Engineering and Evaluation of Process Alternatives in Tactical

Logistics Planning

Michael Glöckner, Stefan Mutke and André Ludwig

Information Systems Institute, Leipzig University, Grimmaischestraße 12, 04109 Leipzig, Germany

Keywords: Logistics, Planning, Model-driven, Process Alternatives, Evaluation.

Abstract: The objective of tactical planning in logistics is the engineering and evaluation of processes within a given

set of possible alternatives. Due to outsourcing and a division of labor, a high number of participants, available

services and thus possible process alternatives arises within logistics networks. The additional wide range of

service description and annotation methods result in a complex planning process. In order to support planning,

a semi-automated approach is presented in this paper that is based on a combined catalog and construction

system (for engineering) and a generic simulation approach (for evaluation) that are able to handle the variety

of description and annotation methods. The basic concepts are presented and afterward associated by a model-

driven approach in order to connect them and make them compatible to work with each other. Finally, a

method is developed to foster a semi-automated engineering and evaluation of process alternatives.

1 INTRODUCTION

Logistics focuses on planning, operating and

monitoring systems that comprise material flow as

well as the related information flow (Gudehus and

Kotzab, 2012). Resulting from the common

paradigms of division of labor and outsourcing, a high

number of participants within logistics systems

arises. Each of them maintains a wide range of IT-

systems as well as a wide range of services with

differing provider-specific descriptions (Arnold et al.,

2012). This complexity is difficult to be handled, e.g.

see (Faber et al., 2002), (Stevenson and Spring, 2007)

in order to negotiate and fulfill specific and individual

logistics contracts. Especially, the fact that the

planning phase of a logistics system forms the basis

of all future operations and system’s results

implicates a challenging issue that arises from the

high amount of services, their descriptions and

possible combinations.

Planning is generally differentiated into the

commonly accepted classification of strategic (long-

term), tactical (mid-term) and operational (short-

term) planning (Stadtler et al., 2011). Tactical

planning in logistics is typically situated in the

competence area of central logistics departments

(Stadtler et al., 2011), which could also be outsourced

to and represented by a central logistics integrator

(e.g. fourth party logistics service provider (4flow

AG, 2014), (4PL Central Station Deutschland GmbH,

2014) or lead logistics provider), while actual

operation and physical movement of goods is carried

out by subsidiary logistics service providers (LSP)

(Handfield et al., 2013), (Langley and Terry, 2014).

Tactical planning in logistics addresses the flexibility

of processes (volume, delivery and preconditions of

operation) as well as supply chain design,

relationships and inter-organizational information

systems (Stevenson and Spring, 2007), (Esmaeilikia

et al., 2014), (Schütz and Tomasgard, 2011). The term

flexibility means the ability to be easily modified by

maintaining and analyzing a variety of alternatives in

order to choose the best for a specific task under

current conditions (Bibhushan et al., 2014). In

summary, tactical planning in logistics focuses on the

engineering of available process alternatives and their

evaluation (Esmaeilikia et al., 2014).

When analyzing the applied methods of tactical

planning in logistics, literature provides a wide range

of publications addressing that specific topic, see e.g.

(Gudehus and Kotzab, 2012), (Esmaeilikia et al.,

2014), (Rushton et al., 2014), (Hompel et al., 2007).

Consensus of all approaches is a planning procedure

subdivided into several distinct phases, whereas there

are different numbers of phases and aspects to be

considered in each approach. Further consensus could

be found in a non-linear phase-sequence as iterative

loops are allowed and encouraged in order to develop

appropriate solutions. Another important similarity –

as already pointed out – is the development of distinct

Glöckner M., Mutke S. and Ludwig A..

Engineering and Evaluation of Process Alternatives in Tactical Logistics Planning.

DOI: 10.5220/0005377801660176

In Proceedings of the 17th International Conference on Enterprise Information Systems (ICEIS-2015), pages 166-176

ISBN: 978-989-758-097-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

planning alternatives and the subsequently evaluation

of each in order to either approximate the current

solution towards an optimum or to find the best

solution to a given task. However, a common

shortcoming of planning methods is an inadequacy in

a specific description on how to create and evaluate

process alternatives.

Especially tactical planning - as the foundation of

flexibility - in the field of transport and distribution is

underrepresented in research (Esmaeilikia et al.,

2014). Further, the related adaptable IT is important

for inter-organizational information linkage

(Stevenson and Spring, 2007), (Bibhushan et al.,

2014). This leads to additional difficulties as a variety

of annotations and modelling methods exists next to

the variety of IT-systems of the LSP. Hence, the paper

focuses on fostering tactical planning issues on IT-

level. Since tactical planning lacks in a concrete

method for developing different alternatives and this

issue is an essential aspect for flexibility, an approach

is needed that supports the finding and subsequent

evaluation of alternatives. A comprehensive

overview of currently available alternatives of

services and processes in logistics networks is needed

to develop a wide range of potential solutions. Due to

a high number of participants and their diverse

approaches for service description within an open

logistics network (Arnold et al., 2012), (Langley and

Terry, 2014), a suitable solution for engineering and

evaluation of services and processes within the

heterogeneous LSP-landscape (and their related

service descriptions and IT-systems) could be found

in a model-driven approach.

The paper's contribution is a method for linking

engineering and evaluation of process alternatives to

support logistics integrators. After presenting the

basic concepts in section 2, a model-driven approach

is introduced in section 3 that focuses on their

combination using a common metamodel. The

derived method for engineering and evaluation in

section 4 and a summary with future research

prospects in section 5 conclude the paper.

2 BASIC CONCEPTS AND

RELATED WORK

With the issues in mind (engineering of alternatives

and their evaluation), the following section introduces

at first an approach for a combined catalog and

construction system (the logistics service map) for

engineering and afterward focuses on simulation in

logistics as an approach for the evaluation of service

and process alternatives.

2.1 Logistics Service Map

The challenge of retrieving appropriate services with

inhomogeneous descriptions from different IT-

systems (Arnold et al., 2012) that arise from a

complex logistics network with numerous

participants demands a solution that is commonly

accepted by all network participants. Those

challenges create the requirement of presenting the

services of a network in a common way (catalog

function) and combining them to composite services

(modular service construction system function). This

issue can be solved by the concept of the service map

(SM).

The concept of the SM addresses the challenges

by combining these two functions (Glöckner and

Ludwig, 2013). On the one hand a catalog of all

available services and process activities is provided.

Every network participant has to subscribe its

services to this catalog in order to have a commonly

used single point of truth. With these characteristics

the SM covers the conceptual functionality of a

service repository. Though, to increase usability, the

overview could be categorized by the user’s needs in

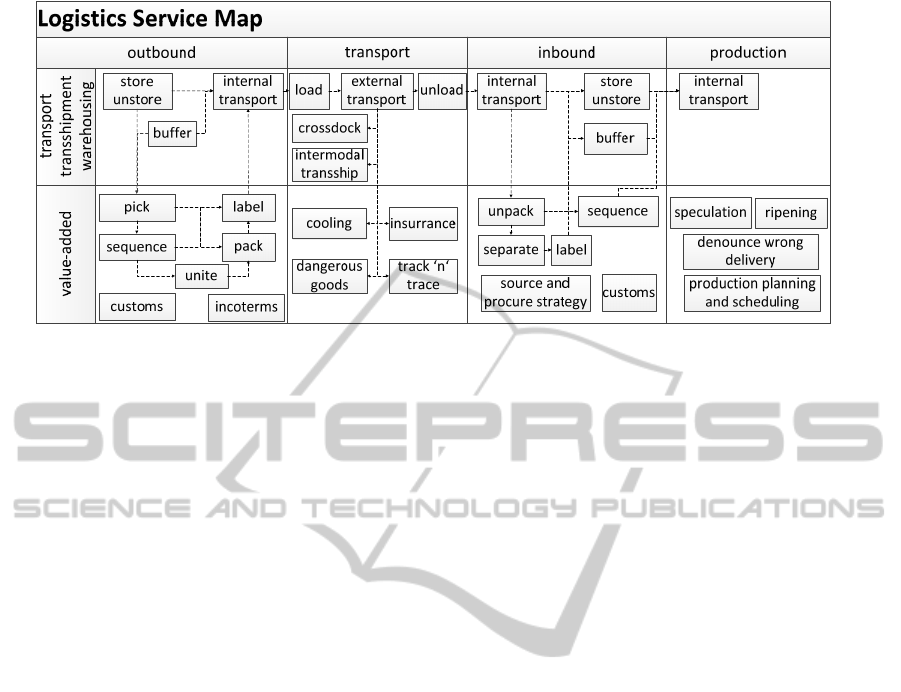

different abstraction layers. As shown in Fig. 1, a

graphical representation with two spatial dimensions

for the user-chosen categories simplifies the

interaction for the users when searching for services

or process activities. In that way, service retrieval is

enhanced and can be done in an intuitive way.

Besides the intuitive manual usage, the catalog

function also fosters a systematic categorization for

(semi-) automated usage and engineering. On the

other hand, the concept includes a modular service

construction system in order to combine atomic

services to composite services. Through combination,

service descriptions of the composite services are also

derived so that they could be transformed into process

models later on, e.g. for mediation and collaborative

planning in networks. With this approach, the

network participants are supported in retrieving

services in different use cases. (1) Adding a new

service provider to the network and match its offered

services to the existing set of services in a logistics

network by adding the new service provider to the

provider list of the particular services. (2) Developing

a new composite service to meet a specific customer’s

need by selecting and composing services from the

SM. Service-specific information and attributes can

be displayed when changing the selected granularity

Figure 1: Exemplary service catalog with two dimensions: ’classic logistics function vs. value-added’ and ’stage-specific’.

to a more detailed level to foster engineering and

management. Moreover, the unique standard of the

used set of services within a network and the

visualization foster a precise mediation and

communication between all stakeholders during the

whole service life-cycle. (3) Finding compensational

service or provider when realizing the urgency for re-

planning or elimination of errors because of

unpredictable disturbances in the network or an

insufficiency in solving a given task. Consequently,

the SM is capable of representing and creating

planning alternatives.

Literature provides a wide variety concerning the

SM concept. Either (a) the term ‘service map’ is used

and also the functionality meets partly the

requirements mentioned above, e.g. (Kohlmann and

Alt, 2009), (Kim et al., 2013), (Vaddi et al., 2012),

(Kutscher and Ott, 2006), or (b) the term is used but

a different substantial functionality is addressed, e.g.

(Mi Sun Ryu et al., 2006) or (c) the term is not used

but the described concept partly includes

functionality for the mentioned purpose, e.g.

(Kohlborn et al., 2009), (Fleischer et al., 2005).

Collectively, none of the approaches comprise both

functionalities of catalog and construction system. As

the SM concept comprises both, its functionality

enables the engineering of services for a later

combination to more complex processes. Hence, the

creation of process alternatives could be realized with

the use of this concept.

2.2 Simulation in Logistics

The planning of value-added logistics services is

performed using several different models (e.g.

process model, service profile, and simulation

model). A rough plan, including each sub-service and

their temporal dependencies, is represented by a

process model. Based on this, dynamic aspects of

logistics systems can by analyzed using simulation.

The main task of simulation in logistics is to study the

behavior of complex logistics services (e.g. lead

times, transport volumes and capacities) to ensure

that customers’ requirements can be met. Thus, it is

possible to analyze the flow of goods through the

logistics system with regard to the capacity to identify

bottlenecks at an early stage. As a result, simulation

models of logistics networks can be used to evaluate

different process alternatives and consequently

improve the decision-making process in the tactical

planning. Especially discrete-event simulation (DES)

is appropriate to enhance decision support in the

planning process by analyzing several system

configurations, which differ in structure and behavior

(VDI-Richtlinie, 2010). However, the use of

simulation also leads to a number of problems.

As mentioned previously, different models

(process model, provider models and simulation

model) are used within the planning process. This is

a major problem because each time a model is slightly

modified any of the other related models must also be

revised. As already outlined in the introduction, the

modeled information itself could also differ from one

provider to another whereby a wide range of

descriptions and used annotations arises within a

network with a high number of participants. This

increases the modeling effort. Further, building

simulation models requires special training and

experience to avoid errors. It is a methodology that is

learned over time. Consequently, the creation and

analysis of simulation models could be expensive

while consuming an enormous amount of time. This

can lead to a non-profitable use of simulation (Banks,

1998). As a consequence, the effort for the

development of simulation models has to be reduced.

In terms of planning logistics systems several models

are used. These models build upon one another and

show dependencies among each other. A change in a

model also implicates and claims changes in

subsequent models. To ensure the interaction between

simulation and other models, simulation techniques

have to be well-integrated in the planning process

(Mutke et al., 2012). It is necessary that the created

process models within the planning process, based on

a separate description of each logistics service, can be

transformed automatically into a simulation model.

Accordingly, an approach to combine different

heterogeneous planning models in order to force the

reuse of already modeled information is needed. This

requirement aims to minimize the planning effort of a

logistics Integrator by reusing already modeled

information. In addition, manual errors in the creation

of a simulation model are avoided. Furthermore, the

need for special training and special experience in

simulation model building is reduced.

In this section an approach is presented to

transform process models into simulation models in

order to reuse already modeled information and thus

reduce modeling effort. Related work is presented by

describing different simulation approaches that have

influenced the development. Simulation is widely

used in the field of logistics in order to plan logistics

systems. Ingalls discusses the benefits of simulation

as a method to study the behavior of logistics

networks (Ingalls, 1998). Additionally, advantages

and disadvantages are illustrated for the analysis of

supply chains with the use of simulation. A concrete

simulation approach is not provided. In (Cimino et al.,

2010), a commonly applicable simulation framework

for modeling supply chains is presented. Contrary to

(Ingalls, 1998), they focus on a more technical

perspective as they show an overview of event-

discrete simulation environments in terms of domains

of applicability, types of libraries, input-output

functionalities, animation functionalities, etc. Cimino

et al. also show how and when to use certain

programming languages as a viable alternative for

such environments. A modeling approach and a

simulation model for supporting supply chain

management are presented by Longo and Mirabelli in

(Longo and Mirabelli, 2008). They also provide a

decision making tool for supply chain management

and, therefore, develop a discrete event simulation

tool for a supply chain simulation. All these

approaches are relevant for developing an integrated

planning and simulation approach. However, all these

approaches satisfy the logistics integrator’s specific

requirements (Mutke et al., 2012) only partially. The

development of simulation models based on process

models is insufficiently considered.

In addition, we make use of transformation

approaches for defining transformation models as a

mediator between process and simulation models. In

both approaches of (Petsch et al., 2008) and (Kloos et

al., 2010) a transformation model is used in an

additional step in order to derive a simulation model

from an already existing process model. Both

approaches take the fact that process models are

independently defined from simulation requirements.

In practice, process models serve to foster

transparency or documentation and to analyze the

requirements for the introduction or implementation

of new information systems. However, both

approaches assume that a process model is defined

using Event-driven Process Chain. Cetinkaya

proposes a comprehensive theoretical framework for

model driven development in the field of M&S for the

efficient development of reliable, error-free and

maintainable simulation models (MDD4MS

framework) (Cetinkaya, 2013). In a case example it is

shown, MDD4MS framework is applicable in the

DEVSbased discrete event simulation domain. The

transformation of the BPMN elements into DEVS

components has provided an effective way to easily

model and simulate business processes. However, the

MDD4MS framework currently provides only model

transformation method from BPMN process model

(conceptual modeling language) to DEVS (platform-

independent simulation model) and from DEVS to

Java (platform-specific simulation models).

Furthermore, the required parameters for simulation

were added directly in the Java code and thus can be

performed by simulation experts only. Huang

describes another interesting approach for Automated

Simulation Model Generation (Huang, 2013). The

proposed method can use existing data to

automatically generate simulation models. Therefore,

a domain meta-model and the model component

library have to be designed before the existing data

can be used to provide the information about the

model structure and parameterization. However, in

contrast to our research the use of existing process

models as source models are not considered.

Nevertheless, the use of existing data for the

parameterization of simulation models shows

similarities to our research.

The added value of the simulation approach

presented in this paper is the automatic

transformation of existing process models to

simulation models as described in the following. A

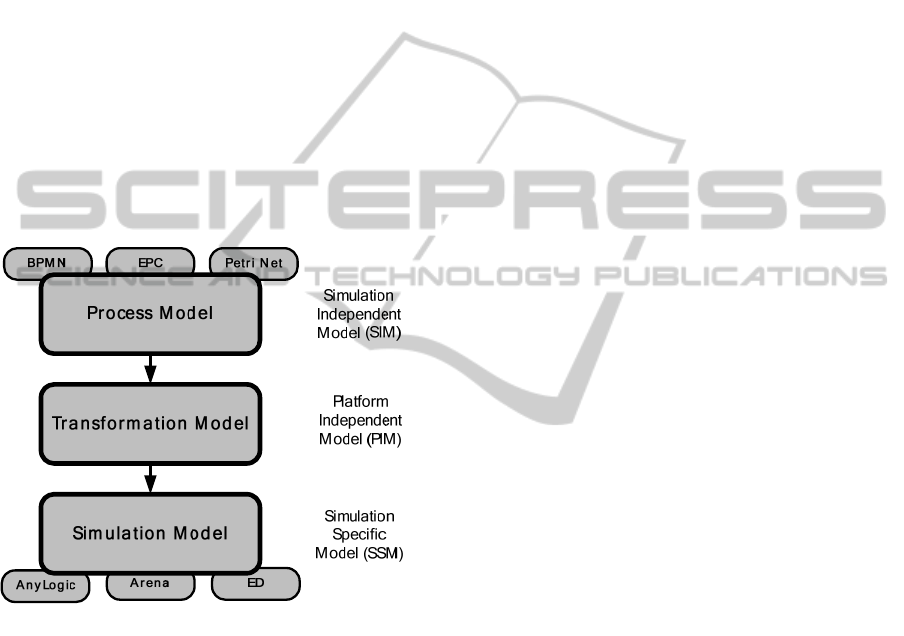

process model, e.g. Business Process Model and

Notation (BPMN) or Event-driven Process Chain

(EPC), is simulation independent, i.e. the model does

not contain any information regarding to the dynamic

aspects such as arrival times, processing times or

capacities. The process model is transferred into a

transformation model and enriched with information

required to run a simulation. However, the

transformation model is platform independent and

therefore cannot be executed in a specific simulation

tool. The specific simulation models (e.g. Enterprise

Dynamics (ED), Arena) are generated from the

transformation model. The structure of the

transformation model is described in more detail in

(Mutke et al., 2013a). Fig. 2 illustrates this approach.

Even though simulation provides a possibility to

evaluate process alternatives, the main problem in the

current context is a dependency on existing process

models in order to conduct their evaluation via

simulation models. Accordingly, a combination with

the former presented SM concept appears to be a

suitable approach for an integrated engineering and

evaluation of process alternatives. The connection of

both concepts is presented in the following section.

Figure 2: Transformation approach from process models to

simulation models.

3 MODEL-DRIVEN

CONNECTION OF CONCEPTS

The combination of the presented concepts for

engineering and evaluation of process alternatives is

realized with a model-driven approach. General

information about and a foundation of model-driven

development and metamodeling can be found in

(Atkinson and Kuhne, 2003). The basic idea of this

approach is to create metamodels for the several

concepts that conform to a common metametamodel.

As models are derived from those metamodels and

thus conform to them as well, interconnection and

data-consistency can be ensured between models with

a (transitive) common metametamodel. In the

beginning the distinct metamodels of both concepts

are introduced and connected at the end of the section.

3.1 Service Map Metamodel

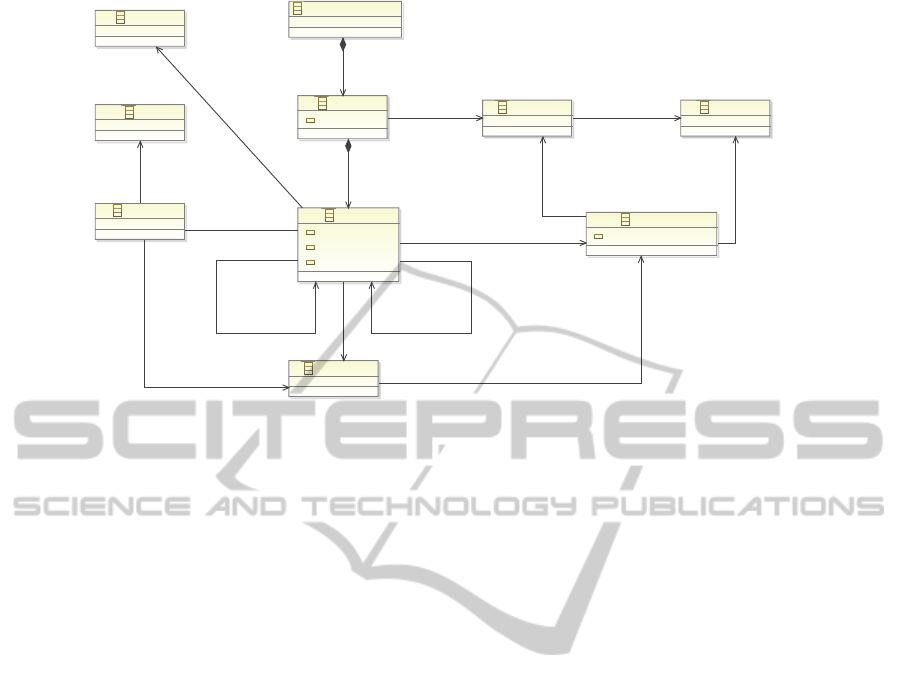

Fig. 3 shows the current version of the SM metamodel

(Glöckner et al., 2014). The SM supports the

categorizing and development of services. Instances

of the SM can be derived by the logistics integrator

from the metamodel to describe specific service

catalogs of a network. The advantage of a

metamodeling approach is a high abstraction that

provides a high reusability in a wide range of cases

and a simple interaction between several instances.

The SM metamodel follows the restrictions of the

service modelling framework (SMF) (Augenstein and

Ludwig, 2013), i.e. based on the EMOF (Essential

Meta Object Facility) compatible Ecore

metametamodel of the Eclipse Foundation.

Each instance of the SM metamodel consists of

exactly one catalog containing services available

within the network. This catalog is structured using

categories that depend on a specific domain (i.e.

logistics in our case). Thus, the catalog represents a

structured overview of services, each capable of one

or more capabilities. These capabilities belong to

specific categories and are restricted by the concrete

domain. For instance, on a high level capabilities

represent the ability to transport, store or to fulfil

more complex composite and value adding services.

In order to provide capabilities in terms of services, a

provider owns specific resources like trucks or

warehouses which are consumed during service

execution but typically are available again afterward.

Each provider is also allowed to specify zero or more

service level agreements (SLA) for its services in

which it specifies service level constraints and service

provisioning in terms of payment. Finally, services

can either depend on other services or are restricted

not to work with other services. Exemplary,

restrictions for the transportation of dangerous goods

could be mentioned, see (ADR, 2012). Therefore,

each service contains references to others which are

either available for the definition of a composite

service (allowedSiblings) or not (deniedSiblings).

With the metamodel the contained information

itself as well as the existing connections and attributes

between several classes are structured and thus

facilitate retrieval processes and allow an information

based connection to other types of models or between

different instances of SMs.

Figure 3: Service Map Metamodel.

3.2 Generic Simulation Metamodel

The generic simulation metamodel also follows the

approach of the service modelling framework (SMF)

(Augenstein and Ludwig, 2013), i.e. based on the

EMOF compatible Ecore metametamodel of the

Eclipse Foundation.

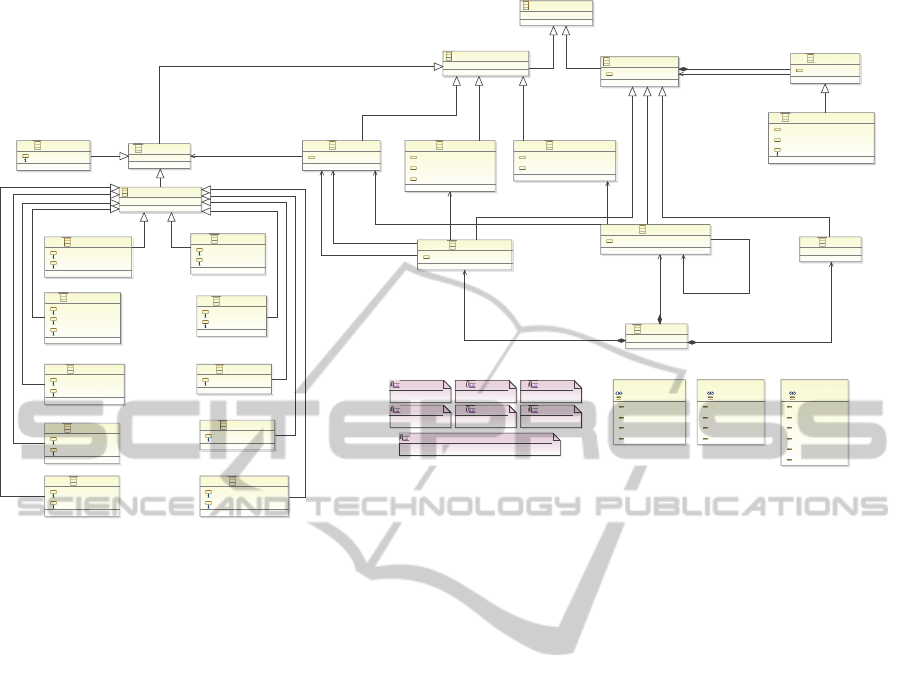

In the following, the approach is described in

more detail and it is shown how the generic

simulation metamodel (platform independent) was

created considering the basic concepts of DES and the

specific requirements from the perspective of a

logistics integrator. Process models describe

functional or structural aspects that are relevant for a

process. Depending on the used process model

notation, these functional aspects (e.g. Task in

BPMN, Function in EPC, Transitions in Petri Net)

represent the different partial logistics services (LSs)

as part of the overall process in the scope of a logistics

integrator's planning process. In (Hoxha et al., 2010)

an approach for formal and semantic description of

services in the logistics domain using concepts of

service orientation and semantic web technologies is

presented. The approach also categorizes and

describes modular LSs such as transport, handling,

storage, value-added services, etc. using a logistics

ontology. Concepts of this ontology are used in this

research paper to refer to the description of specific

LSs from the functional aspects depending on the

used process model language (Task, Function or

Transition). Thus, each functional aspect is assigned

to a specific logistics service type. Consequently, the

result is a process model including all LSs necessary

to meet customers' requirements. Despite having a

process model and using this model as the basis for

creating a simulation model, for simulation additional

information as to the pure visualization of the

processes is necessary. Therefore, literature was

analyzed concerning information that is additionally

required to create a simulation model and relating

basic concepts were derived (Entities, Events,

Attributes, Activities and Delays) (Mutke et al.,

2013b). In addition to these basic concepts of DES, a

simulation also has logistics-specific properties.

Therefore, two simulation tools using an application-

oriented modeling concept (ED and Arena) have been

used to create different examples of simulation

models in order to study transport volumes and

capacities. These tool-dependent models have been

analyzed and compared in terms of used modeling

concepts and the required data. The common

concepts of these tool-dependent models and the

basic concepts of DES were used to create the

metamodel shown in Fig. 4.

The generic simulation metamodel basically

consists of SimulationElements,

SimulationParameters and Relations. A Source

generates goods at predefined time periods and they

leave the model at the Sink. The purpose of an

Activity is to manipulate goods in some ways, e.g. to

store or to transport them. Therefore, Goods enter an

activity and remain there for a certain time period.

Moreover, an activity is assigned to a certain

ServiceType which defines the specific functionality

of this activity. These three main concepts are

subsumed under SimulationElements. All Time

periods can also be specified more precisely with the

help of Distribution functions. Regarding the service

id : EString

name : EString

type : EString

Service

id : EString

name : EString

type : EString

Category Domain

count : EInt

Catalog

count : EInt

ServiceMapModel

description : EString

Capability

description : EString

Provider

Resource

SLA

Finance

capableOf

1..*

allowedSiblings

0..*

deniedSiblings

0..*

uses

1..*

owner

0..*

paymentTerms

1..*

contains

0..*

ownedBy

0..*

dependentOn

1

structuredBy

1..*

belongsTo

1..*

restrictedBy

1

catalog

1

enables

0..*

specifies

0..*

owns

0..*

Figure 4: Generic Simulation Metamodel.

type, a Capacity is an additional characteristic of an

activity. For instance, an activity with the service type

“warehouse service” is restricted by a maximum

capacity and has a certain queuing strategy. Time,

capacity, goods and distribution are subsumed under

SimulationParameters. The connecting elements

between the activities are represented by two different

kinds of Relations. On the one hand, relations can be

simple, i.e. without specific characteristics. On the

other hand, a connection between activities can be

represented by ConditionalRelations with additional,

specific characteristics (conditions, probabilities).

Depending on values of these characteristics, in a

simulation either one or the other path is used.

With this metamodel, it is possible to create

simulation-tool-independent models, which contain

all information necessary to perform a simulation.

Further, a structure is built between several

information aspects and thus fosters a parameter

specific evaluation and improvement of processes.

3.3 Connection of Metamodels

The metamodels are kept simple and only consists of

a few essential elements and their relationships. As

both follow the SMF of (Augenstein and Ludwig,

2013) it is possible to interconnect models and model

elements from different models, respectively with the

common service model (CSM) (Augenstein et al.,

2012). The CSM approach contains a metamodel for

integration and transformation of differing models.

Purpose of the CSM is to uniformly interweave

distinct service models, each representing unique

aspects of a service, and thus on model-level enables

a generic and modular service model. Both models

are defined through the same modeling language on

metamodel-level, i.e. Ecore metametamodel. Hence,

we are able to reuse information contained in these

models and to easily interweave them. The

metamodels are defined in Ecore but could be easily

implemented in other frameworks as well.

The Service is the central element of the SM

metamodel. As services implicate a kind of input and

output connected to a certain capability and can

contain sub-services, a connection to the Activity

element of the generic simulation metamodel is

suggested. Hence, an interchange of information and

an automated workflow can be implemented to

combine engineering and evaluation of process

alternatives.

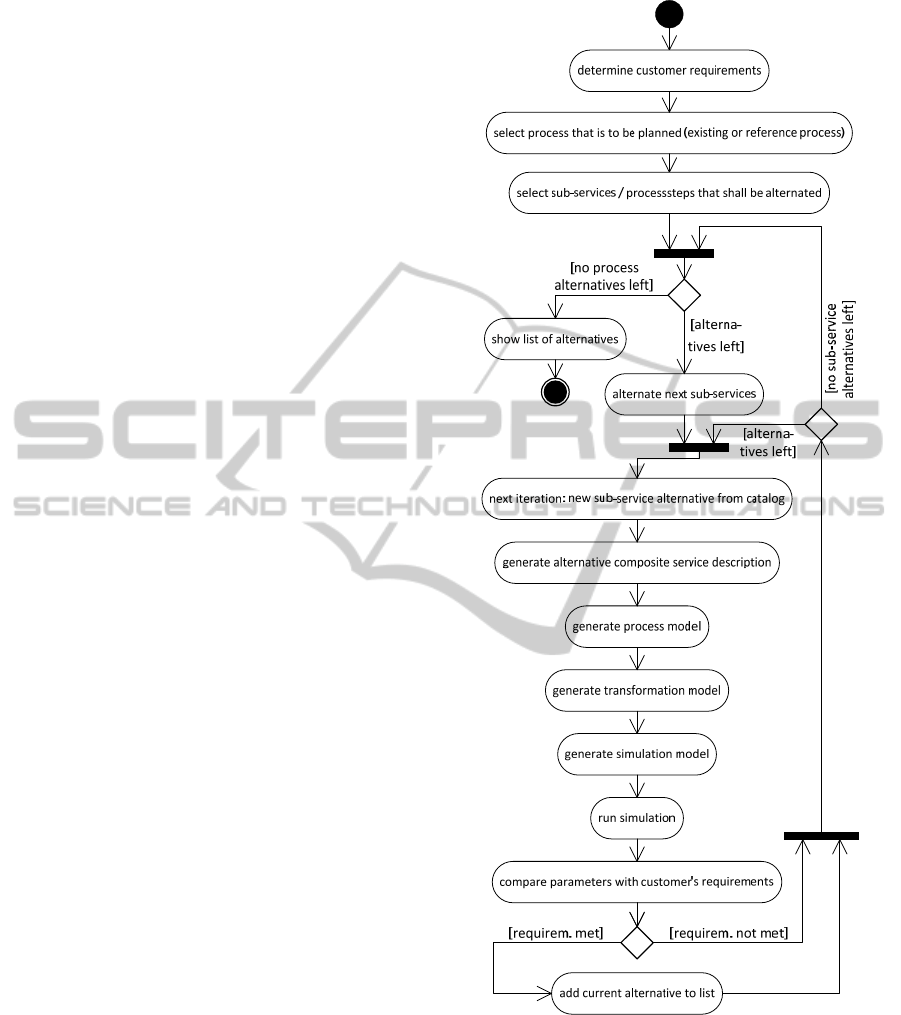

4 METHOD ENGINEERING

In this section a method for semi-automated

engineering and evaluation is developed. The leading

approach is a process model for method engineering.

After connection of the basic approaches a brief flow

Activit

y

serviceType : ServiceType

Time

unit : UnitOfTime

Capacity

maxCapacity : EInt

queueStrategy : EString

Simulation

Good

type : EString

name : EString

description : EString

ConditionalRelation

condition : EString

probability : EFloat

hasCondition : EBoolean

Source

maxNewEntities : EInt

Sink

Distribution

Constant

value : EDouble

<<enumeration>>

UnitOfTime

HOUR

MINUTE

SECOND

DAY

DistributionFunction

Weibul

beta : EDouble

alpha : EDouble

Beta

beta : EDouble

alpha : EDouble

Gamma

beta : EDouble

alpha : EDouble

Normal

mean : EDouble

stdDev : EDouble

Triang ular

min : EDouble

mode : EDouble

max : EDouble

LogNormal

logMean : EDouble

logStd : EDouble

Uniform

min : EDouble

max : EDouble

Poisson

mean : EDouble

NegExp

mean : EDouble

Erlang

expMean : EDouble

k : EDouble

SimulationObject

SimulationElement

name : EString

SimulationParameter

Relation

name : EString

<<enumeration>>

ServiceType

Default

Transp ort

Picking

Handling

Storage

ValueAdded

<<enumeration>>

QueuingStrategy

FIFO

LIFO

SORTED

RANDOM

ServiceLabelConditional

SourceSink Good Activit

y

http://www.eclipse.org/emf/2002/Ecore

timePeriod

0..1

capacity

0..1

subActivities 0..*

period 0..1

elements 0..*

start 1..*

end 1..*

newEntities

0..1

firstEntity

0..1

processedObject

1

outgoing 0..*source 0..1

target 0..1

chart illustrates the results and contribution of this

paper.

The process model for method engineering

presented by Ralyté and Roland outlines two different

strategies for assembling so called ‘method

components’, ‘method chunk’ or ‘method fragments’.

Depending on the characteristics, either an

association strategy or an integration strategy is

proposed for assembling method components (Ralyté

and Rolland, 2001). The first strategy is

recommended for method components without any

common elements. This case occurs e.g. when basic

components are working in a serial manner, i.e. the

output of one component is used as the input for

another component. Thus, by associating the two

initial components a method can be created that

provides a larger coverage than any of the basic ones.

Hence, the objective of this assembling process

strategy is to retrieve connection points and building

a bridge between them. In contrary, the latter strategy

concentrates on merging overlapping elements in two

components that focus on similar tasks but with e.g.

different solving strategies. The range of possible

results remains similar but functionality is enhanced.

The focus of this assembling process strategy is the

retrieval of overlapping elements in order to merge

them. Consequently, the association strategy is

suitable for the purpose of this paper. Engineering

and evaluation are two different ‘method

components’ that focus each on solving different

tasks. Further, the output of the engineering, i.e. one

or more process alternatives, constitutes the input for

the subsequent evaluation. The non-existence of

common elements, which is to be recognized when

comparing the given metamodels, underlines the

decision for the association strategy as well as the

serial characteristic of the designated final

functionality of the two initial components.

The figuring out of connection points for the

association of the basic components is also based on

the approach of Ralyté and Roland, taking (Castano

and Antonellis, 1993) and (Jilani et al., 1997) into

account. Mainly, the original approach focuses on

detecting semantical and structural similarities

between the elements of the two components that are

to be connected. By evaluating their common

properties and links, several similarity measures are

calculated to conduct the assembly later on. However,

an adapted and for the purpose of this paper

simplified argumentative-deductive version is used.

As already outlined, the Activity element of the

simulation metamodel comprises an input-output

relation for a specific object. Further, there exists the

possibility to divide activities into sub-activities and

they are always restricted by a certain capacity. This

complies with the Service element of the SM

metamodel. A service also focuses on taking an input

object in order to releasing a modified output object.

The division into subservices or combination to

composite services also complies with the activity-

pendant. Finally, as a service always depends on a

certain resource and those resources have inherent

distinct capacities, a similarity can be postulated

between those aspects. As the original purposes of the

two metamodels strongly differ, no other similarities

can be figured out. In summary, the analysis of the

metamodels shows that the suggested possible

connection point from the former section, which was

stating a possible association between the Activity and

the Service element, can be confirmed.

Following (Ralyté and Rolland, 2001), the

‘specification of method requirements’ is outlined in

the introduction in section 1 and the ‘construction of

the basic method components’ is conducted through

the cited literature of section 2 and 3. Subsequently,

the paper now proceeds with the ‘assembly’ by

determining the order of the components, identifying

the connection point, i.e. the product of the first

component that constitutes the source for the second

one, and merging both. The final result is shown in

Fig. 5. The engineering of an alternative before

evaluating it implies the order of the components.

Moreover, an iterative loop is obligatory until all

possible alternatives are calculated. Connection point

between the two components is the process model of

the composite service that is the output of the

construction system, as it is simultaneously the input

for the transformation model for the later simulation.

The final method starts with the determination of

customer requirements and the selection of the

process or composite service from the repository that

is to be (re-)planned. After selecting the process steps

or sub-services that are to be alternated and analyzed

the loop iteration starts. When no alternatives are

available, an empty list of alternatives is presented to

the user. As long as alternatives are still available, for

every chosen (sub-) service all available alternatives

from its category in the catalog are selected to create

a new composite service in the construction system.

With the derived description of the composite service,

the engineering of the process alternative is

conducted and a process model is created as the

output of the first method component. The process

model as the source of the generic simulation

approach, is transformed into the transformation

model, enriched with necessary simulation

parameters, which could be analyzed and inserted e.g.

from former operation statistics (like service profiles

(Roth et al., 2014)) to fully automate the method, to

subsequently run the simulation in order to conduct

the evaluation of the process alternative. If the

customer’s requirements are met by the current

alternative, it is added to the list that will be shown to

the user later on. If not, the procedure continues

without saving. If all available possibilities within

one category for a specific sub-service are evaluated,

the next sub-service is chosen to be alternated. After

all sub-services have been alternated and all possible

process alternatives have been evaluated, the final list

with all alternatives, which meet the given customer’s

requirements, is presented to the user. Sorted by its

preferences, e.g. SLA, lead time, costs, the user could

choose its favored alternative that is to be

implemented afterward.

A simple use case could be a customer that is

unsatisfied with the current performance of its supply

chain that was planned by the logistics integrator. By

analyzing the current performance parameters the

lack in a certain transportation and a packing services

is revealed. Hence, the integrator selects those

services within the supply chain to be alternated and

the resulting alternatives to be evaluated regarding the

customer’s required performance parameters.

Another use case could be a disturbance within a

supply chain through an insolvency of one LSP

within the network. Hence, cheap or reliable

alternative LSP are to be found for the affected supply

chain processes.

5 CONCLUSIONS

As current planning approaches in literature lack in a

specific description on how to create process

alternatives that are evaluated afterward, this paper

presented a new method for engineering and

evaluation of process alternatives in tactical logistics

planning. The method consists of two basic concepts,

the service map as a combined catalog and

construction approach for service engineering and a

generic simulation approach for evaluation. Both

concepts are especially designed for working in an

environment of heterogeneous service descriptions

and process models. By combining both concepts

through a model-driven approach, the basis for

interweaving the contained information is ensured.

With the process model for assembling methods from

sub-components, an associated method for combined

planning and evaluation is finally developed.

Figure 5: Activity diagram of resulting method.

Academic implication of the current article is a

first method towards automated and integrated

engineering and evaluation of process alternatives in

the heterogeneous field of logistics. Current literature

about planning in logistics does only propose to

create several alternatives and to evaluate them, but

does not provide explicit methods on how to do so.

Hence, the current paper also aims at motivating

further research by the community in the field of IT-

supported fostering of planning.

Managerial implications cover the development

of interest in (semi-)automated planning support.

Further, cited references could be used to gain deeper

understanding in particular fields of interest.

Limitations of our approach can be found in the

focus on one specific modelling framework, i.e. the

Ecore metametamodel. However, it is based on the

EMOF constraints and thus, it is transferable to other

frameworks as well.

With this in mind, future work could cover a

transfer to other platforms. Further, a refinement and

the development of differing approaches of the

automated engineering of process alternatives seems

interesting. An evaluation with sample data from case

studies is an urgent topic for upcoming research.

ACKNOWLEDGEMENTS

The work presented in this paper was funded by the

German Federal Ministry of Education and Research

in the project Logistik Service Engineering und

Management (LSEM) under the reference BMBF

03IPT504X (www.lsem.de).

REFERENCES

4flow AG, 2014. 4flow Supply Chain Services.

4PL Central Station Deutschland GmbH, 2014. 4PL Central

Station Deutschland - leading provider in Europe for

Fourth Party Logistics services.

ADR, 2012. European Agreement Concerning the

International Carriage of Dangerous Goods by Road:

Applicable as from 1 January 2013. United Nations,

New York [etc.].

Arnold, U., Oberländer, J., Schwarzbach, B., 2012.

LOGICAL - Development of Cloud Computing

Platforms and Tools for Logistics Hubs and

Communities FedCSIS 2012, Wroclaw, Poland, 9-12

September 2012, Proceedings, in . Federated

Conference on Computer Science and Information

Systems (FedCSIS), 2012, pp. 1083–1090.

Atkinson, C., Kuhne, T., 2003. Model-driven development:

a metamodeling foundation. IEEE Software. 20, 36–41.

Augenstein, C., Ludwig, A., Franczyk, B., 2012.

Integration of Service Models - Preliminary Results for

Consistent Logistics Service Management, in . 2012

Annual SRII Global Conference. IEEE Computer

Society, Los Alamitos, Calif, pp. 100–109.

Augenstein, C., Ludwig, A., 2013. The Service Meta

Modeling Editor - Bottom-Up Integration of Service

Models, in . Design Science at the Intersection of

Physical and Virtual Design. Springer-Verlag, Berlin

Heidelberg, pp. 386–393.

Banks, J., 1998. Handbook of simulation principles,

methodology, advances, applications, and practice.

Wiley Co-published by Engineering & Management

Press, New York.

Bibhushan, Prakash, A., Wadhwa, B., 2014. Supply Chain

Flexibility: Some Perceptions, in . The Flexible

Enterprise. Springer India, New Delhi, pp. 321–331.

Castano, S., Antonellis, V. d., 1993. A constructive

approach to reuse of conceptual components.

Cetinkaya, D., 2013. Model Driven Development of

Simulation Models: Defining and transforming

Conceptual Models into Simulation Models by Using

Metamodels and Model Transformation.

Cimino, A., Longo, F., Mirabelli, G., 2010. A general

simulation framework for supply chain modeling: state

of the art and case study. International Journal of

Computer Science Issues. 7, 1–9.

Esmaeilikia, M., Fahimnia, B., Sarkis, J., Govindan, K.,

Kumar, A., Mo, J., 2014. Tactical supply chain

planning models with inherent flexibility: definition

and review. Annals of Operations Research.

Faber, N., Koster, René B.M. de, Velde, Steef L. van de,

2002. Linking warehouse complexity to warehouse

planning and control structure: An exploratory study of

the use of warehouse management information systems.

International Journal of Physical Distribution &

Logistics Management. 32, 381–395.

Fleischer, J., Herm, M., Homann, U., Peter, K.,

Sternemann, K.-H., 2005. Business Capabilities als

Basis fähigkeitsorientierte1 Konfigurationen. ZWF -

Zeitschrift für wirtschaftlichen Fabrikbetrieb. 100,

553–557.

Glöckner, M., Augenstein, C., Ludwig, A., 2014.

Metamodel of a Logistics Service Map, in W.

Abramowicz and A. Kokkinaki, eds. Proceedings of the

17th International Conference on Business Information

Systems. Springer-Verlag, Berlin Heidelberg, pp. 185–

196.

Glöckner, M., Ludwig, A., 2013. Towards a Logistics

Service Map: Support for Logistics Service

Engineering and Management, in T. Blecker, W.

Kersten and C. Ringle, eds. Pioneering solutions in

supply chain performance management: Proceedings

of the Hamburg International Conference of Logistics

(HICL) 2013. Eul, Lohmar, Köln, pp. 309–324.

Gudehus, T., Kotzab, H., 2012. Comprehensive logistics.

Springer-Verlag, Berlin Heidelberg.

Handfield, R., Straube, F., Pfohl, H.-C., Wieland, A., 2013.

Trends and Strategies in Logistics and Supply Chain

Management: Embracing global logistics complexity to

drive market advantage. Bundesvereinigung Logistik,

Hamburg.

Hompel, M. ten, Schmidt, T., Nagel, L., 2007.

Materialflusssysteme: Förder- und Lagertechnik.

Springer-Verlag, Berlin Heidelberg.

Hoxha, J., Scheuermann, A., Bloehdorn, S., 2010. An

Approach to Formal and Semantic Representation of

Logistics Services, in K. Schill, B. Scholz-Reiter and L.

Frommberger, eds. Workshop on Artificial Intelligence

and Logistics (AILog), pp. 73–78.

Huang, Y., 2013. Automated Simulation Model Generation.

Ingalls, R. G., 1998. The value of simulation in modeling

supply chains, in D. J. Medeiros, E. F. Watson, J. S.

Carson and M. Manivannan, eds. Proceedings of the

30th Conference on Winter Simulation. IEEE Computer

Society Press, pp. 1371–1376.

Jilani, L. L., Mili, R., Mili, A., 1997. Approximate

component retrieval: An academic exercise or a

practical concern, in . Proceedings of the 8th Workshop

on Istitutionalising Software Reuse, Columbus, Ohio.

Kim, J., Lee, S., Park, Y., 2013. User-Centric Service Map

for Identifying New Service Opportunities from

Potential Needs: A Case of App Store Applications.

Creativity and Innovation Management. 22, 241–264.

Kloos, O., Schorcht, H., Petsch, M., Nissen, V., 2010.

Dienstleistungsmodellierung als Grundlage für eine

Simulation. 5, in O. Thomas and M. Nüttgens, eds.

Dienstleistungsmodellierung 2010. Physica-Verlag

HD, pp. 86–106.

Kohlborn, T., Fielt, E., Korthaus, A., Rosemann, M., 2009.

Towards a Service Portfolio Management Framework,

in . ACIS2009 - Australian Conference on Information

Systems, pp. 861–870.

Kohlmann, F., Alt, R., 2009. Aligning Service Maps - A

Methodological Approach from the Financial Industry,

in R. H. Sprague, ed. Proceedings of the 42nd Annual

Hawaii International Conference on System Sciences.

IEEE Computer Society Press, pp. 1–10.

Kutscher, D., Ott, J., 2006. Service Maps for

Heterogeneous Network Environments, in . MDM 2006

Japan. IEEE Computer Society, Los Alamitos, Calif.

Langley, J., Terry, L., 2014. 2014 Third-Party Logistics

Study. The State of Logistics Outsourcing.

Longo, F., Mirabelli, G., 2008. An advanced supply chain

management tool based on modeling and simulation.

Computers & Industrial Engineering. 54, 570–588.

Mi Sun Ryu, Hong-Shik Park, Sang-Chul Shin, 2006. QoS

class mapping over heterogeneous networks using

Application Service Map, in . Networking,

International Conference on Systems and International

Conference on Mobile Communications and Learning

Technologies, 2006. ICN.

Mutke, S., Augenstein, C., Ludwig, A., 2013a. Model-

based integrated planning for logistics service

contracts, in E. Bagheri, D. Gasevic, M. Hatala,

Motahari Nezhad, H. R. and M. Reichert, eds. 17th

IEEE International Enterprise Distributed Object

Computing Conference. IEEE Computer Society, pp.

219–228.

Mutke, S., Klinkmüller, C., Ludwig, A., Franczyk, B.,

2012. Towards an Integrated Simulation Approach for

Planning Logistics Service Systems, in F. Daniel, K.

Barkaoui and S. Dustdar, eds. Business Process

Management Workshops. Springer-Verlag, Berlin

Heidelberg, pp. 306–317.

Mutke, S., Roth, M., Ludwig, A., Franczyk, B., 2013b.

Towards Real-Time Data Acquisition for Simulation of

Logistics Service Systems, in D. Pacino, S. Voß and R.

Jensen, eds. Proceedings of the International

Conference on Computational Logistics 2013.

Springer-Verlag, Berlin Heidelberg, pp. 242–256.

Petsch, M., Schorcht, H., Nissen, V., Himmelreich, K.,

2008. Ein Transformationsmodell zur Überführung von

Prozessmodellen in eine Simulationsumgebung, in P.

Loos, M. Nüttgens, K. Turowski and D. Werth, eds.

Modellierung betrieblicher Informationssysteme -

Modellierung zwischen SOA und Compliance

Management, pp. 209–219.

Ralyté, J., Rolland, C., 2001. An Assembly Process Model

for Method Engineering, in . Advanced Information

Systems Engineering. Springer-Verlag, Berlin

Heidelberg, pp. 267–283.

Roth, M., Mutke, S., Klarmann, A., Franczyk, B., Ludwig,

A., 2014. Continuous Quality Improvement in Logistics

Service Provisioning, in W. Abramowicz and A.

Kokkinaki, eds. Proceedings of the 17th International

Conference on Business Information Systems. Springer-

Verlag, Berlin Heidelberg, pp. 253–264.

Rushton, A., Croucher, P., Baker, P., 2014. The handbook

of logistics and distribution management:

Understanding the supply chain. Kogan Page, London.

Schütz, P., Tomasgard, A., 2011. The impact of flexibility

on operational supply chain planning. International

Journal of Production Economics. 134, 300–311.

Stadtler, H., Fleischmann, B., Grunow, M., Meyr, H.,

Sèurie, C., 2011. Advanced Planning in Supply Chains:

Illustrating the Concepts Using an SAPa APO Case

Study. Springer, New York.

Stevenson, M., Spring, M., 2007. Flexibility from a supply

chain perspective: definition and review. International

Journal of Operations & Production Management. 27,

685–713.

Vaddi, S., Mohanty, H., Shyamasundar, R., 2012. Service

Maps in XML, in V. Potdar, ed. Proceedings of the

CUBE International Information Technology

Conference. ACM, [S.l.], pp. 635–640.

VDI-Richtlinie, 2010. 3633, Blatt 1: Simulation von

Logistik-, Materialfluß- und Produktionssystemen.