Supply Chains Modelling and Simulation Framework

Graph-Driven Approach using Ontology-based Semantic Networks and Graph

Database

Mahmoud Elbattah and Owen Molloy

National University of Ireland, Galway, Ireland

ABSTRACT

Successful supply chains management has become a

key

factor for enterprises to achieve and maintain their

competitive advantage. The increasing complexity and

agility of supply chains are sustainably growing

challenges. Simulation provides advantages over

traditional analytical methods in planning and

optimisation of supply chains. This paper presents a

comprehensive framework for the modelling and

simulation of supply chains. A graph-driven

methodology is adopted considering supply chains as

"Big Graphs". The research will utilise semantic

networks, and develop a supply chain ontology to

construct semantic-based models of supply chains. The

framework proposes the use of graph databases for

storing and maintaining complex supply chain models

and ontologies. Furthermore, the framework will

provide automatic generation of simulation models to

help non-simulation experts. The applicability and

validity of the proposed framework will be

investigated within a case study of healthcare supply

chains, during which a specific ontology for healthcare

supply chains will be produced as well.

1 STAGE OF THE RESEARCH

The research can still be considered in an early stage.

The initial steps included conducting a thorough

literature review concerning: i) Conceptual modelling

of supply chains, ii) Supply chain simulation tools and

iii) Supply chain ontology. Based on the limitations

and gaps exposed in the literature, the paper proposes

a framework for the conceptual modelling and

simulation of supply chains.

2 OUTLINE OF OBJECTIVES

The proposed framework aims at the following:

Providing a semantic-based modelling method

for supply chains that is capable of capturing

and describing supply chain knowledge.

Developing generic ontology for supply chains

based on the SCOR reference model.

Developing specific ontology for healthcare

supply chains.

Investigation of the potential advantages of

using graph databases for capturing and

maintaining the knowledge of supply chain

models.

Investigation of the flexibility and scalability

provided by graph database in case of building

complex large-scale supply chain models.

Automatic generation of simulation models

based on high-level conceptual models to help

non-simulation experts easily run and modify

simulation experiments using one of the state-

of-the-art simulation software.

Inspecting the applicability and validity of the

proposed framework in a dynamic industry,

particularly a healthcare supply chain.

3 RESEARCH PROBLEM

The complexity of supply chains continues to grow

due to collaborative planning and connections among

supply network participants. In addition, supply chains

are required to be responsive, agile, lean, scalable, and

flexible with respect to uncertain information.

Simulation is being more and more accepted to be

an important part of the analysis and optimisation

practice of supply chains management. However,

building simulation models for supply chains involves

many challenges.

Firstly, the difficulty of conceptual modelling of

supply chains, involving an abstraction process, used

to capture the essence of a real system into a

simulation model. The literature lacks a common

modelling methodology that can help describe details

of a supply chain and capture essential elements and

9

Elbattah M. and Molloy O..

Supply Chains Modelling and Simulation Framework - Graph-Driven Approach using Ontology-based Semantic Networks and Graph Database.

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

relationships as well as their dynamics. The need for

such methodology has been acknowledged by

(Gunasekaran, Macbeth, 2000), (Jain, Workman,

Collins and Ervin, 2001), (Min and Zhou, 2002),

(Gunasekaran, 2004) and (Zee, 2005).

Secondly, the shareability of supply chain models

has become an inevitable demand since the model can

be developed and shared across a network of various

and distant participants. Standard supply chain

ontology can help sharing models. However, the

literature lacks what can be considered as a standard

ontology for supply chains, especially for specific

industries like healthcare or perishable goods.

Thirdly, the majority of the simulation tools

produced by academia and industry for supply chains

were mostly designed for simulation experts. Auto-

generated simulation models can be considered as a

more realistic demand due to the highly increasing

complexity of supply chain models, which implies

more time and costs to build simulation models.

Finally, the scalability of supply chain models is a

considerable need, especially for rapidly growing

supply chains. The majority of existing systems rely

on XML to store supply chain models. Although XML

has acknowledged advantages for information inter-

changeability, document-oriented techniques might not

help with model scalability according to (Chatfield,

2009), especially for more complex and large-scale

supply chains.

4 STATE OF THE ART

Since the advent of supply chain management, both

academia and industry have presented a significant

amount of studies and tools for the modelling and

simulation of supply chains. This section reviews the

literature concerning the following areas:

The conceptual modelling methodologies of

supply chains.

The simulation tools of supply chains.

The presented endeavours for identifying supply

chain ontology.

4.1 Supply Chain Conceptual Models

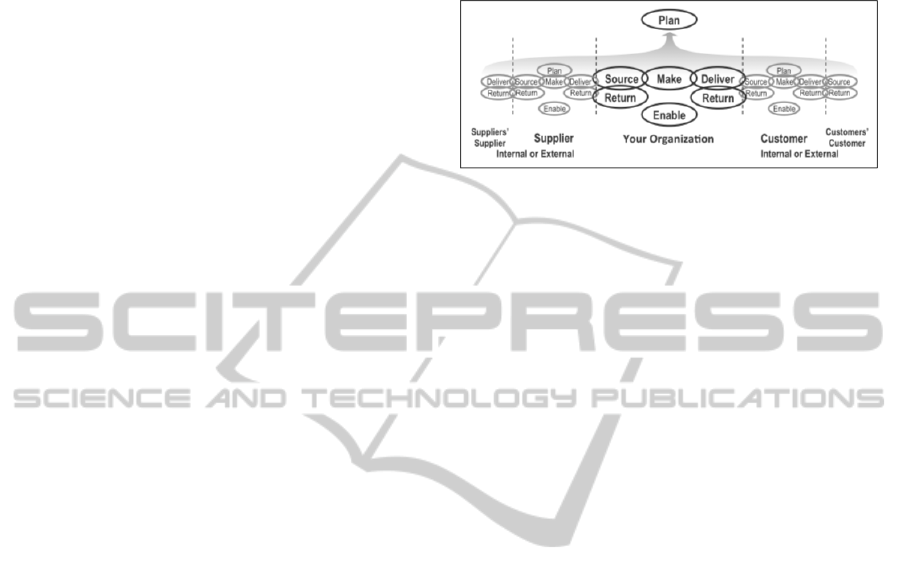

First, the SCOR (Supply Chain Operations Reference

Model) model, which can be regarded as one of the

most widely accepted reference models for supply

chains. SCOR has been developed and being

maintained by the Supply Chain Council (SCC) Inc.

The SCOR model has been developed to describe the

business activities associated with all phases of

satisfying a customer's demand. The model contains

several sections and is organized around six primary

management processes: Plan, Source, Make, Deliver,

Return and Enable, as shown in Figure 1. (Supply

Chain Council, 2012)

Figure 1: The six major management processes of SCOR.

Many studies adopted SCOR as a basis for building

either abstract or simulation models for supply chains

such as (Jeffrey, Edward, 2003), (Samuel, Sunil,

2005), (Yuh-Jen, Yuh-Min, 2009), (Fredrik, Mirko,

2009) and (Jack, Kincho, 2010). According to

(Fredrik, Mirko, 2009), the advantages of the SCOR

model are:

Providing the modeller with a solution to the

problem of different levels of details in

simulation model since SCOR has predefined

levels of aggregation.

Defining performance metrics for each level.

However, SCOR has been criticized in other

studies. According to

(Guixiu, Frank, 2004), SCOR

does not provide a concrete realisation of a conceptual

framework that can be integrated to a company’s

existing systems. Furthermore, (Chatfield, 2009)

accounted the following SCOR’s shortcomings:

SCOR makes the translation of the supply chain

description into an object-oriented model less

than straightforward.

The descriptions and measurements of SCOR

do not have the content and detail necessary for

building robust quantitative models.

On the other hand, the object-oriented approach

has been also embraced in literature. (Manuel, Hin-

Tat, 2003) used the UML during the object-oriented

development process to analyze and visualize the

design of supply chains. (Biswas, Narahari, 2004)

developed DESSCOM, an object-oriented framework

for supply chains modelling and decision support.

Another object-oriented modelling methodology

consisting of agents, jobs, and flows was developed by

(Zee, 2005).

Supply chains were also modelled in terms of

multi-criteria decision analysis. An ANP-based

(Analytic Network Process) approach was used by

(Ashish, Ravi, 2006) to model the metrics of lean,

agile supply chains. However, the pairwise

comparison required by ANP models can limit the

SIMULTECH2014-DoctoralConsortium

10

numbers of decision criteria, which might be an

obstacle in case of modelling more complex supply

chains.

A considerable endeavour has been presented by

(Chatfield, 2004) and (Chatfield, 2009) to standardise

the process of modelling supply chains. The study

developed an XML-based language for modelling and

simulation of supply chains, SCML (Supply Chain

Modelling Language). However, XML-based models

can incur some drawbacks. First, since XML is

double-tagged, the file length will increase, as opposed

to files generated by a less strictly designed language

that allows single-tagged elements. Additionally, since

XML files are ASCII text files, the file size, measured

in bytes of storage, will be greater than if the

information were stored as binary data or as another

file structure, which can impose further limitations on

modelling large-scale supply chains.

4.2 Supply Chains Simulation Tools

Three main approaches used for supply chain

simulation are: i) Discrete Event Simulation (DES), ii)

Systems Dynamics (SD) and iii) Agent-Based

Simulation (ABS). However, discrete event simulation

has been largely preferred in literature. Numerous

DES tools for supply chains were produced by studies

such as (Ettl, Feigin, 1996), (Tomoyuki, Tetsuya,

2000), (Richard, David J., 2001), (Edward J., Ali,

2003), (Juqi, Wei, 2004), (Chatfield, 2006).

Agent-based simulation approach has received

growing attention in recent studies. An agent-based

modelling and simulation framework for supply chain

risk management was developed by (Tiffany J., 2012).

(Luis, Sophie, 2011) proposed FAMASS, a framework

for providing a uniform representation of distributed

advanced supply chain planning using agent

technology. (Karam, Erwan, 2010) used an

Operational Agent Model (OPAM) that was

implemented and simulated in a specific agent-based

software architecture.

The Systems Dynamics approach was mainly

adopted within continuous simulation models of

supply chains. For instance, (Patroklos, Dimitrios,

2005), (Vo, Thiel, 2006) and (Sameer, Anvar, 2011)

used Systems Dynamics for simulating the behaviour

and relationships of supply chains, and to determine

impacts such as demand variability and lead-time on

supply chain performance.

Despite the many simulation tools developed in

academic research, they have not been widely

embraced, as evident from the current status and usage

of those tools. Furthermore, the literature lacks

recognition that supply chains are neither completely

discrete nor continuous but a mixture of both,

therefore should be modelled appropriately to reflect

this. The need for constructing supply chain models

with discrete-continuous aspects has been recognised

by (Young, Min, 2002), (Mustafa, Theopisti C., 2007)

and (Dmitry, Alexandre, 2012).

4.3 Supply Chain Ontology

An ontology can provide a formal explicit

specification of shared knowledge, which can offer

practical grounded solutions for designing and

modelling supply chains. However, the adoption of

ontologies in supply chain modelling has been given

little consideration in the literature.

(Fayez, Rabelo, 2005) presented supply chain

simulation ontology based on the SCOR model. The

ontology was developed using Protégé tool and

encoded with the RDF standards.

(Y. Ye, D. Yang, 2008) presented an ontology-

based architecture for implementing semantic

integration of supply chain management. The ontology

was developed with no specific industry focus and

consisted of ten top-level classes: Supply_Chain,

SC_Structure, Party, Role, Purpose, Activity,

Resource, Transfer_Object, Performance and

Performance_Metric.

(Yan, Dong, 2008) developed a supply chain

ontology called Onto-SCM. They utilised the IDEF5

schematic language to visually represent core concepts

and relationships in Onto-SCM. The precise syntax

and formal semantics of Onto-SCM were defined with

Ontolingua, a mechanism for writing ontologies in a

canonical format.

On the other hand, ontologies of general enterprise

modelling were previously used for supply chains

models. For instance, TOVE ontologies by (J. Lin,

M.S. Fox, 1996), Enterprise Ontology (EO) by (M.

Uschold, M. King, 1998) and IDEON ontology by

(Madni, W. Lin, 2001).

Based on the ontology literature, it is believed that

the literature has the following limitations:

Apart from (Fayez, Rabelo, 2005), the ontology

mainly addressed the strategic level of supply

chains, giving less consideration to the tactical

and the operational levels.

Many of the developed ontologies were not built

on a standard basis that can help sustainable

development in the supply chain community.

The ontologies apparently lacked classification

of the defined attributes into continuous and

discrete, which could help build combined

discrete-continuous simulation models.

The literature lacks industry-specific ontologies,

SupplyChainsModellingandSimulationFramework-Graph-DrivenApproachusingOntology-basedSemanticNetworks

andGraphDatabase

11

for example in the healthcare domain. Generic

ontologies might not be adequate for describing

more detailed processes at the tactical and

operational levels.

5 METHODOLOGY

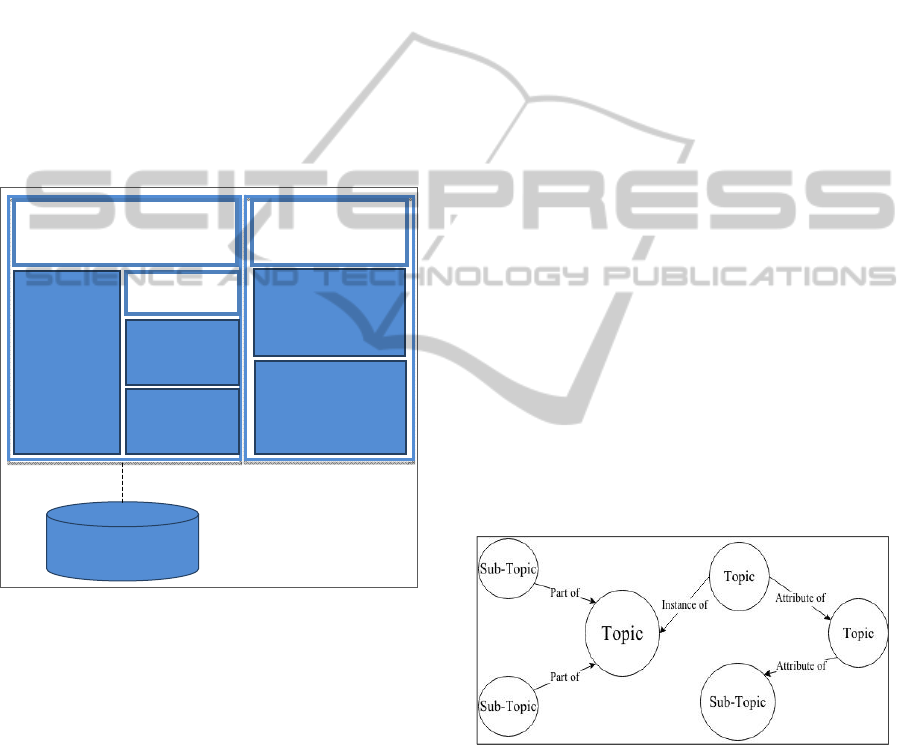

The proposed framework is fundamentally based on a

graph-driven methodology for the modelling and

simulation of supply chains. The methodology

considers the supply chain as a big graph that forms a

complex network of connections. Accordingly, the

methodology utilises the potentials of semantic

networks and graph databases to construct supply

chain conceptual models and ontologies. Figure 2

demonstrates the main components of the framework.

Figure 2: Main components of the proposed framework.

5.1 Supply Chain Modelling Approach

The first principal objective of the proposed

framework is to provide the conceptual modelling

methodology that can effectively describe and capture

the knowledge of supply chains. The modelling

methodology should involve an abstraction process for

determining what part of the real-life system will be

modelled and at what level of detail. Conceptual

modelling was described as the “art” in the science of

simulation according to (Jain S., Workman R., 2001).

The modelling methodology should address two main

points:

Conceptually, how should supply chain

knowledge be represented?

How can the conceptual models facilitate the

shareability of supply chain knowledge?

5.1.1 Supply Chain Big Graphs

The supply chain comprises a virtual complex network

of participants including suppliers, manufacturers,

wholesaler, retailers and customers. The network

participants are connected through upstream and

downstream linkages in the different processes and

activities to produce some service or product.

Apparently, it can be conceivable to consider

modelling supply chains as constructing “Big Graphs”.

Accordingly, the framework adopts a graph-based

method to model and capture the knowledge of supply

chains. Furthermore, graph modelling provides a

suitable form for sharing models with diverse sorts of

experts or decision makers.

5.1.2 Modelling Supply Chains as Semantic

Networks

A semantic network is a graph structure for

representing knowledge in patterns of interconnected

nodes and arcs (Shapiro, Eckroth, 1992). The proposed

framework utilises the common graph-based nature of

supply chains and semantic networks to build

semantic-driven supply chain models. Hence, the

supply chain participants are modelled as nodes

(entities) that are interconnected via arcs (predicates)

that can represent properties or relationships. Those

predicates will be explicitly described by ontology.

Figure 3 depicts a simple example of a semantic

network.

Figure 3: Example of a Semantic Network.

Semantic networks have the advantage of being a

declarative graphic representation of knowledge. In

addition, semantic networks can be understandable by

human and machines as well. Various semantic

models have been built based on the concept of

semantic networks, the RDF model for instance.

5.1.3 Supply Chain Ontology

Developing supply chain ontologies is a pivotal

Graph Database

Simulation

Model

Auto-Generator

Simulation

Software

(AnyLogic)

Semantic

Networks

Supply Chain

Conceptual Model

Core

Ontology

Ontology

Domain

Ontologies

Simulation

Model

SIMULTECH2014-DoctoralConsortium

12

element to provide expressiveness and semantics to

capture comprehensive supply chain knowledge. The

framework adopts ontologies to provide standards of

information, shared vocabulary and conceptualisation

of problem-oriented data for supply chains. The

ontology will consist of two main categories:

i) Generic Ontology:

Initially, the framework will use a SCOR-driven

process to define classes, subclasses, properties, and

instances that can represent the various supply chain

levels. The adoption of the SCOR model is due to

being the most shared and widely accepted concept

within the supply chain community, and it has been

largely used in literature to describe and model supply

chains.

A hierarchy of concepts will be driven from the

SCOR processes and performance measures to

describe the taxonomy of supply chain knowledge.

The top level of the ontology hierarchy should

represent primary processes of a supply chain in a

strategic aspect. The generic ontology is based on the

six primary management processes defined by SCOR:

Plan, Source, Make, Deliver, Return and Enable.

Moreover, a ’Hybrid’ process was added to provide

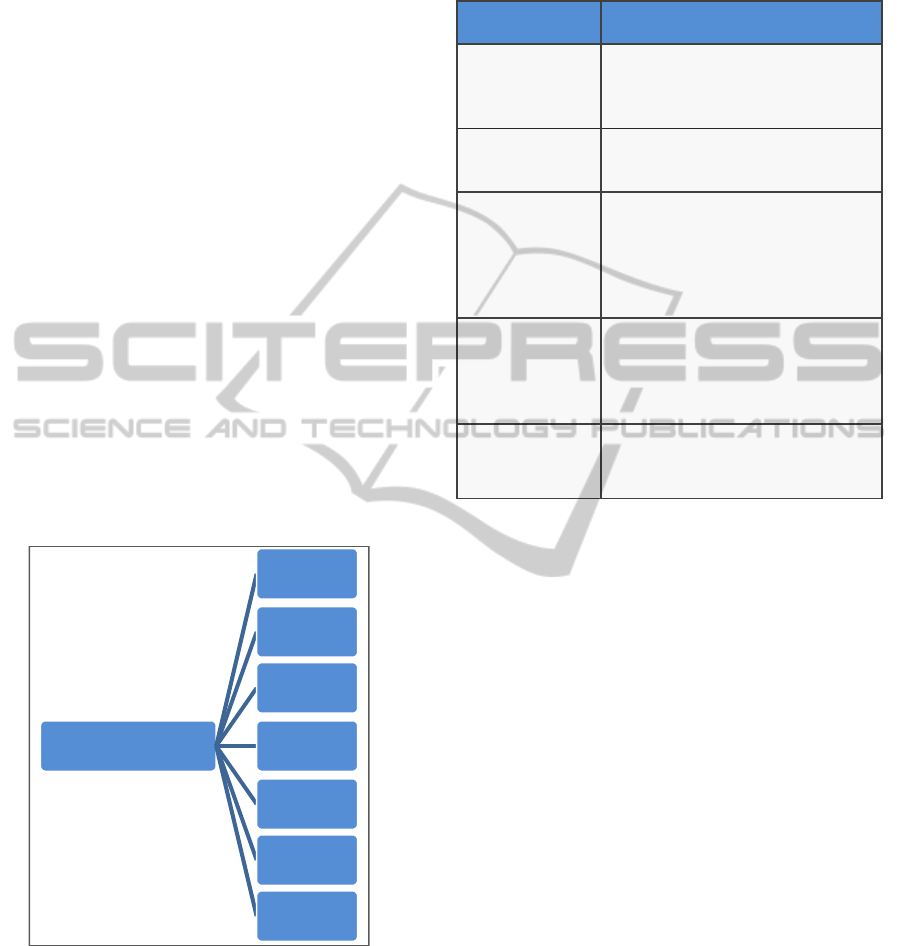

more flexibility. Figure 4 outlines the main classes of

the generic ontology.

Figure 4: Main classes of the SCOR-based generic ontology.

Further ontology attributes are extracted based on

the performance attributes defined by SCOR. Those

attributes can describe process details at the tactical

and operational levels of supply chains. In addition,

the extracted attributes should be classified into

discrete or continuous attributes. Table (1) presents the

main categories of performance attributes defined by

the SCOR model.

Table 1: The SCOR performance attributes.

Performance

Attribute

Definition

Reliability

Reliability focuses on the

predictability of process outcomes.

Examples: On-time, the right

quantity, the right quality.

Responsiveness

The speed at which a supply chain

provides products to the customer.

Examples: cycle-time metrics.

Agility

The ability to respond to external

influences such as marketplace

changes to gain or maintain

competitive advantage.

Examples: Flexibility and

adaptability metrics.

Costs

The cost of operating the supply

chain processes. This includes cost

of labour, material, management

and transportation.

Example: Cost of Goods Sold.

Asset

Management

Efficiency

The ability to efficiently utilise

assets. Examples: Inventory days of

supply and capacity utilization.

ii) Domain Ontologies:

The framework is concerned with covering one of the

gaps in literature accounted for the lack of specific-

industry ontologies for supply chains. Therefore,

industry-specific ontology is developed, healthcare

supply chain in particular.

5.2 Storing Supply Chain Models and

Ontologies using a Graph Database

Based on the graph-driven approach, the framework

utilises graph databases for storing both the supply

chain model and the defined ontology. A graph

database is a storage engine which supports a graph

data model backed by native graph persistence, with

access and query methods for the graph primitives

(Robinson, Webber, 2013).

5.2.1 Storing Supply Chain Models

Graph database can provide a flexible schema to store

and map the nodes and edges of the supply chain

graph. Accordingly, the graph data model of graph

databases can help build and store more complex

large-scale supply chain models. Furthermore, the

graph-based data storage provides a considerable

advantage for model scalability over traditional XML-

based documents.

Generic SCOR-Based

Onoltogy

Plan

Source

Make

Deliver

Return

Enable

Hybrid

SupplyChainsModellingandSimulationFramework-Graph-DrivenApproachusingOntology-basedSemanticNetworks

andGraphDatabase

13

5.2.2 Storing Supply Chain Ontology

Graph database can provide a suitable environment for

storing, maintaining and querying supply chains

ontology due to the following reasons:

Graph database can handle storing complex

ontologies because of the flexible graph-based

model.

Graph database is a schema-less data store,

which is ideal for scalability.

Graph database models are typically faster for

associative datasets.

Graph database provides a robust model to

query ontologies.

The common graph-based manner of graph

databases and the RDF model helps export the

ontology with RDF-based format, which is

important for the model shareability.

5.3 Automatic Generation of

Simulation Models

A tool will be developed that can automatically

generate simulation models. The tool translates the

high-level conceptual models of supply chains into

simulation models ready to run experiments. The

purpose of the auto-generation is to help non-

simulation experts build and modify simulation

models with different scenarios.

5.4 Simulation Software

It is not planned to produce a new simulation tool,

however the framework will work along with one of

the state of the art simulation software. The literature

review included surveying the available simulation

tools provided by academia and industry in order to

select the appropriate tool.

AnyLogic simulation software was selected for

that purpose. AnyLogic was considered for the

following:

The capability of providing a multi-perspective

simulation approach, including Discrete Event

Simulation, Systems Dynamics and Agent-

Based Simulation.

Supporting seamless integration of discrete and

continuous simulations.

Providing Java-based simulation models, which

helps model extensibility.

Providing an extensive statistical distribution

function sets that provide a platform for

simulating the uncertainty inherent in supply

chains.

6 EXPECTED OUTCOME

In principal, the framework will present a graph-driven

methodology to address the modelling and simulation

of supply chains. The framework is expected to

provide the following:

Semantic-based modelling of supply chains that

can improve the flexibility of building supply

chain models.

Higher shareability of supply chain models

through visual graph-based models.

Flexibility for modelling complex large-scale

supply chains using graph database.

Generic ontology for supply chains.

Specific ontology for healthcare supply chains.

Classifications of ontologies into discrete and

continuous attributes, which can help build

combined discrete-continuous models.

Flexibility and scalability for developing,

maintaining and querying ontology based on

graph databases.

Helping non-simulation experts by automatic

generation of simulation models ready to run

experiments using one of the state-of-the-art

simulation software.

REFERENCES

Dmitry Ivanov , Alexandre Dolgui , Boris Sokolov, 2012.

Applicability of optimal control theory to adaptive

supply chain planning and scheduling, Annual Reviews

in Control 36.

Mustafa Ozbayrak, Theopisti C. Papadopoulou, Melek

Akgun, 2007. Systems Dynamics Modelling of a

Manufacturing Supply Chain System, Simulation

Modelling Practice and Theory 15.

Young Hae Lee, Min Kwan Cho, Seo Jin Kim, Yun Bae

Kim, 2002. Supply Chain Simulation with Discrete-

Continuous Combined Modelling, Computers &

Industrial Engineering 43.

Ian Robinson, Jim Webber, Emil Eifrem, 2013. Graph

Databases, O'Reilly Media, p.75.

D. J. van der Zee, J. G. A. J. van der Vorst, 2005. A

Modelling Framework for Supply Chain Simulation:

Opportunities for Improved Decision Making, Decision

Sciences Volume 36 Number 1.

Gunasekaran, A., 2004. Supply chain management: Theory

and applications, European Journal of Operational

Research, 159(2), 265–268.

Gunasekaran, A., Macbeth, D. K., & Lamming, R., 2000.

Modeling and analysis of supply chain management

systems, Journal of the Operational Research Society,

51, 1112–1115.

Min, H., & Zhou, G., 2002. Supply Chain Modelling: Past,

Present and Future, Computers and Industrial

SIMULTECH2014-DoctoralConsortium

14

Engineering, 43(1–2), 231–249.

Jain S., Workman R., Collins L.M., Ervin E. 2001.

Development of a High-Level Supply Chain simulation

model. Proceedings of the 2001 Winter Simulation

Conference.

Dean C. Chatfield a, Terry P. Harrison, Jack C. Hayya,

2009. SCML: An Information Framework to Support

Supply Chain Modelling, European Journal of

Operational Research 196, 651–660.

Supply Chain Council, 2012. Supply Chain Operations

Reference Model, Supply Chain Council. Revision 11.0.

Jack C. P. Cheng, Kincho H. Law, Hans Bjornsson, Albert

Jones, Ram D. Sriram, 2010. Modelling and Monitoring

of Construction Supply Chains, Advanced Engineering

Informatics 24, 435–455.

Yuh-Jen Chena, Yuh-Min Chenb, 2009. An XML-Based

Modular System Analysis and Design for Supply Chain

Simulation, Robotics and Computer-Integrated

Manufacturing 25, 289–302.

Fredrik Persson, Mirko Araldi, 2009. The Development of a

Dynamic Supply Chain Analysis Tool—Integration of

SCOR and Discrete Event Simulation, Int.

J.ProductionEconomics121, 574–583.

Samuel H. Huanga, Sunil K. Sheoranb, Harshal Keskara,

2005. Computer-assisted supply chain configuration

based on supply chain operations reference (SCOR)

model, Computers & Industrial Engineering Vol. 48,

Issue 2, 377–394.

Jeffrey W. Herrmann, Edward Lin, Guruprasad Pundoor,

2003. Supply Chain Simulation Modeling Using The

Supply Chain Operations Reference Model, ASME 2003

Design Engineering Technical Conferences.

Guixiu Qiao, Frank Riddick, 2004. Modelling Information

for Manufacturing-Oriented Supply-Chain Simulations,

Proceedings of the 2004 Winter Simulation Conference.

Manuel D. Rossetti, Hin-Tat Chan, 2003. A Prototype

Object-Oriented Supply Crain Simulation Framework,

Proceedings of the 2003 Winter Simulation Conference.

Biswas, S., & Narahari, Y. 2004. Object Oriented Modelling

and Decision Support for Supply Chains. European

Journal of Operational Research, 153, 704-726.

Dean C. Chatfield, Terry P. Harrison, Jack C. Hayya, 2004.

XML-Based Supply Chain Simulation Modelling,

Proceedings of the 2004 Winter Simulation Conference.

Ashish Agarwal, Ravi Shankar, M.K. Tiwari, 2006.

Modelling the metrics of lean, agile and leagile supply

chain: An ANP-based approach, European Journal of

Operational Research.

Ettl, M., Feigin, G., Lin, G., Yao, D. 1996. A Supply

Network Model with Base-Stock Control and Service

Requirements, Operations Research Journal Volume 48

Issue 2.

Dean C. Chatfield, Terry P. Harrison, Jack C. Hayya, 2006.

SISCO: An object-oriented supply chain simulation

system, Decision Support Systems Volume 42, Issue 1.

Juqi Liu, Wei Wang, Yueting Chai, Yi Liu, 2004. EASY-

SC: A Supply Chain Simulation Tool, Proceedings of

the 2004 Winter Simulation Conference.

Tomoyuki Kitagawa, Tetsuya Maruta, Yoshitomo Ikkai,

Norihisa Komoda, 2000. A Description Language based

on Multi-Functional Modelling and a Supply Chain

Simulation Tool ,IEEE International Conference on

Systems, Man, and Cybernetics.

Richard A. Phelps, David J. Parsons, Andrew J. Siprelle,

2001. SDI Supply Chain Builder: Simulation from

Atoms to the Enterprise, Proceedings of the 2001 Winter

Simulation Conference.

Edward J. Williams, Ali Guna, 2003. Supply Chain

Simulation and Analysis with SimFlex, Proceedings of

the 2003 Winter Simulation Conference.

Tiffany J. Harper, 2012. Agent Based Modelling and

Simulation Framework for Supply Chain Risk

Management, Air Force Institute of Technology.

Luis Antonio de Santa-Eulalia, Sophie D’Amours, Jean-

Marc Frayret, 2011. Agent-Based Simulations for

Advanced Supply Chain Planning: The FAMASS

Methodological Framework for Requirements Analysis,

CIRRELT.

Karam Mustapha, Erwan Tranvouez, Bernard Espinasse,

Alain Ferrarini, 2010. Agent-Based Supply Chain

Sim

ulation: Towards an Organization-Oriented

Methodological Framework, 8th International

Conference of Modelling and Simulation.

Patroklos Georgiadis, Dimitrios Vlachos, Eleftherios

Iakovou, 2005. A system dynamics modelling

framework for the strategic supply chain management of

food chains, Journal of Food Engineering 70.

Sameer Kumar, Anvar Nigmatullin, 2011. A system

dynamics analysis of food supply chains – Case study

with non-perishable products, Simulation Modelling

Practice and Theory 19.

Vo T. L. H., Thiel D., 2006. A System Dynamics Model of

the Chicken Meat Supply Chain faced with Bird Flu,

University of Nantes and ENITIAA Nantes, LEM-

LARGECIA, France.

Mohamed Fayez, Luis Rabelo, Mansooreh Mollaghasemi,

2005. Ontologies for Supply Chain Simulation

Modeling, Proceedings of the 2005 Winter Simulation

Conference.

Y. Ye, D. Yang, Z. Jiang, L. Tong, 2008 .An Ontology-

Based Architecture for Implementing Semantic

Integration of Supply Chain Management, International

Journal of Computer Integrated Manufacturing 21 (1) .

Yan Ye, Dong Yang, Zhibin Jiang, Lixin Tong, 2008.

Ontology-Based Semantic Models for Supply Chain

Management, International Journal of Advanced

Manufacturing Technology, 37(11-12), 1250-1260.

A. M. Madni, W. Lin, C. C. Madni, 2001 .IDEONTM: An

Extensible Ontology for Designing, Integrating and

Managing Collaborative Distributed Enterprises,

Systems Engineering 4 (1) 35–48.

J. Lin, M. S. Fox, T. Bilgic, 1996. A Requirement ontology

for engineering design, Proceedings of the 3rd

International Conference on Concurrent Engineering, pp.

343–351.

M. Uschold, M. King, S. Moralee, Y. Zorgios, 1998. The

enterprise ontology, The Knowledge Engineering

Review 13 (1) 31–89.

Stuart Charles Shapiro, David Eckroth, 1992. Encyclopedia

of Artificial Intelligence, Wiley, second edition.

SupplyChainsModellingandSimulationFramework-Graph-DrivenApproachusingOntology-basedSemanticNetworks

andGraphDatabase

15