Overall Equipment Effectiveness and Overall Line Efficiency

Measurement using Fuzzy Inference Systems

Hasan Moradizadeh and Rene V. Mayorga

Faculty of Engineering, University of Regina, Regina, Canada

Keywords: Intelligent Systems, Fuzzy Inference Systems, Overall Equipment Effectiveness, Overall Line Efficiency,

Six Major Losses in Industry.

Abstract: Increasingly, Intelligent Systems (IS) techniques are being used to solve both complex problems and

industrial problems with uncertainty. They also can implement the operator’s knowledge (experience) into

the system. This Paper aims to improve and compute the well-known manufacturing metrics: the Overall

Equipment Effectiveness (OEE), and Overall Line Efficiency (OLE), using IS techniques. The proposed

methodologies to improve the OEE and OLE weakness are based on Fuzzy Inference Systems. These

techniques result in an effective way to measure OEE and OLE considering different weight of losses and

also the difference in machine’s weight factors. Moreover, they allow the operator’s knowledge to be taken

into account in the measurement using uncertain input and output with implementation of linguistic terms.

1 INTRODUCTION

In the existing intense competitive economic

environment, manufacturing plants intend to reduce

their manufacturing costs as well as maintaining the

quality of their products. Total Productive

Maintenance (TPM) is normally implemented to

optimize the manufacturing equipment effectiveness

and improve their reliability as a result of

eliminating six major losses in industry (I.P.S. Ahuja

and J.S. Khamba, 2008). These losses include

breakdown, adjustment losses, idle times and small

stops, start up and yield, and defect and rework.

Overall Equipment Effectiveness (OEE) is one of

the most important TPM’s key performance

indicators that has been increasingly used in industry

not only for controlling and monitoring the

productivity of production equipment but also as an

indicator and driver of process and performance

improvements (Jose Arturo Garza-Reyes et al.,

2010). Overall Line Efficiency (OLE) is also being

used to show how well a manufacturing line is

running compared to how well it could be running.

This metric take into account each of the machine’s

OEE.

Recent studies (D. Kotze, 1993; M. Lesshammar,

1999; R. Wudhikarn and W. Manopiniwes, 2010)

been done and major improvements have been

achieved to measure OEE; however this metric has

some flaws. First, for continuous flow processes

such as oil refinery, metal smelting and power

stations calculating the performance rate is more

difficult due to lack of cycle time of their products.

Also weighting of each OEE element is different in

different industries or processes. For example

quality losses may have a different contribution in

OEE in processes where the material is expensive

and the product cannot be reworked rather than in

manufacturing line with short cycle time and cheap

raw material. Also operator/user knowledge can be

implementing in measuring OEE using linguistic

term in Fuzzy Inference Systems. Furthermore, OLE

cannot be measured easily in complex

manufacturing lines where each machine has a

different weight factor. As an example, an

unbalanced manufacturing line is assumed. A

machine that is the bottleneck has a more effect on

the line efficiency rather than a machine that barely

operates.

This study aims to improve and calculate the

OEE and OLE weaknesses by implementing

Intelligent Systems (IS) techniques. To do so, the

proposed methodology is presented and its

experimental results are analyzed.

199

Moradizadeh H. and Mayorga R..

Overall Equipment Effectiveness and Overall Line Efficiency Measurement using Fuzzy Inference Systems.

DOI: 10.5220/0005155101990204

In Proceedings of the International Conference on Fuzzy Computation Theory and Applications (FCTA-2014), pages 199-204

ISBN: 978-989-758-053-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

2 OEE & OLE

Overall Equipment Effectiveness (OEE) can be

implemented to benchmark, analyze and improve a

production process by measuring inefficiencies and

groups them in different categories (B. Dal et al.,

2000). The most common inefficiency causes in

industry are those called “six big losses.” These

losses can be categorized in downtime losses, speed

losses, and quality losses. To find a way to monitor

and improve a manufacturing process, six big losses

are addressed as follows.

(1) Downtime losses: Downtime is the most

important loss for equipment effectiveness

improvement since other metrics cannot be

addressed if the manufacturing process is down.

Tooling failures, unplanned maintenance, equipment

breakdowns are some examples of downtime losses.

(2) Setup and Adjustment: This loss is the time

between the last acceptable part produced before

setup to the first consistent acceptable parts

produced after setup and adjustment. This is often a

set of adjustments to machines and/or equipment in

order to produce a product that meets the standard

requirements.Warm up time and changeovers can be

represented as setup and adjustment losses in a

manufacturing process. These losses are considered

in calculation of the availability factor.

(3) Small Stops: These stoppages occur when the

machine stops due to a temporary problem such as

an activated sensor that shuts the machine down

automatically. These minor stoppages are usually

less than 10 minutes and can be dealt with by the

operator and generally there is no need to call a

maintenance team.

(4) Reduced Speed: Knowing the ideal cycle time

of a machine and comparing it with the actual cycle

time, it will be possible to monitor low running or

reduced speed losses. Machines may run at the speed

less than the ideal run rate for various reasons.

Training level of operators, and worn equipment can

be categorized as the aforementioned reasons. Small

stops and reduced speed are known as speed losses

and are taken into account in performance factor

calculation.

(5) Start up Rejects: Startup losses occur in the

initial start of a machine up to the stabilization of its

products quality. A root cause analysis can be done

to pinpoint the potential causes of rejects and to

prevent similar losses from occurring in the future. It

is necessary to note that reworks, scraps and

incorrect assembly, all are considered as rejects in

the production processes.

(6) Production Rejects: This loss occurs in a

steady-state production and is not attributed to start

up. Damage, scraps, and reworks, are some

examples of production reject losses.

The last two losses are considered quality losses

and affect the quality factor of OEE.

The traditional method of OEE calculation

considers availably, performance, and quality

factors as follows:

Availability: Availability is the ratio of actual

production time that a machine is working divided

by the time the machine is planned to work.

A=

Operation time

Planned production time

Performance: Performance of a machine is the

percentage of total number of parts on that machine

to its production rate. In simple words, performance

measures the ratio of actual operating speed of the

equipment and the ideal speed (M. Lesshammar,

1999).

P =

Ideal cycle time

Operation time

Total pieces

Quality: To gain insight into the quality aspect of

a production process the quality portion of OEE is

defined. The Quality metric represents good

(acceptable) units produced by machine divided by

the total units produced by that machine in the

production time.

Q=

Acceptable Pieces

Total Pieces

Given the above, the OEE is normally calculated as

follows:

OEE = A × P × Q

Therefore OEE takes into account the six major

losses. Significant improvement can be achieved

within a short period by eliminating these losses in

industry as a result of enhanced maintenance

activities and equipment management (M. Maran et

al., 2012).

In a situation where a manufacturing line

consists of unbalanced/decoupled machines OEE

alone is not sufficient (Braglia et al., 2009). Also

OEE is measured for an isolated individual

equipment and controlling a single tool does not

seem to be effective (Richard Oechsner et al., 2002).

OLE evaluates the line Efficiency in the production

phase and takes into account of effectiveness (OEE)

FCTA2014-InternationalConferenceonFuzzyComputationTheoryandApplications

200

of machines in a manufacturing line. For a

manufacturing line with n machines where all

machines have same weight factors OLE is

computed as:

OLE =

OEE

1

+ OEE

2

+… + OEE

n

n

However, in a case where machines have

different weight factors and cycle times, OLE

calculation is more complex. This study also aims to

improve accuracy of the OLE measurement by

implementing user/expert knowledge into the system

using IS techniques.

3 METHODOLOGY

Implementing Fuzzy Inference Systems in OEE and

OLE measurement as proposed in this Paper it is a

truly novel methodology and offers several

advantages over traditional methods. First,

measurement can be done for all production

processes in different industries regardless of their

products. Moreover, different weight factors can be

allocated to OEE factors involved in the

measurement depending on the process. Also, OLE

can be measured for factories with a variety of

production lines and machines with various weight

factors. In this Paper the Mamdani and Sugeno

Fuzzy Inference Systems are used to improve the

OEE weaknesses and also to take advantage of the

operator’s knowledge of the process. Also Mamdani

FIS is used to measure OLE in unbalanced

manufacturing line where machines have different

contribution in the line efficiency.

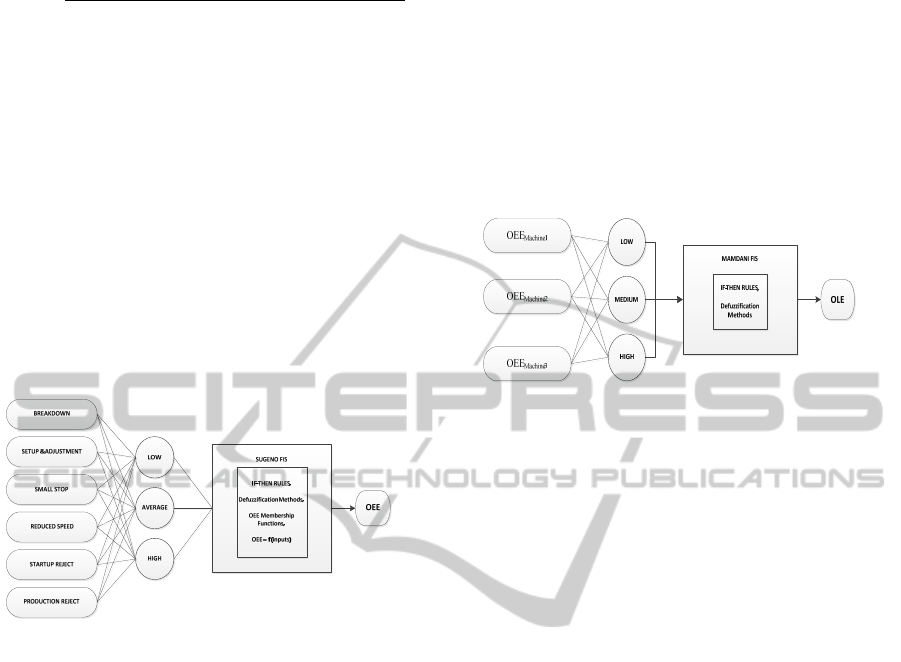

3.1 OEE Measurement using Mamdani

FIS:

In this method, availability, performance, and

quality, are calculated based on their associated

losses involved in an equipment effectiveness

reduction. Here Matlab Fuzzy Toolbox is used to

examine the accuracy of the proposed methodology.

In order to complete the OEE measurement, the six

main losses in industry are considered as inputs of

the FIS. As mentioned earlier; breakdowns, and

setup and adjustment are two losses associated with

the availability factor. Small stops and reduced

speed cause inefficiency and performance reduction.

Finally start-up and process rejects are quality losses

that are involved in overall equipment effectiveness.

Given the six losses as inputs, the OEE of the

machine is the sole output of Mamdani FIS System.

Once inputs and output of the system are

determined, the next step for the system to reach its

goal is to set antecedent-consequent (if-then) rules.

Like determining inputs and outputs, operator

experience/knowledge plays an important role in this

step by applying weight factors to each input into the

system. Setting inaccurate rules has a big negative

impact on results. Using linguistic terms [low,

average, high] for input parameters helps to measure

OEE when inputs cannot be measured accurately.

Note that the number of membership functions of

each input is not limited and may be varied depend

on the process and possibility of measuring inputs.

Here 3 Generalized bell-shaped membership

functions [low, average, high] are assigned to each

input and 5 Generalized bell-shaped membership

functions [very low, low, average, high, very high]

are output, here OEE, qualifiers. Center of area

(COA) diffuzification method is used to convert the

fuzzy output to crisp output. Also, 729 if-then rules

are set to represent the real system more accurately.

Figure 1: OEE measurement using Mamdani FIS.

3.2 OEE Measurement using Sugeno

FIS:

The Sugeno FIS is also implemented to measure

OEE in processes that weight factor of inputs can be

described in coefficients of an equation. For instance

if all associated inputs of OEE measurement (six big

losses) have the same weight factor, the OEE can be

presented as follows:

OEE=

Brk+Stad+Sml+Red+Str+Prr

6

This can be modeled as a first order Sugeno

fuzzy model. In a case where the quality factor has a

severe impact on OEE; the Sugeno fuzzy Inference

System can be modeled with more concentration on

quality losses as follows:

OverallEquipmentEffectivenessandOverallLineEfficiencyMeasurementusingFuzzyInferenceSystems

201

OEE=

Brk+Stad+Sml+Red+(2xStr)+(4xPrr )

10

Like the Mamdani FIS, Matlab Fuzzy Toolbox is

used here. After determining the inputs and their

weight factors in OEE measurement and also outputs

of the Sugeno FIS; the operator knowledge of the

manufacturing process can be applied to the system

by setting fuzzy if-then rules. This system can be

implemented in the processes where six major losses

(inputs) cannot be measured accurately, however

each input can get a weight factor depends on the

contribution in OEE measurement. In this case 3

generalized bell-shaped membership functions [low,

average, high] are assigned to each input and 3

outputs are considered as functions of inputs and

their weight factors. Also 3 if then rules are set to

represent the real system.

Figure 2: OEE measurement using Sugeno FIS.

3.3 OLE Measurement using Mamdani

FIS:

The OLE can also be calculated, taking into account

each machine’s OEE in the manufacturing line. Due

to complexity of OLE calculation in manufacturing

lines with different types of machines, different

cycle times, and also different weigh factors; Fuzzy

Inference Systems are also proposed here to measure

the Overall Line Efficiency. This method, the

effectiveness (OEE) of every single machine in the

manufacturing line is an input of the FIS. Inputs can

get linguistic terms [low, average, high] that are

presented as Generalized bell membership functions.

Also, OLE is the output of the Mamdani FIS that is

resulted in Fuzzy linguistic terms [low, average,

high] and is diffuzified in crisp output using COA

method. The operator’s knowledge of the system can

be best applied into the FIS with setting accurate if-

then rules that represent the real life system. The

weight factor of each machine in the manufacturing

line can be taken into account in rule setting. For

instance, if we assume a manufacturing line with 3

machines where machine 2 is the bottleneck in this

process, and its cycle time is noticeably higher in

comparison to machine 1 and machine 3, the

following rule can be set to assure that machine 2

has a bigger impact on this line efficiency.

If OEE

Machine2

is low then OLE is low

(regardless of OEE

Machine1

and OEE

Machine3

)

Here 29 rules are set to represent the production

process in the real system.

Figure 3: OLE measurement using Mamdani FIS.

4 EXPERIMENTAL RESULTS

First, common situations in industry are considered

and values of inputs are given to the system and the

OEE and OLE are obtained. Also, the considered

scenarios are compared to demonstrate the accuracy

of the proposed methodologies (M. Moradizadeh,

2014). Here, a brief explanation of each scenario

along with a table of inputs and results is presented.

Please note that these methodologies can be

implemented for general and diverse production

systems (M. Moradizadeh, 2014), regardless of

manufacturing process and variation and vagueness

of the inputs.

4.1 OEE Measurement using Mamdani

FIS

Here a typical (but general) industrial scenario is

presented. Some other industrial scenarios are also

presented in (M. Moradizadeh, 2014). A machine in

a manufacturing plant has been selected and its OEE

is to be measured. Assume there are qualitative

losses associated with this machine in the past

month; however, its performance rate is average and

also the machine was available to operate properly

(no major downtime) in this period. Therefore the

following assumptions are considered:

Although a minor breakdown occurred in this

period; the machine was running continually

and its operator considers the value of

breakdown loss as low.

FCTA2014-InternationalConferenceonFuzzyComputationTheoryandApplications

202

There were not setup and adjustment losses

involved with the machine, and these losses are

considered to be low.

Within the last month small stops occurred

during running time and have been fixed by the

operator so small stops loss is considered

average for this machine.

Machines’ ideal cycle time for pressing the

metal part is 12 seconds however its actual

cycle time is measured as 15 seconds and

reduced speed loss has considered average by

operator.

There was not a considerable amount of startup

rejects and this loss considered low in this

period.

Qualitative issues have been observed and

noticeable number of non-conforming parts has

been produced by this machine within last

month. Therefore the process reject loss is

considered to be high is this period.

In this manufacturing plant the availability

factor has a higher weight factor rather than

performance and quality due to the short cycle

time and inexpensive material. Also, the Total

Productive Maintenance (TPM) and Single

Minute Exchange of Die (SMED) are being

implemented to increase the running time of

machines and reduce the setup and adjustment

time.

The following Table presents the results considering

the aforementioned parameters as inputs of

Mamdani FIS to measure OEE:

Table 1: OEE measurement using Mamdani FIS,

Experimental results.

Inputs

Linguistic

Term

Input

Value

Output

Deffuzified

Output

Value

Brk Low 15

OEE 74.8

Stad Low 10

Sml Average 38

Red Average 36

Str Low 18

Prr High 65

Note that, in traditional methods of OEE

calculation, the result, which is the average of

inputs, is 69.67%.

4.2 OEE Measurement using Sugeno

FIS

Three pneumatic presses (scenarios) are assumed in

a manufacturing plant and their OEE are to be

measured using a Sugeno FIS.

Following assumptions are considered as inputs

to the Sugeno FIS system:

Due to its material price, quality losses must be

identified and reduced in this manufacturing

plant.

Qualitative loss costs are drastically more than

other losses associated with OEE.

Table 2: OEE measurement using Sugeno FIS,

Experimental results.

Inputs

Weight

Facto

r

Scenario

1

Scenario

2

Scenario

3

Brk 2 14 32 8

Stad 1 8 4 6

Sml 1 31 28 31

Red 1 17 11 21

Str 3 9 26 6

Prr 4 77 12 8

OEE 65.08% 80.58% 89.67%

In order to measure the OEE more accurately

this company decided to assign different weight

factors to inputs. The Table above shows the weight

factor for each input, the value of each input for

these scenarios, and also the obtained OEE for each

scenario.

4.3 OLE Measurement using Mamdani

FIS

A manufacturing line is assumed with three different

machines. Each machine contributes in Overall Line

Efficiency; however, the machine 2 is the bottleneck

on this line and plays a more important role in the

OLE measurement. Therefore, the operator uses

his/her knowledge to set rules in the Mamdani FIS in

order to measure the OLE more efficiently. Also it is

necessary to note that this technique can be used for

any type of manufacturing line with a variety of

machines to measure its efficiency.

The following Table provides experimental

results obtained for different scenarios (represented

each by a row) from the Mamdani FIS:

OverallEquipmentEffectivenessandOverallLineEfficiencyMeasurementusingFuzzyInferenceSystems

203

Table 3: OLE measurement using Mamdani FIS,

Experimental results.

Scenario OEE

1

OEE

2

OEE

3

OLE

1 0.68 0.75 0.69 0.639

2 0.97 0.84 0.76 0.749

3 0.81 0.62 0.69 0.656

4 0.81 0.77 0.7 0.68

5 0.89 0.53 0.76 0.656

6 0.85 0.85 0.56 0.703

7 0.74 0.81 0.74 0.676

8 0.79 0.84 0.61 0.692

5 CONCLUSIONS

This Paper presents truly novel Intelligent Systems

(IS), in particular Fuzzy Inference Systems,

approaches and methodologies to measure the

commonly used indicators in many industries:

Overall Equipment Effectiveness and Overall Line

Efficiency. The proposed techniques can be easily

implemented to improve the accuracy and reduce the

limitations of the OEE and the OLE measurements.

These IS techniques, in particular the Fuzzy

Inference Systems (FIS) offer valuable and

significant new ways to measure the OEE and the

OLE in industry. Dealing with uncertainty and

vague data, taking advantage of user’s knowledge of

the system, and also the ability of adding weight

factors of inputs to the system, are some of the great

advantages of applying FIS in the OEE and the OLE

measurement.

REFERENCES

I. P. S. Ahuja, J. S. Khamba, "Total productive

maintenance: literature review and directions",

International Journal of Quality & Reliability

Management, Vol. 25 Iss: 7, (2008) 709 – 756.

Jose Arturo Garza-Reyes, Steve Eldridge, Kevin D.

Barber, Horacio Soriano-Meier, "Overall equipment

effectiveness (OEE) and process capability (PC)

measures: A relationship analysis", International

Journal of Quality & Reliability Management, Vol. 27

Iss: 1, (2010), 48 – 62.

D. Kotze, “Consistency, accuracy lead to maximum OEE

benefits”, TPM Newsletter, vol. 4, no. 2, 1993.

M. Lesshammar, “Evaluation and improvement of

manufacturing performance measurement systems –

the role of OEE”, International Journal of Operations

and Production Management, vol. 19, no. 1, pp. 55-

78, (1999).

R. Wudhikarn and W. Manopiniwes, “Autonomous

maintenance using total productive maintenance

approach: A case study of synthetic wood plank

factory”, Technology Innovation & Industrial

Management Conference, TIIM2010, Pattaya,

Thailand, in press.

B. Dal, P. Tugwell and R. Greatbanks, “Overall

Equipment effectiveness as a measure of operational

Improvement”, International Journal of Operations &

Production Management, vol. 20, no. 12, (2000),

1488–1520.

M. Maran, G. Manikandan, K.Thiagarajan,

“Overall Equipment Effectiveness Measurement By

Weighted Approach Method”, International

Association of Engineers Vol. 2.,(2012).

M. Moradizadeh, “Overall Equipment Effectiveness and

Overall Line Efficiency Measurement Using

Intelligent Systems Techniques” M.A.Sc. Thesis,

Faculty of Engineering, University of Regina, Canada,

April, 2014.

Braglia, M., Frosolini, M., & Zammori, F., “Overall

equipment effectiveness of a manufacturing line

(OEEML)”. Journal of Manufacturing Technology

Management, Vol. 20 Iss: 1, (2009), 8 – 29.

Richard Oechsner, Markus Pfeffer, Lothar Pfitzner, Harald

Binder, Eckhard Müller, Thomas Vonderstrass, “

From overall equipment efficiency (OEE) to overall

Fab effectiveness (OFE)”, Materials Science in

Semiconductor Processing, Vol. 5, Iss 4–5, (2002),

333-339.

LIST OF ACRONYMS

IS Intelligent Systems

FIS Fuzzy Inference Systems

OEE Overall Equipment Effectiveness

OLE Overall Line Efficiency

Brk Breakdowns

Stad Setup & adjustment

Sml Small stops

Red Reduced speed

Str Start-up rejects

Prr Production rejects

Coa Center of area

FCTA2014-InternationalConferenceonFuzzyComputationTheoryandApplications

204