Test of New Control Strategies for Room Temperature Control

Systems

Fully Controllable Surroundings for a Heating System with Radiators

Nina Kopmann, Rita Streblow and Dirk Müller

RWTH Aachen University, E.ON Energy Research Center, Institute for Energy Efficient Buildings and Indoor Climate,

Mathieustr. 10, 52074 Aachen, Germany

Keywords: Single Room Heating Control, Hardware-in-the-Loop, Thermostatic Valve.

Abstract: About one third of Germany’s energy demand is used for room heating thus offering a huge potential for energy

savings. The development of intelligent home energy systems should optimize the energy consumption of

buildings. In Germany the most common way to control the room temperature while heating is to use a

thermostatic valve. This temperature-control system is self-sustaining but has no possibility to communicate to the

heating system or other devices in the household. For the test and development of new control strategies and the

appropriate components a Hardware-in-the-Loop test bench for hydraulic network applications is developed at the

E.ON Energy Research Center. This test bench allows the test of a heating system of a flat in a controllable

surrounding under dynamic boundary conditions. In this paper the new test bench concept will be described.

1 INTRODUCTION

The development of home energy systems forces

more and more the investigation of new control

systems for single room heating control. In Germany

the most common way to control the temperature in a

room while heating is to use a thermostatic valve. The

user can define a set temperature and the thermostatic

valve reduces or increases the volume flow in the

radiator to adapt the heat output of the radiator. This

temperature control system is self-sustaining but has

no possibility to communicate to the heating system

or other devices in the household. New electrical

valves are designed to control the room temperature

and to communicate with the home energy system.

The use of these electrical actors is still in a

developing state, and especially new investigations

have to be tested in controllable surroundings.

This paper will show a test bench concept to develop

and test new control strategies and components for

single room heating. To combine the advantages of

static experiments with fixed boundary conditions

and the dynamic uncontrollable field studies we use a

hardware-in-the-loop (HiL) system. The HiL testing

is applied in many laboratories for the test and

development of building automation control systems

and heat supply units, as described in Barth, 2010 and

Bianchi, 2005. The special feature of the described

test bench is the reproduction of the room

environment under dynamic and controllable

surroundings.

2 CONCEPT OF THE TEST

BENCH

With the test bench described in this paper it is

possible to test room temperature control systems in

dynamic and controllable surroundings realized with

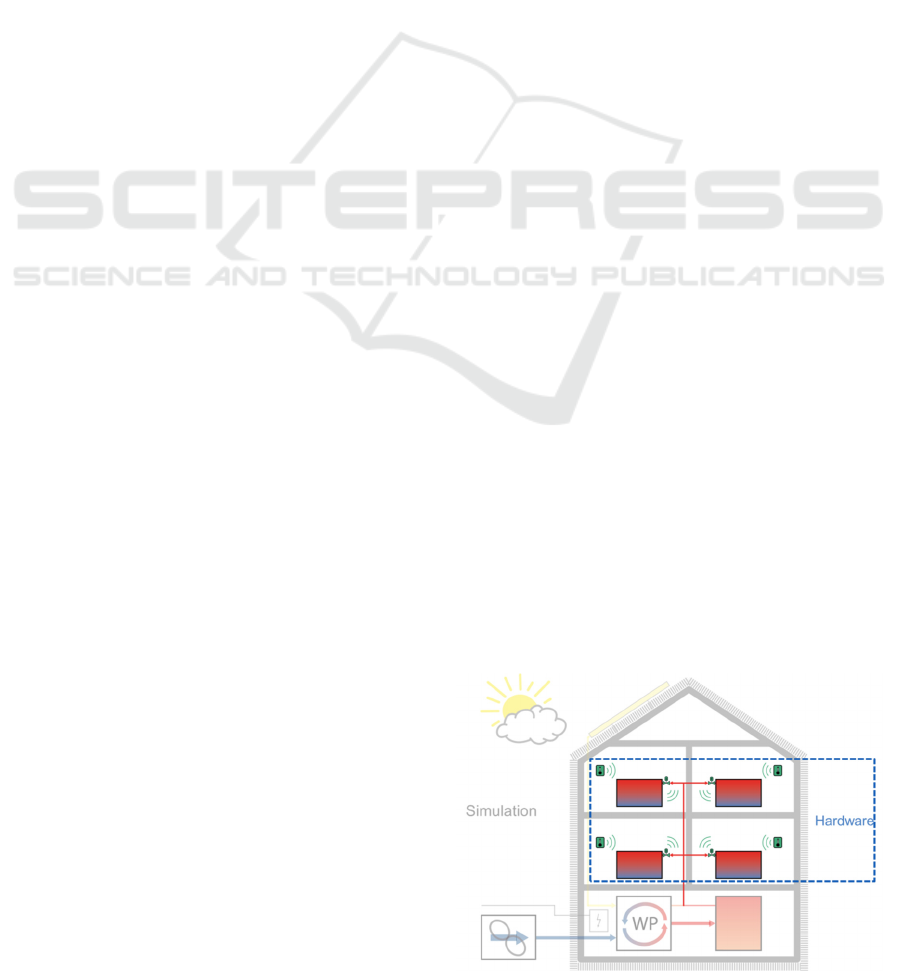

a HiL coupling, see Figure 1.

Figure 1: Scheme of the HiL test bench for single room

heating control systems and components.

277

Kopmann N., Streblow R. and Müller D..

Test of New Control Strategies for Room Temperature Control Systems - Fully Controllable Surroundings for a Heating System with Radiators.

DOI: 10.5220/0005478902770282

In Proceedings of the 4th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS-2015), pages 277-282

ISBN: 978-989-758-105-2

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

The real hardware (radiator, thermostatic valve,

hydraulic net and if applicable heat supply unit) will

be examined under dynamic boundary conditions,

which will be defined using a coupled simulation in

Modelica.

The test bench consists of four rooms, which are

heated with radiators. The hydraulic network is

similar as in a small flat. These four rooms are

coupled with a dynamic simulation in Modelica, so

that each room can react dynamically as it exchanges

the boundary conditions with the simulation. The type

of building and the weather can be changed in the

simulation setup. To test the direct communication

with the heat supply system, the system has the

possibility to provide the heat by an installed

condensing boiler or water/water heat pump. But

even other heat supply systems can be simulated and

the supply conditions can be emulated at the test

bench.

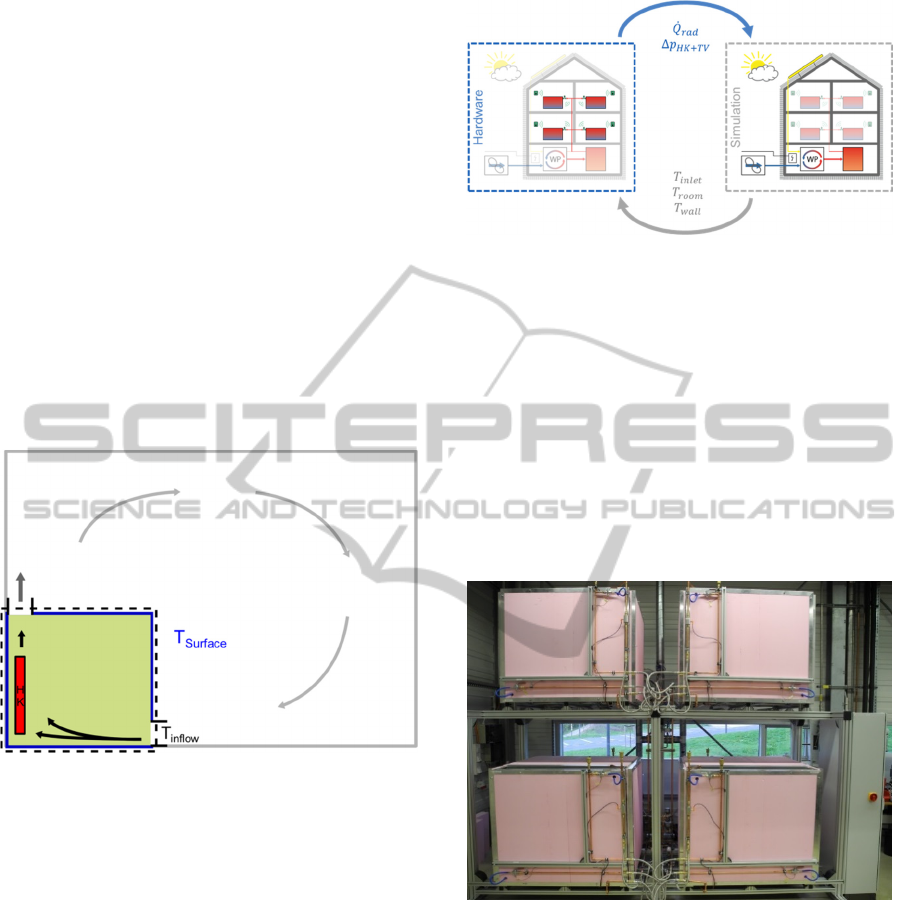

Figure 2: Reduced space requirements by downsizing the

volume of each room.

To reduce the required space for the test bench we

downsize the enclosing volume of the radiator to

about 3 to 4 m³ as shown in Figure 2. More

information about this concept can be found in

Kopmann et al., 2011. The boundary conditions

influencing the heat emission of a radiator are the

surface temperatures of the enclosing walls and the

room’s air temperature. These boundary conditions

are calculated in Modelica and relayed onto the test

bench. We use the measured heat emission of the

radiator and the pressure drop at the thermostatic

valve as boundary condition for the simulation. The

HiL concept is shown in Figure 3.

Figure 3: Data transfer using the HiL coupling.

2.1 Description of the Supply Structure

The four coupled rooms are installed in a rack

construction which allows changing the components

in each cabin individually, see Figure 4. Radiators of

type 22 with a nominal heat output of 1570 W at

70/60/20 are installed in three rooms and the fourth

room contains a radiator of type 11 with only 890 W

nominal heat output. Each room is arranged with a

standard valve body and the control component

(thermostatic valve or electrical actuator) can be

changed easily.

Figure 4: Installation of the four coupled rooms.

For the evaluation of the single room heating control

the important parameters in each cabin are measured.

The heat emission of each radiator is determined with

the inlet and outlet temperature (

,

,

,

) and the

volume flow

,

. The working process of the

installed control valve is measured by the pressure

drop

and the valve lift . And the condition of

each room can be described with the indoor air

temperature

and the defined surface and inlet air

temperatures (

,

).

SMARTGREENS2015-4thInternationalConferenceonSmartCitiesandGreenICTSystems

278

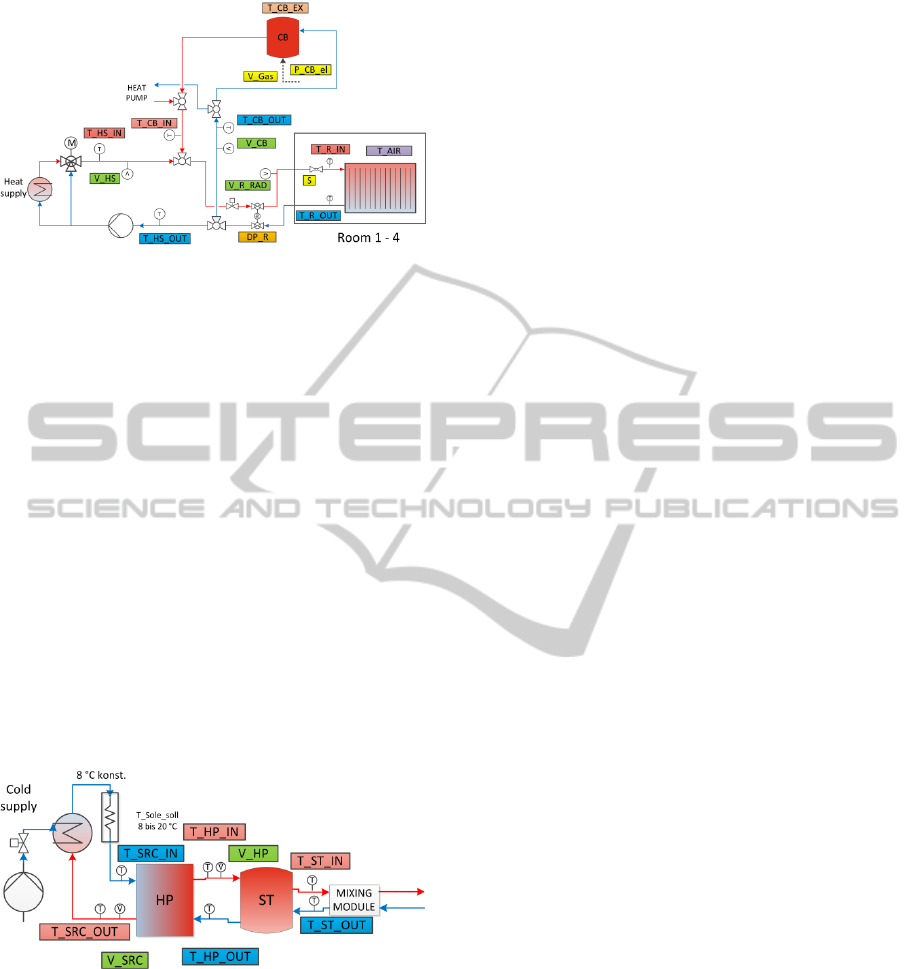

Figure 5: Installed supply structure of the test bench.

There are three possible supply units installed at the

moment. On the one hand the central heat supply of

the test hall provides the required supply temperature

,

of a simulated heat source. The control of the

supply temperature

,

is realized with a three-

way-valve in the form of a bypass control system, see

Figure 5 on the left side. The inlet and outlet

temperature (

,

,

,

) and the volume

flow

of the supply system are measured to

determine the total heat output of the system.

On the other hand an installed condensing boiler

allows the test of a real hydraulic heating network of

a small flat. For the analysis of the boiler efficiency

the gas flow

,

, the electric consumption

,

and the exhaust temperature

,

can be measured,

shown in the upper part of Figure 5. The evaluation

of the heat output of the condensing boiler is possible

by measuring the appropriate temperatures

(

,

,

,

) and the volume flow

.

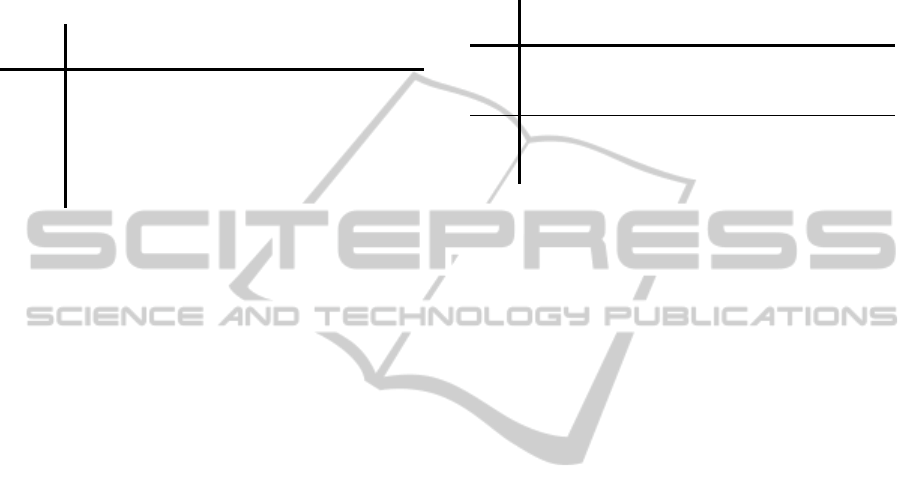

Figure 6: Supply structure for the water/water heat pump

system.

For further research activities it is interesting to test

the performance of the four coupled rooms in

combination with a heat pump. Therefor the supply

structure of the test bench provides the integration of

a water/water heat pump, a storage tank and an

appropriate mixing module. The included testing

equipment, shown in Figure 6, measure the important

state values of the heat pump source

(

,

,

,

,

), the circuit between heat

pump and storage tank (

,

,

,

,

) and the

temperatures after the storage tank (

,

,

,

).

The heat pump needs a defined inlet temperature

of 8 to 20 °C, which represents the heat source. The

infrastructure of the test hall provides a constant

supply temperature of 8 °C, and the higher

temperatures are realized with a heating rod.

2.2 Definition of the Boundary

Conditions

The ambient air temperature and the simulated room

parameters (

,

) influence the heat output

and with it the air temperature

in the small scaled

room. As mentioned above these simulated

parameters need to be converted into the correct

boundary conditions for the small-scaled ambient.

In this paper we will describe the idea of the

small-scaled concept and first results regarding the

control system and the behaviour of the setup will be

shown. Further information about the conversion into

the small-scaled boundary conditions will be

published in an upcoming proceeding, as the received

results are not verified yet.

The surface temperature

is a function of

the simulated wall and room temperature, and also

dependent of the according view factors of the scaled

room parameters. These view factors are described in

Glück, 1990. The inlet air temperature

and the

volume flow are a function of the current room

temperature, which correlation is shown in Kopmann

et al., 2011. But also the ambient temperature

influences the inlet air temperature as lower ambient

temperatures results in a higher heat output and that

means larger temperature gradient of the air in a real

room.

=

,

,

)

=

,

)

In this paper we will present the characteristic of the

test bench in terms of static boundary conditions

without any room temperature control. The maximum

heat output will be examined by using low

temperature supply boundary conditions according

the surface and the inlet air temperature

(

,

). Furthermore the stability and the

repeatability of the static boundary conditions are

examined and lately the control mode of the system is

shown.

2.2.1 Heat Output of the Test Bench

The Table 1 shows the summarized heat amount of

the four coupled rooms. The presented temperatures

TestofNewControlStrategiesforRoomTemperatureControlSystems-FullyControllableSurroundingsforaHeating

SystemwithRadiators

279

are the mean values of all four rooms in the time

period considered. The influence of the supply

temperature

is shown by using three different

temperature levels 75 °C, 60 °C and 45 °C. The total

volume flow of the heating water in all three states is

constantly 6 l/min and the total air flow 440 m³/h.

Table 1: Heat output using static, low boundary conditions

at three different supply temperatures.

∑

[W]

[°C]

[°C]

[°C]

75

6215

22.9

SD=0.08K

10.1

SD=0.04K

15.7

SD=0.06K

60

4353

19.9

SD=0.05K

10.0

SD=0.03K

15.4

SD=0.02K

45

2600

17.7

SD=0.05K

9.9

SD=0.02K

15.4

SD=0.01K

A high supply temperature (

=75 °) and low

boundary conditions (

= 10 °,

=

15,0 °) result in the maximum heat output of 6.2

kW. In this case the air temperature

in the cabin

is in a warm state with 23 °C.

Lower supply temperatures result in lower heat

output and respectively lower air temperatures.

2.2.2 Stability of the Setup

To test different control strategies a stable and

controllable surrounding is important. The

measurements in Table 1 are obtained using a surface

temperature of 10 °C and an air inlet temperature of

16 °C. The surface temperature in all three states is

adjusted correctly. The air inlet temperature is about

0.4 to 0.7 K above the set-point due to an insufficient

air cooling.

The mean standard derivation (SD) in all cases of

the surface and the air inlet temperature is < 0.05 K

which means a nearly constant control. The air

temperature in the cabin has a standard derivation of

< 0.08 K, which means that the boundary conditions

are stable enough to test control algorithm in this

setup.

2.2.3 Repeatability of the Setup

For the comparison of different control strategies and

various components the repeatability of the setup is

an important fact. Therefore two analysed data of

each of the supply temperatures 75 °C and 45 °C are

displayed in Table 2. These series of measurements

were obtained using the same boundary conditions as

mentioned above.

The measured results, for the supply temperature

of 45 °C, show nearly identic results in all mentioned

data. The difference of the heat output and the air

temperature in the cabin in the two analysed series is

less than 1 %.

Table 2: Repeatability of the measured data at two supply

temperatures.

∑

[W]

[W]

[°C]

[°C]

[°C]

[°C]

75

6215

-134

2%

22,9

+0,7

3%

15,7 23,4

6081 23,6 16,8 24,3

45

2600

-11

0,4%

17,7

+0,1

0,6%

15,4 23,1

2589 17,8 15,5 23,2

The comparison of the heat output at a supply

temperature of 75 °C is also satisfactory with a

difference of 2 %. Especially when the increase of the

temperature in the test hall

of 1 K between the

two analysed series is considered.

The installed air cooling unit provides a

temperature level below the hall temperature for the

air supply temperature (

). The maximum

temperature difference between the hall temperature

and the air inlet temperature

is about 8 K

providing an air volume flow of 400 m³/h with the

installed cooling capacity. That means that the higher

ambient temperature in the second measurement

series using a supply temperature of 75 °C results in

a higher inlet temperature of the cooled air. Hence the

air temperature in the cabin

rises by 1 K and as a

consequence the heat output of the radiator decreases.

These results illustrate that the repeatability of the

measurements is dependent of the correct control of

the boundary conditions.

2.2.4 Control Mode

For the use of dynamic boundary conditions at the test

bench, it is important that the temperature control

units adapt satisfactory after the set-point is changed.

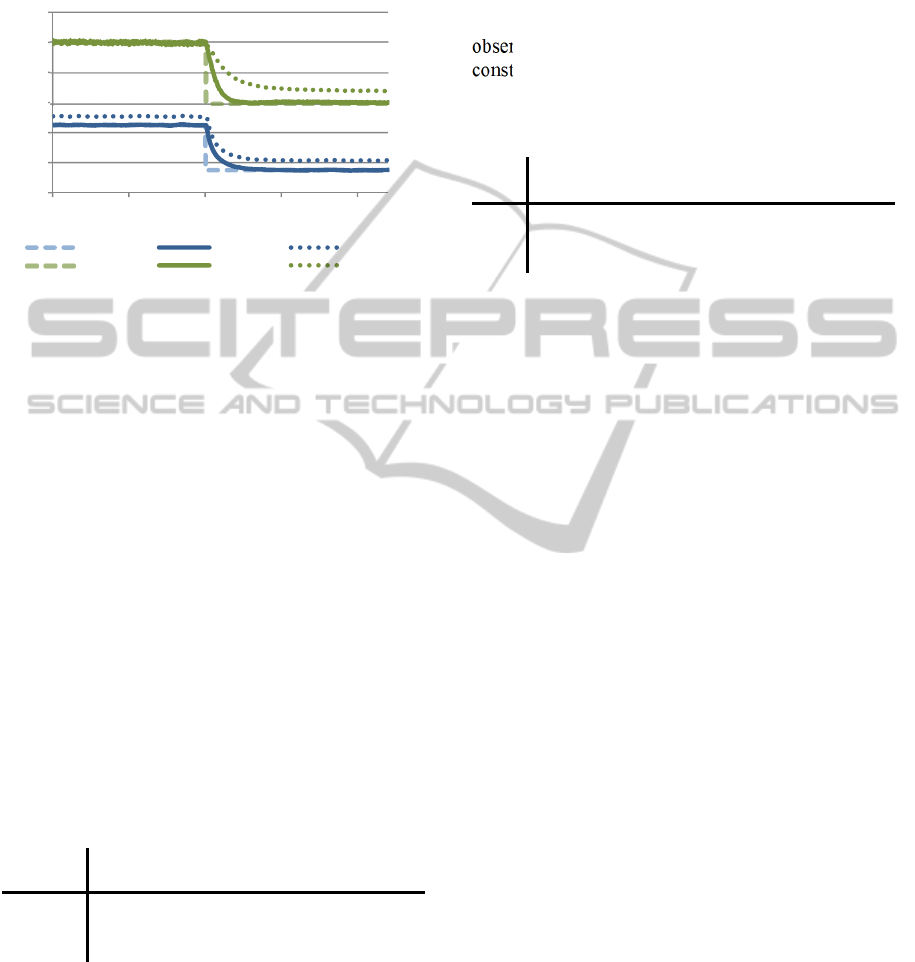

To analyse the control mode of the setup, Figure

7

shows the profile of the surface temperature (blue

lines) and the air inlet temperature (green lines) at a

set-point change. The set-point of the air inlet is

reduced from 20 °C to 16 °C and the set-point for the

surface temperature is reduced from 14.5 °C to 11.5

°C.

In the diagram we have to distinguish between the

surface temperature

and air inlet tempe-

rature

(dashed lines) and the controlled

temperatures (

,

,

) of these control units (solid

SMARTGREENS2015-4thInternationalConferenceonSmartCitiesandGreenICTSystems

280

lines). The control temperatures are necessary due to

the large dead times in the control loops, which forces

an appropriate control value closer to the manipulated

variable.

Figure 7: Control response of the surface temperature and

the air inlet temperature.

The set-point of the air inlet is controlled using an

electrical heater and the controlled temperature

is

measured directly behind this heating unit. The

control needs only 15 minutes to adapt to the new set

point and has a low control deviation (

=

19.97 °) and a stable control response ( =

0.06 ), see Table 3. Behind the control unit with the

electrical heater the air flow passes a short air duct

before being inducted in the cabin. Using an inlet air

temperature of 20 °C, which is similar to the hall

temperature

, the controlled temperature

corresponds with the air inlet temperature

at the

cabins. Lower air inlet temperatures result in higher

heat losses in the air ducts so that the temperature

increases about 0.8 K before being inducted in the

cabin. A cascade control will be implemented for

further investigations to eliminate the control

deviation.

Table 3: Mean temperatures and standard deviation to

analyse the control mode of the air inlet temperature.

,

[°C]

[°C]

[K]

[°C]

[K]

air

20 19.97 0.06 19.87 0.03

16 16.02 0.02 16.84 0.04

To control the surface temperature

the inlet

temperature of the cooled walls

,

is used as the

controlled value. The control is also satisfactory, as

the set point is adapted after 20 minutes without

control deviation and a negligible standard derivation

of 0.02 K, see Figure

7

and Table 4. The actual surface

temperature

is obtained from the arithmetic

average of the inlet and the outlet temperature of the

capillary tubes which are used to provide the surface

temperatures. Compared to the controlled

temperature this surface temperature has a constant

deviation of 0.6 K, which hardly depend on the

temperature level. This constant deviation should be

observed for further investigations by using a

constant set-point adjustment.

Table 4: Mean temperatures and standard deviation to

analyse the control mode of the surface temperature.

,

[°C]

,

[°C]

,

[K]

[°C]

[K]

sur-

face

14.5 14.50 0.02 15.07 0.02

11.5 11.50 0.01 12.15 0.01

3 CONCLUSIONS

In this paper we describe the possibility to test and

develop new control strategies and components for

single room heating control under controllable and

dynamic boundary conditions. First the concept of the

new test bench is shown and the supply structure

including the monitoring technique is described. The

results of the considered measurement series give an

overview of the behaviour of the test bench setup. The

heat output of the radiators in the cabins, the stability

and the repeatability of the measurements and the

control mode of the setup were analysed. There were

obtained some aspects to improve the control for

further investigations. These aspects will be applied

in the early future and shown in a following

publication.

ACKNOWLEDGEMENTS

Grateful acknowledgement is made for financial

support by BMWi (German Federal Ministry for

Economic Affairs and Energy), promotional

reference 03ET1169C.

We also appreciate the good cooperation with our

project partners Vaillant GmbH and Fraunhofer

Institute for Solar Energy Systems.

REFERENCES

Barth, M., Fay, A., Wagner, F. Frey, G., 2010. Effizienter

Einsatz Simulationsbasierter Tests in der Entwicklung

automatisierungstechnischer Systeme. In: Tagungs-

10

12

14

16

18

20

22

11:00:00 11:30:00 12:00:00 12:30:00 13:00:00

Temperature in °C

Time

T_KT_set T_KT_in T_surface

T_HT_set T_HT T_inlet

TestofNewControlStrategiesforRoomTemperatureControlSystems-FullyControllableSurroundingsforaHeating

SystemwithRadiators

281

band Automation 2010, S. 47-50, 15-16. Juni 2010,

Baden-Baden.

Bianchi, M., Shafai, E., Geering, H. P., 2005. Comparing

New Control Concepts for Heat Pump Heating Systems

on a Test Bench with the Capability of House and Earth

Probe Emulation, Proceedings of the 8th IEA Heat

Pump Conference: Global Advances in Heat Pump

Technology, Applications and Markets, Las Vegas,

NV, June 2005.

Glück, B., 1990. Wärmeübertragung – Wärmeabgabe von

Raumheizflächen und Rohren, Verlag für Bauwesen.

Berlin, 2. Auflage.

Kopmann, N., Adolph, M., Müller, D., 2011. Entwicklung

eines Prüfstandes zur Abbildung eines hydraulischen

Heizungsnetzwerks. In: Deutsche Kälte-Klima-Tagung

2011, Aachen, 16.-18.11 2011 / Deutscher Kälte- und

Klimatechnischer Verein. Hannover : DKV, 2011. –

ISBN 978–3–932715–47–1, S. AA IV 05.

SMARTGREENS2015-4thInternationalConferenceonSmartCitiesandGreenICTSystems

282