Medical Device Software Process Improvement

A Perspective from a Medical Device Company

Marie Travers and Ita Richardson

Lero - the Irish Software Engineering Research Centre, University of Limerick, Limerick, Ireland

Keywords: Software Development Process, Medical Device, Regulated Environment, Process Improvement, Change

Management.

Abstract: When manufacturing medical devices there are many constraints that have to be taken into account such as

safety, compliance with regulations and traceability. To do this, well-defined processes are used. With this

in mind we examine how process improvement is implemented in a medical device company while

managing the resultant change. The case study presented in this paper investigates the use of Kotter’s

Change Model to support the implementation of process improvement in a medical device company. The

results of the case study demonstrate that Kotter’s change model was an appropriate model to use. The sense

of urgency Kotter stipulates was inherent in the company. The team was aware that change was needed. A

flaw in Kotter’s approach is that there is no recommendation for a pilot project. Having a pilot project

worked well for this company as it helped to eliminate stress and anxiety. A further case study is planned in

the company to observe how the process is working after implementation of the full project.

1 INTRODUCTION

In the healthcare industry, medical devices are

manufactured to aid patients. To safeguard patient

safety and minimize risk such devices are regulated.

The regulatory body in the USA is the Food and

Drug Administration (FDA) whereas in Europe the

regulatory body is the European Commission (EC)

using the Medical Devices Directive (MDD) (EU

Council 1993), (EU Commission 2007). Regulators

can also approve standards such as the International

Organization for Standardization (ISO) standards.

Recently the MDD (2012) amended its definition

of a medical device to include software. Therefore,

software can, in certain cases, be classed as a

standalone medical device. In addition, medical

device software embedded within a medical device

or used in the manufacturing of a device is also

subject to regulation.

In our research, we are interested in how MD

companies cope with change of processes.

Therefore, this paper documents a single case study

where the company changed their documentation

process from being document-centric to being

artefact-centric. It was important for this company

to undergo change in a controlled manner, which

would not affect their regulatory status. We studied

the software development process of a medical

device company to see how they developed and

implemented the software documentation process.

2 SOFTWARE FOR THE

MEDICAL DEVICE INDUSTRY

The medical device industry faces persistent

challenges, including competitors, government

regulations, and productivity and quality issues. To

remain competitive, they must reduce costs,

streamline Research and Development, increase

accountability, incorporate traceability and

accelerate time to market.

Standards and guidelines have been developed to

aid in achieving the safest possible product. For

example in America the U.S. code of federal

regulations title 21 part 820 governs the quality

system regulations.

The international standard (ANSI/AAMI/IEC

2006) governs Medical Device (MD) software

development life cycle (SDLC) processes. A set of

processes, activities, and tasks that are needed within

a MD SDLC process are defined by The

International Electrotechnical Commission (IEC)

62304 (Cawley et al 2011). However, these authors

462

Travers M. and Richardson I..

Medical Device Software Process Improvement - A Perspective from a Medical Device Company.

DOI: 10.5220/0005223904620469

In Proceedings of the International Conference on Health Informatics (HEALTHINF-2015), pages 462-469

ISBN: 978-989-758-068-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

also point out that reading the standards can lead to

incorrectly thinking that a waterfall-type software

development methodology is the best methodology

to use. They suggest that companies should ensure

knowledge of Annex B of the IEC 62304 standard.

Individual MD companies can decide which

methodology to use.

2.1 Literature Review and Related

Work

McCaffery et al (2012) point out that with regulatory

compliance in mind, MD companies usually use a

SDLC such as the V-model. Agreeing with this,

Cawley et al (2011) also state that more emphasis is

being put on how to improve SDLC processes such

as by using a more iterative development

methodology (Spence, J.W. 2005; AAMI 2012).

Having studied the use of SDLCs in MD companies

another issue that arises is that there does not seem

to be a method for quantifying just how much

process is enough (Cawley et al 2011). To ascertain

where too much rigour is being applied and possibly

reducing the amount of work required, Cawley et al

(2011) recommend carrying out a process review.

Companies attempting to improve their products

also have to change their development processes to

ensure high quality products (Hayes and Richardson

2008). Companies implementing process change can

benefit from using a change management model but

published models usually relate to organization

change as opposed to process changes (Hayes and

Richardson 2008).

Introducing change must be a formalised planned

process. Even though it is sometimes considered that

having a process can be an overhead, change

management techniques have shown that when

change is planned it is more likely to be successful

(Forte 1997). Most planning models assume that

changes in organisations are planned changes

(Hayes and Richardson 2008). The models stipulate

that, for successful change, certain sequential steps

need be executed. Kotter’s model is one such change

management model. The steps described by Kotter

(2005) are:

Establish a Sense of Urgency

Form a Powerful Guiding Coalition

Create a Vision

Communicate the Vision

Empower Others to Act on the Vision

Plan for and Create Short-Term Wins

Consolidate Improvements and Produce Still

More Change

Institutionalise new approaches

Focusing on the implementation of process

improvement in a medical device company, this

paper investigates the hypothesis that “Eight Steps to

Transforming your Organisation” (Kotter 2005) is a

suitable framework for such a change.

The literature review revealed there is no model

available to provide software development teams’

guidance on end-to-end software development that

conforms to regulatory requirements. Burton (2008)

proposes an alternative process improvement model

and he states that even though there are standards

and guidelines it not possible to guarantee complete

regulatory compliance and existing process

improvement models are not broad enough.

2.2 The Company

MedIn (an alias) is a medical device company with

branches located in Ireland and abroad. Within the

particular plant we investigated, Research and

Development is performed along with the

manufacturing of commercial MDs. The MDs

contain embedded software. When developing a

product, MedIn always start with identifying the

intended use, as this will establish the device class,

which in turn identifies what regulations and

standards must be complied with. Their risk analysis

process can help determine the class of device.

Currently, each of these product development

processes are documented and reviewed at every

phase in a document-centric approach. The

company decided to move to an artefact-centric

approach for managing their product development

processes. To facilitate this, MedIn have chosen a

software product from a leading software provider.

This software provider offers artefact-centric

product development solutions.

For MedIn this software provider had the main

advantage of:

Provision for regulatory compliance such as

electronic signatures and adherence to FDA

standard 21 CFR part 11

In addition, artefact-centric approaches aid:

Time-to-market

The software can provide better visibility into

the progress of product development, and

reduce the work needed to maintain

traceability and respond to change.

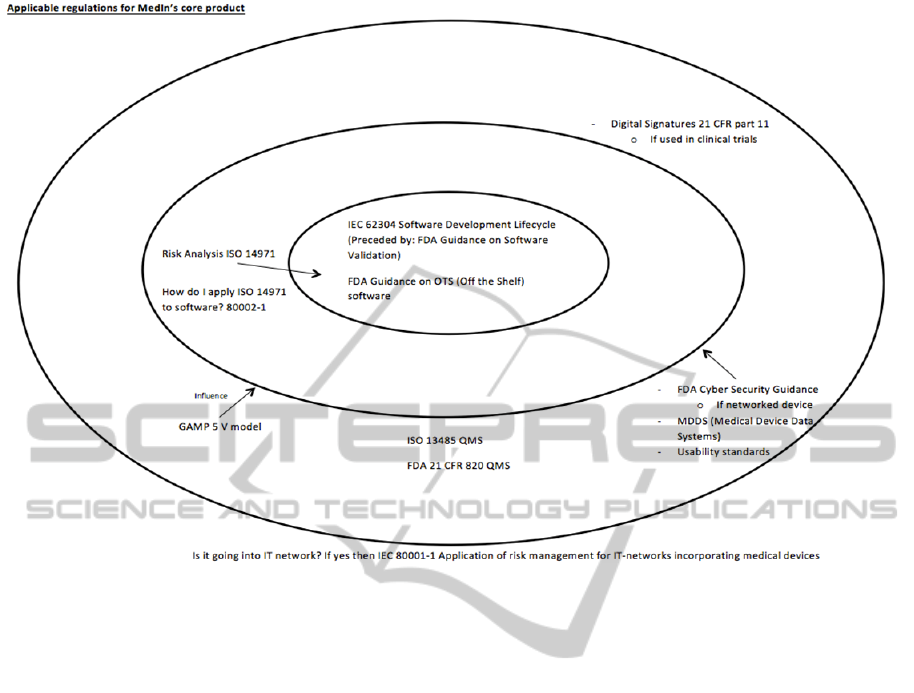

MedIn are applying software process improve-

ment in a safety critical environment while

minimizing risk and adhering to regulations. Figure

1 shows the applicable regulations for MedIn’s core

product. The primary or core regulations are:

MedicalDeviceSoftwareProcessImprovement-APerspectivefromaMedicalDeviceCompany

463

Figure 1: Regulations applicable to MedIn.

IEC 62304 Software Development Lifecycle

FDA guidance on Off The Shelf (OTS)

software

Next the risk management regulation applicable

is ISO 14971. The guidance document on how to

apply ISO 14971 is found in 80002-1. Finally the

following regulations influence the product, namely:

GAMP 5 V model

ISO 13485 Quality Management System

(QMS) for use in Europe

FDA 21 CFR 820 Quality Management

System (QMS) for use in USA

MDDS (Medical Device Data Systems)

Usability standards

If a networked device then

o FDA Cyber Security Guidance

o IEC 80001-1

If device used in clinical trials then

o Digital Signatures 21 CFR part 11

MedIn purchased an artefact-centric software

package from a leading software provider. Training

on the application of the software was given by the

chosen software provider to key personnel identified

within MedIn such as the quality team and the

software development team. A small sample project

was chosen to demonstrate and test the use of this

new approach. When complete the plan is to test and

use this new approach with a live project.

MedIn plan in the future to further improve their

process by moving from the current SDLC process

of a V-model to an agile software development

process. To implement this they have identified that

this might have to be achieved with smaller

deliveries, which is in fact smaller V-model

deliveries.

3 RESEARCH APPROACH

After completing a literature review of software

development within healthcare, we were interested

in understanding how process improvement within

MD companies is carried out. Therefore our

research question was as follows:

How does a medical device company plan

(manage change) and implement process

improvements while also adhering to

regulations governing its medical device

products?

The approach taken was to commence a single

case study within a MD company. One of the

authors spent three months onsite and became

HEALTHINF2015-InternationalConferenceonHealthInformatics

464

immersed in one project. This project was set up to

support the company in moving from a document-

centric approach to more integrated, artefact-centric

approach for managing their product development

processes. The company viewed this proposed

process improvement as a change management

issue. They were particularly concerned with how to

manage this change effectively while also remaining

compliant to the relevant regulations?

In addition to being a participant-observer on the

project, the researcher held one-to-one interviews

with software development team members. The 7

interviewees were all experienced in product

development processes. They included software

developers, a quality engineer and regulatory

manager. The interviewees’ work experience

spanned 5 to 20 years.

As recommended by Miles and Huberman

(1994) triangulation (applying a combination of

research methods) was used to facilitate the

validation of information and to remove bias.

Artefacts were collected on site such as process and

procedure documents, policy documents,

presentations, organisational charts, relevant

standards and email correspondence. This provided

the authors with a rich collection of project data and

statistics. Participant observations, interview data,

and artefacts were analysed to understand the case

study. We reviewed the data within the structure of

Kotter’s Change model, which allowed us to

understand how change had been made within the

organization, whilst still maintaining the regulatory

requirements, which are so important from its sales’

perspective. This facilitated the gaining of a holistic

view of the working environment. We analysed the

data focusing on Kotter’s steps 1 to 6. Steps 7 and 8

are outside the scope of this paper.

4 RESEARCH FINDINGS

4.1 Software Process in MedIn

Regardless of any change to the documentation

process, it was important that the SDLC continued to

adhere to the relevant regulations. In MedIn,

processes are described and documented. These, in

turn, are mapped to a relevant standard. Standards

have accompanying guidance documents to aid

interpretation. Usually medical device software

developers develop software with a plan driven

sequential SDLC, such as the V-Model (McCaffery

et al 2012).

Within MedIn software to be produced can be

divided into one of three groups of software process:

Development

Maintenance

Customization

For development in MedIn the V-model is used.

For class A devices developed in MedIn the V-

model used but Architecture Design, Unit test and

Code reviews are optional. MedIn do Verification

&Validation (V&V) but it is optional in the

regulations.

From our case study analysis, key factors were

identified which affect the SDLC process within

MedIn, namely safety, regulations, standards and

business focus.

To address these factors the following Quality

Processes are employed in the company:

Quality Management

Risk Management

Change Management

Configuration Management

Software Safety Classification

Traceability

It is the responsibility of the CTO to manage

SDLC processes – User Requirements, Verification

and Validation Planning, Specification Design,

Traceability, Pre-Production, Internal Validation,

Customer Acceptance and Production. In addition,

he has responsibility for the implementation of the

Quality Processes listed above.

4.1.1 Development Process

The current software development approach within

MedIn is the V-model. This is the standard V-model.

In the future MedIn plan to use the agile model for

software development. To incorporate the agile

model for development with medical devices it is

envisaged that there would be more frequent

releases. The releases will have less functionality.

MedIn plan to break the proposed release version

into multiple deliverables each containing a sub-set

of the overall functionality. The core principle here

is that the sub-sets shall be fully documented and

tested in their own right – so in theory could be

released individually. In practice though, they will

not release to customers until they have all

functionality for the full release ready. Agile will not

remove the need documentation, as this is necessary

for regulation compliance. Overall MedIn want to

become more iterative and get more feedback.

MedicalDeviceSoftwareProcessImprovement-APerspectivefromaMedicalDeviceCompany

465

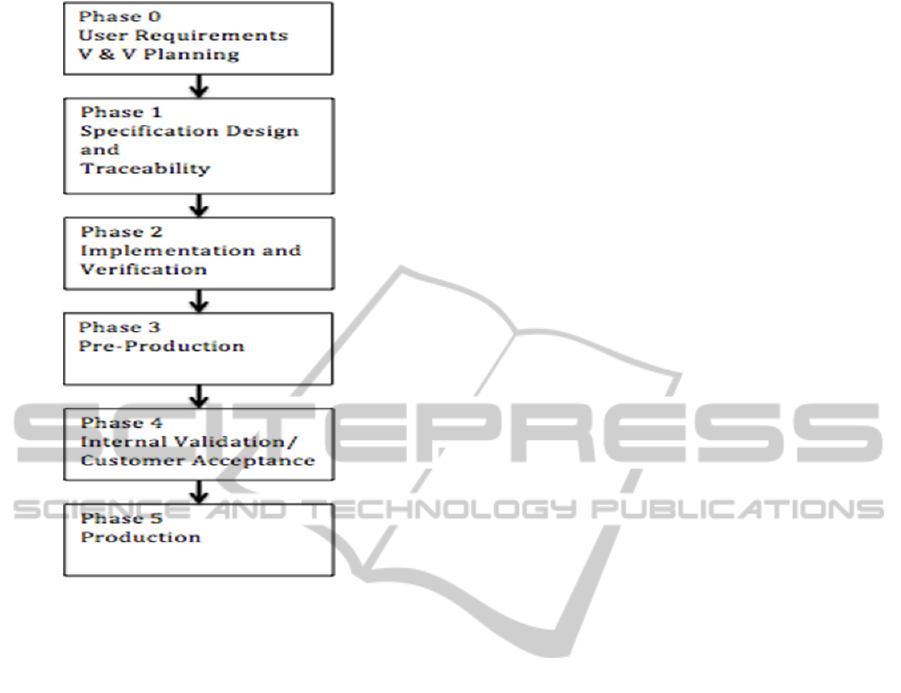

Figure 2: Customization Process within MedIn.

4.1.2 Maintenance Process

The Maintenance process can be either a non-

conformance request or a modification

implementation. If a modification implementation

then it can take the form of a new feature or a

change request.

4.1.3 Customization Process

The customization process in MedIn differs from the

development process and is done in phases as shown

in Figure 2. MedIn find that these phases work more

efficiently for the specific needs of a customization

task.

4.2 Analysis of Change

Further to understanding the software development

process, we analysed the change, which the

company was undergoing with relation to its

documentation. We discuss our findings in terms of

each of Kotter’s (2005) steps.

4.2.1 Establish a Sense of Urgency

Having analysed the use of Kotter’s model during a

software process change project in a development

company, Hayes and Richardson (2008) agree that,

prior to any change, the need for such a change must

be communicated to everyone in the organisation.

They further state that management should be

behind the change and that the development team

must be motivated to realise the change. Lack of

urgency is a common reason why many

organisations fail when implementing a change

(Hayes and Richardson 2008).

MedIn are a medical device company that uses

processes to develop their medical devices while

also adhering to the relevant regulations governing

its medical device products. Prior to implementing

the new system, MedIn used a document-centric

approach for managing their product development

processes. This process was a manual paper based

approach where for regulatory compliance all

documents had be reviewed and manually signed by

the quality control department. The documents were

then stored and easily accessible to a regulatory

auditor for regulatory compliance. In MedIn as the

current process was no longer useful it was taking up

too much time for employees, adding unnecessary

complexity to projects and clouding visibility on

project status. Each document had to be individually

signed after each review by the software quality

team members. It was then stored in a suitable

location so that it was readily accessible for

regulators to inspect. This document-centric

approach involved members of staff having to

process and file each document. This had been

recognised by management and employees and was

the driving force behind the change that was being

undertaken.

Further disadvantages were:

Using documents to manage the product

development process clouded visibility into

project status

Design transfers between teams were

complicated by using documents

Accountability was hindered

Creating, managing, and reviewing

documents were the most time-consuming

tasks

Management and employees recognised that this

situation could not continue. It was cumbersome

and not cost-effective in a competitive market. In

summary, the sense of urgency came from

throughout the company.

Therefore, MedIn investigated moving away

from a document-centric approach to another

approach but they were restricted in that any new

approach had to be regulatory compliant. One

HEALTHINF2015-InternationalConferenceonHealthInformatics

466

method that offers regulatory compliance is an

artefact-centric approach. An artefact-centric

approach relies not on documents but on commercial

software to create, track, and trace individual

artefacts and work items. The advantages in moving

to an artefact-centric approach that MedIn had

identified were:

Time-to-market

The software can provide better visibility into

the progress of product development, and

reduce the work needed to maintain

traceability and respond to change

4.2.2 Form a Powerful Guiding Coalition

Kotter (2005) recommends gradually involving

different members of the organisation in the change

to form a project team. In the case of MedIn it began

with the Chief Technology Officer (CTO) of the

company getting support from other senior

management. The CTO reviewed and identifed a

suitable software product to facilitate the planned

change in process while still adhering to relevant

regulatory constraints. Key staff members were also

identified and chosen to be trained initially on how

this new process could work. Time was allocated

for the members to implement a pilot project with

the new process. The guiding coalition was driven

by the CTO. However, as other key staff members

were involved, there was an involvement from staff

throughout the company.

4.2.3 Create a Vision

For organisational change, Kotter also recommends

that a clear vision and plan for implementing change

is needed. To aid the management of regulatory

compliance MedIn decided to use a software

package to track product development artefacts,

verification and validation artefacts, internal

validated IT systems, and other activities.

Management within MedIn identified the need to

develop an implementation plan which stated the

objectives of the change. This was used as the basis

to identify the vision of the project. From this,

management were enabled to plan the training

needs, staff and the scope of the pilot project.

4.2.4 Communicate the Vision

Communication of the vision should come from

senior management. Once the implementation and

training plans were identified, management had a

vehicle by which they could carry out this

communication effectively. They were able to

discuss implementation with all employees who

subsequently undertook the relevant training.

Therefore, employees became aware of relevant

tasks to be completed in the project and of their roles

within the project. Kotter’s (2005) Step 4

recommends communication of the vision should

come from senior management. This was the case in

MedIn, as the project was driven by the CTO.

4.2.5 Empower Others to Act on the Vision

Obstacles, such as organisational structure should be

removed. At MedIn the project began with staff

training followed by a pilot implementation before a

planned rollout the new artefact-centric approach to

all projects. The importance of the vision was

evident to the team members as the actions that were

put in place such as the pilot project demonstrated

that, from a Senior Management point of view, this

was an important project which needed to be worked

on by everyone. The team members were keenly

aware that the existing process was very time

consuming and burdensome and that the proposed

vision was a more time efficient process.

4.2.6 Plan for and Create Short-term Wins

Change should have clear goals and objectives and

take place in small steps. Within MedIn, this was

done by allocating relevant team members to carry

out a pilot project. The pilot project which Kotter

does not mention actually worked well for MedIn. It

allowed the team members to become acquainted

and familiar with how the new process should work.

4.2.7 Kotter’s Steps 7 and 8

Kotter’s (2005) Step 7 Consolidate Improvements

and Produce More Change recommends that

management or change advocates should be become

more involved in the process thus ensuring

continuation of changes. Kotter’s (2005) step 8

Institutionalise New Approaches recommends that

for success change has to be implemented so that it

is now part of the organisation’s culture.

Currently these last two steps are out of the scope

of this case study as the process change is not yet

complete. A further visit is planned to MedIn to

observe how the process is working after

implementation of the change.

5 DISCUSSION

For this case study Kotter’s change model was

MedicalDeviceSoftwareProcessImprovement-APerspectivefromaMedicalDeviceCompany

467

appropriate. The sense of urgency Kotter stipulates

was inherent in the MedIn project. The team was

aware that change was needed. A flaw in Kotter’s

approach is that there is no recommendation for a

pilot project; this actually worked well for MedIn as

it helped to eliminate stress and anxiety. There were

specific aspects of the model that were overlooked

and there were elements that were necessary. For

instance Kotter’s (2005) step 5 Empower Others to

Act on the Vision was nessessary for team members

to have awareness of the importance of the vision.

The team members were given the time to carry out

a pilot project using the new artefact-centric

approach.

At the end of the 3-month case study the change

implemented thus far was working well and to an

organized plan going forward. A further case study

is planned to see if this move to this new approach is

working as planned.

6 CONCLUSIONS

We studied the SDLC within a MD company.

Cawley et al (2011) point out that many MD

companies are pre-occupied with complying with

regulations and that MD companies are looking at

how to manage process improvement while not

affecting regulatory compliance (Cawley et al 2011,

2013). This was found to be true in our case study

also. There does not seem to be a method for

quantifying just how much process is enough. This

is a significant challenge facing medical device

companies. They further recommend auditing

existing processes to review where improvements

could be made to maybe, for example, save time.

They also note that the challenge for researchers is

to develop architectures and methodologies that

facilitate advancements while being flexible to how

the regulators might respond.

The research presented in this paper documents a

single case study in MedIn. We have demonstrated

that process improvement when managed through

the use of a model will support the implantation of

change in an organisation. While Kotter’s change

model (2005) was a good basis, there were specific

aspects of the model that were overlooked and there

were elements that were necessary. Therefore a

more tailored and specific framework is required.

Due to regulation restrictions and business concerns

such as time to market, MD companies have to

implement change in an organised and planned

fashion.

7 FUTURE WORK

A futher case study is planned in the future within

MedIn, allowing us to study how process

improvement change has been managed in the

longer term. We recognise that doing a single case

study presents changes which are specific to one

company, but analysing these changes allows us to

recognise the difficulties faced by and strategies

used by MD companies when implementing change.

We have a starting point upon which to build our

research and to investigate change management

within the MD industry.

ACKNOWLEDGEMENTS

This research is partially supported by Science

Foundation Ireland (SFI) through Grant No.

03/CE2/I303.1 within Lero – The Irish Software

Engineering Research Centre (http://www.lero.ie).

REFERENCES

AAMI (2012) TIR45:2012 Guidance on the use of AGILE

practices in the development of medical device

software 2012, Association for the Advancement of

Medical Instrumentation.

ANSI/AAMI/IEC (2006) 62304:2006 Medical Device

Software-Software life cycle processes, 2006,

Association for the Advancement of Medical

Instrumentation. p. 67.

Burton, J., (2008) A Software Risk Management

Capability Model for Medical Device Software,

Unpublished thesis (PhD), University of Limerick.

Cawley, O., Wang, X., Richardson, I., (2013) Regulated

Software Development-An Onerous Transformation,

in Foundations of Health Information Engineering and

Systems: Springer, 72-86.

Cawley, O., Richardson, I., Wang, X., (2011) Medical

Device Software Development - A Perspective from a

Lean Manufacturing Plant, O’Connor, R. V., Rout, T.,

McCaffery, F., and Dorling, A., ‘Software Process

Improvement and Capability Determination’, Berlin,

Springer, 84 – 96.

EU, Council Directive (1993) 93/42/EEC of the European

Parliament and of the Council, Concerning Medical

Devices, E. Council, Editor 1993, Official Journal of

the European Union.

EU, Directive (2007) 2007/47/EC of the European

Parliament and of the Council, 2007, Official Journal

of the European Union.

FDA (2009) Code of Federal Regulations 21 CFR Part

820, U.F.a.D. Administration, Editor April 2009.

HEALTHINF2015-InternationalConferenceonHealthInformatics

468

Forte, G., (1997) Managing Change for Rapid

Development, IEEE Software 14(6), 114–123.

Hayes, S. & Richardson, I., (2008), Scrum Implementation

using Kotter’s Change Model, 9th International

Conference on Agile Processes and eXtreme

Programming in Software Engineering, Limerick,

Ireland, Lecture Notes in Business Information

Processing 2008, vol 9, Part 6, 10th-14th June, pp.

161-171.

Kotter, J., (2005) Leading Change: Why Transformation

Efforts Fail, Harvard Business School Press, Boston.

McCaffery, F., Casey, V., Sivakumar, M.S., Coleman, G.,

Donnelly, P., Burton, J., (2012) Medical Device

Software Traceability, Software and Systems

Traceability, Ed. Zisman A., Cleland-Huang J. and

Gotel, O., Springer Verlag Publishers, pp 321 – 340.

MEDDEV 2.1/6 (2012) Guidelines on the qualification

and classification of stand alone software used in

healthcare within the regulatory framework of medical

devices, European Commission.

Miles, M., Huberman, A. (1994) Qualitative Data

Analysis, 2nd edn. SAGE Publications, USA.

Spence, J.W. (2005) There has to be a better way!

[software development] in AGILE Conference, July

24 - July 29, 2005. Denver, CO, United states: Inst. of

Elec. and Elec. Eng. Computer Society, 272-278.

MedicalDeviceSoftwareProcessImprovement-APerspectivefromaMedicalDeviceCompany

469