Analysis and Modeling of a Platform with Cantilever Beam using

SMA Actuator

Experimental Tests based on Computer Supported Education

Leandro Maciel Rodrigues

1

, Thamiles Rodrigues de Melo¹, Jaidilson Jó da Silva

2

, Angelo Perkusich

2

and José Sérgio da Rocha Neto

2

1

Post-Graduate in Electrical Engineering - PPgEE – COPELE, Campina Grande-PB, Brazil

2

Electrical Engineering Department (DEE), Federal University of Campina Grande, Aprígio Veloso Street, 882, Campina

Grande-PB, Brazil

Keywords: Modeling, Platform with Cantilever Beam, Shape Memory Alloy, Computer Supported Education.

Abstract: This paper presents a test platform with cantilever beam that uses a SMA (Shape Memory Alloy) as actuator

and strain gauges as sensors to study of the beam deformation. From the data acquired by means of heating

and cooling processes, the engineering students can observe the hysteresis behavior of the SMA wire.

Besides, the study of this platform provide to the students can put in practice their knowledge about data

acquisition, system identification, modeling and programming based on computer supported education.

1 INTRODUCTION

Mechanical systems, such as industrial machinery,

civil construction and transport vehicles are often

subject to internal and external excitations, which

result in undesirable vibrations, disturbing operators

and in some cases, putting at risk the structural

integrity of the system. This phenomenon has

mobilized a significant number of researchers and

there are numerous specialized publications in this

area (Li et al, 2014).

The vibration control of flexible structures has

been the subject of studies by many researchers.

According to these studies, the integrated use of

sensors, actuators and controllers would enable a

system to respond in a controlled manner to external

excitations, looking for the effects that would lead

the response amplitude levels to deviate from

acceptable levels (Schmidt, 2014).

Shape Memory Alloys (SMA) have been

considered as one of the most interesting smart

material systems, and they have great potential for

applications in modern active structures, mainly as

electrical or thermal actuators. Previously, strained

SMA actuators recover their original shape when

heated above a critical temperature. In the case of

SMA actuators type wire under uniaxial tensile

mechanical load, this shape recovery corresponds to

a contraction, and the actuator provides useful

external mechanical work (Nascimento et al, 2008).

Due to this phenomenon, the SMA can be used

as sensors and/or actuators in aerospace, oil and

automotive industries, in orthodontic, orthopedic and

robotic applications, or vibration and shape control.

When used as thermomechanical actuators, in which

heating is performed by Joule effect resulting from

the application of a certain intensity of current, SMA

become an attractive alternative due to its large

deformation and good recovery in systems where

great strengths, large deformation and low

frequencies are required (Lima et al, 2010), (Suzuki

and Kagawa, 2010).

Modeling is the process of obtaining equations or

graphs to represent, as closely as possible the

characteristics or behavior of a real system. The

importance of modeling real systems is evidence

when the results can be used to provide a better

understanding of the system (Ljung, 1999).

System identification is an alternative procedure

that aims to build a model to explain, at least in part

and approximately, the relationship of cause and

effect present in a database without the need for

prior knowledge of the physics of the process

(Ljung, 1999).

In this context, this work presents an

experimental methodology for engineering students

perform the modeling of a test platform with

238

Rodrigues L., Rodrigues de Melo T., Jó da Silva J., Perkusich A. and da Rocha Neto J..

Analysis and Modeling of a Platform with Cantilever Beam using SMA Actuator - Experimental Tests based on Computer Supported Education.

DOI: 10.5220/0005443902380243

In Proceedings of the 7th International Conference on Computer Supported Education (CSEDU-2015), pages 238-243

ISBN: 978-989-758-108-3

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

cantilever beam dedicated to the deformation study.

From the data acquired, the students can obtain a

relationship between the voltage applied in the SMA

actuator type wire (which provocate deformation on

the beam) and the deformation measured by a strain

gauge sensor on the platform. Besides, the students

can observe the hysteresis behavior of the SMA

wire.

Using the MATLAB tool for system

identification, the students can generate

mathematical models for the test platform and

posteriorly, to implement a control strategy to

control the beam deformation.

2 MATERIALS AND METHODS

2.1 Test Platform

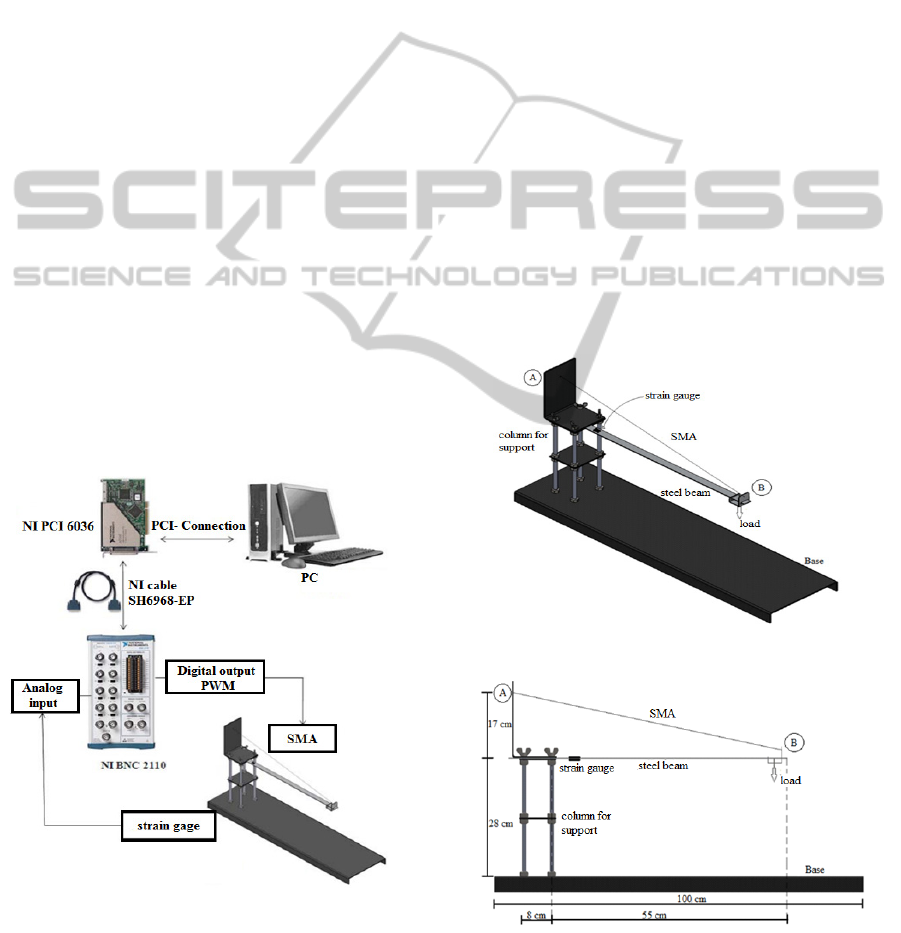

The measuring system implemented for study of the

platform with cantilever beam is constituted by: the

physical structure of the test platform; two strain

gauge sensors; a SMA wire; a set of connector

blocks to make the connection between a PC and the

platform; and an Human Machine Interface (HMI),

developed in LabVIEW software, for monitoring of

the beam deformation and sending commands to the

SMA actuator.

The complete measuring system can be seen in

Figure 1.

Figure 1: Scheme of the measuring system implemeted for

data acquisition and acting of the SMA actuator.

The physical structure of the test platform shown

in Figure 2 is composed by three parts:

• Base: A flat rectangular base, made of iron, and

with dimensions: 100 cm x 25.7 cm x 3.5 cm (L

x W x H);

• Support Column: A column built on the base,

consisting of four screws 28 cm long and 1 cm in

diameter, arranged in a spaced manner to form a

rectangle; two rectangular fastening plates

measuring 10 cm x 12 cm; and a third plate of 22

cm, positioned vertically for attachment of the

SMA wire (detail A of Figure 2);

• Beam: A steel beam 55 cm long, 2.6 cm wide and

2 mm thickness. One of the ends of the beam is

clamped to the support column by means of two

clamping plates and the other end is free, but

connected to the actuator of SMA through a

small metal piece (detail B of Figure 2).

The strain gauges sensors are glued on the top

and bottom faces of the beam, in order to obtain data

on the deformation of the beam. The SMA actuator

type wire can pull the beam or release it. At the ends

of the SMA wire, the electrical terminals are

connected, which provide the electrical signal

activation, making electric current pass through the

wire and by Joule effect making it to contract more

or less depending on the current intensity.

(a) Isometric view.

(b)

Side view

Figure 2: The physical structure of the test platform:

Isometric (a) and Side (b) view of the platform.

AnalysisandModelingofaPlatformwithCantileverBeamusingSMAActuator-ExperimentalTestsbasedonComputer

SupportedEducation

239

The sensors and the SMA actuator are connected

to the PC via a BNC connector block manufactured

by National Instruments, named as NI BNC 2110

model. This connector is linked to the PC via an

internal PCI card model, named as NI PCI 6036-E

(NATIONAL INSTRUMENTS, 2010).

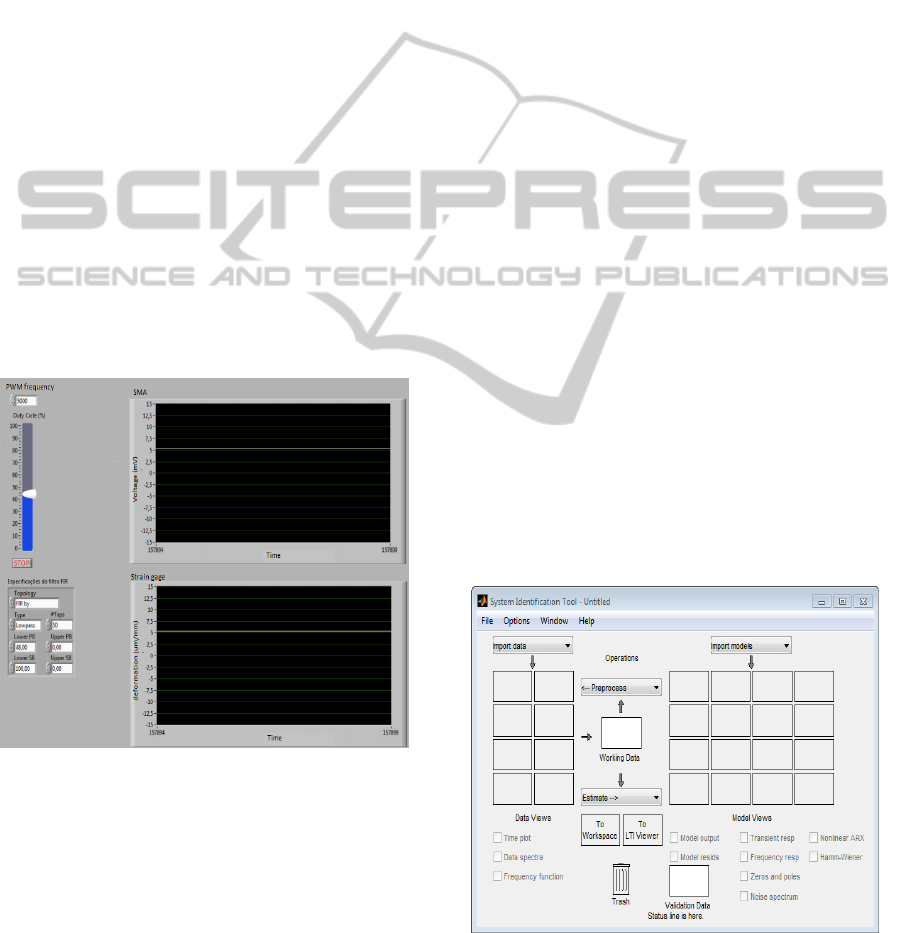

From the PC, the informations about the test

platform can be seen by means of the HMI

implemented via LabVIEW software, as observed in

Figure 3. On the HMI, the engineering students can

view in the graphical boxes the deformation of the

beam in μ/ (micrometer per milimeter) and a

sample of the RMS voltage that is applied on the

SMA. The signal that is sent to the SMA is a PWM

(Pulse Width Modulation), in which the students can

choose the frequency and the duty cycle of the

PWM.

After being performed the test, the data

collected during the experiment can be stored for

later viewing. This is done using a LabVIEW tool

that allows integration of this software with

MATLAB. The block in LabVIEW that makes the

interaction with the MATLAB is the “MATLAB

Script”. When the student stops the test pressing the

STOP button in the software interface, then the data

is sent to MATLAB and stored in variables.

Figure 3: The screen of the HMI implemented in

LabVIEW software for monitoring of the beam

deformation.

2.2 Experimental Methodology

To observe the hysteresis behavior of the SMA wire

in study, it is necessary to plot the heating and

cooling curves of this actuator. These curves can be

obtained by means of the relationship between the

voltage applied on the SMA (a sample of the RMS

voltage) and the deformation suffered by the beam

when the SMA is heated or cooled.

Hence, a set of measurements are realized and a

statistical treatment is made, in order to calculate the

arithmetical average and the standard deviation and

then to verify a confidence interval.

The heating curve is generated applying on the

SMA a PWM signal with 1 kHz of frequency and

10% of duty cycle, and after 25 seconds, the duty

cycle is increased in 10%. This action is repeated

until it reaches a duty cycle of 100%. The same

process is made to obtain the cooling curve, but with

decreasing duty cycle of 10% until it reaches 10% of

duty cycle.

2.3 Mathematical Models

Due to the actuator has different behaviors when

occour the heating and cooling processes, then it is

interesting that students obtained different models

for each process.

To identify and generate a model for the test

platform, the engineering students use a MATLAB

tool called ident, as shown in Figure 4. From the

data obtained in the tests, models of different orders

are generated by clicking in “Estimate -> Process

models” in the window.

Using the ident, the students can also to validate

the models, to compare the output model generated

and the output measured, and to qualify with an

index how they fit.

Thus, the validation of the models are done by

means of a set of measurements does not used for

modeling. These measures are imported in the

“Validation Data” box, also present in the window.

Figure 4: Interface of the System Identification toolbox

(ident) of the MATLAB.

CSEDU2015-7thInternationalConferenceonComputerSupportedEducation

240

Two models are used for modeling of the

platform with cantilever beam: First Order with

Dead Time (FOPDT) model and Second Order with

Dead Time (SOPDT) model, which are shown in

Equation (1) and (2), respectively:

(

)

=

+1

(1)

where: G(s) is the transfer function of the system in

study, the steady-state gain,

the transport delay

and

the time constant.

(

)

=

+1(

+1)

(2)

where:

is the first time constant and

is the

second time constant of the system in study.

3 RESULTS

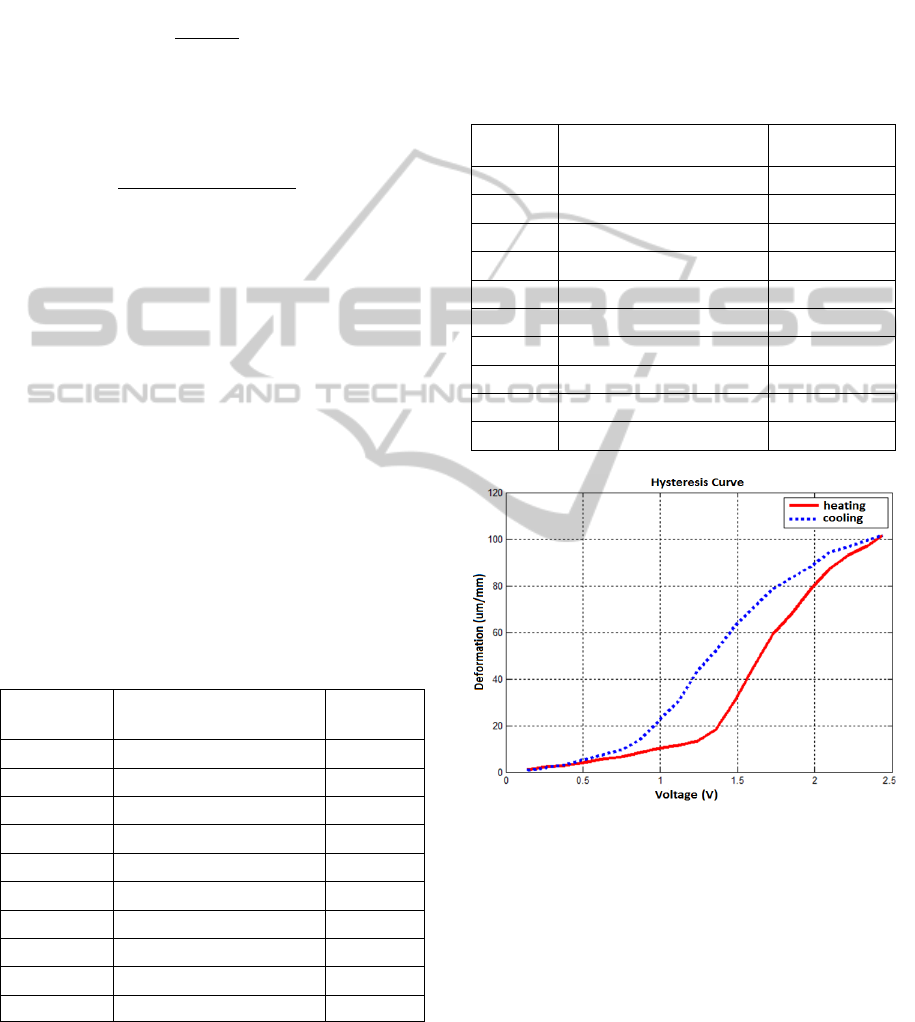

3.1 Hysteresis Behavior

After to acquire the measurements, the engineering

students realized the statistical analysis, in which

calculated the arithmetical average and the standard

deviation of the data.

In Table 1 is shown the relationship between a

set of the RMS voltage measured in the SMA and

the deformation of the beam measured with the

strain gauges sensors, when the SMA is heated.

Table 1: Average values and standard deviation when

SMA is heated.

Voltage (V) Deformation (/)

Standard

deviation

0.38 2.87 0.21

0.62 5.60 0.59

0.88 8.50 0.27

1.12 11.65 0.31

1.36 18.27 0.18

1.60 45.43 0.31

1.84 68.14 0.54

2.08 87.18 0.90

2.32 97.02 0.36

2.44 101.78 0.68

In Table 2 is shown the relationship between a

set of the RMS voltage measured in the SMA and

the deformation of the beam measured with the

strain gauges sensors, when the SMA is cooled.

From the data of Voltage and Deformation

presented both the tables, the students can plotted

the heating and cooling curves and consequently,

can observed the hysteresis behavior of SMA

actuator, as shown in Figure 5. The solid line

represents the heating process and the dotted line

represents the cooling process.

Table 2: Average values and standard deviation when

SMA is cooled.

Voltage

Deformation (/)

Standard

deviation

2.44 101.78 0.68

2.21 96.77 0.75

1.97 88.27 0.21

1.72 78.54 0.75

1.48 62.47 0.75

1.23 43.61 0.68

0.99 22.29 0.95

0.75 9.76 0.21

0.50 5.28 0.61

0.26 1.85 0.36

Figure 5: Graphic of hysteresis of the SMA actuator

obtained by engineering students from the experimental

methodology adopted.

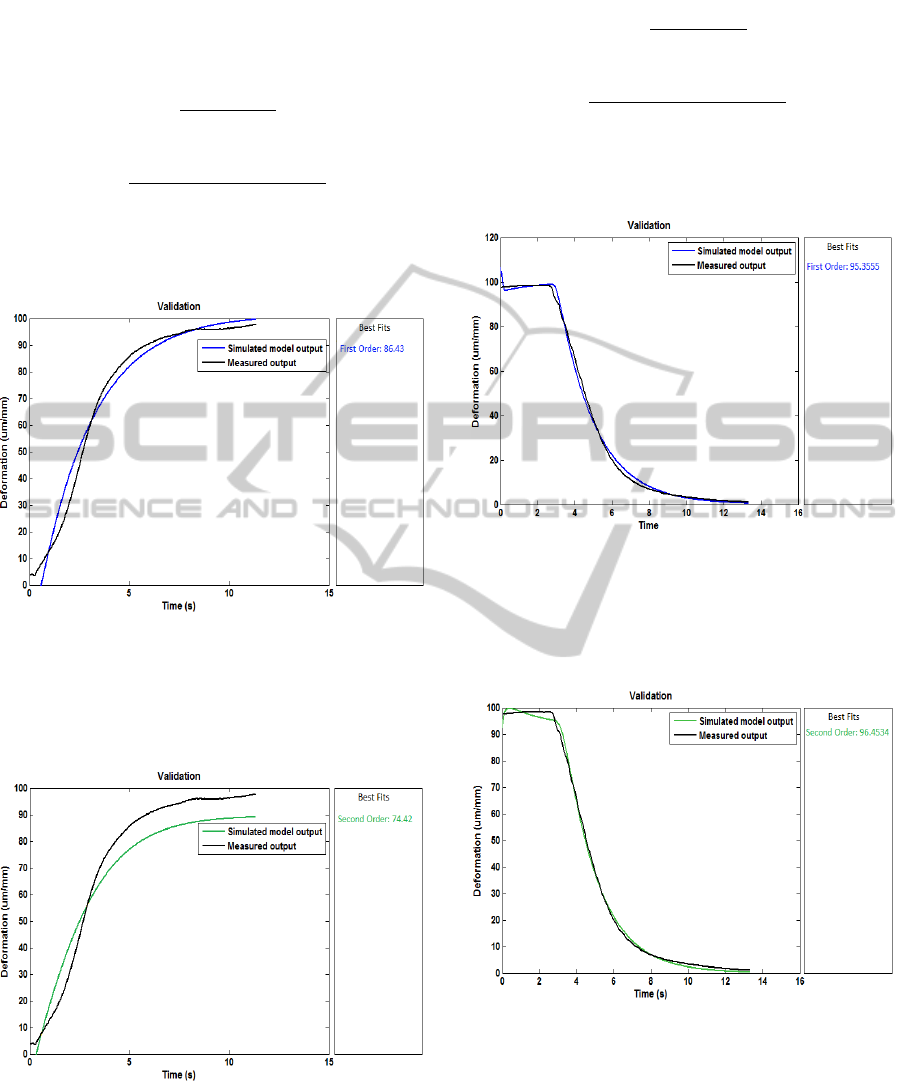

3.2 Modeling and Validation

Using as input the data of a set of the RMS voltage

measured in the SMA and as output the data of the

deformation of the beam measured with the strain

gauge, were generated FOPDT and SOPDT models

in MATLAB tool for heating and cooling of the

SMA wire.

AnalysisandModelingofaPlatformwithCantileverBeamusingSMAActuator-ExperimentalTestsbasedonComputer

SupportedEducation

241

In Equations (3) and (4) are presented the

FOPDT and SOPDT models, respectively, obtained

by students for heating process:

(

)

=

41.68

.

2.63 + 1

(3)

(

)

=

36.85

.

(

1.78 + 1

)

(1.49 + 1)

(4)

The FOPDT model curve obtained for heating

process can be seen in the Figure 6. The model fits

the output measured 86.43%.

Figure 6: Validation FOPDT model curve obtained for

heating process.

The SOPDT model curve obtained for heating

process can be seen in the Figure 7. The model fits

the output measured 74.42%

Figure 7: Validation SOPDT model curve obtained for

heating process.

Similarly, in Equations (5) and (6) are presented

the FOPDT and SOPDT models, respectively,

obtained by students for cooling process:

(

)

=

41.05

.

0.98 + 1

(5)

(

)

38.22

.

(

0.89 + 1

)

(0.13 + 1)

(6)

The FOPDT model curve obtained for cooling

can be seen in the Figure 8. The model fits the

output measured 95.35%.

Figure 8: Validation FOPDT model curve obtained for

cooling process.

The SOPDT model curve obtained for cooling

process can be seen in the Figure 8. The model fits

the output measured 96.45%.

Figure 9: Validation SOPDT model curve obtained for

cooling process.

The four models generated for the test platform

fits with the output measured more than 74% based

on ident index.

Comparing the two models obtained for heating

process based on ident index, the students

considered the FOPDT model a better model than a

SOPDT model.

CSEDU2015-7thInternationalConferenceonComputerSupportedEducation

242

Likewise, comparing the two models obtained

for cooling process, the students consider both types

of models as good, because the FOPDT and SOPDT

models have almost the same value of index.

4 CONCLUSIONS

In this work, it was presented an experimental

methodology for engineering students performed the

modeling of a test platform with cantilever beam

that uses a SMA wire as actuator. By means of the

MATLAB tool for system identification, the

students could obtain the mathematical models and

to make the validation of them.

Furthermore, the students observed that the

hysteresis behavior of the SMA wire is associated to

the beam deformation, verifing the importance of

generating different models for heating process (by

Joule effect, increasing the current in the SMA) and

cooling process (decreasing the current in the SMA)

of the actuator.

From the FOPDT and SOPDT models, the

students can implement a control strategy, for

example using a PID control, to control the beam

deformation, in order to reduce or eliminate

disturbances, such as vibrations, on the physical

structure of the test platform.

Other possibility was the students used the data

acquired and the models obtained for developing of

a soft sensor, i.e., in case of fail of the real sensor,

the measures can be estimated by means of data

stored on the PC.

Therefore, the study of the platform with

cantilever beam provide to the engineering students

a way for putting in practice its knowledge about

system identification and modeling, data acquisition

and programming based on computer supported

education.

ACKNOWLEDGEMENTS

The authors would like to thank CAPES and PPgEE-

COPELE for financial support.

REFERENCES

Li, S., Li, J., Mo, Y., 2014. Piezoelectric Multimode

Vibration Control for Stiffened Plate Using ADRC-

Based Acceleration Compensation. IEEE Transactions

on Industrial Electronics; 61(12):6892-6902.

Lima W. M., Araujo, C. J., Valenzuela, W. A. V, Rocha

Neto, J. S., 2010. Deformation Control of a Flexible

Beam under Low Frequency Loading using Ni-Ti-Cu

SMA Wire Actuator. ABCM Symposium Series in

Mechatronics - Vol. 4 - pp.110-119.

Ljung, L., 1999. System Identification: Theory for the

User. Prentice Hall, 2

nd

Edition.

Nascimento, M. M. S. F., Araújo, C. J., Almeida L. A. L.,

Rocha Neto, J. S., Lima, A. M. N., 2008. A

Mathematical Model for the Strain–Temperature

Hysteresis of Shape Memory Alloy Actuators. In

Materials and Design, vol. 30, pp. 551-556.

NATIONAL INSTRUMENTS, 2010. MultiFunction DAQ

Accessories Datasheet.

Schmidt, R., 2014. Smart Structures - Modelling and

Simulation. 11th World Congress on Computational

Mechanics (WCCM2014). July 20 - 25, Barcelona,

Spain.

Suzuki, Y., Kagawa, Y., 2010. Active Vibration Control

of a Flexible Cantilever Beam Using Shape Memory

Alloy Actuators. Smart Materials and Structures.

AnalysisandModelingofaPlatformwithCantileverBeamusingSMAActuator-ExperimentalTestsbasedonComputer

SupportedEducation

243