Topology Optimisation of Rotating Automation Components for

Machine Tools – Methodology, Cost Effectiveness and Examples

Gerhard Kehl, Paul Jickeli, Martin Schietinger and David Blank

University of Applied Sciences, Faculty of Engineering Management, Esslingen, Germany

Keywords: Finite Element Simulation, Topology Optimisation, Simulation Costs, Return on Investment.

Abstract: Light weight constructions possess a variety of general benefits in application, such as higher energy

efficiency, increase of acceleration or payload. But especially the reduction of costs over the entire product

life cycle is increasingly in the focus. By application of topology optimisation for rotating automation

components a significant improvement is possible. On the other hand any simulation effort has to be judged

as an entrepreneurial action for which a return on investment (ROI) has to be ensured. The simulation tasks,

results and in conclusion the ROIs for some exemplary optimisations in the field of manufacturing machines

are presented and assessed as success stories for the use of simulations in practice.

1 INTRODUCTION

The application of lightweight construction offers a

variety of benefits, such as improved energy

efficiency, acceleration and increased payloads. In

addition to the use of lightweight raw materials and

lightweight manufacturing methods, there is also

potential in the area of structural design

optimisation. This can be tapped by employing

computer aided optimisation methods (Klein, 2013).

Some finite element software packages offer

integrated topology optimisation functionality for

this purpose. They are useful for the simulation of

structural components during the concept

development and design phases. ANSYS and

ABAQUS e.g. support the consideration of static

load cases to enable the development of load

efficient structures.

Initially, it is important to understand the effects

of different load cases in order to be able to optimise

structural components that are used in machine tools

(Brandenberger, 2004). Apart from the consideration

of load bearing structural components (e.g. machine

beds), the study of automation components such as

tool changers, tool magazines and pallet changers

might also be economically promising (Keller,

2005). If these components represent the

unproductive secondary processing time and set-up

time of machine tools, they promise improvements

in movement in addition to the material and energy

savings.

2 BASELINE INVESTIGATION

Firstly, topology optimisation is carried out and

discussed for stationary 2D rectangular element

models (according to the idea of Schumacher, 2005

and 2011), after which the observations will be

extended to rotating 2D models. Then some practical

applications are presented. The following boundary

conditions apply for the 2D rectangular model:

Design space: Height 100 mm, width 50 mm.

The design space is discretised with about 30,000

8-node quadratic elements.

The two lower corners each contain a fixed

point.

The force application point is 75% of the height.

All forces are introduced in the plane, have the

same value and each force is acting in the

positive coordinate direction.

As an optimisation constraint, the mass reduction

is defined such that 20% of the design space

should be filled with material.

The end goal is to maximize the static rigidity.

Topology optimisation is carried out with the

following load cases:

a) Horizontal force

b) Vertical force

c) Horizontal and vertical force applied

simultaneously

d) Horizontal and vertical force applied

sequentially with equal weighting to optimise

the structure

441

Kehl G., Jickeli P., Schietinger M. and Blank D..

Topology Optimisation of Rotating Automation Components for Machine Tools – Methodology, Cost Effectiveness and Examples.

DOI: 10.5220/0005501904410446

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 441-446

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

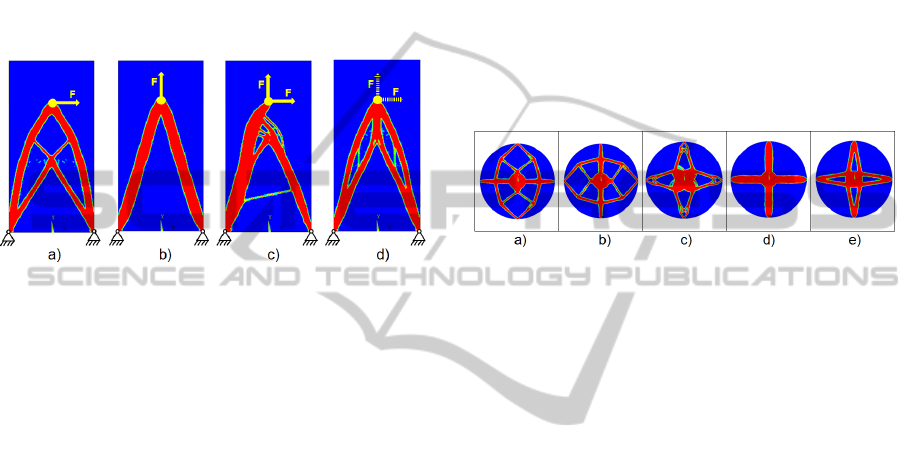

Figure 1 shows the obtained structures for all

four optimisations which show many differences.

The structures of a) and b) are plausible in view of

load efficiency. It is also apparent that the structure

d) clearly results from the superposition of a) and b).

Interestingly, however, structure c) is asymmetrical

and only suitable for the simultaneous occurrence of

the horizontal and the vertical force in the assumed

directions. However, the structure c) is not suitable

for the exclusive occurrence of either the horizontal

force or the vertical force, as well as for the case that

one of the two forces is inverted.

Figure 1: Topology optimisation for 2D rectangular

models with different load cases.

From this baseline investigation, the important

finding is that the optimised geometry has a high

sensitivity to the load cases applied. However this

could be overcome by providing the structure with

some initial geometry constraints to ensure a

sensible outcome. Furthermore, for a valid optimised

structure a load case needs to be applied in which all

loads are considered.

3 STUDIES WITH ROTATING

SYSTEMS

Topology optimisations are performed and then

discussed for 2D circular discs with point masses.

The technical data is based on practical

implementation and the following boundary

conditions apply:

Design space: Homogeneous, massless disc with

a diameter of 500 mm.

The design space is discretised with about 30,000

8-node quadratic elements.

The disc centre is modelled as rigidly fixed.

The four identical point masses (m = 1 kg) are

arranged symmetrically on the periphery of the

disc at 90 ° intervals.

Also as previously, as an optimisation constraint,

the mass reduction is defined such that 20% of

the design space should be filled with material.

As before the final aim is to maximize the static

rigidity.

Topology optimisation is carried out with the

following load cases:

a) Linear acceleration with 2g horizontally

b) Linear acceleration with 2g vertically

c) Angular acceleration α = 720°/ s

2

d) Angular speed ω = 360°/s

e) Combined load case of: a), b), c) and d) with a

load case weighting vector of (2,2,1,1)

Figure 2 shows the differences between the

optimised structures obtained for the given load

cases of the rotating disc.

Figure 2: Topology optimisation with homogenous 2D

circular discs with four equally spaced point masses at the

extremities.

The structures for a) to d) are plausible in view

of load efficiency. Structure b) is simply a 90 degree

phase change from structure a). Structure e) is

created by superposition of the structures a) to d)

and is optimal with reference to the given laod cases

and weighting.

Such optimisation results can often be implemented

in practical structural design. An initial presentation

of the methodology in more detail follows below.

This will then be applied to examples from the

machine tool industry with respect to rotating

automation components such as tool changers, tool

magazines and pallet changers, where this method

in particular might be economically promising.

4 METHODOLOGY FOR

TOPOLOGY OPTIMISATION

Topology optimisations with combined load cases

are useful when dealing with real problems, with the

ultimate aim being practical application of the

solutions found. For this purpose, the following

procedure has proven itself:

1. In machine tools, a variety of tools and work

piece pallets with standardised mechanical

interfaces can be used. The central basic body

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

442

of the rotational automated moving component

normally comprises of regular geometric

repetitions. The aim is to keep the analytical

model small and thus shorten the optimisation

procedure. The first thing to consider is the

ability to use the symmetry conditions (mirror

symmetry, axial symmetry and cyclic

symmetry). It should be noted that the

symmetry always relates simultaneously to

geometry and loads.

2. The next step is to determine whether a

simulation by 2D or 3D model is appropriate.

A 2D model can significantly shorten the

calculation process. 3D models should be

applied to the topology optimisation only when

absolutely necessary. This happens for

example, if forces are not applied within the

plane considered, but in a parallel plane some

distance away or perpendicular to the plane.

3. Static load cases should be solved individually

to determine whether loads and boundary

conditions are reasonably defined. Stresses and

deformations have to be determined and

compared for each load case. If there are load

cases that do not contribute significantly to a

combined load case, these load cases may be

neglected in the topology optimisation.

4. Next, the topology optimisation is performed

with each load case. Is the optimised topology

solution sensible with respect to the loads

applied in the load case?

5. Based on the previous results, the weighting of

the load cases for the combined load case is to

be determined. The default could be an equal

weighting of all load cases, but the weight

function should at least be reasonably varied

for trial purposes.

6. Even if the target mass for the optimised

component is known exactly, it is

recommended that the mass reduction be

changed for testing purposes. This could lead

to significantly different structures that provide

more ideas for the design implementation of

the results in practice.

7. If possible, topology optimisations should be

performed with different optimisation

algorithms for comparison (with ANSYS: OC

and SPC).

5 COST-EFFECTIVENESS OF

TOPOLOGY OPTIMISATION

Overall, this approach has been applied in a number

of topology-optimised components to reduce costs

and improve the characteristics of the component

such as weight, inertia and stiffness. Subsequently,

three components will be presented. The examples

of the successful application for 2D or 3D

optimisation of rotating automation components for

machine tools are:

Double gripper arm of a tool changer for a

grinding machine (2D)

Tool magazine for a grinding machine (3D)

Double gripper arm for a tool changer of a

machining centre (3D)

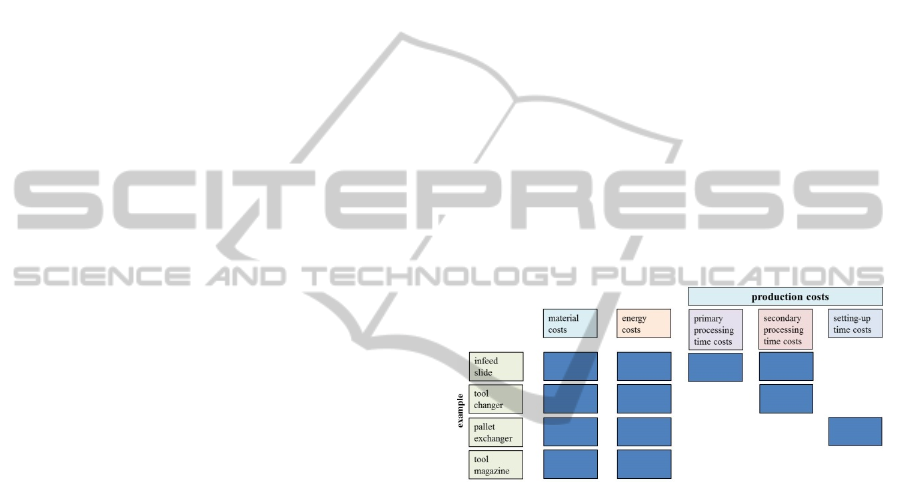

For the overall goal of reducing costs in the

context of the entire product life cycle (Nyhuis, 2009

and Wiendahl, 2010), Figure 3 shows the

effectiveness of the topology optimisation of various

machine tool components with regard to the usual

types of costs considered (Witt, 2006). This proves

to be critical to the assessment of the soundness of

topology optimisation when involving machine

utilization by the user.

Figure 3: Effectiveness of the topology optimisation with

regards to the type of costs.

A topology optimisation on a tool changer with

the aim of reducing mass can influence material

costs, but also the operating energy costs.

Furthermore the production costs of a machining

centre with this weight-reduced tool changer are

favourably influenced by more rapid tool changes.

In the topology optimisation of a tool magazine

however, there is usually no reduction in production

costs to be substantiated, because the tool magazine

movement happens isochronical to machining

processes.

6 DOUBLE GRIPPER ARM OF A

TOOL CHANGER FOR A

GRINDING MACHINE

In this case the tool changer arm conducts rotary as

well as linear movements for every tool change.

TopologyOptimisationofRotatingAutomationComponentsforMachineTools-Methodology,CostEffectivenessand

Examples

443

Therefore, a part with reduced mass and reduced

mass moment of inertia reduces the secondary

processing time.

As all relevant forces lay within the plane

considered, a 2D topology optimisation was

sufficient. The topology optimisation was conducted

with a combined load case containing the following

load cases:

a) Linear acceleration (1g horizontally)

b) Gravitational force (1g vertically)

c) Angular acceleration α = 180°/ s

2

d) Angular speed ω = 90°/s

The optimisation result obtained from the design

room was used as the basis for an optimised

geometry. Final calculations showed about 35%

increased stiffness for the same mass compared to

the original geometry of the grinding wheel changer

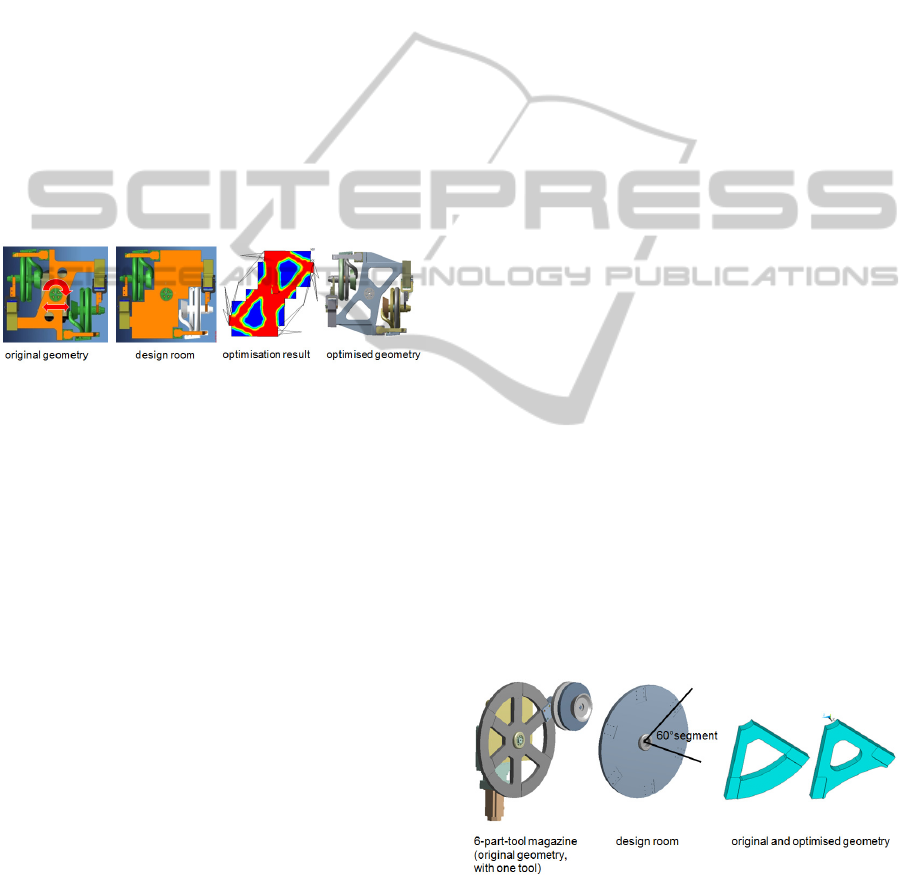

(Figure 4).

Figure 4: Topology optimisation of a tool changer of a

grinding machine.

Although a stiffening is advantageous, another

alternative was examined. This provided the same

stiffness with a 27% lower mass and a 32% lower

moment of inertia. This made increased linear and

rotational accelerations possible, while using the

same drive equipment. A detailed cost-benefit

analysis was made for this topology optimisation.

This was judged as an entrepreneurial action, for

which a ROI (return on investment) can be

determined. The analysis yielded the following

results:

The grinding machine manufacturer had to

invest an initial one-off € 834 development costs

(including staff for analysis and design, software,

hardware, equipment costs) for the topology

optimisation of this component. The machine

manufacturers benefits initially by the reduction of

material costs by € 33 per grinding machine.

Furthermore the machine user registers a

productivity gain of € 152 per grinding machine for

a duration of 10 years. Thus, from a macroeconomic

point of view, the payback of this amount is received

with five machines. However, for this type of

machine, a total of 1000 units are planned, this

topology optimisation provides a surplus of

approximately € 184,166 in the long term. The

majority of the profit goes to the users of these

grinding machines (€ 152,000), but the machine

manufacturer gains a profit as well (€ 32,166).

While it remains uncertain whether the machine

user is ready to pay in advance for the productivity

growth through an investment, an increase in

efficiency of the grinding machine due to this

optimisation would strengthen the market position of

the machine manufacturer over the competitor’s

(Jickeli, 2014).

7 TOOL MAGAZINE FOR A

GRINDING MACHINE

The disc-shaped tool magazine shown in Figure 5

supplies six different grinding wheels for a grinding

machine controlled by a forward timing device. Due

to the placement of the tool magazine disc in the

vertical plane and projecting tool holders with

grinding wheels, gravity loads apply in a plane

parallel off-set to the disc plane such that a 3D

model is required. The calculation expense can be

reduced by neglecting the load case "angular

acceleration" by symmetry conditions (6 x 60 °).

Even a reduction to a 30° segment would have been

possible. Using topology optimisation load-oriented

grooves in the disc and material savings on the outer

contour, an increase in the stiffness-to-mass ratio of

29% was realised. Manufacturing as a cast part thus

shows reduced material costs. The mass moment of

inertia was reduced by 24%. A reduction in the chip-

to-chip time was not found in practice however, as

the motion of the tool magazine can be performed

simultaneously during machining. However, the

reduced driving torque required results in energy

savings during operation.

Figure 5: Topology optimisation of a tool magazine of a

grinding machine.

The cost-benefit analysis for this component

yielded the following results: For the topology

optimisation of this component € 549 development

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

444

costs (including staff for analysis and design,

software, hardware, equipment costs) were assumed.

This can be compared with a material cost reduction

of € 47 per grinding machine. Surprisingly, the

energy savings due to reduced mass moment of

inertia is calculated as less than € 1, despite taking

10 years of operation into account. One reason for

that is, that the inertia of the drive itself is a multiple

of the inertia of the optimised tool magazine.

Nevertheless, this measure makes sense

economically from a quantity of twelve units, even if

the payback time due to lack of relevance for chip-

to-chip time clearly occurs later, compared to double

gripper arm of the tool changer. It is still

indisputable, based on the planned sales, that this

optimisation is the right decision from an

entrepreneurial point of view (Schietinger, 2014).

8 DOUBLE GRIPPER ARM OF A

TOOL CHANGER FOR A

MACHINE CENTRE

The double gripper arm in Figure 6 provides the

automated exchange of cutting tools between a tool

magazine and spindle within a machining centre, via

rapid linear and rotary movements. The machine by

Gebr. Heller Maschinenfabrik GmbH (HELLER

MCH 280C) can handle very heavy tools of up to 35

kg during a tool change and reaches a chip-to-chip

time of approximately 6.8 seconds.

The aim was to investigate how to further reduce

the chip-to-chip time, but above all to increase the

reliability of the tool change, so that jamming of

tools in the spindle or in the tool supply position is

ruled out under all operating conditions.

Therefore, a topology optimisation of the

geometry has been applied with cyclic symmetry (2

x 180°), so that only the half models of the double

gripper arm are shown. 3D models were considered,

since in addition to the already known load cases of

gravitational force and rotational movement, there

are also significant extraction forces from the tool

interface of the clamping system. These forces apply

in axial direction of the tool and are therefore out of

plane.

As a result of the topology optimisation and

redesign, the component on the bottom right of

Figure 6 shows increased stiffness-to-mass ratio of

21% for typical operating loads compared to the

original component (top right). Additionally, there

was a 19% increase in fatigue resistance, thus

increasing the reliability of the tool change.

Figure 6: Double gripper arm: Function and half models of

the original / optimised component.

9 CONCLUSIONS

Rotational motion components in machine tools

often occur in automation solutions for tools and

work piece flow. Systematic topology optimisation

is a way to improve their technical and economic

characteristics. However, they have to be justified as

economical business decisions in advance. A means

for this is the consideration of the amortisation of

topology optimisations. This can occur at different

unit numbers for various components due to the

influence of cost types. Experience has shown that

the optimisation of components for reduced primary

processing times, secondary processing times, and

set-up times often turns out to be commercially

successful, even in small quantities.

REFERENCES

Klein, B., 2013. Leichtbau-Konstruktionen. Springer

Vieweg-Verlag Wiesbaden.

Brandenberger, M., Kehl, G., 2004. Coupled Simulation

using FEM, MBS and Control Simulation Tools using

the Example of a Machine Tool. In: Proceedings of the

NAFEMS Seminar Mechatronics in Structural

Analysis, Wiesbaden.

Keller, K., Kehl, G., 2006. Coupled FE Analysis of

Structure and Control of High Dynamic Machine

Tools considering the Machining Centre HELLER

MCH 250 as an Example. In: Proceedings of the

PERMAS Users Conference, Strasbourg.

Schumacher, A., 2005. Optimierung mechanischer

Strukturen – Grundlagen und industrielle

Anwendungen. Springer-Verlag Berlin Heidelberg.

Schumacher, A., Ortmann, C., 2011. Topology

Optimization – Research State of the Art. Proceeding

of the Automotive CAE Grand Challenge 2011,

Hanau.

TopologyOptimisationofRotatingAutomationComponentsforMachineTools-Methodology,CostEffectivenessand

Examples

445

Nyhuis, P., Wiendahl, H.-P., 2009. Fundamentals of

Production Logistics Theory, Tools and Applications.

Springer-Verlag Berlin Heidelberg.

Wiendahl, H.-P., 2010. Betriebsorganisation für

Ingenieure. Hanser-Verlag München.

Witt, G., 2006. Taschenbuch der Fertigungstechnik.

Hanser-Verlag München.

Jickeli, P., 2014. Strukturoptimierte Bauteile für reduzierte

Nebenzeiten von Werkzeugmaschinen – konstruktive

Gestaltung und Wirtschaftlichkeitsbetrachtung.

Bachelor thesis at the University of Applied Sciences

Esslingen.

Schietinger, M., 2014. Strukturoptimierung von

Werkzeugmaschinenmagazinen mit Wirtschaftlich-

keitsbetrachtung. Bachelor thesis at the University of

Applied Sciences Esslingen.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

446