts: (1)

dynamic simulation mechanism; (2) bearing system

of power mechanism; (3) performance parameter

testing end of gun; (4) hydraulic power source.

Dynamic simulation mechanism is shown in Figure

5. Where, dotted line box indicates power source;

solid double lines are hydraulic pipeline connection;

bold solid double line arrows represent nonrigid

connection.

DesignofFiringImpulseSimulatorandAnalysisofItsKeyResearchandDevelopmentTechnologies

455

Industrial control

computer

Display Printer

Power control

front-end computer

Twisted-pair cable > 70 m

Impulse mechanism

front-end computer

Measurement

front-end computer

Electro hydraulic

servo controller

Hydraulic drive

mechanism

Impulse mechanism

Power supply

Impulse head

Wave generator

Muzzle

Gun parameters

under test

Displacement sensor Firing rate sensor

Figure 5: FIS system function block diagram.

2.2.2 Principle of Impulse Effect

There are many impulse generation types as explosion,

gravity, acceleration, electrical driven, hydraulic pressure,

etc. In this design, hydraulic power source is adopted,

which uses momentum transfer principle to simulate firing

impulse of gun. The impulse blow process is shown in

Figure 6.

Figure 6: Principle of muzzle impulse procedure.

As velocity generator (1) accelerates (6) impulse

head (3) to certain speed, impulse head separates (7)

from speed generator. Then, waveform generator (2)

set between gun muzzle (4) and impulse blow head

forms strikes on gun muzzle. In collision process,

transmission of pounding head momenta to gun

forms strong impulse force and acceleration. Where,

control on impulse blow waveform, impulse width,

impulse force and impulse acceleration could be

realized through modulating the stiffness of

waveform generator. After impulse, recovery device

(5) of pounding head retrieves impulse head (9), and

prepares for next impulse test.

3 ANALYSIS ON KEY

TECHNIQUES

3.1 Analysis of Counter Recoil Force

Firing dynamics simulation with gun impulse

simulation test technology is a feasible way for

repeated examination on counter recoil mechanism.

As counter recoil mechanism constitutes the core

component of gun, its comprehensive evaluation

improves safety factor in operation. Forces on

counter recoil mechanism determine forces imposed

on gun carriage, performance parameters of counter

recoil mechanism, and firing stability, etc.

Therefore, working conditions of counter recoil

mechanism determine the forces conditions on gun.

Recoil motion equation is shown in Equation (1).

p

tR

d

d

h

W

M

FF

t

(1)

Variable substitution of t to x in Equation (1) is

made to research relationship between recoil

resistance F

R

and recoil length λ, we get

ddd d

ddd d

WWx W

W

txt x

(2)

According to equation (2), we have

p

tR

d

d

h

W

M

WFF

x

(3)

Integrating Equation (4) from the start of free recoil

to any route point x,

pt R

000

ddd

Wxx

h

M

WW F x F x

2

pt R

00

1

dd

2

xx

h

M

WFxFx

(4)

At the end of recoil motion, we have x = λ,W = 0,

so

pt R

00

dd0Fx Fx

(5)

Generally, route λ at the end of recoil motion is far

larger than route x

0k

at after effect time. Namely, at

the end of after effect time, recoil motion would

continue instead of stop. Yet recoil force F

pt

vanishes after x

0k

. So the upper limit λ of integration

in above equation for F

pt

could be substituted by x

0k

,

with result unchanged.

0

pt R

00

dd

k

x

F

xFx

(6)

This equation shows such a conception that the total

power of recoil forces on recoil part equals to that of

resistance to recoil. Let

RR

0

d/

F

Fx

(7)

R

F

is mean resistance, namely the integral mean

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

456

value along the whole recoil length λ, which can also

be expressed as:

RR

0

d/

F

xF

(8)

If the total power

R

0

dFx

of resistance to recoil is a

constant, the relationship between resistance to

recoil and recoil length can easily be seen from

above equation. Namely, as

R

F

increase, λ decreases;

as

R

F

decrease, λ increase. Yet the total power

pt

0

d

k

x

Fx

of recoil force is variable, total power of

resistance to recoil

R

0

dFx

is not a constant. It can be

described as follows: suppose the resistance to recoil

F

R

= F

pt

, then recoil part would not recoil, namely x

K

= 0, total power

pt

0

d

k

x

Fx

equals to zero; if F

R

= 0, i.e.

recoil motion is realized under free recoil conditions,

the route at the end of ulterior period is

x

0k

, the total

power would be

0

pt

0

d

k

x

Fx

, without doubt we can get

a maximal total power at this moment. In this way,

total power of recoil force on recoil part changes

with resistance to recoil. Generally, the selected

resistance to recoil

F

R

is much less than recoil force

F

pt

. Therefore, total power is close to integral value

0

p

t0

0

d

k

x

Fx

, whereas

0k

2

p

t0 0k

0

1

d

2

x

h

Fx MW

.

According to the analysis above, counter recoil

mechanism works as a kinetic energy absorption

device for free recoil motion. While firing on gun

carriage, the total power of recoil force to gun is

equal to that of resistance to recoil, and is

approximately the same size as maximal free recoil

kinetic energy. As long as the shooting momenta (or

impulse) on recoil part of gun can be simulated with

firing impulse simulation test technology, the same

recoil motion characteristics as living firing for

recoil part of gun can be generated, which mainly

include parameters as recoil route length, recoil

velocity, acceleration (recoil kinetic energy), recoil

and counter recoil time, maximal resistance to recoil

and work of resistance, etc.

3.2 Confirmation on Mass and Speed

of Impulse Head

According to impact working principle, as impulse

head is accelerated to certain initial speed v

1

to

impact on gun in test along specified axis direction,

analysis on axis direction can be simplified as shown

in Figure 7.

System under test

Hydraulic

velocity

generator

Impact wave generator

Accelerate to v

Impact mass

Figure 7: The principle diagram of FIS.

Suppose shock pulse generator and recoiling part

take on mass of

m

1

and m

2

respectively, their impact

happens along axis direction. In the shocking

process, shock pulse generator transmits the

momenta to recoiling part, and generates

corresponding impact impulse load. As the internal

force in collision process is far larger than external

force, momentum conservation theorem can be used

for the system composed of these two parts along

axis direction. Thus, we get Equation (9). The

obtained impact momenta

P

2

of recoiling part is

gotten from required integration of impulse load.

11 11 2

mv mv P

(9)

Where,

m

1

is mass of shock pulse generator; v

1

is

initial impact speed of shock pulse generator;

1

v

is

residual impact speed of shock pulse generator;

P

2

is

the obtained impact momenta of recoiling part.

Using conservation of energy theorem to system

composed of shock pulse generator and recoiling

part before and after impact. As leading end of

shock pulse generator is a stiffness tunable elastic

impact programmer, and back end of recoiling part

is impact cushioning device, their impact is a non-

perfect elastic collision existing kinetic energy

rejection

E

. According to conservation of energy

theorem, we get Equation (10). The obtained kinetic

energy

E

2

from impact is determined by impact

impulse loading curve.

22

11 11 2

11

22

mv mv E E

(10)

Where,

E

2

is the obtained energy after impact

loading on recoiling part;

E

is the lost kinetic

energy in collision process.

Suppose the ratio of specific energy loss to

obtained impact energy of recoiling part is

α.

Reorganizing Equation (9) and (10), we get

Equation (11) and (12).

111 2

mvv P

(11)

111 11 2

21mvv vv E

(12)

Suppose the ratio of residual speed and initial speed

of shock pulse generator is β, we can get Equation

(13) and (14) from Equation (11) and (12).

DesignofFiringImpulseSimulatorandAnalysisofItsKeyResearchandDevelopmentTechnologies

457

2

1

2

21

1

E

v

P

(13)

2

2

1

2

2

1

21 1

P

m

E

(14)

For definite impact mission, the required impulse

waveform can be obtained by modulating impact

programmer after making clear shock pulse

generator mass m

1

and initial speed v

1

. In addition,

relevant impact impulse P

2

and E

2

are confirmed for

certain corresponding energy ratio α.

Shock pulse generator mass m

1

should be

confirmed first. On occasions of guaranteeing

impact impulse, increase in m

1

would reduce the

requirement of initial speed v

1

. As such, m1 should

be as large as possible. On the other hand, over size

of m1 could result in large residual speed of shock

pulse generator, which influences the effective

transmission of energy. Besides, large residual speed

would increase requirements on buffer and braking

system. Therefore, system design should guarantee

the residual speed be within 10%, i.e. β is no bigger

than 0.1.

From the above two principles, taking β in

equation (14), we can get m

1

.

2

2

1

2

0.61

1

P

m

E

(15)

Secondly, initial speed v

1

of shock pulse generator is

determined. Based on the given mass of shock pulse

generator, we can see from equation (11) that initial

speed is determined by impact momenta P

2

of

recoiling part in test. While taking β = 0.1, we can

get v

1

.

3.3 Research on Security Protection

Problem

Security protection of FIS is an important problem,

where passive protective layers as non-interference

physical construction, adequate component strength,

rational hydraulic and mechanical buffer guarantee

the security of FIS from bottommost level.

Security design for driving system of speed

generator provides basic safeguard and means for

security protection of system, which is active

executor of protection actions.

Hardware and software protect of control system

are uppermost protective layer for ultimate

realization of active protection strategy.

3.3.1 Mechanical System

In working process of FIS, it is required to guarantee

that no mechanical impacts between mechanical part

and actuating mechanism happen. Rational design

requirements and criteria for each component of FIS

are given out based on analysis of stressed state,

which gives out detailed calculation of strength,

stiffness, longevity, etc. and retains high enough

safety system and proper design allowance. To

prevent component damage in impact process,

mechanical cushioning device of shock pulse

generator need to be designed for residual energy

absorption of shock pulse generator. In this way,

impact effect on other components is reduced

effectively, which further ensures the safety,

reliability and long-time running of FIS.

3.3.2 Safeguard of Driving System

Driving system is both operative part of FIS and

specific safeguards executor. In order to guarantee

the safe operation of FIS, security protection

function is designed for hydraulic driving system.

Protection mode shown in Figure 9 can be adopted

in design of driving system, i.e. locking valve is

used to lock driving system on certain location when

system failures occur.

3.3.3 Safeguard of Loading System

When system failures appear, automatic switch from

loading control to position control is realized to keep

the system in the current position, which avoids

further damage on equipment. While control system

problem makes positioning safeguard unachievable,

the system links up cavity A and cavity B of hydro-

cylinder, thus the forces exerted on system in test

approaches zero, which realizes safeguard function.

3.3.4 Safeguard of Control System

The following measures can be adopted for

hardware protection of control system:

Monitoring and alarm of lines: main lines

including control and power supply loops as

control element, driven element, sensors, etc. are

monitored at real time. Once open wire or plug

loosening state is detected, protective treatment

can be proceeded in time by control system;

Millisecond level monitoring plant of computer

failure: millisecond level computer failure

monitoring plant (also called watchdog) could

detect running status of real-time controller in

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

458

real time. Once failure or system halted appears

on real-time controller, system control would be

taken over by watchdog. Then, security

protection process is triggered to realize security

protection of system.

4 EXPERIMENTAL VALIDATION

4.1 Technical Specification of FIS

Technical specifications mainly include: maximal

recoil driving force, force cell precision, angle

range, adapting initial height, forward and astern

speed, maximal route, hydraulic cylinder retraction

speed, forward positioning error, positioning holding

time, tacho-generator precision, impact frequency,

simulation precision, performance parameter

measuring accuracy, etc.

Maximal recoil force: no less than 4000kN;

Force cell precision: no less than 0.5%;

Angle range: 0°-45°;

Adapting firing line altitude: 500mm-2000mm;

Impulse velocity: 10m/s (adjustable with

program);

Hydraulic cylinder rapid retraction speed:

0.1m/s;

Forward positioning error: ±5mm;

Impact frequency: impulses up to 2-3 rounds per

minute;

Performance parameter measuring accuracy:

superior to 1% F.S.

In order to check if impact test data of FIS satisfies

requirements of system design, its key parameters

need to be validated by actual test. Key technical

indexes of firing impact test model include duration

of shock pulse, impact force, impulse, impact

acceleration peak value, continual impact number,

impact speed, angle regulating range, etc. In this

paper, we give out validation results of three major

parameters as impulse duration, impact force and

impulse.

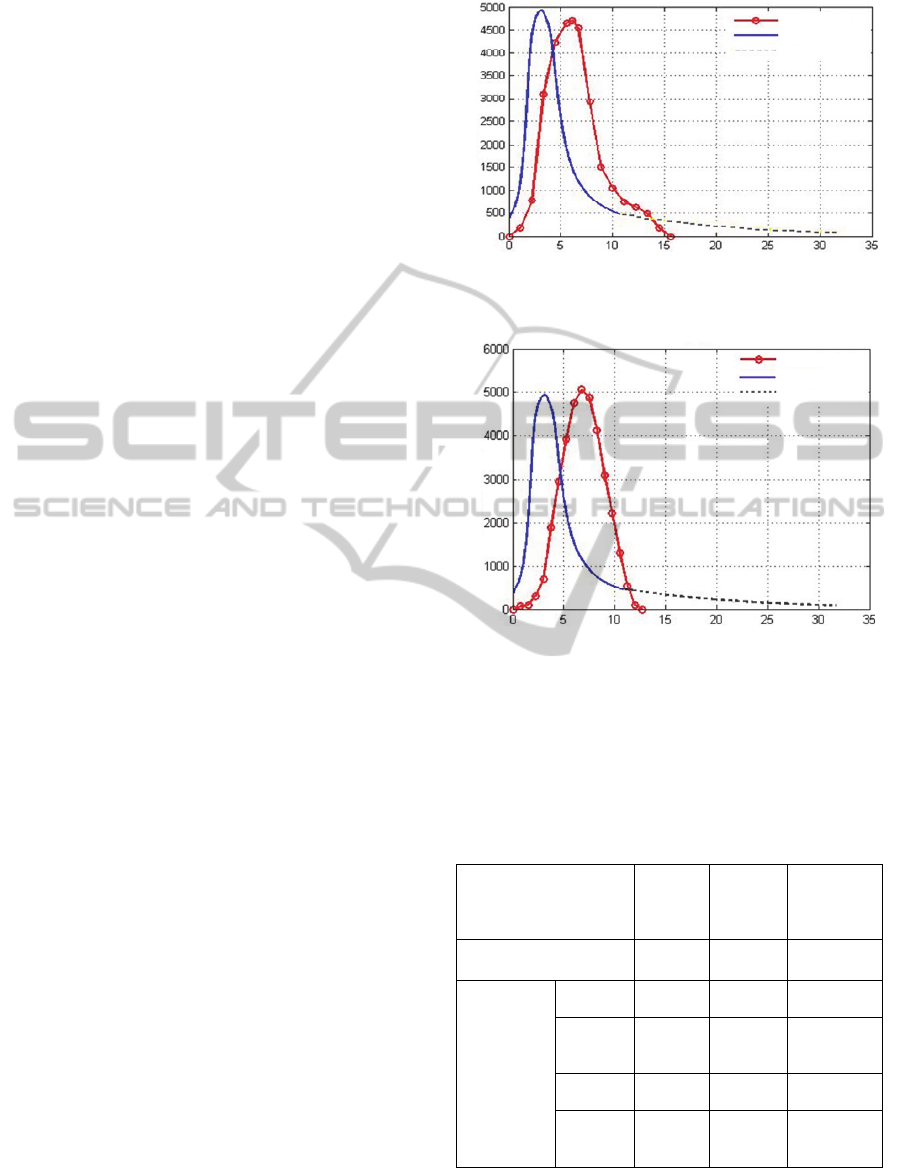

4.2 Comparison Validation Test with

Live Firing

Take live firing test data of certain shrapnel as truth

value, live firing impact (resultant force in gun bore)

curve is built. Three simulation impact tests of this

gun are carried out with FIS, correlation curves of

three simulated impact to live shrapnel are shown in

Figure 8 and 9.

Time t (ms)

Simulation

Live firing

Aftereffect

Impact force F (kN)

Figure 8: Contrast curve of a howitzer live firing with 1

st

simulation firing.

Time t (ms)

Simulatio

n

Aftereffect

Live firing

Impact force F (kN)

Figure 9: Contrast curve of a howitzer live firing with 2

nd

simulation firing.

Comparative data of three simulated impulses to

howitzer live firing for three kind of major

parameters are shown in Table 1.

Table 1: Comparative data of simulated impact to howitzer

live firing on certain gun.

No.

Total

impulse

Ns

Impulse

duration

ms

Maximum

impulse

force

kN

Live firing 27002 33.50 4813.5

Simulation

First 27794 15.60 4704.6

Relative

error

%

2.94 -53.43 -2.26

Second 27018 12.68 5048.8

Relative

error

%

0.06 -62.15 4.89

DesignofFiringImpulseSimulatorandAnalysisofItsKeyResearchandDevelopmentTechnologies

459

5 CONCLUSIONS

In validation process for simulated impact of FIS,

measured data of bore pressure resultant force of a

howitzer 1 living firing is taken as truth value.

Simulation effect of FIS can be established via

comparisons of 2 simulated impact force values.

The following conclusions can be obtained from

measured test data and calculated results in Table 1:

Comparison results of selected three key

parameters as impulse, duration of shock pulse

and maximal impact force can be used as

simulation credibility assessment basis of FIS;

Maximum error of total impulse is 2.94 %,

maximal value error of impact force is 4.89 %,

which meet design requirements of 15% on

simulation error;

Maximum error for impulse duration is -62.15 %,

which do not meet design requirement of 15% on

simulation error;

The shape of bore pressure resultant force curve

in live firing is basically in accord with impact

force curve of FIS.

Maximum error for two impulse durations all exceed

50 %, the main reason is that live firing data include

20ms after pill's getting out of gun bore, namely

after-effect period. If after-effect period is

subtracted, maximum error for impulse duration

satisfies required simulation precision of 15%.

There are several advantages of the FIS over live

fire testing. For example, FIS is easily operated

indoors, not weather dependent. It also enables test

engineers to examine any failure repeatedly during

weapon approval test. FIS can be operated

approximately two to three times per minute thereby

enabling test engineers to examine the recoil

systems' response to repeated rapid firing. However,

the most important benefit of FIS is reduction in the

cost associated with live fire testing of large caliber

tank and howitzer cannons, which averages $500 to

$2K per round.

REFERENCES

Aberdeen Test Center, 1994. Report of Survey Conducted

at U. S. ARMY COMBAT SYSTEMS TEST ACTIVITY,

Center of Excellence for Best Manufacturing Practices

ABERDEEN, MD.

Aberdeen Test Center, 2010. Firing Impulse Simulator

[online]. DoD TechMatch. Available from

http://www. dodtechmatch.com/DOD/Lab/View

Facility.aspx?id=71348. [Accessed on 7

th

February,

2015].

Cast, M., 2001. Army test move to ‘virtual proving

ground’. National Defense, (11), 62-64.

Di, C. C., Liu, L., Zheng, J., and Chen, Y. C., 2012a.

Numerical simulation on dynamic recoil test with gun

muzzle subjected to high-velocity impact. Explosion

and Shock Waves, 32 (3), 323-327.

Di, C. C., Yang, Y. L., Qin, J. Q., and Cui, K. B., 2012b.

Influences research of impact factors on gun recoil

tester. Chinese Journal of Gun Launch & Control, (2),

25-28.

Faller, J. G., 1997. Simulating firing loads provides

flexibility and test repeatability [online]. Available

from http://www.thermotekusa.com. [Accessed on 7

th

February, 2015].

Gao, T., He, C., Fan, Z. J., and Guo, H. L., 2014. Analysis

and evaluation of artillery fire simulation test. Key

Engineering Material, (620), 632-637.

Lang, F. Y., and Li, W. J., 2012. Design of a Large

Caliber Self-Propelled Gun Shooting Simulation

device. Chinese Journal of Gun Launch & Control,

(3), 52-54.

Liu, L., Di, C. C., Pan, B. Q., and Yao, J. J., 2011. Design

and research on gun dynamic recoil simulation test

mechanism. Chinese Journal of Gun Launch &

Control, (1), 36-40.

Sanders, P., and Patenaude, A., 1996. Study on the

Effectiveness of Modeling and Simulation in the

Weapon System Acquisition Process, Final Report of

Department of Defense of America, Washington D.C.

Yao, Y. W., 2001. Simulation test system of gun recoil

and numerical calculations. Acta Armamentarii, 22(2),

152- 155.

Zhao, F. Q., Hua, L., and Yang, Z. J., 2003. Study on test

and measurement for recoil mechanism of a tank gun.

Chinese Journal of Gun Launch & Control, (s), 94-96.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

460